Audipack VCL-1UP User manual

© Audipack

VCL-1UP

Installation manual

Montage handleiding

Videoconference Camera Lift

© Audipack

EN.

The VCl is solely suitbale for lifting camera’s, small speakers and microphones.

NL.

De VCL lift is alleen bedoelt voor het heffen van kleine camera’s, speakers en

microfoons.

EN.

Ones installed it is possible to set the height of the top finishing by adjusting /

shortening the winded rods of the top bracket.

NL.

Eenmaal geinstalleerd in het meubel, is het mogelijk om de top afwerking op

j=hoogte te stellen met de verstelbare / in te korten draadeinden in de beugel.

EN.

Adjusting max. height by changing position of bolt as indicated.

NL.

Maximale hoogte afstelling door aangegeven bout positie aan te passen.

EN.

Adjusting min. height by loosening security nut and change position for bolt.

Fasten nut after adjusting.

NL.

Minimale hoogte afstelling door aangegeven borgmoer te lossen en bout positie

aan te passen. Daarna borgmoer weer vastzetten.

•© Audipack

EN.

Accessing internals.

NL.

Toegang tot binnenwerk.

•© Audipack

EN.

View internals.

NL.

Intern aanzicht.

•© Audipack

EN.

The VCL is equipped with a mechanical anti pinch safety. When the lift is

obstructed downwards, the motor will be disconnected from the camera carrier.

When tghis happens the system make sound different and possibly starts

trembling.

Reassemble the this spindle attachment.

NL.

De VCL is voorzien van een mechanische afknelbeveiliging. Als de lift wordt tegen

gehouden in neerwaartse richting i=ontkoppeld de spindelmoer van de camera

loopwagen. Dit is merkbaar door een ander geluid of trillend product.

IN dat geval kunt u de moer weer terugplaatsen in het patroon van de loopwagen.

•© Audipack

EN.

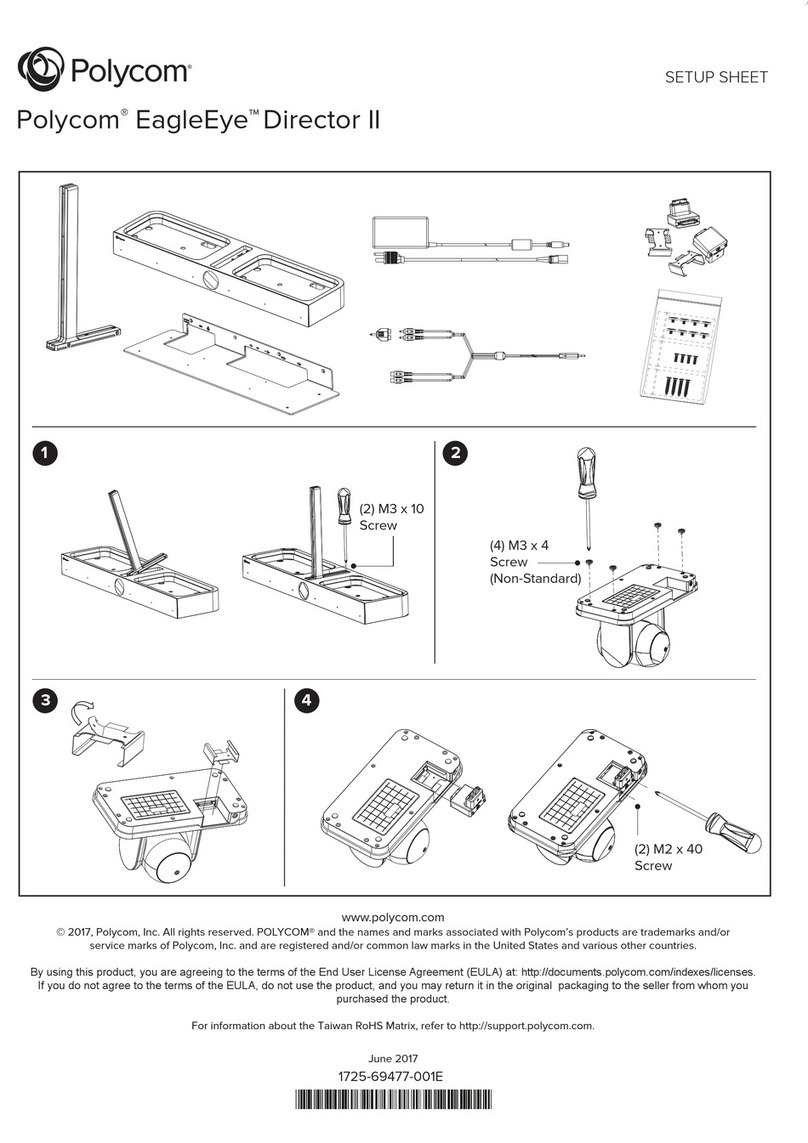

Camera can be installed on the platform, fastened with the tripod mounting

option.

It is free to drill holes in the camera mounting plate to fasten the camera.

NL.

De camera kan geplaats en gemonteerd worden op het platform gebruikmakend

van de camerastatief gat in de camera. Het is vrij om montagegaten te boren in

het platform voor de camera.

•© Audipack

Common Information

Note:

Your Audipack product is equipped with a DC 24 volt control as below.

This control has been designed to control an external product suitable for

controlling by contact closures.

This type of control is also available as a set inclusive a IR remote set part no.

260218 or as an RF remote control set part no. 260219.Refer to the manual of the

IR and RF module for connecting and programming.

Cautions:

The relay control is not suited to high revving motors

Do never overload the relay control

The relay control should always be mounted inside an appropriate housing

The wiring which is connected to the relay control has to be wrapped by a tie-rap

The relay control may only be plugged to a grounded power-point

Properties:

The motor needs to be braked before switching the direction

It is possible to have the motor run for a pre-set time (impulse push).

It is possible to connect a safety relay to the control print (i.e. for an emergency

button). The connector is suited only to an external standardized relay.

If the relay control is mounted in machines used within the reach of bystanders, or

over bystanders, the following safety guidelines have to be observed.

Installation and connections may only be carried out by qualified staff

The power cable must be conform (3x1 mm²) EN60227

Warning

A.

While the machine is in motion, the operator should have full sight over the

machine

B.

The control buttons have to be installed in a place which offers the operator full

sight over the machine

C.

No bystanders may stand under the machine, or within the radius of the machine,

if the lowest point of the machine is less than 2 meters above the floor.

D.

If the machine shows up damage during testing or normal operation, the machine

should be taken out of service. The machine should be repaired by a qualified

installer. The machine should be released by a qualified installer.

E.

If the machine is damaged or fractured, the operator should have the machine

repaired by a qualified installer or by Audipack.

•© Audipack

Connections and settings

Description connectors

Connector 1:

Main current connector 24 DC

Pin 1: safety relay (potential free)

Pin 2: safety relay (potential free)

Pin 3: + 24 DC connection

Pin 4: - 24 DC connection

Connector 2:

DC motor connection

Pin 1: -

Pin 2: Motor -

Pin 3: Motor +

Connector 3:

Optional IR/RF PCB connector

Connector 4:

Programming connector

Connector 5:

All below connections are potential free contacts

Pin 1: over service position switch (not for all products)

Pin 2: GND

Pin 3: end switch UP

Pin 4: GND

Pin 5: end switch DOWN

Pin 6: GND

Connector 6:

All below connections are potential free contacts

Pin 1: external control DOWN

Pin 2: GND

Pin 3: external control UP

SW3:

Print switch impulse push

1 = OFF

ON = ON

•© Audipack

Impulse push

It is possible to activate the external system for a preset time.

Before the impulse push can be activated, the dip/switch on the print has to be

activated. The running time can be preset with the potentiometer on the print. Use

exactly fitting tools to set the running time. Turn the potentiometer to the right to

increase the running time (maximally 240 seconds).

External safety relay or emergency button connection

If a safety relay or emergency button is required, this can be connected to position

1 and 2 of connector 1. The connection loop has to be removed before using this

connection.

Technical specifications

PCB:

24 Volt DC 10A

The power cable must be conform (3x1 mm²) EN60227

Binding the wiring together

All wiring must be wrapped together by a tie-rap to prevent the wiring from falling

out of the connector. The tie-rap will always keep the loose thirds in the

connector.

•© Audipack

Installation diagram:

•© Audipack

© Audipack

Audipack's general conditions of sales and delivery apply to all of

Audipack's deliveries. These conditions can be downloaded from Audipack's

website, www.audipack.com, or will be sent by post on request.

Audipack liefert ausschließlich unter die allgemeine Verkauf- und

Lieferungsbedingungen von Audipack. Diese Bedingungen sind zum

downloaden verfügbar auf die Webseite von Audipack, www.audipack.com,

oder werden Ihnen auf Anfrage per Post gesendet.

Alle leveringen geschieden uitsluitend volgens de Algemene Verkoop- en

Leveringsvoorwaarden van Audipack. Een afschrift hiervan kunt u

downloaden van de website van Audipack, www.audipack.com, of wordt u

op aanvraag gestuurd per post.

Les conditions de vente et de livraison de Audipack s'appliquent à tous les

livraisons de Audipack. Cette conditions sont disponible sur le site internet

de Audipack, www.audipack.com, où seront envoyé par poste sur demande.

Audipack reserves the right to make changes in specifications and other information contained in this document without prior written notice.

The information provided herein is subject to change without notice. In no event shall Audipack be liable for any incidental, special, indirect, or

consequential damages whatsoever, including but not limited to lost profits, arising out of or related to this manual or the information

contained herein, even if Audipack has been advised of, known, or should have known, the possibility of such damages.

AUDIPACK

Industriestraat 2-4

2751 GT Moerkapelle

The Netherlands

Tel: +31(0)795931671

Fax: +31(0)795933115

Email: audipack@audipack.com

www.audipack.com

Table of contents

Popular Conference System manuals by other brands

Tadiran Telecom

Tadiran Telecom FlexSet 120S user guide

Codian

Codian MCU 4200 Series Getting started

Actia

Actia ACU6 user manual

Polycom

Polycom RealPresence DMA 7000 System Operation guide

Sony

Sony IPELA PCS-G70 quick start

Xantrex

Xantrex GT Series Three Phase Ethernet Communications... installation guide