HEUTE Neptun SCS1 dry User manual

Operating Manual EN

Neptun SCS1 dry

Sole Cleaning System

2

Important – Read rst

Only put the machine into operation once you have read and un-

derstood the operating instructions. We shall be happy to answer

any questions you may have.

HEUTE® dry sole cleaning system Neptun SCS1 dry cleans dirty

soles of working and safety shoes and boots. HEUTE® dry sole

cleaning systems are built and tested in accordance with the latest

safety regulations. The faultless fuctionality and operational assur-

ance of the device can only be guaranteed if the generally applica-

ble safety precautions and device-specic safety information in this

operational manual are observed during use. The guarantee is not

valid in relation to damages caused by a failure to observe this op-

erating manual. The manufacturer assumes no liability for personal

injury or damage to property arising as a result of this. In the event

of problems please contact our service department immediately.

Intended use

HEUTE® Neptun SCS1 dry sole cleaning systems are used for the

external cleaning of closed shoes and boots by means of electrically

driven brushes. Other use is not permitted! Only use the spare parts

approved for use with the machines by the manufacturer. Operation

is only permissible in closed rooms whilst observing the regulations

mentioned in the chapter "Safety instructions".

Use in potentially explosive environment is not permitted.

Foreseeable misuse

The sole cleaning machine is not suitable for use as follows:

- Cleaning and care of human body parts and objects that are not

parts of a shoe.

- Use as a tool for working on surfaces.

- Use with the addition of uids - the machine is designed exclusively

for dry operation.

Safety instructions

Read this operational manual carefully and follow

our instructions for starting up and use.

The machine must not be changed or modied

because this may lead to risks such as a short circuit,

electric shock, re. Maintenance and repair must be

carried out exclusively by persons authorised for the

purpose, using original parts only.

The use of non-original spare parts or the implemen-

tation of unauthorised modications to the machine

will result in cancellation of the declaration of

conformity issued by the manufacturer/distributor

and sign as well.

Use the machine in closed rooms only.

Operation is only permissible at ambient tempera-

tures between 0° C and 40° C.

The machine is not suitable for permanent operation.

It is essential to consider the values for short-time

operation (STO) mentioned on page 9 (Technical

data).

Do not continue using the machine when the cleaning

brushes are worn. This may damage the shoes. The brush-

es must be replaced by a qualied person.

The design complies with the protection class IP55. The

voltage supply is three-phase 400 V + grounding - power:

0,75 kW. Observe the specic data provided on the

factory label.

During use, the motor may heat up to temperatures upt to

90° C. Do not touch the hot motor without safety gloves.

Use by children, in particular when unattended, must be

ruled out. Make sure that any contact between (house-

hold-) animals and the machine is ruled out.

Please observe without fail that whilst the roller brushes

are used, no shoelaces, tongues and straps on the sides

of the shoes/boots will touch the ground. They can be

caught by the roller brushes, which could cause injuries

or damage of the footwear.

Always disconnect the mains plug prior to cleaning,

service and repair work. Do not continue to use the

machine if the machine or the control cabinet with cabling

are damaged.

Ensure that the machine is installed at ground level.

Enter and use the machine only with closed shoes/boots

appropriate for dry cleaning.

The machine may only be passed through. Hasty

movements (running) can lead to accidents (falling).

Support the safe footing when passing always by holding

with both hands on the handrails.

Do not touch rotating brushes, whilst the machine is in

operation.

Excessive contact pressure during use of the brushes

can lead to damage of shoes/boots!

Stop using the machine, if the brushes do not rotate

freely and hazardous foreign objects affect the function.

The user is responsible for any personal injury and

damage to property that arise due to improper use,

faulty machine connection and/or operating errors.

When installed in commercial facilities, comply with the

industrial safety regulation applicable on site as well as

the accident prevention regulations issued by the profes-

sional associations for electrical systems and operating

equipment.

3

Table of contents

Important – read rst 2

Intended use 2

Foreseeable misuse 2

Safety instructions 2

Welcome 3

Scope of delivery 3

Declaration of conformity 3

Enviromental protection 3

Overview 4

Installation and commissioning 6

General information 6

Transport and installation 6

Electrical connection 6

Precaution while commissioning 6

Operation 6

Cleaning principle 6

Service and maintenance 7

Control 7

Cleaning 7

Maintenance 7

Recommended service intervals 7

Change of roller brushes 7

Cleaning of surfaces 8

Cleaning of roller brushes 8

Disassembly of brush axle 8

Access to gear motors 9

Trouble shooting 9

Technical data 9

Wiring diagrams 10

Part drawings 12

EN

Welcome

Dear Customer, we would like to thank you for purchasing one of our

HEUTE® industrial sole cleaning machines. You have purchased a

quality product, which - if used properly - will provide clean results

for many years.

This operating manual is a part of the machine, which contains im-

portant information on commissioning, operation and maintenance.

Please keep these operating instructions for future reference!

Scope of delivery

Sole cleaning machine, control cabinet, operating manual.

Declaration of conformity

The manufacturer herewith conrms the following machine of type

Neptun SCS1 dry complies with the directives listed below:

- Machinery directive (2006/42/EG)

Authorized representative Steffen Moersch,

same address as manufacturer.

Christian Löwe, Geschäftsführer

HEUTE Maschinenfabrik GmbH & Co. KG

Environmental protection

Disposal of transport packaging

The packaging materials of your new machine are environmentally

friendly and recyclable. Please help by disposing the packaging in

an environmentally friendly manner. The packaging must not be given

to children to play with. There is a risk of suffocation caused by the

cardboard packaging and plastic lms.

Disposal of the product

Old devices that are no longer in use are not worthless waste. Valua-

ble raw materials can be recovered through environmentally friendly

disposal. Please inform yourself about the current disposal methods

by contacting the person responsible within your company or your

local authority.

4

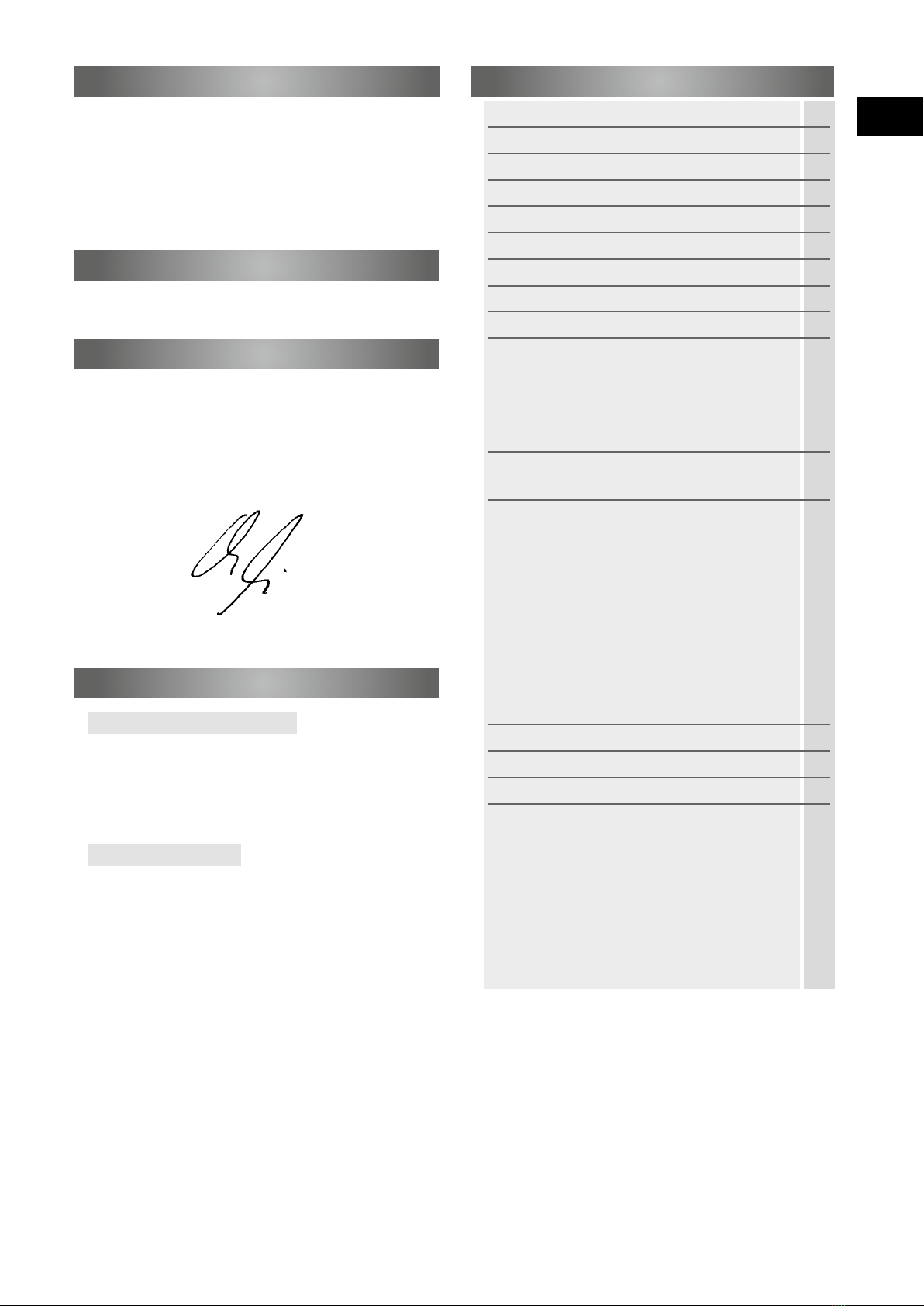

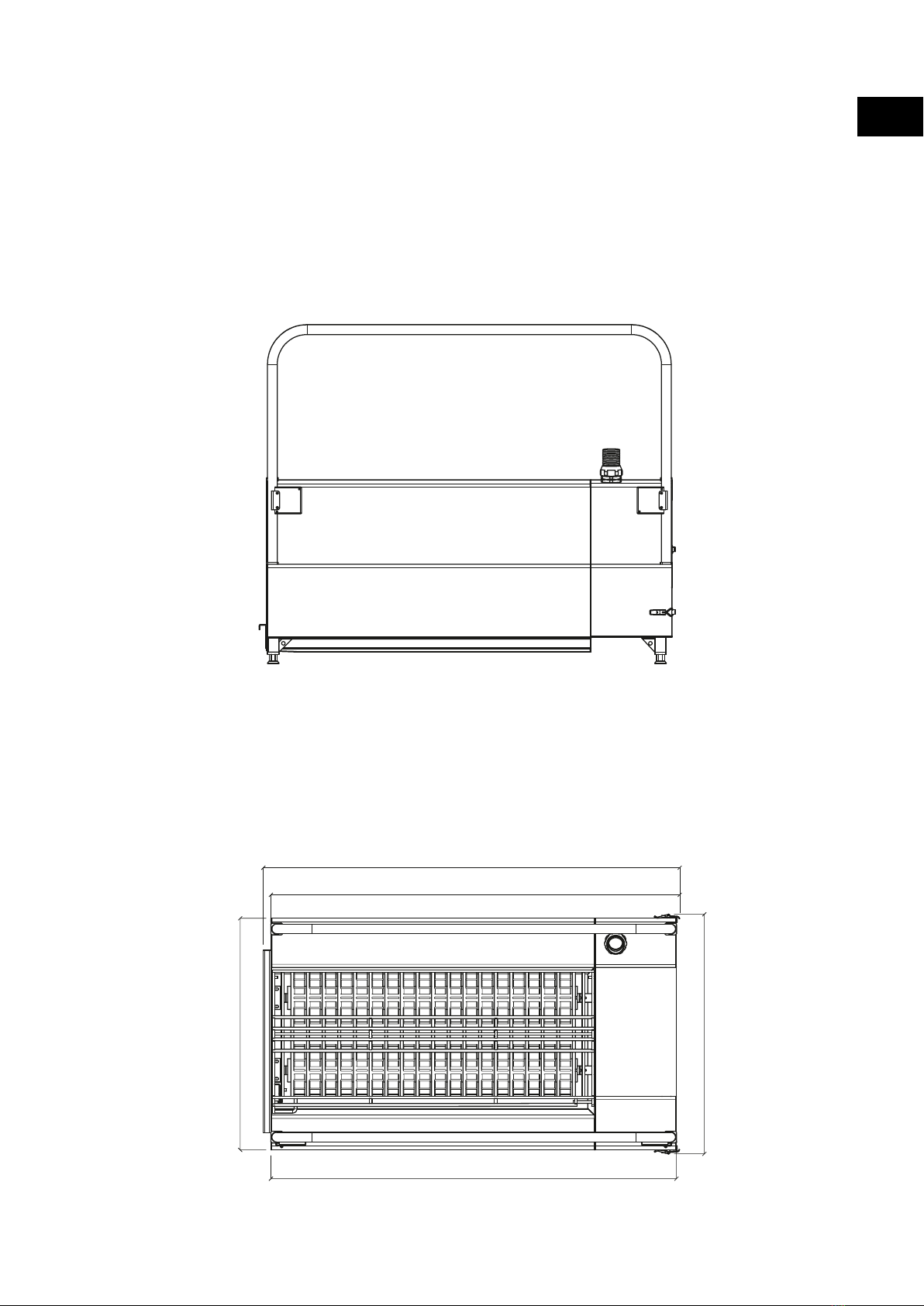

Overview

Control Cabinet:

Dim.: 430 x 330 x 200 mm

Adjustable feet

ABS

Power supply 400 V, 3-phase +

grounding 50Hz P=0,75 kW

PVC hose to protect electrical

supply line (length = 2m)

Reection sensor barrier

Reection

sensor barrier

Reector

Reector

Step grid

Inspection ap,

Reective sensor barrier

2 roller brushes Ø180 mm,

length = 1000mm

850 mm

1170 ± 15 mm

904 mm266 ± 15 mm

5

EN

1400 mm

850 mm

877 mm

1437 mm

1411 mm

6

Installation and commissioning

General information

Please follow below mentioned advices to protect the stainless steel

housing of the sole cleaning machine during storing, before installa-

tion, commissioning and use.

- Protect the machine against environmental inuences like rain,

sunshine and frost. Use the machine only in closed rooms.

- To avoid contact corrosion (e.g. carbon steels, steel spanes, tools

for steel processing) the surface of the machine must not be in

touch with other kind of steels.

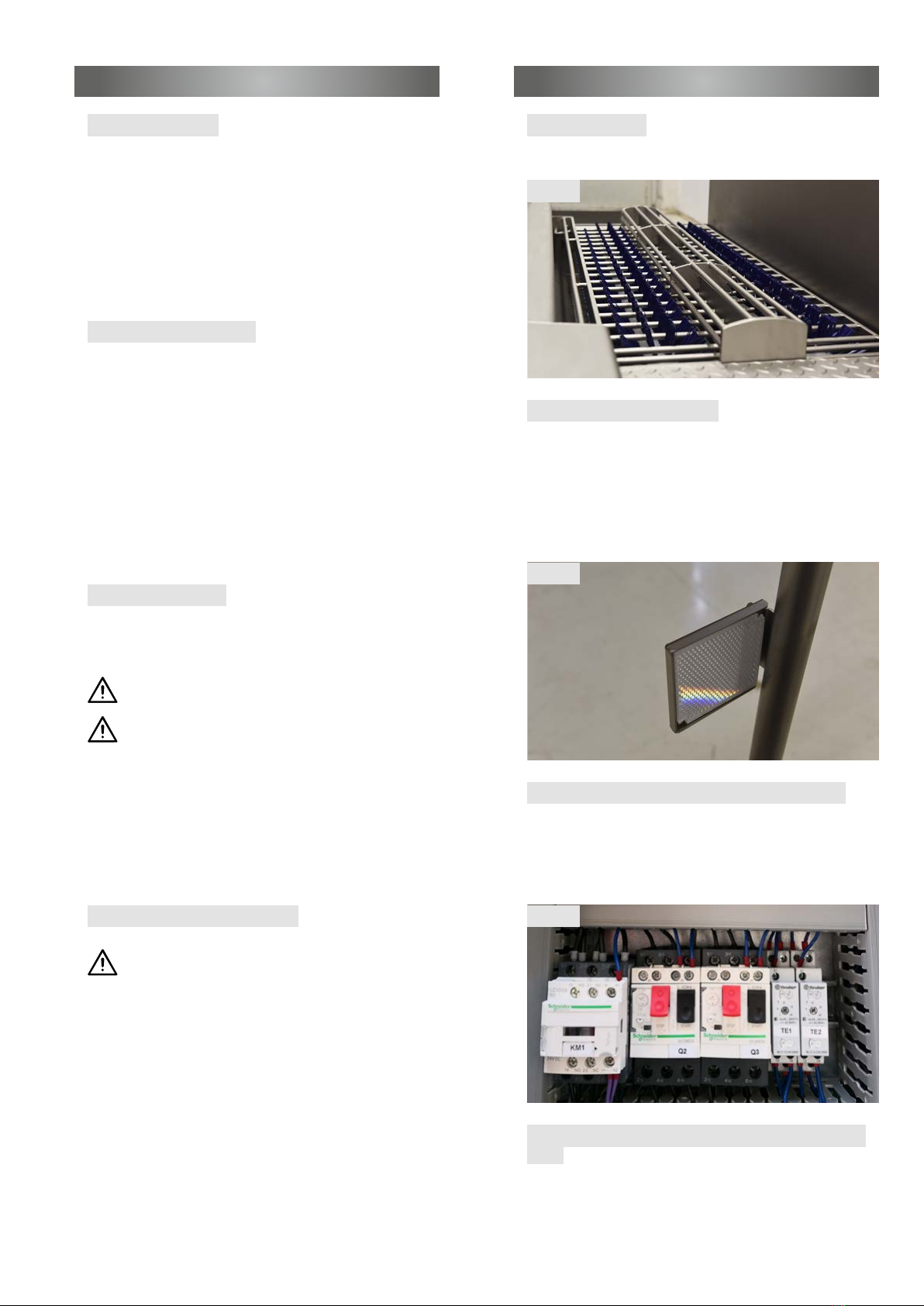

Operation

Cleaning principle

- Cleaning of shoes and boots with horizontal roller brushes (Fig. 1)..

Transport and installation

Weight of the machine is abt. 175 kg. Due to the heaviness,

transportation and unpacking should be done by 2 workers using

suitable means of transport.

Use the machine in closed rooms only. When choosing the place of

installation please consider the necessary space 1430 x 877 mm

and the availability of power supply (more details see further course

of chapter Installation and commissioning). When setting up the

machine, make sure that the dirt drawer can be pulled out complete-

ly at the front. The Control cabinet has to be xed at suitable place

on the wall. The ground must be level and slip protected. To ensure

stability level out any uneven oor areas by adjusting the feet under

help of a spirit level.

Electrical connection

- 3-phase 400 V + grounding, power: 0,75 kW

- Connection to the clamps in the control cabinet (see sector Techni-

cal data > conguration of clamping strips)

Take care that available voltage in your country is corres-

ponding to machine's voltage!

Machine's power supply must be electrically protected

against indirect contacts:

- High sensitive difference power protection device max. 30 mA.

- This protection must be provided by the house installation and is

not supplied with the machine.

- The control cabinet should be mounted approx. 1,2 m above oor

level for easy accessibility.

- Turn-on and check rotating direction of the brushes.

Precaution while commissioning

Never remove or block the contact switches on the housing,

which are active when the grid is closed/down. When

opening the grid during operation these will automatically

turn off the power supply and will stop the rotation of the

brushes.

Use of sole cleaning function

The sole cleaning function starts when entering the machine

(possible from both sides) thus activating an optoelectronic signal

(reection sensor barrier) (Fig. 2) and causes:

- Rotation of roller brushes which are driven by a gear motor.

The function stops when the reection sensor barrier is no longer

occupied.

Adjustment of rotation time of the roller brushes

The desired rotation time for the cleaning operation of the both

roller brushes can be individually adjusted by means of timers

in the control cabinet (Fig. 3). The factory preset value is

10 seconds.

Proper cleaning of the running treads of shoes and

boots

The dwell time (exceedance time) has a signicant inuence on the

cleaning result. Cross the step grid in small steps from one end of

the machine to the other. Use the handrail with both hands all the

time.

Fig. 1

Fig. 2

Fig. 3

7

EN

Recommended service intervals

Below mentioned intervals are based on our experiennce. In this

regard, however, the real applications play the decisive part (kind of

contamination, service period, et cetera.) That is the reason why you

have to adapt the intervals according to your own experience.

Service and maintenance

Service and maintenance should be carried out only by custom-

er service technicians. To secure optimal functioning of the sole

cleaning machine, it should be controlled, cleaned and serviced in

regularly intervals. HEUTE® cleaning machines are service reduced

and reliable. However, there are components which will wear out after

a correspondingly long service life and/or reduce the cleaning result.

Unplug the power supply at the control cabinet prior to all

interventions in the machine.

In case of unintended opening of the grid the rotation of the

roller brushes stops automatically.

Control

The machine should be checked for correct function regularly. While

doing so, inspect whether components are damaged or worn and

whether the machine is able to ensure the required cleaning effect.

No foreign object is allowed to be within the rotary area of the roller

brushes.

Cleaning

The cleaning intervals of the machine depend on the in-plant oper-

ating conditions. With increasing dirt, shorten the cleaning intervals.

With decreasing dirt, extend the cleaning intervals accordingly.

Maintenance

The Neptun SCS1 dry is considered to be very low-maintenance and

reliable. However, there are some components, which will wear out

after a long period of service and will reduce the cleaning quality -

e.g. brushes.

Brushes, the bristles of which, for example, have snapped off or got

too soft to be able removing dirt in active manner, point to excessive

wear.

Suitable spare parts can be purchased from the specialist dealer or

manufacturer.

Instructions on replacement of wearing parts are described below in

the chapter Service and maintenance.

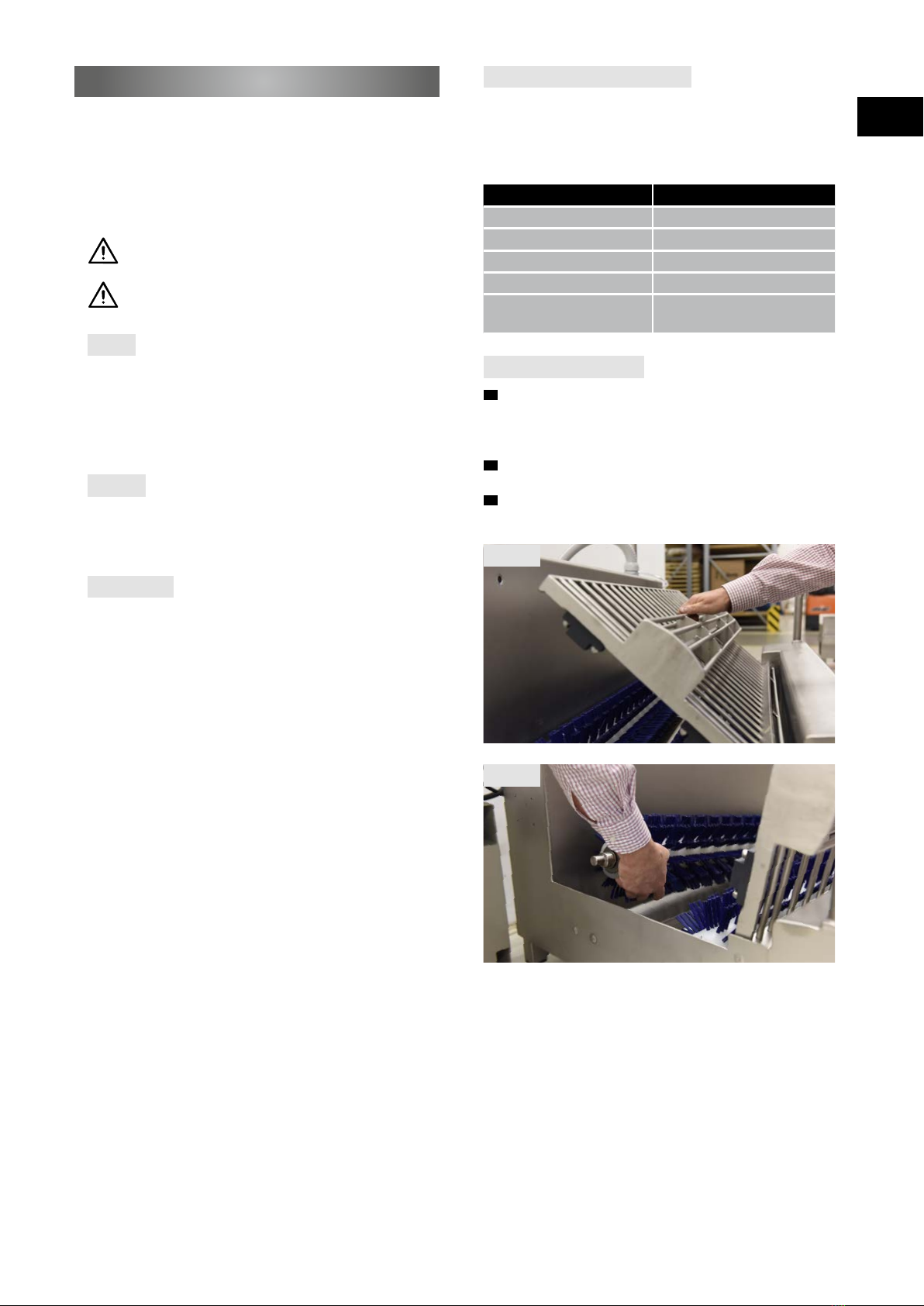

Change of roller brushes

1. Lift up the grid (locking function when open) to get access to

the two roller brushes and to activate the switching-off fuction of

the machine. The roller brushes can be removed without special

tools (by two persons, if necessary) (Fig. 4).

2. Horizontal roller brushes: Pull the front side up (Fig. 5). The roller

brushes are driven by a cross pin placed on the gear motor side.

3. When re-inserting the roller brushes make sure that the cross

pin is positioned correctly and the brush ts properly.

Fig. 5

Fig. 4

Service

Interval

Dirt removal from drawer 1 x /week

Control 1 x /week

Cleaning of surfaces 1 x /week

Cleaning of brushes 1 x /month

Change of roller brushes every 5-7 years,

earlier when worn

8

Cleaning of surfaces

The micro-blast stainless steel surface is made of stainless steel

type 304.

During the cleaning work, the following has to be noted, and

cleaning has to be carried out always by thoroughly ushing with

clear water:

-Avoidance of contact with carbon steel

-No use of steel sponge, grinding powder

-No use of chlorine products and bleaching agents

Cleaning of roller brushes

The nylon brushes must be cleaned dry or wet during the cleaning

intervals, depending on the degree of soiling. Dry cleaning can be

carried out by knocking/sucking off the dirt particles with the brush

removed (see Change of roller brushes). A wet cleaning of the nylon

brushes must be carried out with plenty of water without pressure

(no high pressure cleaner) or by spraying or soaking. Use a mild

additional cleaning medium for wet cleaning, make sure that the

cleaner does not contain any corrosive components.

Disassembly of brush axle

1. Remove roller brush (see chapter Service and maintenance >

Change of roller brushes)

2. Remove Allen screw on the front longitudinal side of the brush

body with suitable tool (Fig. 6).

3. Remove snap ring located at the face of the brush body with

suitable tool, and subsequently extract the distance washer.

4. Now the brush can be pulled off the axle (Fig. 8).

5. When assembling, put the pin in the center position of the brush,

tighten the grub screw, insert distance washer (ø 30 mm) and

mount the snap ring.

Fig. 8

Fig. 7

Fig. 6

9

EN

Fig. 9

Access to gear motors

Remove the side cover by opening both clamping brackets – no tools

required (Fig. 9).

Technical data

Dimensions: 143,7 cm x 82,7 cm x 117,5 cm

(width x depth x height)

Weight: 175 kg

Connected values: three-phase 400 V + grounding

Power: 0,75 kW

Protection category: IP55

Short-time operation (STO): 8 min

Airborne noise emission: less than 80 dB(A)

Troble shooting only by qualied personell

Machine does not work

Power supply interrupted or malfunction of

components

Please consult qualied specialists

The motor is blocked or runs rough

Foreign objects are inside running parts

Immediately disconnect the machine from the

power supply. Inspect the machine and roller

brushes for foreign objects (turning the roller

brushes by hand), and remove such matter

The machine is very loud during the cleaning

process

Foreign objects are inside running parts

Immediately disconnect the machine from the po-

wer supply. Inspect the machine and roller brushes

for foreign objects (turning the roller brushes by

hand), and remove such matter

or

Inspect the roller brushes for correct t

10

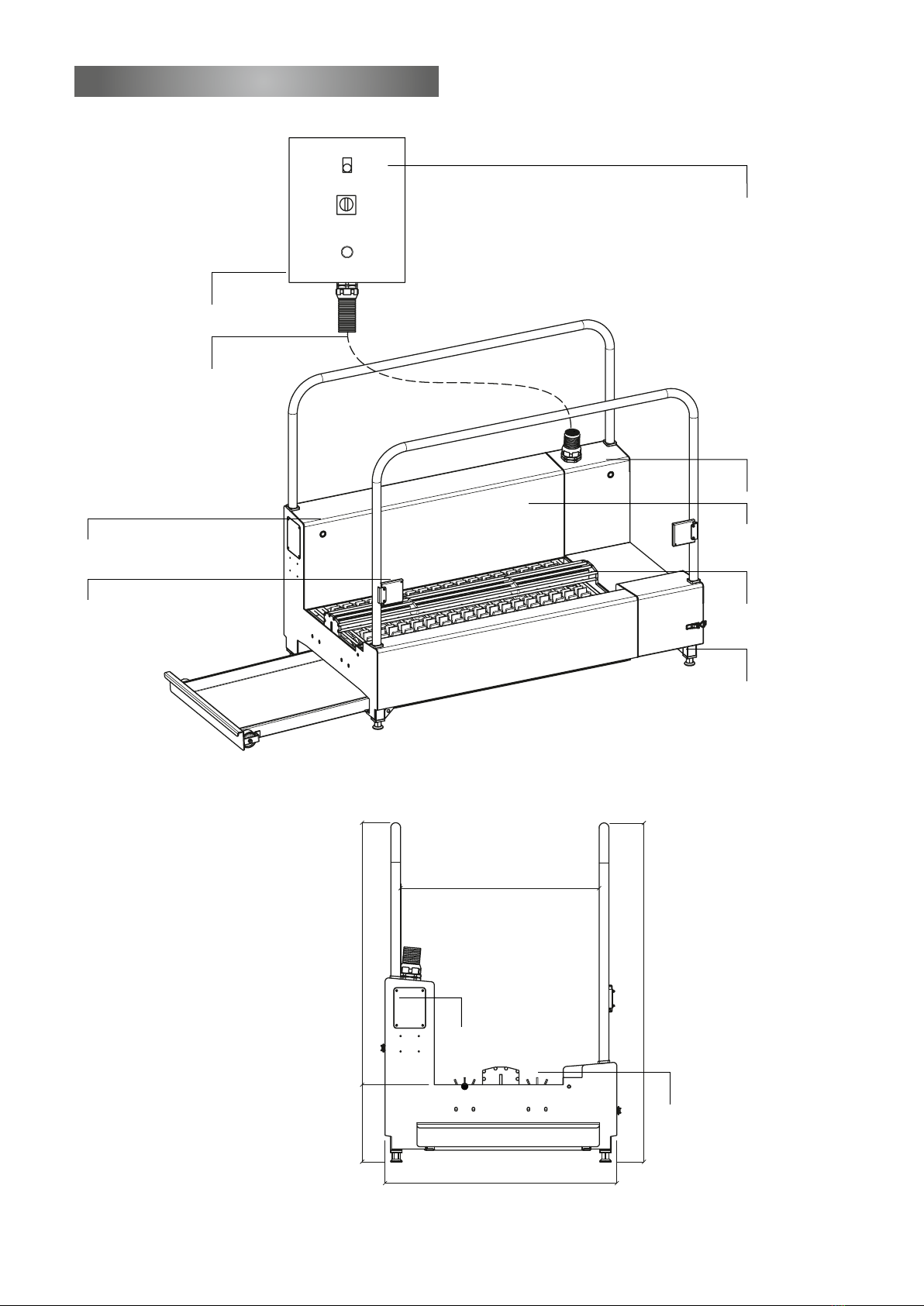

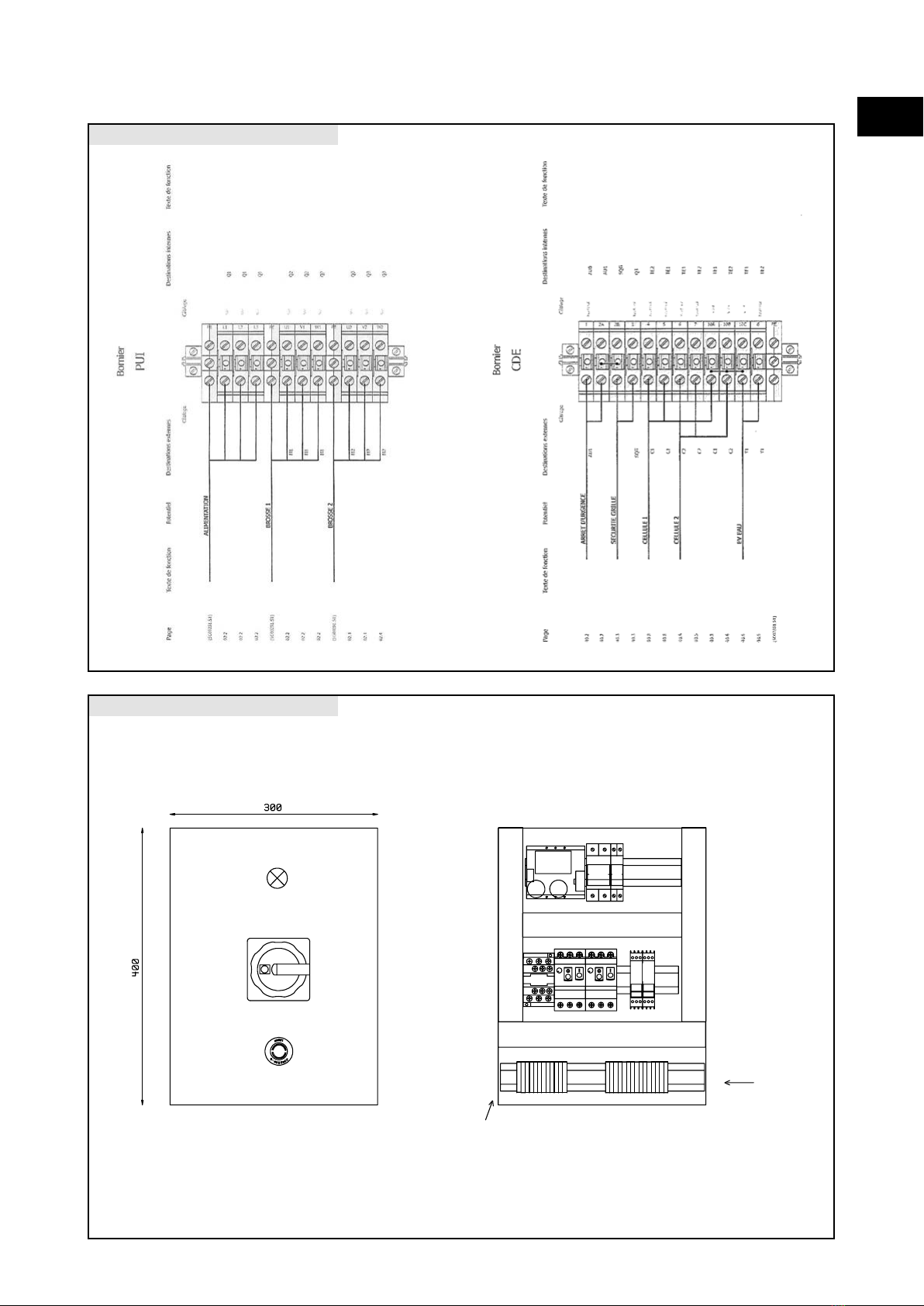

Wiring diagram II

Wiring diagram I

Wiring diagrams Neptun SCS1 dry

3 * 400 Volt

L13

L12

L12

L11

L11

M

3

M

3

PUI

1

2

3

4

5

6

Q1

25A

1

2

3

4

5

6

KM1

03-20

1

2

3

4

5

6

Q2

- -

1 A

0.37 Kw

UVW

M1

PUI

1

PUI

4

PUI

2

PUI

5

PUI

3

PUI

6

1

2

3

4

5

6

Q3

- -

1A

0.37 Kw

UVW

M2

PUI

7

PUI

8

PUI

9

PUI

L12

03-2

L11

03-2

Clamping strips and connections

Disconnect

switch

Adjustment

to A1

Brush 1 Brush 2

Power

Adjustment

to A1

11

Conguration clamping strips

Conguration control cabinet

EN

1

2

3

4

5

6

7

8

9

1

2A

2B

3

4

5

6

7

10A

10B

10C

8

AU0

F1 F2

U1

Q2 Q3

KM1

TE1

TE2

PUICDE

POWER ON

H1

ARM

clamping strips 1-3

internal clamping

strips

12

Part drawings Neptun SCS1 dry

3

14 5 7

1

8

6

2

4

12

11

910

13

Nr Item Article No.

1 Coupling – stainless steel 06800501

2 Axle of the roller brush, diam. 180x180 mm, stainless steel 304 06800502

3 Roller brush nylon, diam. 180 mm, length 1000 mm, bre 1 mm 06800503

4 Axial bearing 06800504

5 Position switch grid AP3T13Z11 06800505

6 Gear motor P=0,37kW M05C D1 06800506

7 Gear motor P=0,37kW M05C B1 06800507

8 Bearing D20 Nylatron 06800508

9 Nut Perfect CEPFV36 06800509

10 Gasket for connection piece PG36 06800510

11 Connection piece PG36 06800511

12 PVC hose GP 40x46 06800512

13 Light barrier OGP300IFM (24V CC) 06800513

14 Reector E20739 06800514

Höhscheider Weg 37 · 42699 Solingen · Germany

Phone: +49(0)212-380 310 · Fax: +49(0)212-380 31-49

E-mail: info@heute-gmbh.de · Internet: www.heute-gmbh.de

EN • 02-2019

Table of contents

Other HEUTE Ultrasonic Jewelry Cleaner manuals