enz P360 User manual

Operating Manual

English USA

September 22

│ Version

1.

6

P360

(07.2500A/B)

Operating Manual

September 2022 Version 1.6 ©2022 enz® technik ag Page 1 of 3

Content

Preface ................................................................ 4

1 Safety ............................................................. 5

1.1

Noncompliance with the safet information and its

consequences. ..................................................................... 5

1.2

Target group ............................................................... 5

1.3

User requirements ...................................................... 5

1.4

Explanation of general safet instructions ................. 5

1.5

Information provided in these operating instructions6

1.6

Explanation of specific safet instructions ................. 6

1.7

Intended use ............................................................... 6

1.8

Safet warnings for modifications .............................. 7

1.9

Protective equipment for working in manholes,

excavations, and channels .................................................. 7

1.10

General safet instructions ................................... - 10 -

2 Legal ............................................................. 12

2.1

Cop right .................................................................. 12

2.2

Exclusion of liabilit .................................................. 12

2.3

Warrant conditions ................................................. 12

3 Propeller nozzle P360 (0 .2500A/B) .............. 13

3.1

Application area (07.2500A/B) .................................. 13

3.2

Technical data ........................................................... 13

3.3

Propeller nozzle P360 ............................................... 14

3.4

Part names ................................................................ 15

4 Commissioning ............................................. 16

4.1

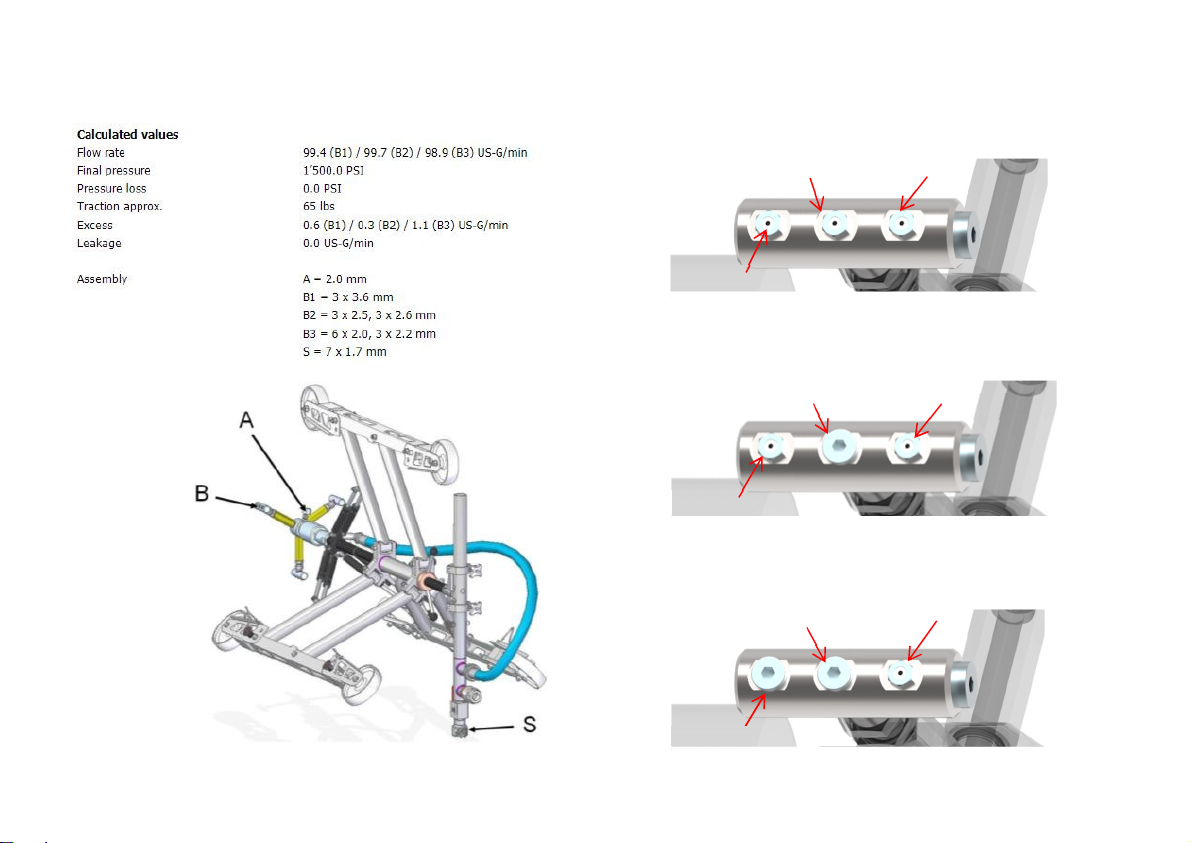

Fitting options based on enz® JetCalc ....................... 16

4.2

Example fitting options ............................................. 17

4.3

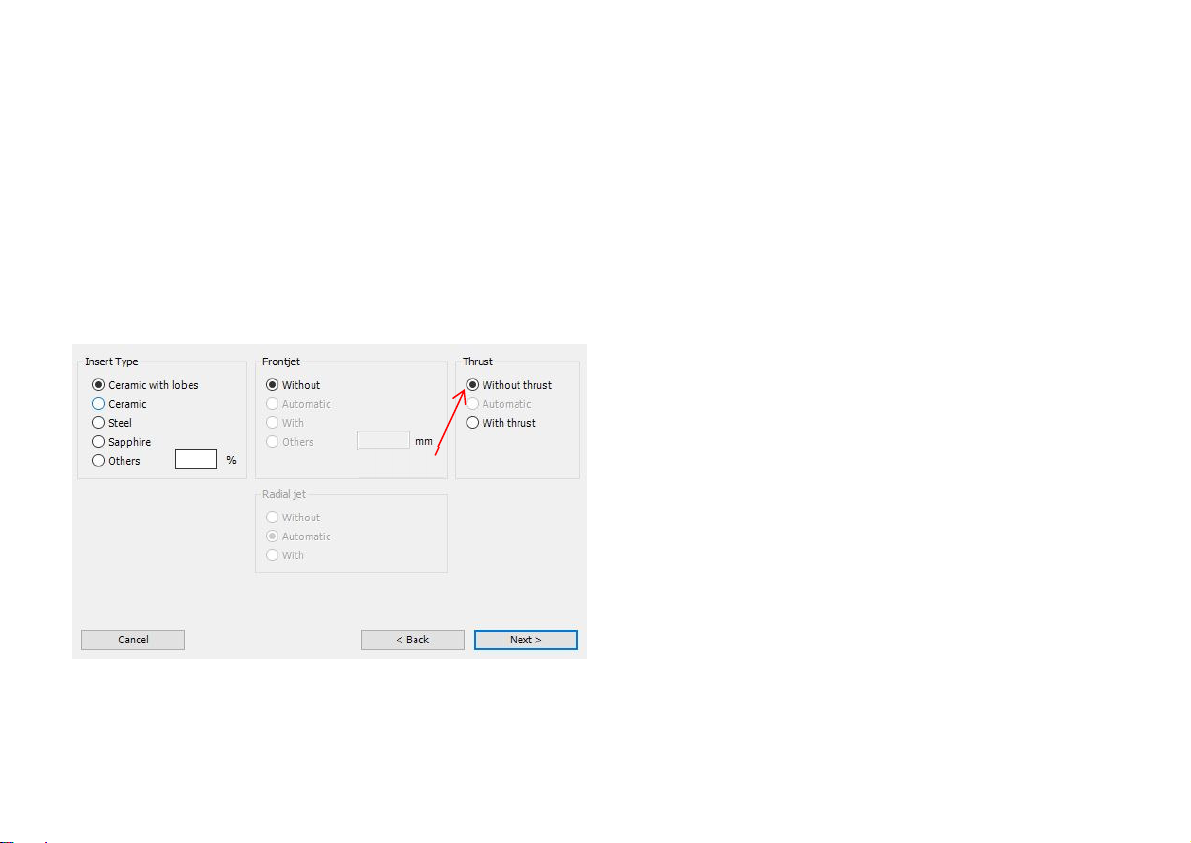

Working without thrust ............................................ 18

4.4

Drive variants ............................................................ 18

5 Installation ................................................... 19

5.1

Setting up the work area ........................................... 19

5.2

Putting the P360 into the channel ............................ 20

5.3

Installation in the channel......................................... 21

5.4

Installation in circular, arch, and rectangular profiles21

5.5

Installation in an ovoid profile .................................. 22

5.6

Folding the wheel carriers outward .......................... 22

5.7

Winding out the skids ............................................... 23

5.8

Extending the propeller ............................................ 23

5.9

Mounting the thrust part and the connecting hose . 24

5.10

Securing the hose ...................................................... 25

5.11

Connecting the channel rinsing hose ........................ 25

Operating Manual

September 2022 Version 1.6 ©2022 enz® technik ag Page 2 of 3

6 Operation ..................................................... 26

6.1

Increasing pressure ................................................... 26

6.2

Cleaning pipes with minor damage .......................... 26

6.3

Troubleshooting........................................................ 27

After operation ............................................. 28

7.1

Removing the nozzle from the channel .................... 28

7.2

Completing the work process ................................... 28

7.3

Transport .................................................................. 28

8 Maintenance ................................................. 29

8.1

Maintenance after each use ..................................... 29

8.2

Nozzle inserts ............................................................ 29

8.3

Lubricating the spindle ............................................. 30

8.4

Replacing the connecting hose ................................. 30

8.5

Additional work ........................................................ 30

8.6

Care ........................................................................... 30

8.7

Disposal, environmental protection ......................... 30

9 Accessories and spare parts ........................... 31

9.1

Accessories ............................................................... 31

9.2

Propeller nozzle P360 ............................................... 32

9.3

Propeller 007.25004 ................................................. 33

9.4

Skid 007.25005 .......................................................... 34

9.5

Thrust 007.25001 & thrust fastener 007.25002 ....... 35

Operating Manual

September 2022 Version 1.6 ©2022 enz® technik ag Page 4 of 3

Preface

Dear valued customer,

Thank ou for the confidence and trust ou've placed in us b

purchasing one of our products.

We alwa s appreciate suggestions for improvement and con-

structive comments. Your feedback will help us improve the de-

sign of our product and the associated documentation.

If ou have an questions or suggestions, please contact our

Customer Service Department.

enz® technik ag Phone +41 41 676 77 66

Schwerzbachstrasse 10 Fax +41 41 676 77 67

www.enz.co

Person responsible for documentation:

Marc Renggli (Tech. Support / QM Manager)

We reserve the right to modif and further enhance our prod-

ucts without prior notice as a result of technological advances.

Misprints reserved.

Purpose of the document

The purpose of this manual is to instruct ou on how to use our

product correctl , effectivel , safel , and for its intended pur-

pose. The user will be informed about risks, reasonabl fore-

seeable misuse, and residual risks.

Important!

Read carefull before use.

Keep for later reference.

Please read this operating manual thoroughl before using the

cleaning tool. Make sure that all emplo ees who work with

the product know how to use it correctl .

The operating manual must be available to all operating per-

sonnel at all times. It must be kept in an easil accessible place.

If the manual is misplaced or destro ed, a new cop can be

requested from our nearest dealer or from the manufacturer

directl .

Operating Manual

Safety

September 2022 Version 1.6 ©2022 enz® technik ag Page 5 of 3

1 Safety

1.1 Noncompliance with the safety information and

its consequences.

Disregarding these safet instructions ma lead to accidents

and severe personal injuries, material damage as well as

damage to the environment.

The manufacturer cannot be held responsible for an damage

resulting from noncompliance with these instructions.

1.2 Target group

This manual is intended for all persons who will be involved in

the assembl , start-up, and operation of the pipe cleaning tool.

1.3 User requirements

All persons involved with assembl , start-up, and operation of

the tool must

• Be familiar with the field of channel maintenance work

and possess the appropriate technical knowledge.

• Be trained and instructed appropriatel in the use of the

product.

• Have read and understood the operating manual, in par-

ticular the section on “Safety.”

If our personnel do not possess the necessar knowledge, the

must be trained and instructed on it. If necessar , the pipe

cleaning tool manufacturer can provide this instruction and

training.

Onl the maintenance and service activities described in this

manual ma be performed b users who have met the above-

listed requirements. An additional maintenance and service

work ma be performed onl b qualified specialist personnel

from the manufacturer.

1.4 Explanation of general safety instructions

The general safet instructions in this section provide infor-

mation about potential residual risks, which are inherent to the

product and ma occur unexpectedl , despite the proper usage

of the product.

In order to prevent personal injuries, damage to propert and

the environment, all personnel working with this product must

compl with these safet instructions. It is mandator for said

personnel to read and understand the information provided in

this section.

Please refer to the section on "MAINTE-

NANCE."

Operating Manual

Safety

September 2022 Version 1.6 ©2022 enz® technik ag Page 6 of 3

1.5 Information provided in these operating

instructions

DANGER

Noncompliance ma lead to serious injur

or loss of life.

WARNING

Noncompliance ma lead to serious injur

or loss of life and/or long-term disabilit .

CAUTION

Noncompliance ma lead to injur and con-

siderable material damage, financial loss,

or damage to the environment.

Information on the technicall correct and

efficient use of the product.

1.6 Explanation of specific safety instructions

Safet information pertaining to particular situations is high-

lighted in the appropriate section of the operating manual.

1. Intended use

The product is designed to clean the insides of pipes (channel

pipes). The following points must be followed to ensure proper

use of the product.

The cleaning tool ma be used onl in pipes or pipe-

like channels. The profile to be cleaned must be free

of leaks and surrounded b material.

The tool ma be used on the following t pes of pipes:

o PE pipes

o Steel pipes

o Concrete pipes

For use in pipes made of other material, please consult

the manufacturer.

The product ma be operated onl in pipes with

correctl installed and defect-free connections.

Cleaning areas (manholes, pipe branches, etc.) need

to be sufficientl secured during the operation, includ-

ing during construction and cleaning work.

Operating Manual

Safety

September 2022 Version 1.6 ©2022 enz® technik ag Page of 3

During the cleaning operation, no personnel are

allowed inside the pipes or at either end of the pipes.

The maximum pressure indicated on the nozzle ma

not be exceeded.

Wastewater ma not be drained into watercourses

(creeks, rivers etc.).

The product must be inspected to ensure it is in proper

working order before ever start-up.

Defects must be rectified before start-up.

Use the tool onl as intended. (Use onl the correct

wrench for nuts).

Secure the hose lines in such a wa that the cannot

become damaged during operation.

Onl the accessories provided and approved b

enz® technik ag ma be used.

1.8 Safety warnings for modifications

No other changes or modifications to the pipe cleaning tool

ma be performed. Onl parts authorized b the manufac-

turer ma be used. The manufacturer is not liable for damage

resulting from unauthorized changes to the product.

1.9 Protective equipment for working in manholes,

excavations, and channels

The emplo er must provide suitable personal protective

equipment and ensure that it is worn b the emplo ees during

work.

In the following section, the protective equipment prescribed

b Schweizerische Unfallversicherung SUVA (the Swiss Acci-

dent Insurance Organization) will be described.

See also:

Suva

Schweizerische Unfallversicherungsanstalt

Arbeitssicherheit

Postfach, 6002 Lucerne, Switzerland

For information

Phone +41 41 419 51 11

For orders

www.suva.ch/waswo

Fax +41 41 419 59 17

Phone +41 41 419 58 51

Safe entry and working in shafts, excavations, and chan-

nels (in German, French & Italian)

Order n mber: 44062.d

Operating Manual

Safety

September 2022 Version 1.6 ©2022 enz® technik ag Page 8 of 3

Respirators

Suitable working clothing

Self-contained respirator equipment for

spending time in dangerous atmospheres

and for use during rescue operations.

Leak-proof working clothing protects the

skin from becoming soiled and from possi-

ble infections. Visuall conspicuous work

clothing makes the emplo ee more visible

to traffic.

Respirators

Appropriate footwear

Self-rescue respirator equipment (devices

with compressed air tanks or regeneration

devices) for working in channels and for first

aid for injured persons.

Safet footwear should, in particular, have

good grip and be slip-resistant and leak-

proof (e.g. rubber boots).

Rescue harness

Gloves

Rescue harness or protective clothing with a

loop sewn into the neck. During rescue, the

rescue rope will be attached to the neck

loop. Injured persons will be lifted out using

a rescue lifting device with a self-actuating

load brake.

Appropriate gloves will protect ou from

hand injuries and contact with materials

that could impair our health and from un-

treated water.

Operating Manual

Safety

September 2022 Version 1.6 ©2022 enz® technik ag Page 9 of 3

Hardhat

Eye protection

The hardhat will protect our head from

falling objects and from bumping into fixed

components and objects.

Your e es should be protected against grit,

spra ed dangerous substances, etc.

Hearing protection

Lighting independent of the power grid

If there is noise that could damage our

hearing, ou can wear, e.g. earmuffs with

built-in headphones and microphone.

For example, a waterproof flashlight or a

flashlight attached to our hardhat.

Operating Manual

Safety

September 2022 Version 1.6 ©2022 enz® technik ag Page 10 of 3

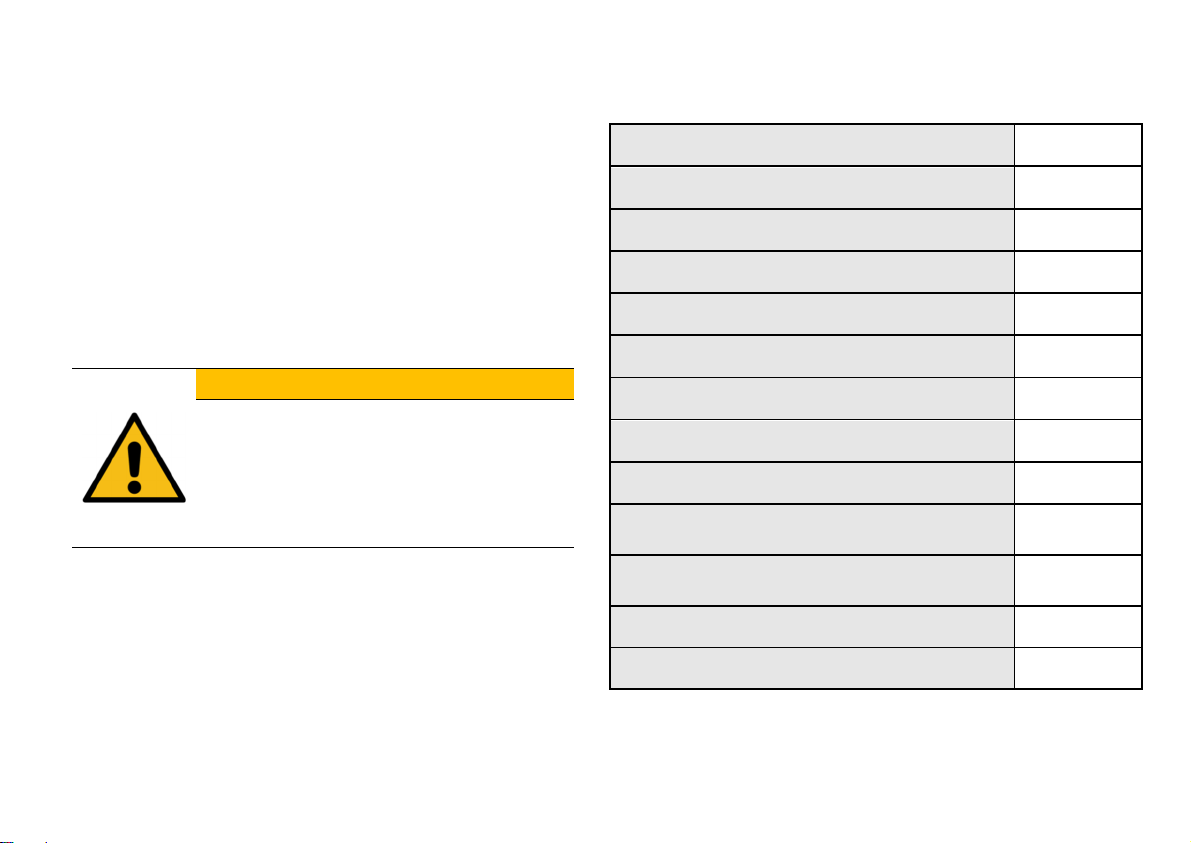

1.10 General safety instructions

Danger! | High-pressure water jets

Warning! | Falling objects

Defects in or unintended use of the product

could cause hazards due to pressurized

water spra . Never remain in the channel

during operation. Ensure that the product is

in perfect condition before operation. Highl

concentrated water jets can cause serious

injur and could even sever limbs. Noncom-

pliance with these safet instructions could

be fatal or lead to serious injur .

Around open manholes, objects can fall into

the manhole and onto the people below.

Never remain directl beneath the manhole

opening when guiding the products in.

Secure the manhole entrance against parts

that could fall. Do not throw an tools or

objects down into the manhole. Do not en-

ter an manhole where there is a danger of

falling. Personnel could become trapped.

Noncompliance with these safet instruc-

tions can be fatal or could lead to serious

injur .

Danger! | Toxic vapors

Warning! | Chemical burns

There can be toxic vapors in channels. Wear

the prescribed protective equipment such as

gas masks, gas warning devices and rescue

harnesses. Inhaling toxic vapors or air that is

contaminated with particles could be fatal

or lead to serious injuries if the particles

enter the lungs.

There ma be unidentified, corrosive, or

otherwise harmful substances in channels.

Put on appropriate protective clothing. Use

the protective equipment prescribed. Other-

wise, ou could suffer from chemical burns

to our skin and e es or become infected

with pathogens.

Operating Manual

Safety

September 2022 Version 1.6 ©2022 enz® technik ag Page 11 of 3

Warning! | Falls from height

Warning! | Hand injuries

Open manholes are to be expected in the

area where ou will be working with the

product. You must warn people about open

manholes. Pa attention to where ou are

walking. Falling from height can be fatal or

could lead to serious injur .

If the product is tampered with, there is a

risk of hand injur due to trapping or abra-

sion. Wear gloves during work. Pa atten-

tion to where ou grip the product. Alwa s

have two people carr heav equipment.

Consequences can include crushing injuries,

abrasions or even the loss of a limb.

Caution! | Sharp objects

Caution! | Trip hazards

If the product is tampered with, there is a

risk of hand injuries due to sharp edges.

Wear gloves during work. Pa attention to

where ou grip the product. Consequences

can include cut injuries to our hands or

other parts of our bod .

Lines and other objects are to be expected

on the ground in the area around where the

product is being used. Pa attention to

where ou are walking. Keep the area of use

tid . Tripping and falling could cause serious

injuries.

Operating Manual

Legal

September 2022 Version 1.6 ©2022 enz® technik ag Page 12 of 3

2 Legal

2.1 Copyright

Without the prior written permission of enz

®

technik ag, this

manual shall not be duplicated partiall or in its entiret . It shall

not be photocopied, reproduced, translated, or converted into

an electronic or machine-readable format.

©2018 enz® technik ag, 6074 Giswil, Switzerland.

All rights reserved

2.2 Exclusion of liability

The manufacturer is not liable for damage that:

Is caused as a result of unauthorized changes to the

product.

Is caused b not following the safet instructions.

2.3 Warranty conditions

In accordance with our sales and deliver conditions, we offer

a warrant . However, the warrant is voided if:

The product is used under conditions that are not per-

mitted b us.

Replacement and accessor parts that are not original re-

placement and accessor parts from enz® technik ag are

used.

If there is damage due to:

o Improper use

o Not following the operating manual

o Unsuitable operating equipment

o Incorrect or improper routing of the hose or pipe-

lines

o Unauthorized changes, modifications or changes to

the product.

Operating Manual

Propeller nozzle P360 (07.2500A/B)

September 2022 Version 1.6 ©2022 enz® technik ag Page 13 of 3

3 Propeller nozzle P360

(0 .2500A/B)

3.1 Application area (0 .2500A/B)

With the propeller nozzle P360, full-circle cleaning is performed

in large channels of Ø23 – 118 inch. The application diameter

can be easil adjusted. It can be used for round, flat, or egg-

shaped profiles. The P360 was designed to be operated with

rec cled water, but it can also be operated with fresh water.

WARNING

The maximum pressure on the P360 ma

not exceed 200 bar (2,900 psi)! The compo-

nents are designed for this maximum pres-

sure and can fail if it is exceeded. Exceeding

the maximum pressure can result in serious

injuries and material damage.

3.2 Technical data

Item no. 0 .2500A/B

Ø x length [inch] 23 x 79

Ø access shaft Min. [inch] 23.5

Thrust jet inserts 7x

Cleaning inserts 9x

Rotational drive inserts 1x

Weight [lbs] 132

Connecting thread [inch] 1″ / 1¼″

Application range Ø [inch] 23 - 118

Volumetric flow at

1500 psi with thrust Min. [gal/min]

79

Volumetric flow at

1500 psi without thrust Min. [gal/min]

39

Working pressure Max. [psi] 2,900

Rec cled water Yes

Operating Manual

Propeller nozzle P360 (07.2500A/B)

September 2022 Version 1.6 ©2022 enz® technik ag Page 14 of 3

3.3 Propeller nozzle P360

Figure 1 Parts overview for P360

1

2

4

13

10 5

11

3

9

14

8

12

6

Operating Manual

Propeller nozzle P360 (07.2500A/B)

September 2022 Version 1.6 ©2022 enz® technik ag Page 15 of 3

3.4 Part names

Key:

1. Wheel carrier

2. Thrust part, including: (4; 5; 6; 7; 8)

3. Star knob

4. Connecting hose

5. Swivel joint

6. Hose cap

. Thrust part

8. Thrust valve

9. Rotar lever

10. Locking pin

11. Cleaning nozzle

12. Propeller arm

13. Propeller, including: (11; 12; 14)

14. Rotational drive

Operating Manual

Commissioning

September 2022 Version 1.6 ©2022 enz® technik ag Page 16 of 3

4 Commissioning

4.1 Fitting options based on enz® JetCalc

The P360's propeller has various options for fitting. Three

propeller arms each with three nozzle inserts plus the separate

rotational drive have to be adjusted to one another.

JetCalc has three different fitting options in order to achieve

the desired flow.

Fitting B1 1 nozzle insert per nozzle head

Fitting B2 2 nozzle inserts per nozzle head

Fitting B3 3 nozzle inserts per nozzle head

If a sufficientl large water flow rate is available, then the clean-

ing result will be best with the B3 fitting. The nozzle inserts

should not be smaller than Ø1.5 mm, because otherwise the

nozzle's abilit to use rec cled water will be impaired.

The rotational speed is changed b selecting a smaller or larger

insert on the rotational drive.

During use, the nozzle rotates in a counter-clockwise direction;

the connecting thread, in contrast, rotates in a clockwise direc-

tion. This prevents the nozzle from detaching itself from the

connecting thread during operation.

If easil damaged pipes need to be cleaned,

then the nozzle inserts can be replaced with

flat jet nozzles.

CAUTION

Never change the direction of rotation!

The direction of rotation prevents the noz-

zle from coming off. Parts of the P360 could

come off if ou change the direction of ro-

tation. This can adversel affect propert ,

plant, and equipment.

Operating Manual

Commissioning

September 2022 Version 1.6 ©2022 enz® technik ag Page 1 of 3

4.2 Example fitting options

(100 US-gpm | 1500 psi net)

Example B3

B3 in this case would be 6 x 2.0 mm and 3 x 2.2 mm. This means

2 x 2.0 mm and 1 x 2.1 mm per propeller arm.

Example B2

With B2, a nozzle insert is replaced with a blind plug.

Example B1

With B1, two nozzle inserts are replaced b blind plugs.

2.0 mm

2.0 mm

2.2 mm

Figure 2 Exa ple B3

2.5 mm

2.6 mm

Blind plug

Figure

3

Exa ple B2

Blind plug

3.6 mm

Blind plug

Figure 4 Exa ple B1

Operating Manual

Commissioning

September 2022 Version 1.6 ©2022 enz® technik ag Page 18 of 3

4.3 Working without thrust

The high-pressure water tap on the thrust part, called the

thrust valve, provides an additional option for controlling the

available water flow rate.

If ou are working without thrust and the nozzle is pulled

through the channel, then all the water can be used for the

cleaning. For this, in the first selection window of the P360, Jet-

Calc provides a fitting option where no thrust jet inserts are

taken into account (S = 7 x 0.0 mm).

The thrust valve must then be completel closed.

4.4 Drive variants

Basicall , there are three variants for how the P360 can be

driven in the channel. All these variants need to be pulled

back from the end manhole to the entr manhole using the

truck's connection hose. The difference is in the options for

how the P360 advances in the channel from the entr man-

hole.

1. The P360 works through the channel from the entr

manhole using the thrust part.

Proximit protection on the propeller (standard)

Thrust valve switched on

2. The P360 is pulled from manhole to manhole. Using a

pre-cleaning tool, the hose is taken to the end manhole.

There, the hose is attached to the P360. The pre-cleaning

tool is returned above-ground. to the truck

Proximit protection on the propeller (standard)

Thrust valve can optionall be switched on or

off

3. The P360 is pulled with a rope from the entr manhole

to the end manhole. For this variant, the pulling equip-

ment supplied with the P360, called the pulling e e, is

mounted on the propeller.

Pulling e e on the propeller (862222.0300)

Thrust valve switched off

Figure 5 JetCalc selection screen for thrust

Operating Manual

Installation

September 2022 Version 1.6 ©2022 enz® technik ag Page 19 of 3

5 Installation

5.1 Setting up the work area

Prior to working with the propeller nozzle, the following actions

must be taken:

Set up barriers and safet equipment (warning triangle,

block off the area, etc.)

The work area must be blocked off and secured so that

there is no risk of falling or traffic-related dangers.

The necessar information on the wastewater flowing

through the manhole must be obtained (chemicals, gas, va-

pors, etc.)

Measuring instruments such as explosive gas meters, ox -

gen meters, gas warning devices, etc. must be readil avail-

able.

You must ensure that the appropriate nozzle sizes for

cleaning the pipes are available. The application range of

each nozzle is listed in the "Technical data" section on

page 13.

The la out of the pipes (manhole drawings) must be

known before starting the work so that the nozzle can be

prevented from emerging at a pipe end. Support person-

nel must be on hand to monitor possible emerging points.

Have the liabilit waiver signed b the customer to protect

against an possible claims for damages.

Figure 6 Blocked off & signed work area

This manual suits for next models

2

Table of contents