Audio Technology NAGRA-D User manual

SERVICE MANUAL

NAGRA-D/DII

20 01002 253

•

~ ~~

AUDIO

TECHNOLOGY

SWITZERLAND

C

CHAPTER I

CHAPTER II

CHAPTER III

CHAPTER IV

CHAPTER V

CHAPTER VI

CHAPTER VII

CHAPTER VIII

INTRODUCTION

MECHANICAL SECTION

CALIBRATION

TIME CODE

TECHNICAL INFORMATIONS

ACCESSORIES

SCHEMATICS

CHAPTER I

1.0 INTRODUCTION

1.0.1 Page numbering

1.1 IMPORTANT NOTES

1.

1.1 . Electrostatic discharge

1.

1.2 Tape care / handling

1.1.3 Output connection

to

a mixer

1.2 NAGRA-D FORMAT

1.2.1 Definitions

1.2.2 Error code format

1.2.3 Track format

1.2.4 Sector format

June 1994

1.0 INTRODUCTION

The concept

of

the NAGRA-D was

to

build a truly professional format that

is

reliable, will last

for many years and lends itself well

to

archiving. The arguments regarding the format, choice

of

tape etc. are not covered here.

The NAGRA-D is a four channel--digital audio recorder having 24 bits-

per

sample recording

on 6.35mm metal oxide tape, on either 5" or 7" reels,

of

the tape type as used by the DASH

or PRODIGI formats.

It

accommodates the sampling frequencies

of

32 kHz, 44.1 kHz and 48

kHz rendering

it

suitable for all types

of

professional recording applications.

The

NAGRA-D

is

transparent

to

the AES bus giving connection possibilities to a wide range

of

external digital

equipment.

The sound

on

the NAGRA-D

is

recorded

on

helical track, by means

of

a rotary head (scanner)

containing 4 separate VHS heads

(2

for recording and 2 for playback), allowing read after

write (off tape monitoring) which can be heard through the two, level adjustable, headphone

outputs. The recorded tracks have a width of70 ttm and a pitch

of

80.7ttm. At the longitudinal

tape speed

of

99.25 mm/s, the scanner makes 62.5 revolutions

per

second (3750

r.p.m.)

for

a sampling frequency

of

48 kHz.

Three

longitudinal tracks (Control, Cue and Time code) are also recorded on the tape.

The

control track is used to synchronize the tape transport during playback. The

CUE

track can

record a mix

of

the four digital inputs, for search features,

or

alternatively it can record an

external cue microphone for commentary applications. This track can be monitored at high

speed,

in

either direction, allowing rapid sequence location audibly. (Please refer to the

instruction manual for the "footprint"

of

the format). The third longitudinal track is the

SMPTE/EBU time code track. The specifications

of

the format can be seen at the beginning

of

chapter

IV

"Time code"

The format

of

the NAGRA-D allows 4.608 x

10

6 bits per second to be recorded, meaning that

on

a 5" reel

of

tape 16.03 x

10

9 bits (16 giga bits). The combination

of

selected tape speed and

number

of

channels to

be

recorded gives tape durations to satisfy almost all applications.

Apart from the two AES digital inputs, four analog inputs are available for either line

or

microphone input sources. When

in

microphone operation each

of

the four inputs is switchable

between "T" powering, + 12V phantom and

+48V

phantom. The signal levels are adjusted

using the input potentiometers, and the levels are indicated on the four microprocessor

controlled meters. Microprocessor control

of

the entire machine gives almost limitless

possibilities, not only as far

as

the digital recording is concerned, but also for external control,

editing, fault diagnosis etc.

NOTE:

June 1994

The NAGRA-D has

no

user selections I switches inside all mode selections etc.

are made via

an

external PC

or

by the MENU mode.

I 1

1.0.1

PAGE

NUMBERING

The page numbering

in

this manual

is

done in such a way so that update

or

replacement pages

may be added at any time. Each page number starts with the number

of

the chapter (in Roman

numerals) followed by the page number.

EXAMPLE

III

-4

This indicates Chapter III page 4

If

a page were to be added after this page but before page 5 then the number on the additional

page would

be

III 4. 1

Each

page

is also marked with the date in the bottom left corner.

If

a new page is received

then the page with the old date should be discarded. Update pages for this manual will

be

sent

out

according to the return

of

the service manual registration form at the beginning

of

this

manual.

June 1994 I 2

1.1 IMPORTANT NOTES

1.1.1 ELECTROSTATIC DISCHARGE

The Nagra-

D's

electronic circuits are all SMD devices using CMOS and MECL technology,

which renders them very susceptible to electrostatic discharge. These circuits are fully

protected while installed

in

the machine, however

if

any

of

the circuits are to be disconnected

and/or removed from the machine then the operator must at all times be connected to ground

via a wrist bracelet and the circuits must only

be

placed on a conductive mat also connected

to

ground. The circuits are printed with the international sign indicating the danger.

1.1.2

TAPE

CARE / HANDLING

Although scissor editing is technically possible on the NAGRA-D, it is not recommended to

touch the tape unless absolutely necessary. Cotton gloves are recommended for this, in order

to prevent moisture (finger prints) from the skin affecting the tape.

Due to the fact that the tape

of

the NAGRA-D is not protected by a cassette, it is

recommended to spool tapes at a slower than maximum speed for storage purposes (see

instruction manual

"MENU's").

If

the tape is rewound at high speed, the trapped air during

rewind causes the tape to wind unevenly on the reel, meaning that the edges

of

the tape stand

proud.

If

the plastic reel is now handled, there is a risk

of

physically damaging the edges

of

the tape. On the lower edge

of

the tape

in

the format

of

the NAGRA-D are the time code and

Control track (see "footprint"

in

the instruction manual) which will cause problems for playing

back the tape

if

the edges

of

the tape are damaged.

June 1994 I 3

1.1.3

OUTPUT

CONNECTIONS TO A MIXER

The NAGRA-D does not have transfonners on its audio outputs. This means that

if

the outputs

are to be connected to the inputs

of

a mixing console so that the four channels can

be

mixed

down to two, then

be

sure that the inputs to the mixer are set to the line position.

If

they are

set to the Phantom

+48

position for example then the output OP-Amps

of

the NAGRA-D may

be damaged.

June 1994 I 4

1.2

THE

NAGRA-D FORMAT

1.2.1 DEFINITIONS

Scanner rotational frequency

1 rotation

of

the scanner

Wrap angle 88°

1.2.2 ERROR CODE FORMAT:

Type

of

coding:

Sample size:

N°

of

samples in an ECC block

N°

of

audio samples / rotation

N°

of

ECC blocks / rotation

N°

of

ECC blocks / track

N°

of

ID samples / track

N°

of

ID samples per block

: FS

/768

= REC1 + PLAYI + REC2 + PLAY2

Reed-Solomon on a Gallois field 256

(8

bit

words), interlaced coding Inner

Cl(38,34,5)

and

outer

C2(l2,9,4)

24 bits

9 x

11

= 99

768 x

4=

3072

3072/99=

31.03

(=32

blocks)

32/2=

16

16

x 99 -1536 = 48

48/16=3

11

samples

of

24 bits (data or ID)

33

columns

of

C2 coding

CNTl

DATA

DATA

DATA DATA

DATA

DATA

DATA

ECCl

E

CC

1

ECCl

ECC1

----

-

CNT2

DATA

DATA

DATA DATA

DATA

DATA

DATA

ECC1 ECC1 ECC1 ECC1

----

CNT3

DATA DATA

DATA DATA

DATA

DATA

DATA

ECC1

ECC1

ECCl

ECC1

-----

CNT4

DATA

DATA

DATA DATA

DATA

DATA

DATA

ECC1

ECC1 ECC1

ECC1

-----

CNT5

DATA

DATA

DATA DATA

DATA

DATA

DATA

ECC'

ECC1

ECC' ECC'

-

---

CNT6

DATA

DATA

DATA

DATA

DATA

DATA

DATA

ECC'

ECC' ECC' ECC'

---

--

CNT7

DATA DATA DATA

DATA

10 10 10

ECC1

ECC1

ECCl

ECC'

-----

CNT8

DATA DATA DATA

DATA

10

10 10

ECC1

ECC1 ECC1

ECC'

----

CNT9

DATA DATA

DATA DATA

10 10 10

ECC1

ECC'

ECC1

ECC'

-----

CNT'C

ECC2

ECC2 ECC2 ECC2 ECC2 ECC2

ECC2

ECC1

ECC'

ECC1

ECC'

-----

CNT"

ECC2

ECC2

ECC2

ECC2 ECC2 ECC2

ECC2

ECC' ECC' ECC'

ECC'

----

CNT1

ECC2

ECC2 ECC2 ECC2 ECC2 ECC2

ECC2

ECCl

ECC'

ECC'

ECC1

June 1994 I 5

1.2.3 TRACK FORMAT

12

: 192 Sectors

1= Preamble (for mechanical stability and

pH

start up) = 128 symbols

2=

Sectors

3= Postamble (for mechanical stability)

1.2.4 SECTOR FORMAT:

1= Sync

8/9

2=

CNT (Counter) 4 Symbols

1 Symbol

1 ECC 1

3= One line

of

ECC block 37 Symbols =

33

data + 4 ECC Inner

Size

of

1 symbol = 8 bits for the DSP

Length

of

a sector

Number

of

sectors per track

Number

of

data bits per track

9 bits on the tape.

42 symbols

16

x

12

= 192

192 x 42 x 9 = 72576

Total bits without sectors 2 x 128 x 9 = 2304 bits

Total number

of

bits per track 72576 + 2304 = 74880 bits

Minimum bit rate = (FSI768) x (360/88) x 74880 Fs x 398.9

The bit rate must be a multiple

of

the sampling frequency:

Bit rate Fs x 400 = 19.2 Mbits/sec for Fs 48 kHz

= 17.64 Mbits/secforFs44.1 kHz

= 12.8 Mbits/sec for

Fs

32 kHz

Number

of

bits per track = 400 x 768/(360/88) = 75093 bits.

June 1994 I 6

Fuses inside the NAGRA-D

Inside the NAGRA-D there are five important fuses, the location and type

of

which needs to

be explained for easier diagnostics.

Open the top deck

of

the machine by loosening the two deck fastening screws on the front

of

the deck plate.

On the power input and protection circuit A-

15

located at the back-

of

the machine mounted

vertically behind the internal battery there are two fuses,

Fl

and F2. Both

of

these fuses are

wire ended soldered fuses located on the right-hand side

of

the circuit.

Fl

is a 5A fuse and is

connected

in

series with the internal battery.

F2

is a

SA

fuse and is connected between the

external

jX)wer

socket and the

jX)wer

circuits

of

the machine. (on early machines this was a 3A

fuse but should be replaced by a 5A)

Remove the bottom

of

the machine by removing the six screws that hold the lower plate on.

On the power converter circuit A23 which runs the full width

of

the rear

of

the machine there

are three more wire ended fuses,

Fl,

2 and 3.

Fl

is a

SA

and protects the

+5V

logic supply for the entire machine.

F2 is a 2A fuse and protects the power supply to the loading motor circuitry only.

F3 is a O.5A fuse and protects the unregulated supply which among other things supplies all

the meter lamps/leds and the all the indication leds.

If

the machine is fitted with the ND-AP auto jX)wering option then there is an additionnal fuse

located on the ND-AP circuit board.

June 1994 I 7

CHAPTER II

MECHANICAL

SECTION

DIS-ASSEMBLY AND RE-ASSEMBLY

June 1994

1.0 Removing the plexi glass cover.

1.1 Removing the dust cover.

1.1.2

Removing the outer tape roller.

1.1.3 Removing the tension rollers.

1.1.4 Removing the rotary tape guide.

1.1.5 Removing the scanner entry and exit guides.

1.1.6 Removing the pinchroller.

1.1.7 Removing the reel-holders.

1.2 Removing the longitudinal headblock.

1.3 Removing the pinchwheel and guide carriage.

1.4 Removing the reel motors.

1.4.1 Re-fitting the reel motors.

1.5 Removing the parking brake arms.

1.5.1 Re-fitting the parking brake arms.

1.6

Removing the complete scanner.

1.6.1 Removing the scanner rotor.

1.6.2

Re-assembly

of

the scanner.

1.7 Removing the capstan motor.

1.7.1 Re-fitting the capstan motor.

1.8 Removing the cam motor.

1.8.1 Re-fitting the cam motor.

1.9 Tension arms.

1.9.1 Re-mounting the tension arms.

2.0

Replacing the pinchwheel and guide carriage

2.1 Tape path height alignment

2.2

Mechanical spare parts list

2.3

List

of

special tools

BE SURE TO READ EACH PROCEDURE THOROUGHLY BEFORE COMMENCING

A list

of

mechanical parts can be found at the end

of

this chapter. The list contains all the parts

mentioned

in

the text and is split up into sections according to the part

of

the machine being

worked on. Some

of

the parts are sub-assemblies and must

be

replaced as a complete item.

When ordering parts be sure to use the full ten digit number as well as the description so

as

to avoid any confusion.

1.0 REMOVING

THE

PLEXI-GLASS COVER

Before attempting any work on the mechanics

of

the NAGRA-D the plexi-glass cover should

be

removed. This is firstly to allow easier access, and secondly to protect

it

from getting

scratched. Open the cover and hold it vertically, hold the two corners nearest to the hinges,

and move the cover about 4mm to the left and it will come away from the machine.

If

the NAGRA-D

is

fitted with the ND-SET 7" reels cover, then this must

be

removed as the

deck plate

of

the machine cannot be lifted with this option fitted.

June 1994 II 1

1.1 REMOVING

THE

DECK PLATE DUST COVER

In order

to

have access

to

the mechanics

of

the NAGRA-D it is necessary to remove the deck

plate

dust cover, which is on the top

of

the machine and is held in place by 5 screws. This

need not be removed unless access to the following parts is needed:

Pinchwheel and guide carriage assembly

Tension arm supports

or

their differential'transformers

Cam motor and drive mechanism and its differential transformer

Reel motor parking brakes.

If

access to any

of

the above is needed then proceed through the rest

of

section 1

of

this

chapter in the order that it is written which will cover all the steps necessary before the dust

cover can be removed.

1.1.1 REMOVING

THE

OUTER

TAPE

ROLLER

To

remove the deck plate dust cover

of

the machine, it is necessary to remove several

mechanical parts. Using a small jewelers screwdriver, as shown in Figure·1, unscrew the top

cap

of

the rotary

tape

guide Oocated directly behind the supply tension roller), and be sure not

to loose the small Mylar washer located under the cap, as well as the height adjustment

washer(s) located under the roller itself (if fitted).

June 1994

I2

1.1.2

REMOVING

THE

TENSION

ROLLERS

Before removing the tension rollers, put a small pencil mark on the deck plate indicating their

position while in PLAYBACK. Next slightly loosen the screw in the bottom

of

each tension

roller (max

1,4

of

a turn) and remove the roller.

The

fixation screws are also indicated in figure

1 below.

Note: On machines up to"serial number 1000520 the"left tension roller is slightly thinner than

the right

one

(approx. 19/100mm).

The

thinner one is recognized by a single

groove

around the top

of

the roller. On machines carrying serial numbers greater than 1000520

both rollers are

of

the new thinner type.

It

is important not to mix up the two types as

the counter roller will not count correctly

if

the two rollers are swapped over.

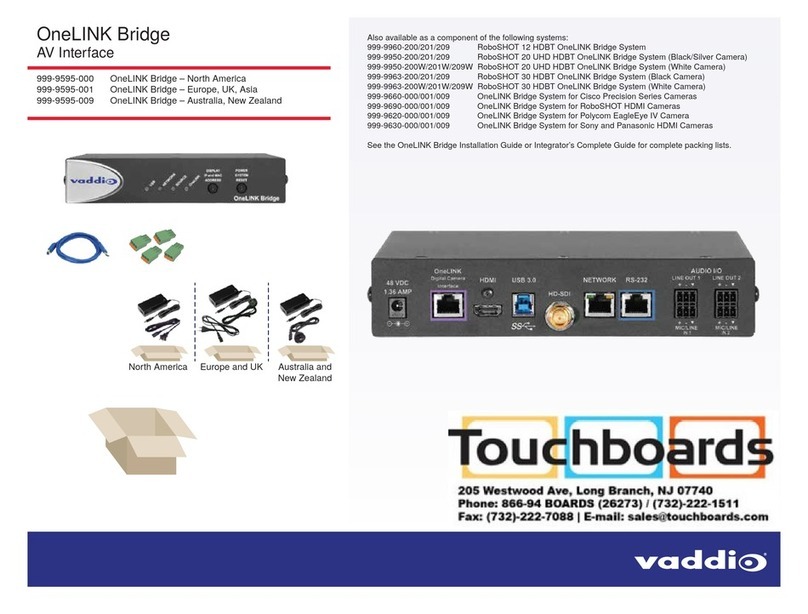

Outer tape guide roller fixing screw -

Left tension roller fixing screw

---

Figure

1:

June 1994

Showing where to unscrew the ourer

rape

roller guide and left

tension roller. The right rension roller pulley is removed in the

same manner.

II3

1.1.3

REMOVING

THE

ROTARY

TAPE

GUIDE

(beside the longitudinal headblock)

It

is

now

necessary to remove the rotary guide located immediately to the right

of

the

longitudinal headblock.

DO

NOT

move the positioning screw located in the right-hand side

of

the

guide,

as this adjusts the mechanical position

of

the control track (covered in the

electrical calibration section

of

this manual),

or

the small screw in the front

lower

edge

of

the

guide (painted red)

as

this will affect the

wrap

of

the tape on the scanner (this is factory

calibrated and 'should NEVER be'touched): SimplY'femove the

main

central

rear

screw holding

the

guide

to the

deck

plate, using a screwdriver, taking

care

not to loose its washer.

Figure

2:

Rotary outer

tape

guide,

showing

the

rear

fixing

screw.

June

1994

II4

1.1.4 REMOVING

THE

SCANNER ENTRY AND EXIT GUIDES

The entry and exit guides

to

the scanner are very critical parts

of

the transport, and should

be

treated carefully. Any mechanical damage to these parts will mean that the machine cannot

be

re-aligned correctly. These two guides must be removed before the deck plate

cover

can

be

removed. This is done by inserting a special driver into the black cut-away screw in the top

of

the guide to

be

removed. Unscrew the guide, using the special tool number

01

90901 089

(the whole guide will turn):'Carefully remove the guide aiong with its support mounting.

NOTE:

The

coloured

scanner guide is the entry guide and sits on the left

of

the

scannner.

In

the drawing below the guide screw is indicated with a normal screwdriver,

however the special tool mentioned above must be used for removing, replacing

and adjusting

of

these guides.

Do not touch the small screw that is painted red in the front

of

these guides as this is used for

the alignment -covered later under ELECTRICAL CALIBRATION, and ensure that when

refitting the guides that the red screw is in front as before.

Figure

3:

Unscrewing

the

scanner exit

guide.

June 1994

IIS

1.1.5 REMOVING

THE

PINCHROLLER

The

pinchroller assembly must also be removed, before the cover can

come

off.

To

do this

proceed as follows:

Insert a screwdriver as shown

in

the diagram below and loosen the fixing screw about a quarter

of

a turn. Insert a flat screwdriver (acting as a lever) on the front edge slightly to the right

of

the main securing screw and use

-this

as

·a lever to slight!y'open -the·support to release the

pressure,

and lift the pinchroller assembly vertically, making sure not to loose the nylon

spacer. Be careful not to loose the pinchroller assembly pressure spring, as the assembly may

come apart once

it

has been removed from the deck.

Figure

4: Indication

of

the

pinch

roller

assembly

with

the

screwdriver.

NOTE: This screw replaces the Allen screw that was fitted to the earlier machines.

June 1994

II6

1.1.6 REMOVING

THE

REEL MOTOR SPOOL HOLDERS

In order that the reel motor dust covers

do

not inhibit the removal

of

the deck plate cover

remove each

of

them by removing the central Allen screw (2.5mm driver) and lifting the

whole reel holder clear. Remove the dust cover from each reel motor by removing the three

screws from each.

NOTE: -On some machines there

may

be a-shim below the -reel-holders,-which is for the

height adjustment, and this should be kept and re-installed when it is refitted.

Once all these mechanical parts have been removed then the 5 screws holding the dust cover

onto the deck can be removed and then the cover itself can be removed, giving access to the

mechanics

of

the machine. When lifting off the dust cover

be

sure that it does not catch the

front

of

the scanner.

This plate may be cleaned with alcohol

if

necessary.

June 1994

II7

1.2 REMOVING THE LONGITUDINAL HEADBLOCK

Removing

of

the longitudinal headblock

may

be necessary

if

either

of

the longitudinal heads

(Erase, time code/cue/control track) are

to

be replaced, but it will definitely be necessary

if

the pinchwheel and guide carriage is

to

be removed

as

the headblock covers the carriage's

fixing screws.

The longitudinal headblock isheltl in"place with three M2;5 x 8 screws fitted with washers.

Carefully remove these screws, and lift the headblock up. The headblock is fixed to the

machine with

an

8 pin rigid connector

as

well

as

a three

pin

wire connector which is fitted with

a small plastic connector. When the headblock

is

loose, lift it up slightly and use a small

screwdriver to remove the three pin connector from its underside. NEVER pull directly on the

wires to remove this connector as they are fragile and will break easily.

Figure

5:

Longitudinal headblock

June 1994

1I8

1.3 REMOVING

THE

PINCHWHEEL AND GUIDE CARRIAGE

In the top center

of

Figure 5 the pinchwheel and guide carriage is attached to the cam

engagement gear via the linkage arm. This link is made with a small pin. This pin is removed

by unscrewing the screw

of

the small spring bracket and removing both the bracket and the pin

below it. Once this has been removed the linking arm can be pulled out

of

the arm and then

the arm pushed out

of

the way. The pinchwheel and guide carriage is fixed to the deck plate

in three places. Each

of

the -fixation points-is -held down with two -screws

of

M 2.5 x 6mm.

Two are located next to the rail on the left-hand side

of

the carriage, and one adjacent to the

rail on the right-hand side. Remove all six screws, along with their washers. Pull the carriage

towards the front

of

the machine

to

avoid the reel motors, then slightly lift the rear end

of

the

carriage and remove

it

from the machine, making sure that it does not catch the lower edge

of

the front panel, or the scanner. Once this is removed, be careful not to loose the right-hand

slider, as this is not secured to the carriage, it is simply pushed on.

r-

I

Fixing

screws

Figure

6:

June 1994

Fixing

screw

--.J

Faalion

of

the

pinchwheel

and

guide

carriage.

(longitudinal headblock

has

been

removed)

119

This manual suits for next models

2

Other Audio Technology Recording Equipment manuals