X-tra 70 H

Elmasonic ultrasonic cleaning unit

Elma GmbH & Co KG · Kolpingstr. 1-7 · D-78224 Singen · Tel. +49 (0) 7731 / 882-0 · Fax +49 (0) 7731 / 882-266 · info@elma-ultrasonic.com

www.elma-ultrasonic.com

Elma Order Nos

Elmasonic X-tra 70 H (230 V) 100 1021

Elmasonic X-tra 70 H (115 V) on request

Stainless steel lid 100 1476

Stainless steel basket (mm / inch)

276 x 126 x 80 / 10.9 x 5.0 x 3.1

100 1361

Additional accessories on request

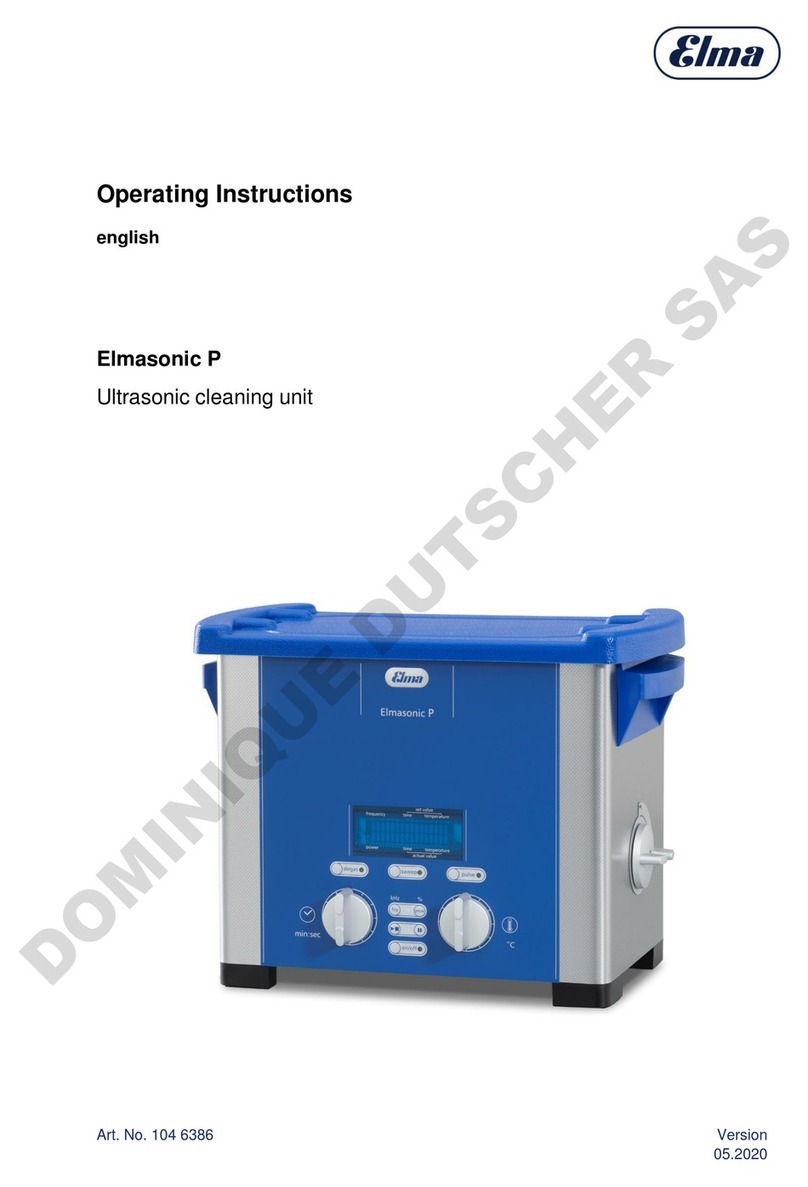

Pictured X-tra 70 H

Technical and optical information are subject to change Elma_ch_01/2011

The extra legue of ultrasonic cleaners “Made in Germany“

● long life through new cavitation-resistant stainless steel tank, with extended warranty for 3 years

● powerful through additional transducer systems

● Sweep – for optimal sound distribution because of electrical oscillation of the sound field

● 2 cleaning modes: “power“ for intensive cleaning, “soft“ for careful cleaning of sensitive materials

● strong heating power for a short heat-up time

● dry-running proof heating elements

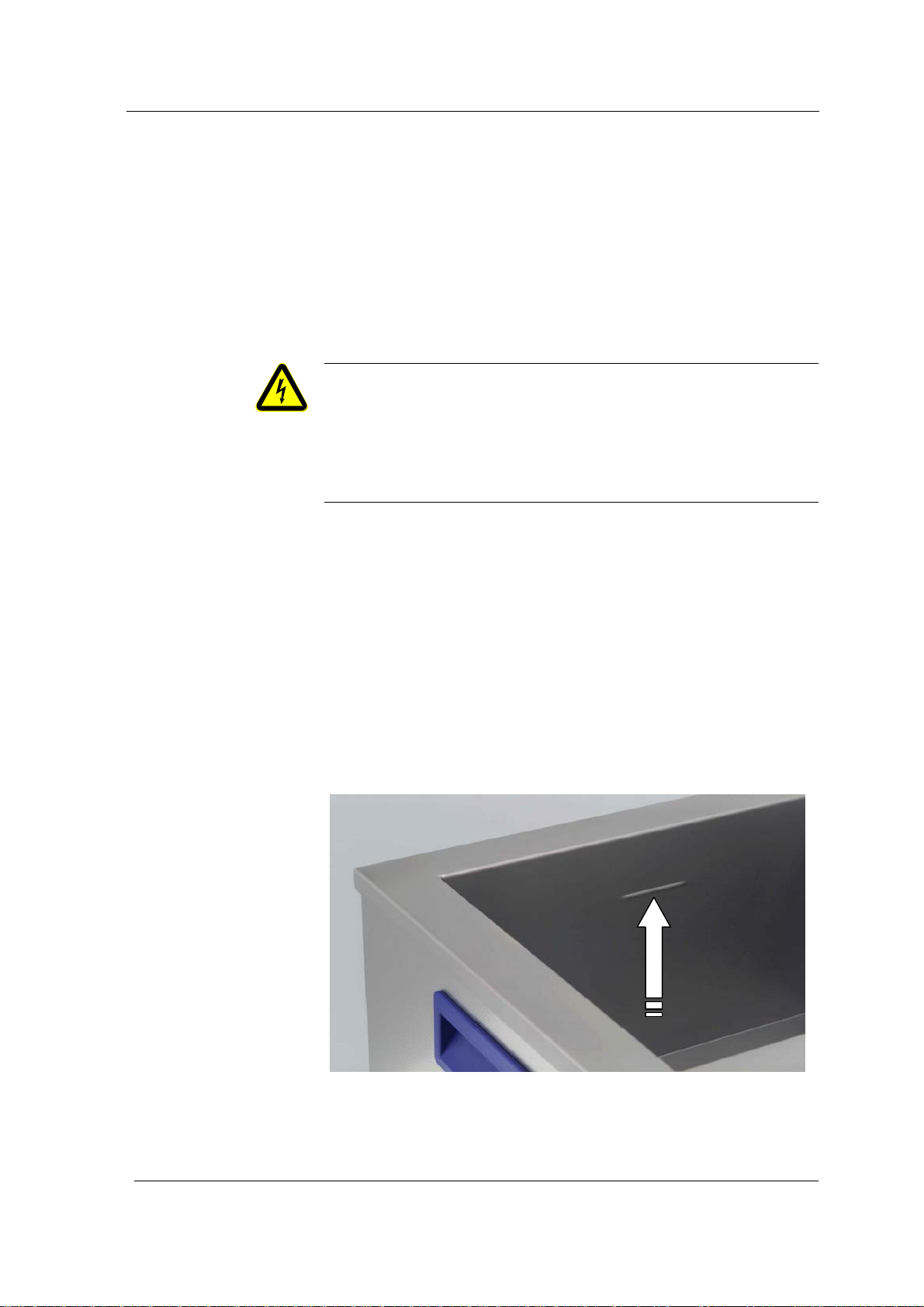

● practical handling through appliance inlet

● fast drainage, with welded pipes

● protected operating panel

● timer for ultrasonic activity, variable between 0 and15 min. and permanent operation

● temperature control 30 - 80 °C

Technical data

Mains voltage (Vac) 100-120V oder 200-240V

Mains connection 1 Ph. / 1N / 1 PE

Ultrasonic frequency (kHz) 35

Power consumption total (W) 600

Ultrasonic power effective (W) 110 / 180

Ultrasonic peak performance max.* (W) 720

Heating (W) 400

Power frequency (Hz) 50 / 60

Unit outer dimensions W / D / H (mm) 360 / 225 / 300

Tank int. dimensions W / D / H (mm) 300 / 150 / 150

Tank max. volume (litres) 6,5

Drain 3/8“

Weight (kg) 9,6

Material tank Stainless steel

Material casing Stainless steel

Protection class IP 20

* The signal form of the wave results in a factor 4 for the

ultrasonic peak max., depending on the modulation of the wave.

X-tra 70 H

Elmasonic ultrasonic cleaning unit

Elma GmbH & Co KG · Kolpingstr. 1-7 · D-78224 Singen · Tel. +49 (0) 7731 / 882-0 · Fax +49 (0) 7731 / 882-266 · info@elma-ultrasonic.com

www.elma-ultrasonic.com

Elma Order Nos

Elmasonic X-tra 70 H (230 V) 100 1021

Elmasonic X-tra 70 H (115 V) on request

Stainless steel lid 100 1476

Stainless steel basket (mm / inch)

276 x 126 x 80 / 10.9 x 5.0 x 3.1

100 1361

Additional accessories on request

product prole

Pictured X-tra 70 H

Technical and optical information are subject to change Elma_ch_01/2011

The extra legue of ultrasonic cleaners “Made in Germany“

● long life through new cavitation-resistant stainless steel tank, with extended warranty for 3 years

● powerful through additional transducer systems

● Sweep – for optimal sound distribution because of electrical oscillation of the sound field

● 2 cleaning modes: “power“ for intensive cleaning, “soft“ for careful cleaning of sensitive materials

● strong heating power for a short heat-up time

● dry-running proof heating elements

● practical handling through appliance inlet

● fast drainage, with welded pipes

● protected operating panel

● timer for ultrasonic activity, variable between 0 and15 min. and permanent operation

● temperature control 30 - 80 °C

Technical data

Mains voltage (Vac) 100-120V oder 200-240V

Mains connection 1 Ph. / 1N / 1 PE

Ultrasonic frequency (kHz) 35

Power consumption total (W) 600

Ultrasonic power effective (W) 110 / 180

Ultrasonic peak performance max.* (W) 720

Heating (W) 400

Power frequency (Hz) 50 / 60

Unit outer dimensions W / D / H (mm) 360 / 225 / 300

Tank int. dimensions W / D / H (mm) 300 / 150 / 150

Tank max. volume (litres) 6,5

Drain 3/8“

Weight (kg) 9,6

Material tank Stainless steel

Material casing Stainless steel

Protection class IP 20

* The signal form of the wave results in a factor 4 for the

ultrasonic peak max., depending on the modulation of the wave.

Elmasonic X-tra 70 H (230 V) 110 1021

200 - 240V

Technical and optical information are subject to change

Änderungen, Verfügbarkeit und Preise der Produkte vorbehalten. Es gelten unsere Allgemeinen Geschäftsbedingungen, u. a. nachzu lesen unter www.beco-professionals.com. Bitte informieren Sie uns, wenn Sie unsere Werbung nicht mehr erhalten möchten.

Technical changes as well as changes in production and prices are subject to our approval. For our terms of delivery and payment please go to www.beco-professionals.com. Please let us know if you don‘t want to receive our promotion anymore.

Sitz der Gesellschaft/Reg. oce: D-21500 Geesthacht · Amtsgericht/Register Court: Lübeck HRB 314 GE · Geschäftsführer/Managing Directors: Jürgen Birkenstock, Marek Birkenstock · USt.Id.Nr./ VAT-Number: DE 135283788 · ILN 40 22739 00000 3 · WEEE.Reg.Nr.: DE12990100

BIRKENSTOCK & CO. GMBH · D-21500 Geesthacht · Germany · k +49 (0) 41 52 / 80 96 80 · +49 (0) 41 52 / 80 96 96 · www.beco-professionals.com

Distributed by: