AU Tool C80 User manual

AUTOOL C80

Fuel System Cleaner

Trademark

AUTOOL Technology Co, Ltd. has registered its trademarks in

different countries, the trademark is .With regard to

the other trademark, service logo, domain, icon and company

name mentioned in this manual, they shall all belong to AUTOOL

and its other affiliated company, in other countries without the

registration yet of these trademark, service logo, domain name,

icon and company name of AUTOOL, here we announce they are

owned by AUTOOL. Any company or person shall not use the

trademark, service logo, domain name, icon and company name

of AUTOOL before getting approved by AUTOOL with written

certificates. Please visit our website www.autooltech.com or

email at [email protected] to contact us.

Caution

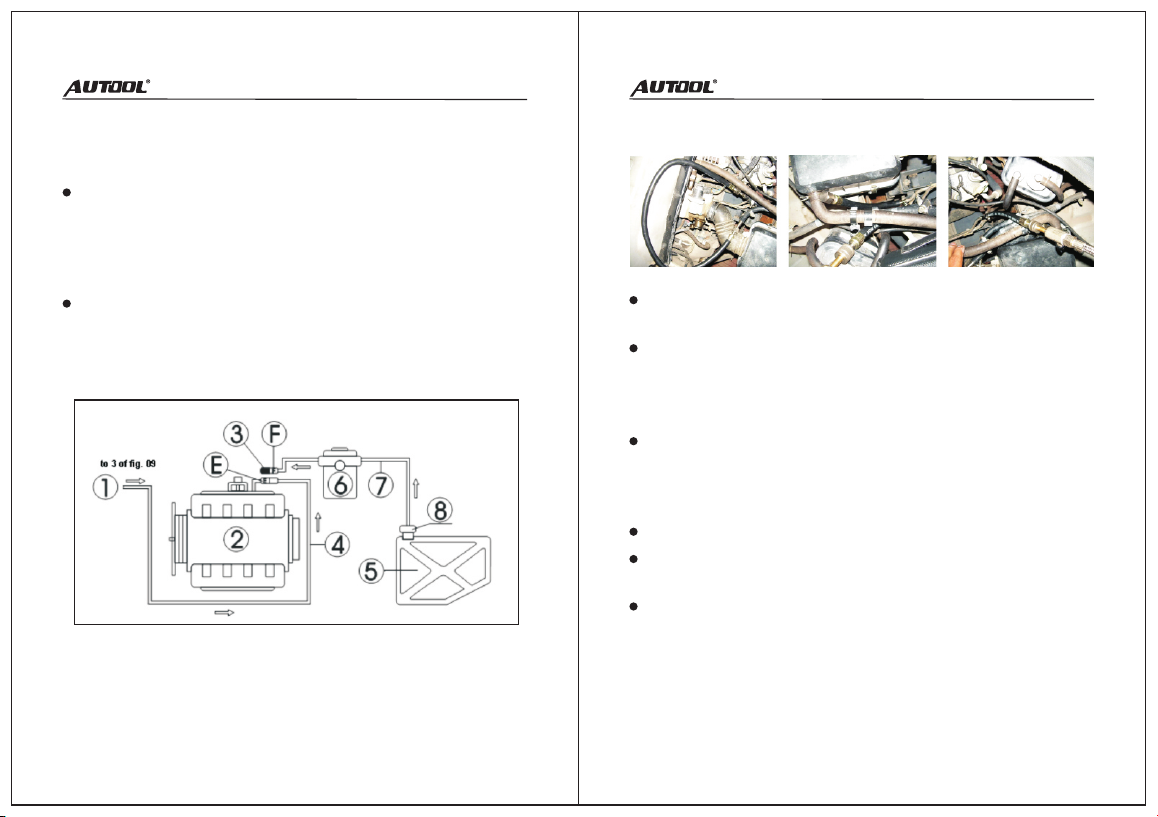

Connecting

The hose line connection of the engine with return hose is

shown as in Fig.01.

Fig.01

Disconnect the connections of fuel supply hoses (C、D) and

fuel return hoses (A、B) of the engine fuel system (wrap the

connector with towel when disconnecting the connector).

Choose proper connectors and connect them to the B end

and C end separately, and then connect the other ends to

corresponding return hose and outlet hose of the unit. See

Fig.01.

Connect the disconnected other ends (A、D) with proper

hose, or remove the fuel pump fuse, or disconnect the power

cable of engine fuel pump.

1-C80 Injector Cleaner & Tester; 2-Engine; 3- Fuel-return hose

from engine; 4- Fuel-inlet hose to engine; 5-Auto filter; 6-Engine

fuel supply hose; 7-Engine fuel return hose; 8- Auto fuel pump;

9-Auto tank

Wear protect gloves and cloth when operating.

Must stop engine if there have any fuel leak!

Bind up the pipe as disconnect the pipe to avoid splash and

fire.

Please prepare at least a fire extinguisher when doing on-

vehicle cleaning.

Please lead the exhaust to outdoor when doing on-vehicle

cleaning, because it contains a variety of toxic and hazardous

gases.

Please put the transmission in N and pull the brake when

doing on-vehicle cleaning.

2

1

Without return hose connecting:

Fig.02

Disconnect the fuel supply hoses (E, F) of engine fuel system

(wrap the connector when disconnecting the connector), and

then choose a proper connector and connect it to the E end.

Reconnect the fuel outlet hose of the unit well and make the

fuel return hose hanging. See Fig.02.

Stop the other end of the disconnected end (F) with a proper

stopper, (use when the fuel pump has the fuel return function

only) or remove the fuse of fuel pump or disconnect the power

cable of fuel pump.

1-C80 Cleaner & Tester; 2-Engine; 3-stopper; 4- Fuel-inlet hose

to engine; 5-Auto tank; 6-Auto filter; 7- Engine fuel supply hose;

8-Auto fuel pump;

The hose line connection of theengine without returnhose is

shown as in Fig.02.

The pictures

Pour the mixture of gasoline and detergent into steel bottle of

the C80.

Close the valve of C80’s fuel-outlet pipe and open the valve of

C80’s air-inlet port and then connect to the compress air.

Adjust the pressure of air within 0.3 to 0.4MPa(3 to

4kgf/cm2) by air control valve.

Connect the fuel supply adaptor of C80 to fuel supply pipe of

the car fuel system, and open the ball valve. Check if it has

some leaking between all the connections. There must have

no any leaking when doing the cleaning work.

Start engine to start flushing the fuel system.

Drain out the pressure in the C80’s bottle after flushing, and

then disconnect the C80.

Restore all of the pipes of the fuel system and check there

have no leaking.

Note: The connection ways for carburetor fuel system is

same to electronic fuel injection system. The pressure in

carburetor fuel system must be 0.07~0.35 kgf/cm2.

3 4

Pour the TWC detergent into the bottle. Open the Ball Valve

and Air Pressure Regulating Valve to keep the air pressure as

zero.

Connect the TWC Flushing Kit to the output pipe of the C80.

Disconnect the Intake Vacuum Pipe which near the throttle

and insert the TWC Flushing Nozzle into Intake Vacuum Pipe

as shown.

The operating procedure of TWC and intake manifold flushing:

Intake Vacuum Pipe

Start the engine, and open the Ball Valve slowly which be sure

to make the detergent into engine vacuum pipe very slowly.

The flushing process needs about 30 or 40 minutes.

Keep the engine speed up to 1000 rpm and press the

accelerator every 3~5 minutes to make the engine speed up to

2000 ~ 3000 rpm and keep this state for 30 seconds. Then

keep idle speed.

Do the flushing procedures as above until to exhaust the

detergent. Then stop engine and reconnect the vacuum pipe.

Start engine as idle speed for about 5 to 10 minutes to exhaust

the detergent in the pipe.

Pour the Throttle Body detergent into the bottle, and close the

Ball Valve of the fuel outlet pipe. Open the ball valve of the air

inlet port and connect to the compressed air. Adjust the air

pressure to about 0.5MPa(5kgf/cm2) and then close the

Ball Valve of air inlet port.

Connect the spray nozzle kit to the fuel outlet port of the C80.

The operating procedure of Throttle body and exhaust pipe

flushing:

Remove the pipe ahead of throttle before flushing as shown.

Put the spray nozzle kit in the throttle body as shown and start

the engine. And then open the Ball Valve of fuel outlet port .

56

Caution

It must initialize the Throttle Position Sensor by automotive

scan tool after cleaning. Otherwise the fault indicating lamp

will lighten on, and PCM will record a DTC.

Keep the engine speed up to 1000 rpm and press the

accelerator every 3~5 minutes to make the engine speed up to

2000 ~ 3000 rpm and keep this state for 30 seconds. Then

keep idle speed.

Do the flushing procedures as above until exhaust the

detergent.

Reconnect the pipes and initialize the throttle.

Warranty Ser vice

There are 3 years' warranty for AUTOOL product main unit and

1 year warranty for the accessories since the day the customers

have received the product parcel.

Repair or replace the equipment will be done according to the

specific fault conditions;

We guarantee that all replacement parts, accessories or

equipment are brand new;

When there is a product breakdown that can not be solved

within 90 days, customer should provide video and pictures as

proof, we will bear the freight cost and provide customer the

accessories in need to replace. After receiving the product for

more than 90 days, the customer shall bear the freight cost,

we will provide the accessory for free to replace.

Warranty Access

Product is bought through non-official AUTOOL purchase

channel.

Product failure is caused by incorrect use of the product, use

for other wrong purpose or human factors.

Warranty Access

Disclaimer: The AUTOOL Technology Co, Ltd. reserves the right

to change product designs and specifications without prior notice.

The physical appearance and color may differ from those shown

in the instruction manual. Please refer to the actual product. If

you have any question, please contact the dealer or the Autool

service center. The company have the final explanation right of

product and shall not bear any consequences due to

misunderstanding.

7 8

Table of contents

Other AU Tool Ultrasonic Jewelry Cleaner manuals