August Penkert SAFEGUARD INOX PREMIUM 2.0 User manual

August Penkert GmbH

Xantener Str. 12

45479 Mülheim (Ruhr)

Germany

Fon: 0208-41969-0

Fax: 0208-41969-22

E-Mail: [email protected]

Postcode 10 15 24

The Modell SAFEGUARD INOX PREMIUM 2.0 is a further development of the

popular SAFEGUARD INOX PREMIUM - the glove for technical assistance. An

improved fit provides even better tactility (dexterity). The SAFEGUARD INOX

PREMIUM 2.0 meets the requirements of the European Standard 388:2016.

Materials meet the requirements of EN 420:2003+A1:2009.

Available in sizes 5 - 12.

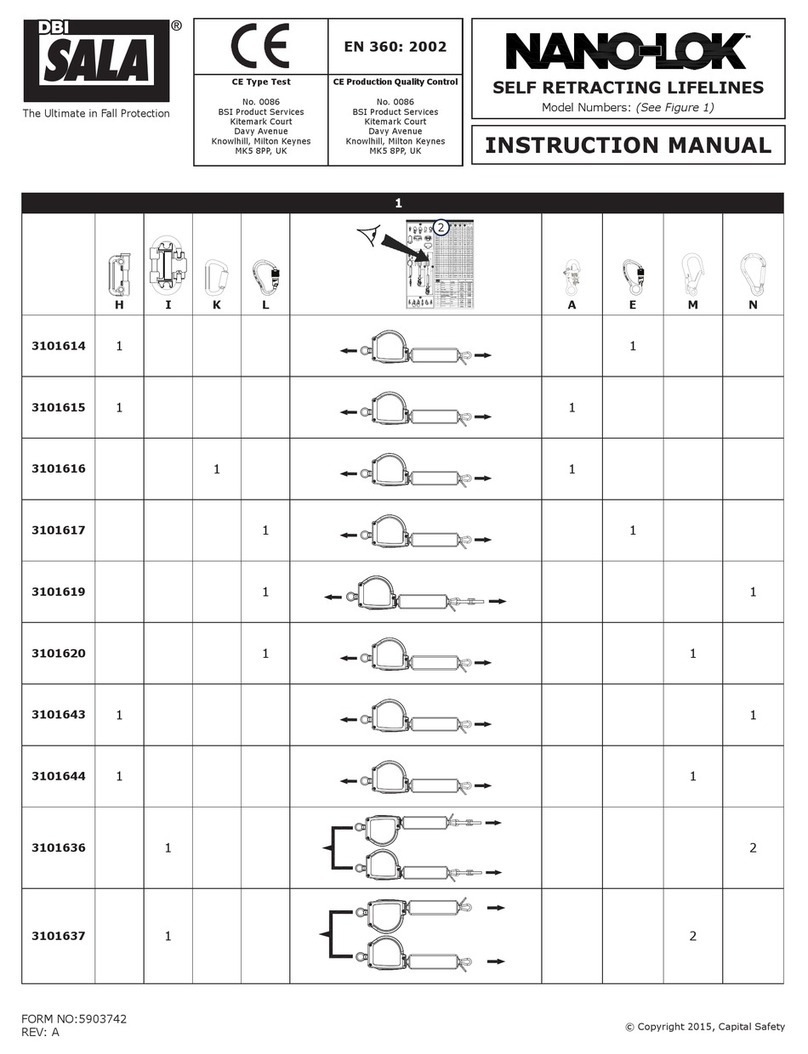

CUTPROTECTIVEGLOVESACCORDINGTOEN388:2016 TECHNICAL DATA

INSTRUCTIONS FOR USE

GUIDE-INFORMATION FOR USE

RESULT

SAFEGUARD INOX PREMIUM 2.0

MODEL:SAFEGUARDINOXPREMIUM2.0 DESCRIPTION

APPLICATION

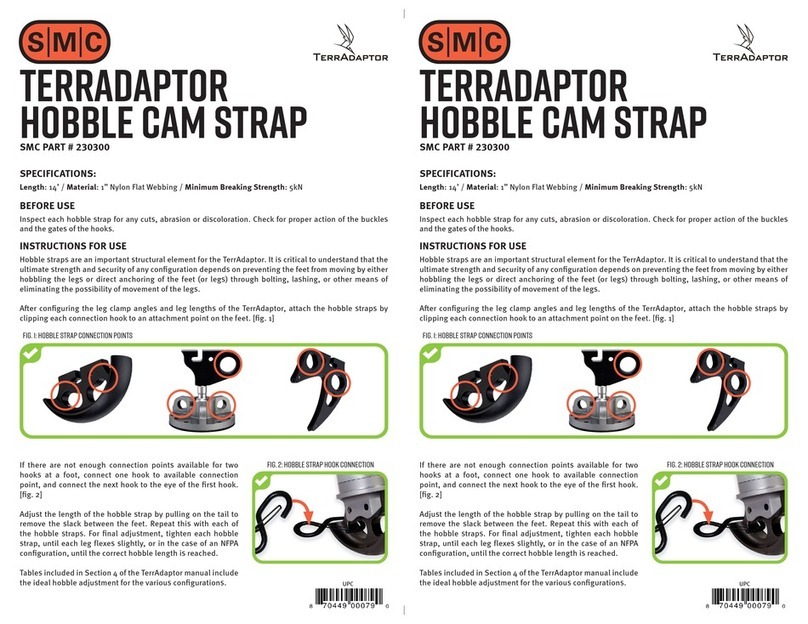

•Double sided knitted fabric made of 60% meta-aramid / 40% para-aramid

Aramid with silicone coating (weight per unit area approx. 520 gr/m2) -

Palm with innovative gel padding (Poron®)

•Reinforcement in the crook of the thumb

•Spantex (93% polyester / 7% spandex)

•Rubberized 3D ankle protection

•Gathered padding in the finger area

•Silicone coating on all sides of the fingertips

•Hand piece completely reinforced with high cut resistant Interlock made of 40%.

KEVLAR® - 60% stainless steel, weight per unit area approx. 200 gr/m².

•Neoprene cuff with velcro fastener

•Eurotex moisture barrier (PUmembrane: waterproof, windproof, breathable )

Attention: no waterproofness in the area of the surface -

Elastic band in the palm of the hand

•Approx.. 6 cm long knitted cuff

•Total length approx. 27 cm (size M)

•Available in sizes 5 - 12

1= lowest power levels; 4 (5) = highest power level (A= weakest and F= highest

power level linear cutting resistance); 0 = indicates that the

glove falls below the minimum power level for the given single hazard. X =

indicates that the glove has not been tested, or

that the test procedure does not appear suitable / applicable.

Note: If blunting occurs during the Coupe Cutting Strength Test, the results of

the Coupe Test are for guidance only, whereas the TDM

Cutting Strength Test provides reference performance results.

Information on the performance level of the TDM test is binding for higher

blunting of the cutting blade in the coupe test. In this case a

Too high power level determined by blade truncation.

Even a high power level when determining the puncture resistance should

not lead to the assumption of protection against puncture of a thin cannula.

Observe the following points when wearing gloves: The glove does

not protect against chemical and bacteriological hazards.

- In cases where there is a risk of moving machine parts getting

caught, this protective glove must not be worn.

- Oil, grease and moisture reduce the cut resistance and increase

the flammability of all gloves and should be avoided.

- The protective gloves are designed for work in a dry environment.

The expiration date (month and year) is indicated on the protective

glove. (Example: 12.2026) It is not known that the performance

levels according to EN388:2016 and EN 420:2003+A1:2009 change

after up to 8 years of proper storage. Note: The production date is

the printed expiration date minus 8 years.

abrasion resistance 3

cut resistance 3

tear strength 4

puncture resistance 4

TDM:section D

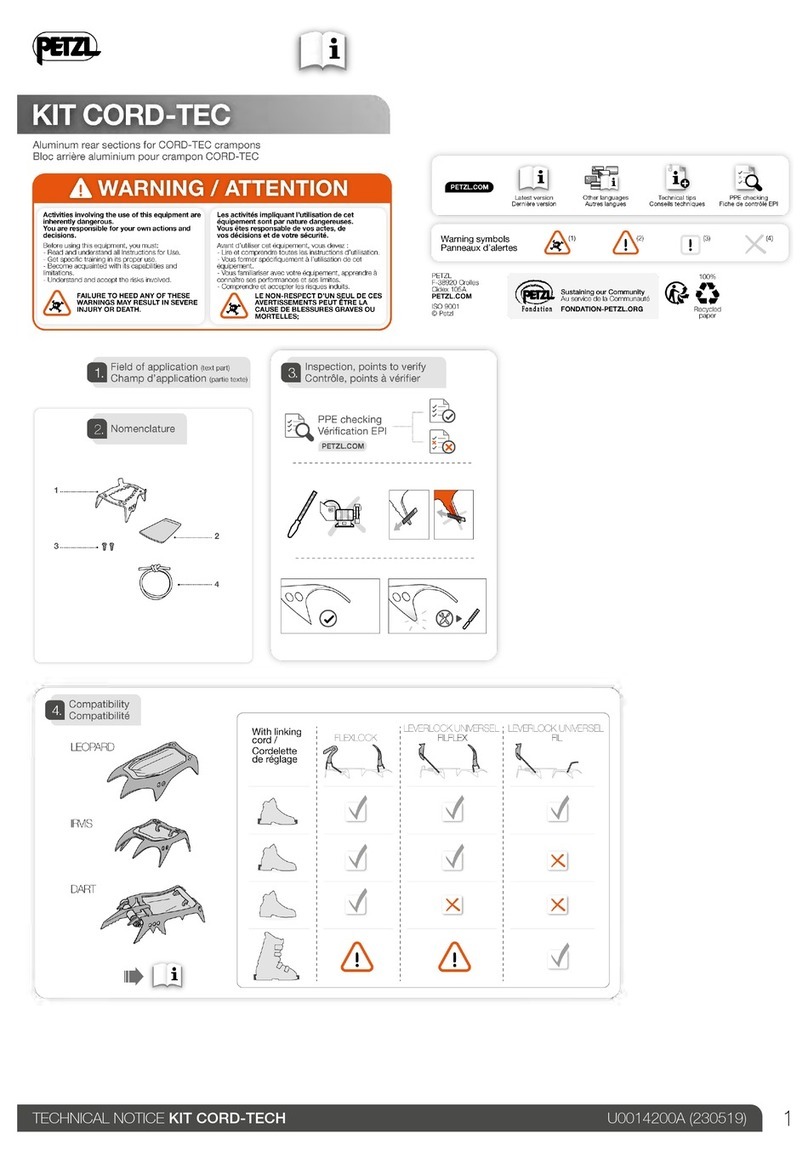

The protective gloves meet the requirements of the European PPE Regulati-

on (EU) 2016/425 and protect against mechanical and thermal risks

(heat) covered by the standards on which the

certification is based.

The applied standards are EN 388:2016 and EN 420:2003+A1:2009.

SAFEGUARD INOX PREMIUM 2.0

INSTRUCTIONS FOR USE

August Penkert GmbH

Xantener Str. 12

45479 Mülheim (Ruhr)

GERMANY

Fon: 0208-41969-0

Fax: 0208-41969-22

E-Mail: [email protected]

Postcode 10 15 24

The marking on the protective glove shows the essential protective

performance characteristics and the contact to the responsible

manufacturer.

August Penkert GmbH

Xanten Str.12

45479 Mülheim on the Ruhr

Phone: 0208-41969-0

Fax: +49 208 41969 22

Please see the sewn-in identification label

The degree of protection required for a particular task depends

on the risks involved. You are ultimately responsible for selecting,

using and operating the protective equipment that is appropriate to

the risks at your workplace. Note that the protective performance

may be adversely affected by application-related wear.

PICTOGRAMS

WARNING

DECLARATION OF CONFORMITY

LIABILITY

We do not accept anyliabilityfor damage caused bya non-targeted

use of the PPE or byanyuse that does not comply100% with the

instructions for use below. Please contact the manufacturer for

further information regarding care instructions, repair and safe

disposal methods.

CARE AND REPAIR

STORAGE

WASH INSTRUCTIONS

The declaration of conformity can be viewed at www.penkert.com

according to washing report

Lars Reuter (Textile Cleaner Master, Hamburg)

These gloves should be stored in their original packaging in a

dry, clean place. Avoid exposing them to moisture or high tem-

peratures.

If you wash the gloves, please use a pH-neutral

detergent.

Dismantle gloves that are so badly damaged that they cannot be

repaired and no longer offer protection.

The gloves which are so severely damaged and no longer provide pro-

tection must not be moved and the protective gloves used must be

disposed of at an appropriate time depending on their use.

GENERAL INFORMATION

3344D

EN 388:2016

EN 420:2003+A1:2009

MIRTAKONTROL d.o.o

Gradiska 3

HR-10040 Zagreb Durava

(NB): 2474

test report no.: OZO271-CPT002/19

CERTIFICATION CLEANING INSTRUCTION