- MANUAL HRC70 HEAT PUMPS 17 20 25 KW - V3

14

The rules and regulations in the country of

installation MUST be respected (standard

C15-100).

• The electrical lines for general power supply to the

circuits must be made in compliance with your

country’s current rules and regulations (standard

C15-100).

• Standard C15-100 determines the cable section to

be used based on acceptable currents.

• Standard C15-100 determines the cable section to

be used based on the following elements :

- Nature of the conductor :

. type of insulation, number of strands, etc...

- Installation mode :

. inuence of conductor and cable groups

. ambient temperature

. tightly or non-tightly installed

. length of cables, etc...

3.4 - Connecting to the power supply

Ensure that the power supply is sucient to supply both the Heat

Pump and the electrical back-up if necessary, taking into account

any other domestic usage of electricity.

Connection to the power supply for each appliance must be done

by a qualied professional with the mains power switched o.

• During transport, the electrical connections

may be subject to accidental loosening.

• To eliminate any risk of abnormal heating, it is

necessary to ensure the placement of the faston

type electrical connections are secure and tighten

the screw connections.

See§ «Spare parts - electrical boxes»

Each appliance is delivered from the factory completely pre-wired.

However, it is necessary to connect the following elements to the

relevant terminals:

• The electrical supply of the power circuit for each appliance

separately : the Heat Pump and the Pilot.

•The dierent temperature sensors, thermostats, and load shedding

device on the Pilot.

• The 2-core sheathed connecting cable (10m length supplied)

between the Heat Pump and the Pilot.

Under no circumstances will the manufacturer be held liable for

any problems which may arise due to improper installation and/or

choice of power supply cable.

Terminal strips

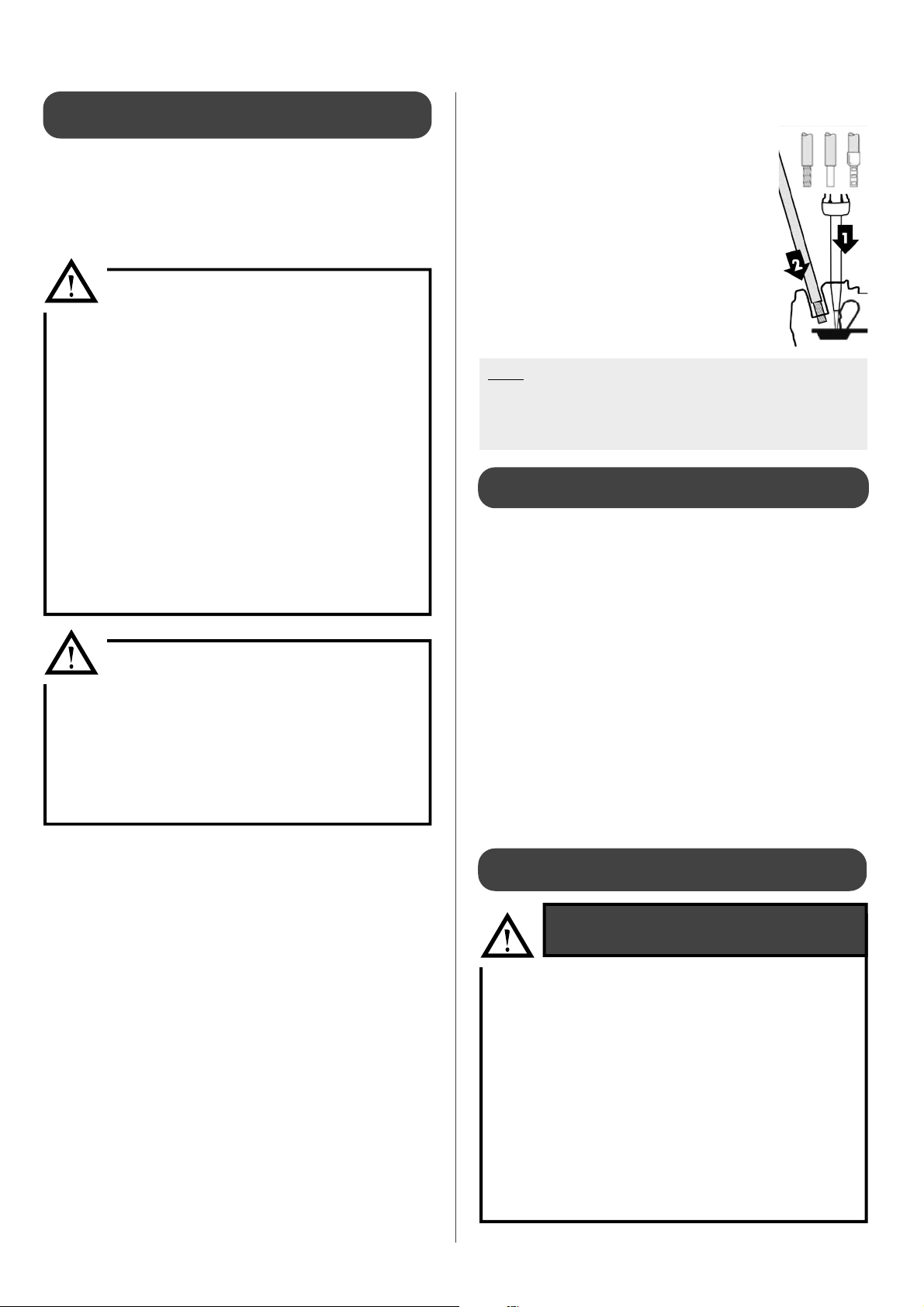

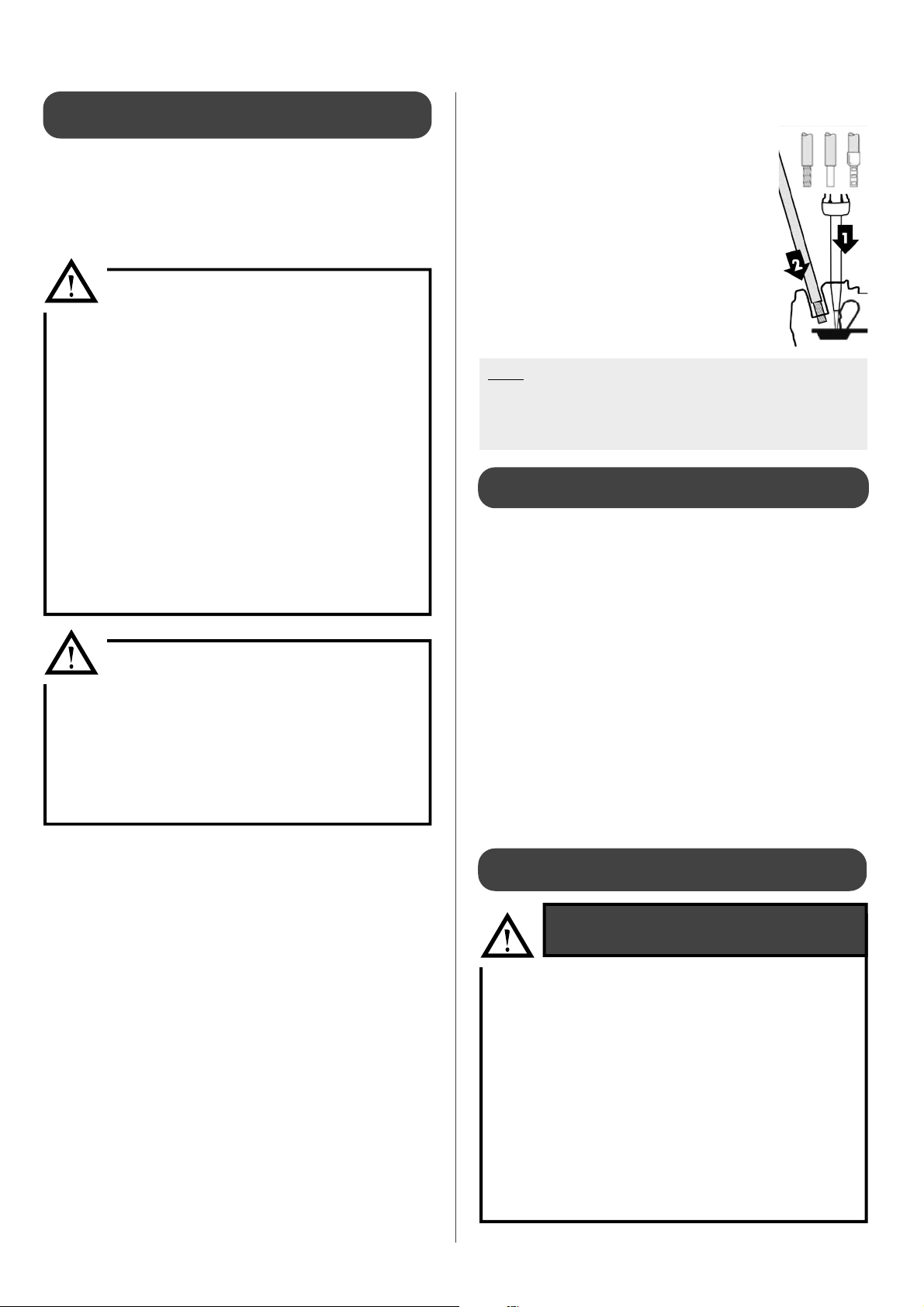

The terminal strips are spring-loaded «Cage Clamps».

For handling, use the following :

- for2,5mm² control terminals or 4mm² -

6mm² power terminals (tetra), use a 3,5 x

0,5mm at-head screwdriver.

- for 10mm² mains power terminals

(single-phase), use a 5,5 x 0,8mm at-

head screwdriver.

1 : Insert the screwdriver into the ap just above

or below the identication number.

2 : Insert the wire into the «CAGE CLAMP» when

the ap is open.

3 : Remove the screwdriver.

Note : The wires must be stripped to the following lengths:

- for the 2,5mm² control terminals: between 10 and 12mm.

- for the mains power terminals: between 18 and 20mm.

- for the intermediary power terminals: between 11 and 13mm.

3.4.1 - Recommendations for connecting the

system to the power supply

Check :

• The power consumption

• Number and thickness of the power supply

cables

• Fuse or circuit breaker ratings

The power supply must come from an electrical protection and

sectioning device which complies with all current rules and

regulation in eect in the country of use.

This CE-approved unit complies with all the essential requirements

of the following directives:

- Low voltage n°2006/95/CE

- Electromagnetic compatibility n° 2004/108/CE

Ensure that the installation is equipped with a properly sized and

connected grounding cable.

Ensure that the voltage and frequency of the general power supply

ts requirements.

The acceptable variation in voltage is:

230 V -10% to +6%50Hz for single-phase+ Ground models

400 V -10% to +6%50Hz for three-phase+ Neutral + Ground models

3.4.2 - Connecting the HRC70 Heat Pump to the

power supply

- It is the responsibility of the installer and of the

clienttoensurethattheapplianceiscompatible

with the power grid before connecting the

HRC70 Heat Pump (see the electricity provider

information form in the Appendix)

- The power grid impedence value must be less

than the Heat Pump impedance Zmax value (see

§ «Connecting the HRC70 Heat Pump to the

power supply»).

- If the electrical installation standards are not

respected there could be irreversible damages

to the HRC70 Heat Pump which are not covered

by the manufacturer’s warranty.

ELECTRICAL INSTALLATION

RECOMMENDATIONS