AudioCodes Mediant 9000 SBC Assembly instructions

Hardware Installation Manual

AudioCodes Session Border Controller Series

Mediant 9000 SBC

Mediant 9080 / 9030 / 9000 Rev. B

Version 7.2 and later

Notice Mediant 9000 SBC | Hardware Installation Manual

Notice

Information contained in this document is believed to be accurate and reliable at the time

of printing. However, due to ongoing product improvements and revisions, AudioCodes

cannot guarantee accuracy of printed material after the Date Published nor can it accept

responsibility for errors or omissions. Updates to this document can be downloaded

from https://www.audiocodes.com/library/technical-documents.

This document is subject to change without notice.

Date Published: November-20-2022

WEEE EU Directive

Pursuant to the WEEE EU Directive, electronic and electrical waste must not be disposed of with

unsorted waste. Please contact your local recycling authority for disposal of this product.

Customer Support

Customer technical support and services are provided by AudioCodes or by an authorized

AudioCodes Service Partner. For more information on how to buy technical support for

AudioCodes products and for contact information, please visit our website at

https://www.audiocodes.com/services-support/maintenance-and-support.

Documentation Feedback

AudioCodes continually strives to produce high quality documentation. If you have any

comments (suggestions or errors) regarding this document, please fill out the Documentation

Feedback form on our website at https://online.audiocodes.com/documentation-feedback.

Stay in the Loop with AudioCodes

Notes and Warnings

For safety, environment and regulatory information, refer to the printed document

“Safety, Compliance and Warranty Information” included in the products packaging.

The device is an INDOOR unit and thus, must be installed ONLY indoors. In addition,

Ethernet port interface cabling must be routed only indoors and must not exit the

- ii -

Notice Mediant 9000 SBC | Hardware Installation Manual

building.

Installation of this device must be in a weather protected location of maximum

ambient temperature of 35°C.

This device must be installed only in a restricted access location.

Service of the device must be made only by qualified service personnel.

AC powered units must be connected only to a grounded AC mains power socket.

Circuit Overloading: Consideration should be given to the connection of the

equipment to the supply circuit and the effect that overloading of the circuits might

have on over- current protection and supply wiring. Appropriate consideration of

equipment nameplate ratings should be used when addressing this concern.

Caution Laser: This device contains a Class 1 LED/Laser emitting device, as

defined by 21CFR 1040 and IEC825. Do not stare directly into the beam or into fiber

optic terminations as this can damage your eyesight.

Caution Electrical Shock: Do not attempt to open or disassemble this device. The

device carries high voltage. Contact with internal components may cause electrical

shock and bodily harm.

For all service and maintenance issues, contact AudioCodes technical support (see

Customer Support above).

Reliable Earthing: Reliable earthing of rack- mounted equipment should be

maintained. Particular attention should be given to supply connections other than

direct connections to the branch circuit (e.g., use of power strips.)

Related Documentation

Document Name

SBC-Gateway Release Notes for Latest Release (LR) Versions 7.4

- iii -

Notice Mediant 9000 SBC | Hardware Installation Manual

Document Name

SBC-Gateway Release Notes for Long Term Support (LTS) Versions 7.4

Mediant 9000 Series SBC User's Manual

Document Revision Record

LTRT Description

41655 Initial document release for Version 7.2.

41557 Management names of Ethernet ports added.

41658 AC power cable warning (Japanese).

41661 SFP network cabling.

41662 SFP configurations; Replacing Copper NIC with Fiber Network Card (new

section); Returning to an Arbitrary Snapshot (updated).

41663 Logo updated; note added to Returning to an Arbitrary Snapshot.

41664 Updates for HPE ProLiant DL360 Gen10 Server.

41666 Default IP address.

41667 Mediant 9030 (and Mediant 9080) added.

41668 LED descriptions for 366FLR, 366T, and PE310G4SPI9LA.

41671 Typo (FLR ports).

41672 Note re fiber support removed in Chapter 5, Fiber Network Card Support.

41673 Added for Version 7.2 and later.

41675 Specifications updated; supported fiber configurations updated.

41676 URL fixed in section Replacing Copper NIC with Fiber Network Card.

41677 Spec. for Mediant 9080 Rev. B disk updated (SATA).

41679 Supported SFP network cards updated.

41700 Product configurations added.

- iv -

Content Mediant 9000 SBC | Hardware Installation Manual

Table of Contents

1 Introduction 1

2 Product Configurations 2

3 Specifications 4

4 Physical Description 5

Physical Dimensions 5

Front Panel 5

Front Panel LEDs 6

Rear Panel 7

Rear Panel LEDs 8

5 Deploying the Device 12

Deploying the Rail Kit 12

Connecting to Power and Replacing Power Supply 12

Connecting Display and Keyboard 14

Connecting Device to IP Network for 1-GbE Copper 14

Connecting Device to IP Network with SFP 16

Viewing Network Port Status 17

6 Fiber Network Card Support 19

Supported Configurations 19

Replacing Copper NIC with Fiber Network Card 19

7 Initial Configuration 21

Reconfiguring Default IP Address to Match Customer Network Settings 21

Licensing the Device 23

8 Installation and Upgrade Issues 24

Installing an HA System 24

Upgrading 24

Reinstalling Software SBC from ISO Image 24

9 Rescue Options 28

-v-

CHAPTER1 Introduction Mediant 9000 SBC | Hardware Installation Manual

1 Introduction

This document describes the hardware of AudioCodes' carrier-grade Mediant 9000 SBC series

and basic deployment.

This document describes the Mediant 9000 series that is based on HPE ProLiant

DL360 Gen10.

To identify the type of Mediant 9000 model, run the following CLI command, as

shown in the examples below:

●Mediant 9080 Rev. B:

show system hardware

CPU: Intel(R) Xeon(R) Gold 6226R CPU @ 2.90GHz, total 64

cores, avx supported

Memory: 98304 MB

Chassis: ProLiant DL360 Gen10

●Mediant 9080 Rev. A / Mediant 9000 Rev. B:

show system hardware

CPU: Intel(R) Xeon(R) Gold 6126 CPU @ 2.60GHz, total 48

cores, avx supported

Memory: 98304 MB

Chassis: ProLiant DL360 Gen10

●Mediant 9030:

show system hardware

CPU: Intel(R) Xeon(R) Silver 4110 CPU @ 2.1GHz, total 32

cores, avx supported

Memory: 32768 MB

Chassis: ProLiant DL360 Gen10

-1-

CHAPTER2 Product Configurations Mediant 9000 SBC | Hardware Installation Manual

2 Product Configurations

The following configurations are available for the Mediant 9080 / 9030 Session Border

Controller product.

Table 2-1: AudioCodes Mediant 9080 / 9030 Session Border Controller Product Configurations

Product Configuration Description

Mediant 9030

M9K30/AC Mediant 9030 Session Border Controller (SBC)

M9K30/AC/R HA-pair of Mediant 9030 Session Border Controllers (SBC)

M9K30/DC Mediant 9030 Session Border Controller (SBC), DC power

M9K30/DC/R HA-pair of Mediant 9030 Session Border Controllers (SBC), DC

power

M9K30/AC/4/10GLR Mediant 9030 Session Border Controller (SBC) with 4 fiber

10GbE-LR interfaces

M9K30/AC/4/10GLR/R HA-pair of Mediant 9030 Session Border Controllers (SBC) with

4 fiber 10GbE-LR interfaces

M9K30/AC/4/10GSR Mediant 9030 Session Border Controller (SBC) with 4 fiber

10GbE-SR interfaces

M9K30/AC/4/10GSR/R HA-pair of Mediant 9030 Session Border Controllers (SBC) with

4 fiber 10GbE-SR interfaces

M9K30/DC/4/10GLR Mediant 9030 Session Border Controller (SBC) with 4 fiber

10GbE-LR interfaces, DC power

M9K30/DC/4/10GLR/R HA-pair of Mediant 9030 Session Border Controllers (SBC) with

4 fiber 10GbE-LR interfaces, DC power

M9K30/DC/4/10GSR Mediant 9030 Session Border Controller (SBC) with 4 fiber

10GbE-SR interfaces, DC power

M9K30/DC/4/10GSR/R HA-pair of Mediant 9030 Session Border Controllers (SBC) with

4 fiber 10GbE-SR interfaces, DC power

Mediant 9080

M9K80/AC Mediant 9080 Session Border Controller (SBC)

-2-

CHAPTER2 Product Configurations Mediant 9000 SBC | Hardware Installation Manual

Product Configuration Description

M9K80/AC/R HA-pair of Mediant 9080 Session Border Controllers (SBC)

M9K80/DC Mediant 9080 Session Border Controller (SBC), DC power

M9K80/DC/R HA-pair of Mediant 9080 Session Border Controllers (SBC), DC

power

M9K80/AC/4/10GLR Mediant 9080 Session Border Controller (SBC) with 4 fiber

10GbE-LR interfaces

M9K80/AC/4/10GLR/R HA-pair of Mediant 9080 Session Border Controllers (SBC) with

4 fiber 10GbE-LR interfaces

M9K80/AC/4/10GSR Mediant 9080 Session Border Controller (SBC) with 4 fiber

10GbE-SR interfaces

M9K80/AC/4/10GSR/R HA-pair of Mediant 9080 Session Border Controllers (SBC) with

4 fiber 10GbE-SR interfaces

M9K80/DC/4/10GLR Mediant 9080 Session Border Controller (SBC) with 4 fiber

10GbE-LR interfaces, DC power

M9K80/DC/4/10GLR/R HA-pair of Mediant 9080 Session Border Controllers (SBC) with

4 fiber 10GbE-LR interfaces, DC power

M9K80/DC/4/10GSR Mediant 9080 Session Border Controller (SBC) with 4 fiber

10GbE-SR interfaces, DC power

M9K80/DC/4/10GSR/R HA-pair of Mediant 9080 Session Border Controllers (SBC) with

4 fiber 10GbE-SR interfaces, DC power

-3-

CHAPTER3 Specifications Mediant 9000 SBC | Hardware Installation Manual

3 Specifications

The following table lists the device's specifications.

Table 3-1: Specifications

Product HW

Revision CPU Memory Disk Chassis

Mediant9030 Rev. A 2 x 8

Cores

2.1 GHz

11-MB

Cache

32 GB

DDR4-

2666/PC4-

21300

Mechanical

hard drive

1-TB SATA

■Chassis type:

1RU

■Network

(max. total 12

ports):

✔1-GbE

(copper):

4-12

ports

✔1 GbE

(SFP): 4-8

ports

✔10 GbE

(SFP+): 4-

8 ports

■Installation

interfaces:

VGA monitor

and

keyboard,

remote

access

through iLO

Mediant9000 Rev. B 2 x 12

Cores

2.6 GHz

19.25-

MB

Cache

96 GB

DDR4-

2666/PC4-

21300

Mechanical

hard drive

600-GB SAS

Mediant9080 Rev. A 2 x 12

Cores

2.6 GHz

19.25-

MB

Cache

96 GB

DDR4-

2666/PC4-

21300

Mechanical

hard drive

600-GB SAS

Rev. B 2 x 16

Cores

2.9 GHz

22-MB

Cache

96 GB

DDR4-

2933/PC4-

23400

Mechanical

hard drive

600-GB SAS

or 1-TB

SATA

For installation instructions of the Mediant 9000 (Gen 8) model, refer to LTRT-41674

Mediant 9000 SBC Hardware Installation Manual Ver. 7.2 and later.

-4-

CHAPTER4 Physical Description Mediant 9000 SBC | Hardware Installation Manual

4 Physical Description

This section provides a physical description of the device.

Physical Dimensions

The device's physical dimensions are listed in the following table.

Table 4-1: Physical Dimensions

Item Description

Physical Dimension 4.29 x 43.46 x 70.7 cm (1.69 x 17.11 x 27.83 in)

Weight (approximate) Between 13.04 kg (28.74 lb) and 16.27 kg (35.86 lb)

Environmental Operational: 10 to 35°C (50° to 95°F)

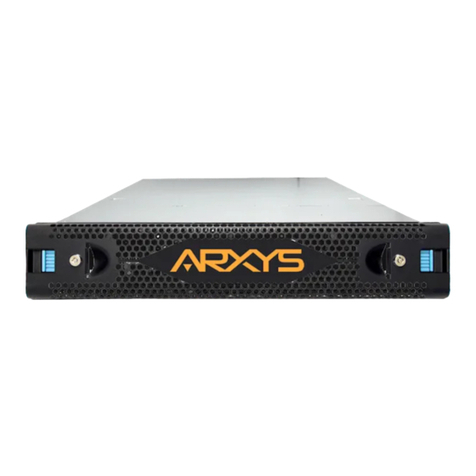

Front Panel

The device features an 8-SFF (Small Form Factor) cage for standard internal storage hard drives.

The device's front panel is shown in the figures below and described in the subsequent table.

Figure 4-1: Front Panel

Table 4-2: Front Panel

Item # Description

1 600-GB SAS drive or 1-TB SATA drive

2 Serial label pull tab

3 Display port

4 DVD-RW and Display port & USB 2.0 port Kit (DVD-RW is currently not

operational). Re-installation of the SBC application can be performed using the

iLO console virtual media.

-5-

CHAPTER4 Physical Description Mediant 9000 SBC | Hardware Installation Manual

Item # Description

5 USB 2.0 port

6 USB 3.0 port

7 iLO Service port

Front Panel LEDs

The front panel LEDs are shown in the following figure and described in the subsequent table.

Figure 4-2: Front Panel LEDs

Table 4-3: Front-Panel LEDs

Item # Description Status

1 UID LED/button* ■Solid blue = activated.

■Flashing blue = Remote management or

firmware upgrade in progress.

✔1 Hz = Remote management or

firmware upgrade in

✔progress

✔4 Hz = iLO manual reboot sequence

initiated

✔8 Hz = iLO manual reboot sequence

in progress

■Off = deactivated.

2 Power On/Standby button/LED

and system power LED*

■Solid green = System on

■Flashing green = Performing power on

-6-

CHAPTER4 Physical Description Mediant 9000 SBC | Hardware Installation Manual

Item # Description Status

sequence

■Solid amber = System in standby

■Off = No power present**

3 Health LED* ■Solid green = Normal

■Flashing green = iLO is rebooting

■Flashing amber = System degraded

■Flashing red = System critical†

4 NIC status LED* ■Solid green = Link to network

■Flashing green = Network active

■Off = No network activity

*When all four LEDs described in this table flash simultaneously, a power fault has occurred.

**Facility power is not present, power cord is not attached, no power supplies are installed,

power supply failure has occurred, or the power button cable is disconnected.

†If the health LED indicates a degraded or critical state, review the system IML or use iLO to

review the system health status.

Rear Panel

The rear panel is displayed in the following figure and described in the subsequent table.

Figure 4-3: Rear Panel - – Mediant 9080 / Mediant 9000 Rev. B

-7-

CHAPTER4 Physical Description Mediant 9000 SBC | Hardware Installation Manual

Figure 4-4: Rear Panel – Mediant 9030

Table 4-4: Rear Panel

Item #

Description

Mediant 9080 / Mediant 9000

Rev. B

Mediant 9030

1 Slot 1: Quad 1-GbE copper

ports

Slot 1: Quad 1-GbE copper ports or Quad 10-

GbE SFP+ ports

2 Slot 2: Quad 1-GbE copper

ports or Quad 10-GbE SFP+

ports

Slot 2: Not used

3 Slot 3: Not used

4 Power supply 2 (PS2)

5 Power supply 1 (PS1)

6 Video port

7 Unsupported NIC ports (dust

covered)

Quad 1-GbE copper ports

Note: These ports can be used only for

signaling (SIP), OAMP, and HA Maintenance.

8 iLO Management Port

9 Serial port

10 USB 3.0 ports

11 On-board FLR Quad 1-GbE copper ports

Rear Panel LEDs

The rear panel LEDs are shown in the following figure and described in the subsequent table.

-8-

CHAPTER4 Physical Description Mediant 9000 SBC | Hardware Installation Manual

Figure 4-5: Rear Panel LEDs

Table 4-5: Rear Panel LEDs

Item # Description Status

1 UID LED ■Solid blue = Identification is activated

■Flashing blue = System is being managed remotely

■Off = Identification is deactivated

2 iLO 5/standard ■(Right LED) NIC activity status:

✔Solid green = Activity exists.

✔Flashing green = Activity exists.

✔Off = No activity exists

■(Left LED) NIC link status:

✔Solid green = Link exists.

✔Off = No link exists.

3 Power supply 2

LED

■Solid green = Normal

■Off = One or more of the following conditions exists:

✔AC power unavailable

✔Power supply failed

✔Power supply in standby mode

✔Power supply exceeded current limit.

4 Power supply 1

LED

■Solid green = Normal

■Off = One or more of the following conditions exists:

✔AC power unavailable

✔Power supply failed

✔Power supply in standby mode

✔Power supply exceeded current limit

-9-

CHAPTER4 Physical Description Mediant 9000 SBC | Hardware Installation Manual

Item # Description Status

5 Quad 1-GbE

copper ports

■(Right LED) NIC activity status:

✔Solid green = Activity exists.

✔Flashing green = Activity exists.

✔Off = No activity exists

■(Left LED) NIC link status:

✔Solid green = Link exists.

✔Off = No link exists

Note: Applicable only to Mediant 9030.

6 366FLR ■Right LED - activity:

✔Off = No network activity on the link

✔Flashing green = Network activity on the link at up

to 1 Gb/s

■Left LED - link:

✔Off = No link (adapter not receiving power or the

cable connection is faulty)

✔On green = Link established at 10/100/1000 Mb/s

7 366T Two LEDs per port:

■LED 1 - activity:

✔Off = No network activity on the link

✔Flashing green = Network activity on the link at up

to 1 Gb/s

- 10 -

CHAPTER4 Physical Description Mediant 9000 SBC | Hardware Installation Manual

Item # Description Status

■LED 2 - link:

✔Off = No link (adapter not receiving power or the

cable connection is faulty) or link established at 10

Mb/s

✔On green = Link established at 100 Mb/s

✔On amber = Link established at 1 Gb/s

8 366T or

PE310G4SPI9LA

■366T – see above.

■PE310G4SPI9LA - two LEDs per port:

✔Upper LED - link speed:

●On blue = 10G link

●On yellow = 1G link

✔Lower LED - link/act:

●Solid green on = link

●Blinks green on = activity

- 11 -

CHAPTER5 Deploying the Device Mediant 9000 SBC | Hardware Installation Manual

5 Deploying the Device

This chapter describes how to deploy the device. The following sections are described:

■Deploying the Rail Kit

■Connecting to Power and Replacing Power Supply

■Connecting Display and Keyboard

■Connecting Device to IP Network for 1-GbE Copper

■Connecting Device to IP Network with SFP

■Viewing Network Port Status

Deploying the Rail Kit

For instructions for deploying the rail system, refer to the printed instructions "Quick

Deploy Rail System Installation Instructions" included in the Rail Systems packaging.

Rack Mount Safety Instructions: When installing the chassis in a rack, implement

the following safety instructions:

●Elevated Operating Temperature: If installed in a closed or multi-unit rack

assembly, the operating ambient temperature of the rack environment may be

greater than room ambient temperature. Therefore, consideration should be

given to installing the equipment in an environment compatible with the maximum

ambient temperature (TA) of 35°C (95°F).

●Reduced Air Flow: Installation of the equipment in a rack should be such that the

amount of air flow required for safe operation on the equipment is not

compromised.

●Mechanical Loading: Mounting of the equipment in the rack should be such that a

hazardous condition is not achieved due to uneven mechanical loading.

●Two people are required to mount the device in the 19-inch rack.

●When attaching the chassis to the rack, it is mandatory to connect it using both

the front-mounting brackets and the rear-mounting brackets (supplied).

Connecting to Power and Replacing Power Supply

This section lists the various warnings, cautions and notes regarding connecting to the power

supply and replacing power supply units.

To reduce the risk of electric shock or energy hazards:

- 12 -

CHAPTER5 Deploying the Device Mediant 9000 SBC | Hardware Installation Manual

●This equipment must be installed by trained service personnel, as defined by the

NEC and IEC 60950-1, Second Edition, the standard for Safety of Information

Technology Equipment.

●Connect the equipment to a reliably grounded Secondary circuit source. A

Secondary circuit has no direct connection to a Primary circuit and derives its

power from a transformer, converter, or equivalent isolation device.

●The branch circuit overcurrent protection for DC power supply must be rated 27

A.

If the DC connection exists between the earthed conductor of the DC supply circuit

and the earthing conductor at the server equipment, the following conditions must be

met:

●This equipment must be connected directly to the DC supply system earthing

electrode conductor or to a bonding jumper from an earthing terminal bar or bus

to which the DC supply system earthing electrode conductor is connected.

●This equipment must be located in the same immediate area (such as adjacent

cabinets) as any other equipment that has a connection between the earthed

conductor of the same DC supply circuit and the earthing conductor, and also the

point of earthing of the DC system. The DC system should be earthed elsewhere.

●The DC supply source is to be located within the same premises as the

equipment.

●Switching or disconnecting devices must not be in the earthed circuit conductor

between the DC source and the point of connection of the earthing electrode

conductor.

●Both Power Supply modules (1 and 2) must be connected. Ensure that you

connect each one to a different AC power supply source. Two Power Supplies

provide 1+1 power load-sharing and redundancy. The AC power sockets are

located on the device's rear panel.

●The two AC power sources must have the same ground potential.

●The device must be connected (by service personnel) to a socket-outlet with a

protective earthing connection.

●Use only a certified 3-conductor power cord, supplied with the unit.

To reduce the risk of personal injury from hot surfaces, allow the power supply or

power supply blank to cool before touching it.

For DC power supply, use only the ring terminals provided with the power supply for

customer-built power connections. Be sure no wire protrudes from the bottom of the

ring terminal barrels.

Make sure that you connect the DC power feed cable to the power source in the

correct polarity. The cable's two wires are color-coded and numbered to indicate

- 13 -

CHAPTER5 Deploying the Device Mediant 9000 SBC | Hardware Installation Manual

polarity:

●Black Wire (1): negative (-) polarity

●Red Wire (2): positive (+) polarity

The device must be connected (by service personnel) to a socket- outlet with a

protective earthing connection

●Before extracting the Power Supply module, disconnect the power cord from the

module.

●Before extracting the Power Supply module (after you have disconnected the

power cord), wait at least three seconds for the capacitors to discharge.

The DC power cord is not supplied. For information, refer to HPE's documentation,

Section Related Options: -48VDC Power Cables.

When connecting both Power Supply modules, the two AC power sources must have

the same ground potential.

For DC power supply, the minimum nominal thread diameter of a pillar or stud type ter-

minal must be 3.5 mm (0.138 in); the diameter of a screw type terminal must be 4.0

mm (0.157 in).

The DC power supply uses two power ring tongues and one ground ring tongue. They

are not interchangeable

Connecting Display and Keyboard

To perform initial configuration, display and keyboard are required.

■Connect the display to the 15-pin HD D-Sub (HD-15) VGA port.

■Connect the keyboard to the USB port.

Connecting Device to IP Network for 1-GbE Copper

This section shows how to connect the device to the IP network using the copper 1-GbE ports.

Intra-building connections of the device require the use of shielded cables grounded at both

ends.

- 14 -

CHAPTER5 Deploying the Device Mediant 9000 SBC | Hardware Installation Manual

The intra-building ports of the equipment are suitable for connection to intra-building

or unexposed wiring or cabling only. The intra-building ports of the equipment must

not be metallically connected to interfaces that connect to the Outside Plant (OSP) or

its wiring. These interfaces are designed for use as intra-building interfaces only

(Type 2 or Type 4 ports, as described in GR-1089–CORE, Issue 4) and requires isol-

ation from the exposed OSP cabling. The addition of primary protectors is not suf-

ficient protection to connect these interfaces metallically to OSP wiring

The device's management interface uses special string names to represent the Ethernet ports,

as shown in the following figure:

Figure 5-1: Management Name per Physical Ethernet Port – Mediant 9080 / Mediant 9000 Rev. B

Figure 5-2: Management Name per Physical Ethernet Port – Mediant 9030

●Mediant 9080 / Mediant 9000 Rev. B: The figure represents a configuration

with 12x1GbE ports. If the device is configured with 10GbE ports (GE_9 until

GE_12), then the correct port order is as follows: GE_12 | GE_11 | GE_10 | GE_

9.

●Mediant 9030: GE_1, GE_2, GE_3, and GE_4 ports can be used only for

signaling (SIP), OAMP, and HA Maintenance. These ports must not be used for

media traffic.

➢To connect the device to the IP network:

■Use an Ethernet cable to connect an RJ-45 network port on the server's rear panel to the

LAN.

- 15 -

Other manuals for Mediant 9000 SBC

2

This manual suits for next models

13

Table of contents

Other AudioCodes Server manuals

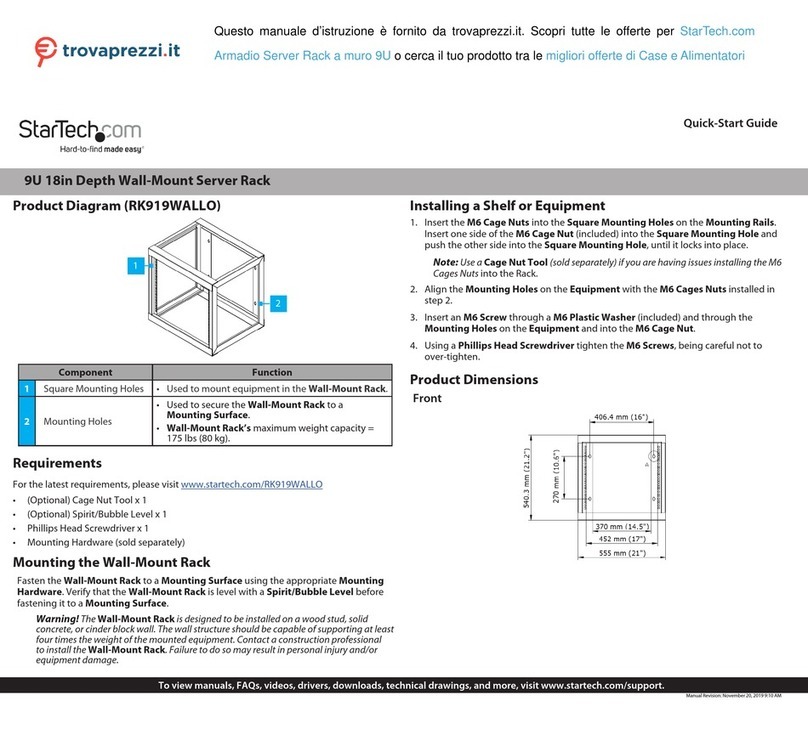

Popular Server manuals by other brands

StarTech.com

StarTech.com RK919WALLO quick start guide

Lenovo

Lenovo ThinkSERVER TS130 warranty and support information

ATEN

ATEN PE6108AV user manual

Rittal

Rittal Micro Data Center Level E operating instructions

Lenovo

Lenovo ThinkServer TD230 Informações de Garantia e Suporte

Wyse

Wyse D00D quick start guide

Appro

Appro VS-2112B Installation & operation manual

Biamp

Biamp VOCIA MS-1 manual

Supero

Supero SUPERSERVER 5017A-EF user manual

Dell

Dell EMC PowerEdge R7515 reference guide

Mitsubishi Electric

Mitsubishi Electric MES3-255C-DM-EN user manual

American Dynamics

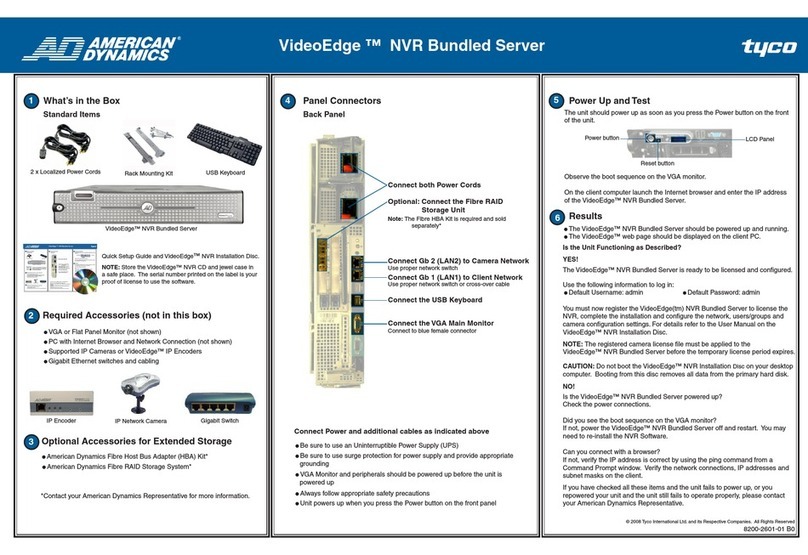

American Dynamics VideoEdge NVR Bundled Server Quick setup guide