auragen G5000 User manual

MAIN INSTALLATION MANUAL

FOR AN AURAGEN®INDUCTION

POWER SOURCE

Vehicle Powered

Mobile Electric Power

Models G5000, G6000D, G6000X, G8500, G8500X

Aura Systems, Inc.

2335 Alaska Avenue, El Segundo, CA. 90245

Phone: (310) 643-5300 - Fax: (310) 643-7457 - Toll Free (800) 909-AURA

Web Site: www.aurasystems.com

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

i

TABLE OF CONTENTS

Subject Page

Section 1 - Introduction

About this Manual.................................................................................................... 1-1

Functional Description of the AuraGen System.......................................................

.

1-1

AuraGen Induction Power Source.......................................................................

.

1-1

Electronic Control Unit (ECU) ............................................................................. 1-1

AuraGen System Specifications..........................................................................

.

1-1

Mountin

g

Kit............................................................................................................

.

1-5

Estimated Installation Time.....................................................................................

.

1-5

Recommended Tools..............................................................................................

.

1-5

AuraGen System Components................................................................................ 1-5

Mountin

g

Kit Contents.............................................................................................

.

1-5

Recommended Tools and Materials for AuraGen System Installation and Test......

.

1-5

Required Additional Installation Materials................................................................ 1-6

How to Obtain Service............................................................................................. 1-6

Returnin

g

AuraGen Components for Warranty or Service ...................................... 1-6

Section 2 - Warning and Safety Precautions

Warnin

g

s and Precautions......................................................................................

.

2-1

Exhaust Gases........................................................................................................ 2-1

General Safety Precautions..................................................................................... 2-2

Movin

g

Parts Safety................................................................................................

.

2-2

Electrical Shock....................................................................................................... 2-2

AuraGen Connection to Buildin

g

s ........................................................................... 2-2

Section 3 - General Installation Instructions for all Vehicles

Cable Routin

g

.......................................................................................................... 3-1

Connectin

g

Output Cable to Induction Power Source.............................................. 3-5

Electronic Control Unit Mountin

g

- All......................................................................

.

3-6

ECU Installation - Commercial................................................................................. 3-8

ECU Installation - Military/Offroad ..........................................................................

.

3-11

ECU Hookup Hardware........................................................................................... 3-13

AuraGen and ECU Wirin

g

Hookup.......................................................................... 3-14

Si

g

nal Harness Installation...................................................................................... 3-14

Si

g

nal Harness Connection at ECU......................................................................... 3-15

Installation of the Control Panel............................................................................... 3-16

Remote Power Strip Connector Installation.............................................................

.

3-17

Output Power Wirin

g

for AC Only - 120/240............................................................ 3-18

Hard Wired Output Power - 120/240 VAC, 20 Amp Service................................

.

3-18

Hard Wired Output Power - 120/240 VAC, 40 Amp Service................................

.

3-20

Output Power Wirin

g

for AC/DC ECU - 120 VAC and 14 or 28 VDC ..................... 3-22

Hard Wired Output Power - 20 Amp 120 VAC Service........................................ 3-22

DC Power and Ground Cable Connections - AC/DC System:.............................. 3-25

Output Power Wirin

g

for DC Only ECU - 14 or 28 VDC ......................................... 3-27

Output Power Wirin

g

for Inverter/Char

g

er System ................................................

.

3-30

Hard Wired Output Power - 120/240 VAC Service..............................................

.

3-30

DC Power and Ground for Inverter/Char

g

er System...........................................

.

3-32

Field Installation of ECU EMI/RFI Filter Kit ............................................................

.

3-33

Manual Transfer Switch - General Familiarization .................................................

.

3-36

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page ii

TABLE OF CONTENTS

Subject Page

Section 4 - Software Installation and System Testing

S

y

stem Requirements.............................................................................................

.

4-1

About AuraEngr ECU Software...............................................................................

.

4-1

Installing AuraEngr Software .................................................................................. 4-1

Help for Installation Problems.................................................................................. 4-2

Creating a AuraEng Shortcut................................................................................... 4-2

Setting Up and Registering Your Software..............................................................

.

4-3

How to Pro

g

ram the AuraGen ECU......................................................................... 4-5

Setup of Equipment for Testing............................................................................... 4-6

Changing Vehicle Types.......................................................................................... 4-7

Usin

g

the ECU Status Monitor................................................................................. 4-7

Drivability Test......................................................................................................... 4-8

Section 5 - Installing the AuraGen into Specific Vehicles

Installation Notes..................................................................................................... Reserved

Application Catalog.................................................................................................. Reserved

Section 6 - AuraGen Troubleshooting Guide Reserved

Figures

Figure 1-1: AuraGen System Specification - AC-Only.............................................

.

1-2

Figure 1-2: AuraGen System Specification - DC and AC/DC................................... 1-3

Fi

g

ure 1-3: AuraGen S

y

stem Specification - G6000X Inverter Char

g

er (ICS).......... 1-4

Figure 1-4: AuraGen System Specification - G8500X Inverter Charger (ICS).......... 1-5

Figure 3-1: Cable Routing - Fire wall.......................................................................

.

3-1

Fi

g

ure 3-2: Cable Routin

g

- Under the Vehicle........................................................

.

3-2

Figure 3-3: Cable Routing - Access Holes............................................................... 3-2

Figure 3-4: Interconnection Diagram ......................................................................

.

3-3

Fi

g

ure 3-5: Pictorial Wirin

g

Dia

g

ram........................................................................ 3-4

Figure 3-6: Liquid Tight Conduit Fittings.................................................................. 3-5

Figure 3-7: G5000 and G6000 Power Strip Connect...............................................

.

3-5

Fi

g

ure 3-8: G8500 Power Strip Connect.................................................................. 3-6

Figure 3-9: ECU Enclosures - Splash Water Environment....................................... 3-7

Figure 3-10:ECU Enclosure - Withour Splash Water Environment.......................... 3-8

Fi

g

ure 3-11: Drill Hole for Rivnut.............................................................................

.

3-9

Figure 3-12: Using the Rivnut Installation Tool........................................................

.

3-9

Figure 3-13: Installing the Rivnut............................................................................. 3-9

Figure 3-14: ECU Mounting - Commercial............................................................... 3-11

Figure 3-15: ECU Mounting - Military/Offroad.......................................................... 3-12

Figure 3-16: Power Cable Conduit Fittings..............................................................

.

3-13

Figure 3-17: ECU Fitting Assembly. .................................. 3-13

Figure 3-18: ECU Terminal Block Connection.........................................................

.

3-14

Figure 3-19: ECU EMI/RFI Filter Connection......................................................... 3-14

Figure 3-20: ECU Signal Cable Installation.............................................................. 3-16

Figure 3-21: ECU Signal Cable Connector..............................................................

.

3-16

Fi

g

ure 3-22: Secure Si

g

nal Harness to ECU...........................................................

.

3-16

Figure 3-23: Remote Power Strip Connector........................................................... 3-17

Figure 3-24: Secure Power Connector to ECU........................................................ 3-17

Fi

g

ure 3-25: ECU Output Power / Hard Wire Connection........................................ 3-18

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

iii

TABLE OF CONTENTS

Subject Page

Figure 3-26: 120 /240 VAC 20 Amp Power Connection to AC Only ECU ...............

.

3-19

Figure 3-27: ECU Output Power / Hard Wire Connection........................................ 3-20

Figure 3-28: 120 VAC, 40 Amp Power Connection to AC Only ECU.......................

.

3-21

Figure 3-29: AC/DC ECU Connection Arrangement (Typical).................................. 3-22

Figure 3-30: ECU Output Power / Hard Wire Connection........................................ 3-23

Figure 3-31:120 VAC, 20 Amp Power Connection to AC/DC ECU..........................

.

3-24

Figure 3-32: ECU DC Power and Ground Terminals...............................................

.

3-25

Figure 3-33 DC Power Cable Connect at ECU........................................................ 3-25

Figure 3-34: DC Power Cable Connect at Battery...................................................

.

3-25

Figure 3-35: DC Power Cable Terminal Boot........................................................... 3-26

Figure 3-36: DC Ground Cable Connection at ECU................................................ 3-26

Figure 3-37: DC Ground Cable Connection at Battery............................................. 3-26

Figure 3-38: 14 Volt Jumper Installation..................................................................

.

3-27

Figure 3-39: DC Only Cable Installation - For Reference Only................................

.

3-28

Figure 3-40: DC Power Cable Connect at ECU....................................................... 3-28

Figure 3-41: DC Power Cable Connect at Battery...................................................

.

3-29

Figure 3-42: DCPower Cable Terminal Boot............................................................ 3-29

Figure 3-43: ECU Output Power/Hard-wire Connection........................................... 3-30

Figure 3-44: 120/240 VAC Power Connection to Inverter/Charger ECU.................. 3-31

Figure 3-45: Inverter/Charger System DC Cable Routing........................................ 3-32

Figure 3-46: Cut Red and Black Wires....................................................................

.

3-33

Figure 3-47: Insulate Ends of Red and Black Wires................................................

.

3-33

Figure 3-48: Remove Output Wires from Terminal Strip.......................................... 3-34

Figure 3-49: Install AC Output Filter Plate ..............................................................

.

3-34

Figure 3-50: Install Output Filter .............................................................................

.

3-34

Figure 3-51: Install Wires on AC Output Power Board............................................. 3-34

Figure 3-52: Install Wires on AuraGen Input Filter................................................... 3-35

Figure 3-53: Install Ferrite Filter on Signal Harness ................................................ 3-35

Figure 3-54: AC Output Reference Colors............................................................... 3-35

Figure 3-55: Manual Transfer Switch System.......................................................... 3-36

Figure 3-56: Manual Transfer Switch Features........................................................ 3-37

Figure 4-1: AuraEngr Password Dialog Box............................................................

.

4-2

Figure 4-2: AuraEngr Main Screen.......................................................................... 4-3

Figure 4-3: Configuration Dialog Box....................................................................... 4-3

Figure 4-4: Find Modem Selection........................................................................... 4-3

Figure 4-5: AuraEngr Password Tab Dialog............................................................

.

4-4

Figure 4-6: Go-On-Line Display............................................................................... 4-4

Figure 4-7: AuraEngr On-line .................................................................................. 4-4

Figure 4-8: AuraEngr Logon Dialog Box ................................................................. 4-5

Figure 4-9: AuraEngr Main Screen.......................................................................... 4-5

Figure 4-10: Configuration Dialog Box.................................................................... 4-5

Figure 4-11: AuraEngr Main Screen........................................................................

.

4-6

Figure 4-12: RegistrationDialog Box........................................................................ 4-6

Figure 4-13: AuraEngr Main Screen .......................................................................

.

4-6

Figure 4-14: AuraEngr Program Upload .................................................................

.

4-6

Figure 4-15: ECU Installation Window..................................................................... 4-7

Figure 4-16: ECU System Status Monitor................................................................ 4-7

Figure 4-17: Control Panel LED Codes - Non-Inverter/Charger Systems...............

.

4-10

Figure 4-18: Control Panel LED Codes - Inverter/Charger Systems....................... 4-11

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

ABOUT THIS MANUAL

This manual provides detailed step-by-step

instructions for installing an AuraGen system

into a select series of vehicles. The instructions

use photographs and line drawings to clarify

each step. Study this manual carefully and

comply with all warnings and cautions. Correct

installation of the AuraGen system will result in

longer unit life, better performance and safer

operation.

This manual contains numerous safety warnings

and cautions. These relate to personal safety

as well as to the safety of the vehicle and the

AuraGen system. A detailed overview of the

warnings and safety precautions is given in

Section 2 of this manual.

In addition, there are specific warnings and

cautions that appear throughout the manual

wherever they are appropriate. Be sure to read

Section 2 of this manual thoroughly before

beginning the installation procedure.

FUNCTIONAL DESCRIPTION OF

SYSTEM

Overall System Description

The AuraGen Induction Power Source System

uses the rotating energy from a vehicle engine

to produce commercial grade AC electrical

power whenever the vehicle engine is running.

The AuraGen produces a substantial amount of

power at normal/near engine idle. When the

power loads increase, the vehicle idle speed is

automatically increased as necessary by adjust-

ing the engine throttle. 5000 watts of power out-

put requires only about 1,300 engine RPM in a

typical V-8 gasoline engine and between 650

and 900 RPM for most diesel applications. Tem-

perature sensors located inside the AuraGen

and ECU will automatically shutdown the sys-

tem in the unlikely event of component overheat-

ing.

AuraGen Induction Power Source

The source of electrical power is the AuraGen

Induction Power Source. This device resembles

an oversized vehicle alternator. It can be

mounted to the engine and mechanically ro-

tated (driven) by a serpentine belt coupled to

the crankshaft. Other drive options available in-

clude direct coupled via hydraulic motion and

via a driveshaft from a PTO located on a trans-

mission.

The AuraGen incorporates a speed sensor for

sensing the rotor RPM, and, as noted earlier, a

temperature sensor for thermal protection. Un-

like a conventional vehicle alternator, the Au-

raGen does not contain built in diodes to con-

vert the generated AC to DC. Instead, the AC

output is supplied through a four-wire power

cable to the ECU.

The Induction Power Sources are offered in dif-

ferent models, each having specific power out-

put capabilities.

AuraGen Electronic Control Unit (ECU)

The ECU is usually located in the rear of the

vehicle.

The AuraGen generates AC power which is sup-

plied to the Electronic Control Unit (ECU). The

ECU converts this to a DC voltage first, then

inverts this, then filters the power to achieve120/

240 volt single phase output.

AuraGen Systems Specifications

The AuraGen and ECUs are offered in various

performance configurations. These differences

are exhibited in the following specification

tables.

1-1

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

Figure 3-3: AuraGen System Specification - G6000X Inverter Charger (ICS)

1-4

AURAGEN PRODUCTS

STANDBY POWER (20 MINUTES) 6000 WATTS 6000 WATTS 6000 WATTS 6000 WATTS

CONTINUOUS POWER 5000 WATTS 5000 WATTS 5000 WATTS 5000 WATTS

AC POWER (CONTINUOUS) 5000 WATTS 5000 WATTS 5000 WATTS 5000 WATTS

AC STANDBY (20 MINUTES) 6000 WATTS 6000 WATTS 6000 WATTS 6000 WATTS

AC PEAK (2 SECONDS) 7200 WATTS 7200 WATTS 7200 WATTS 7200 WATTS

AC VOLTAGE 120 VAC 240 VAC 120 VAC 240 VAC

AC CURRENT (CONTINUOUS) 42 AMPS 21 AMPS 42 AMPS 21 AMPS

AC POWER 2500 WATTS 2500 WATTS 4000 WATTS 4000 WATTS

AC PEAK (2 SECONDS) 3000 WATTS 3000 WATTS 6000 WATTS 6000 WATTS

AC VOLTAGE 120 VAC 240 VAC 120 VAC 240 VAC

AC CURRENT 21 AMPS 11 AMPS 33 AMPS 16 AMPS

ENGINE ON-TO-OFF-TO-ON

TRANSITION

BATTERY DRAW/AC ON/NO LOAD

BATTERY DRAW/AC OFF

BATTERY DRAW

DC POWER

DC VOLTAGE

DC CURRENT

TOTAL HARMONIC DISTORTION

FREQUENCY STABILITY

VOLTAGE REGULATION

VEHICLE BATTERY

ENGINE BELT

POWER-TAKE-OFF

HYDRAULIC MOTOR

GENERATOR

ECU

GENERATOR

ECU

GENERATOR

ECU

GAS ENGINES

DIESEL ENGINES

AUTO START

INTERFERENCE FILTER MODULE

POWER STRIP

TRANSFER SWITCH

UP TO 3500 WATTS

28 VDC

125 AMPS

UP TO 1750 WATTS

125 AMPS

14 VDC

S

P

E

C

I

F

I

C

A

T

I

O

N

S

INVERTER CHARGER (ICS)

G6000X 12 VDC G6000X 24 VDC

YES

YES

YES

24 VDC

12.16"DX6.4"W

20.75"LX13.5"WX8.52"H

65 LBS.

64 LBS.

-40 ”F TO +200 ”F

SEAMLESS

LESS THAN .01 AMPS

APPROX. 100 AMPS PER KW

LESS THAN 2.5%

50/60 –0.15 HZ

1.5%

1200 TO 6000 RPM

750 TO 3600 RPM

YES

YES

YES

TOTAL POWER

AC OUTPUT IN

GENERATOR

MODE/ENGINE ON

AC OUTPUT IN

BATTERY

MODE/ENGINE OFF

DC OUTPUT

AC POWER QUALITY

DRIVE OPTIONS

DIMENSIONS

WEIGHT

OPERATIONAL

AMBIENT

OPERATIONAL

ENGINE SPEED

OPTIONAL FEATURES

10 AMPS NOMINAL

12 VDC

12.16"DX6.4"W

20.75"LX13.5"WX8.52"H

65 LBS.

64 LBS.

-40 ”F TO +200 ”F

-40 ”F TO +120 ”F

N/A

YES

YES

YES

N/A

YES

YES

YES

-40 ”F TO +120 ”F

1200 TO 6000 RPM

750 TO 3600 RPM

SEAMLESS

8 AMPS NOMINAL

LESS THAN .01 AMPS

APPROX. 50 AMPS PER KW

LESS THAN 2.5%

50/60 –0.15 HZ

1.5%

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

MOUNTING KIT CONTENTS

•AuraGen Mounting Bracket

•Supplemental brackets

•AuraGen Pulley Assembly

•Necessary serpentine or V belt(s)

•Throttle control & mounting hardware

•Misc. hoses, idlers, tensioners and fasten-

ers to install brackets.

RECOMMENDED AND REQUIRED

TOOLS AND MATERIALS FOR

AURAGEN SYSTEM INSTALLATION

AND TEST

Recommended:

√S.A.E. wrenches –7/16" through 1-1/4 "

√Metric wrenches –8 mm through 19 mm

√1/4", 3/8" and 1/2" ratchets with exten-

sions

√S.A.E. sockets –7/16" through 3/4"

√Metric sockets –8 mm through 19 mm

√Hose clamp removal tool or pliers

√Power steering pump pulley puller

√Serpentine and/or V belt tensioner tool

√Phillips head screwdrivers

√Wire cutters (large and small)

√Knife

√Hacksaw

√Straight edge (24")

√Torque wrench (10-100 ft-lbs.)

√Crimping tool

√Rivnut tool

√S.A.E. and metric Allen wrench set

√Tape measure

√Volt-ohm meter

√Drill, drill bit, and hole saw set

√Scribe

√Fender covers

√Misc. Items:

Marker , drain pan for engine coolant,

drop light

MOUNTING KIT

The mounting kit allows proper installation and

mounting of the AuraGen to the vehicle engine.

When installed properly, the serpentine belt will

line up with all idlers and tensioners. The

mounting kit is always vehicle and engine

specific. You must have the correct mounting

kit for the particular make, model year and

engine configuration of the vehicle into which

the AuraGen system is to be installed. Each

mounting kit contains a mounting bracket to

which the AuraGen is attached and related

mounting hardware.

Due to possible OEM midyear design varia-

tions, attempts to install an AuraGen kit on chas-

sis models and engine configurations not de-

fined in the AuraGen Induction Power Source

Catalog, or the presence of aftermarket equip-

ment, incompatibilities may be experienced

with the AuraGen mounting kit and/or informa-

tion provided in this manual. Although Aura will

assist the installer to resolve these types of con-

ditions, it cannot be held responsible for addi-

tional installer labor, time, and costs associated

with such variations.

ESTIMATED INSTALLATION TIME

An experienced two person crew will need

between two and four hours for a standard

installation that includes a remote power strip.

AURAGEN SYSTEM

COMPONENTS

•AuraGen Power Induction Source

•AuraGen Control Panel

•AuraGen Electronic Control Unit/Inverter

Charger System (ECU/ICS)

•Mounting hardware for the ECU/ICS

•AuraGen Signal Harness

•Power cable (Not Included with mounting kit.

See Required Additional Material).

1-6

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

REQUIRED ADDITIONAL INSTAL-

LATION MATERIALS

Caution! All electrical wires, plugs, outlets,

and switches used with the AuraGen sys-

tem must be in accordance with the UL

1248 standard.

Required installation materials are;

•Power Cable, 1/2" liquid tight shielded metal

conduit with four (4) #10 AWG multi-strand

conductors. The recommended wire insula-

tion is type THNN (high temperature). Use

different colors (i.e. red, black, white and

green).

•Automotive grade wire loom (1/2", 3/4" and

1.0") temperature rating of 205°C

•Cable ties, different lengths

•Loctite 242 (blue)

•#6 flanged spade terminals (Thomas & Betts

RC10-6FL)

•Electrical tape

•Electrical outlets; 120 VAC-20 amp (GFI rec-

ommended), 240 VAC-20 amp

•Optional: 3/4" and 1.0" rubber insulated

metal clamps (Edel clamps).

•Optional: Remote Power Strip

.

1-7

HOW TO OBTAIN SERVICE

The AuraGen system can only be serviced by

certified AuraGen technicians working for au-

thorized AuraGen distributors, OEM’s, or deal-

ers.

The AuraGen and ECU are not designed to be

field repairable. These components are in-

tended to be removed and replaced as a whole.

RETURNING AURAGEN

COMPONENT(S) FOR WARRANTY

OR SERVICE

In the unlikely event that you need to return an

AuraGen Inductive Power Source, ECU, or

bracket to Aura Systems for service, the

following steps must be performed or the

component(s) will not be accepted by Aura.

1. Complete a Customer Concern Field Prob-

lem Report (CCFPR) and e-mail or fax (310-

643-7457) it to AuraGen Product Support.

AuraGen Customer Service will contact you

with a Return Material Authorization (RMA)

number. If this is a warranty claim, Customer

Service will ask whether you wish to have a

replacement shipped, or a credit applied to

your account.

2. Insert a copy of the CCFPR into the ship-

ping container.

3. Return the component(s) in an appropriate

container (original packing preferred). If you

do not have a appropriate container, one will

be provided.

4. Include the RMA number on the packing slip

and on the outside of the container.

5. Note: Aura Systems does not pay for expe-

dited delivery of warranty or service com-

ponents.

Required Tools:

√Simplex Load Bank, 0-10,000 watts

√ECU Interface Box

√Windows 95/98 PC (laptop recom-

mended)

√AuraEngr Interface Software

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

WARNINGS AND SAFETY

PRECAUTIONS:

Before installing the AuraGen system, read this

manual to become familiar with the equipment

and its features. Operation of the equipment

can be achieved safely and efficiently when the

unit is properly installed and maintained. Most

accidents happen because people fail to fol-

low fundamental rules and precautions.

The following symbols are included in this

manual to advise of any potential dangerous

conditions to the operator, service personnel

from the vehicle wiring harness prior to per-

forming welding repairs on a vehicle. The

AuraGen input fuse, input ground wire as

well as the temperature sensor and RPM

sensor leads need to be disconnected if

welding repairs on a vehicle are necessary.

♦DO NOT run electrical and fuel lines through

the same compartment openings.

♦Have a fire extinguisher on hand.

♦Properly maintain the extinguisher and be-

come familiar with its use.

Extinguishers rated ABC by the NFPA are

appropriate for all applications.

♦Consult the local fire department for the cor-

rect type of extinguisher for different appli-

cations.

VEHICLE EXHAUST GASES ARE

DEADLY!

♦Do not test or operate the AuraGen System

in an enclosed area. Always ensure there

is proper ventilation when testing, operat-

ing and/or installing the AuraGen system.

♦Never sleep in the vehicle with the vehicle

running unless the vehicle is equipped with

an operational carbon monoxide detector

that shuts the engine off if CO levels are too

high.

♦Provide adequate ventilation to expel dis-

charged gases. Inspect the vehicle’s ex-

haust system for leaks according to the ve-

hicle maintenance schedule. Ensure that

the exhaust manifolds are secure and not

warped. Do not use the exhaust gases to

heat the work area.

This symbol is used to warn of im-

mediate hazard which will result in

severe personal injury or product

damage.

This symbol is used to warn of an

electrical hazard or unsafe practice

which may result in personal injury,

product damage or property dam-

age.

This symbol is used to warn of a

mechanical hazard or unsafe prac-

tice which can result in severe per-

sonal injury or death.

For the Equipment:

♦DO NOT engage or disengage the AuraGen

or ECU output connector(s) while the vehicle

engine is running.

♦DO NOT lay any component on caustic

chemical liquids or compounds.

♦Keep outlet covers down while not in use to

prevent any debris from becoming lodged

within the contacts.

♦DO NOT tie electrical wires to any fuel lines.

♦Please disconnect the vehicle battery(s), and

any OEM Electronic Control Module (ECM)

2-1

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR

DEATH:

♦Disconnect the vehicle battery before work-

ing on or around the engine or AuraGen sys-

tem.

♦Use rubber insulating mats or dry wood plat-

forms over floors that are metal or concrete

when working around electrical equipment.

♦Do not wear damp clothing (especially wet

shoes), or allow skin surfaces to be damp

when working withelectrical equipment.

♦Use extreme caution when working with live

electrical components.

♦Follow all state and local electrical codes.

♦Tag any open circuit to prevent accidental

closure.

DO NOT CONNECT THE AURAGEN

SYSTEM DIRECTLY TO THE ELEC-

TRICAL SYSTEM OF ANY BUILD-

ING.

♦Differing voltages between the AuraGen sys-

tem and the utility line can create a potential

for electrocution and property damage, in-

cluding the ECU.

♦Connect the AuraGen system only through

an approved device and only after the

building’s main switch is open.

♦Consult a licensed electrician for all electri-

cal connection matters.

♦Provide proper exhaust ventilation to the ex-

terior of the building or facility for any vehicle

parked in an enclosed area.

GENERAL SAFETY PRECAUTIONS:

♦Hot coolant under pressure can cause se-

vere personal injury. DO NOT open a radia-

tor pressure cap while the engine running.

Stop the engine and allow to cool before very

carefully bleeding the system of pressure.

♦DO NOT operate power equipment when

mentally or physically fatigued, or after con-

sumption of alcohol or any drug that makes

the operation of equipment unsafe.

MOVING PARTS CAN CAUSE SE-

VERE PERSONAL INJURY OR

DEATH:

♦Keep hands, loose clothing and long hair

away from all moving parts.

♦Make sure that fasteners on the AuraGen

are secure. Keep supports and clamps tight

and keep guards in position over fans, drive

belts, etc.

♦Do not wear loose clothing while working on

the AuraGen. Loose clothing and jewelry can

be caught in moving parts.

♦Jewelry can short out electrical contacts and

cause shock or burning.

♦Do not make any adjustments while the en-

gine is running. Use extreme caution around

hot exhaust manifolds, ignition wires, mov-

ing parts, etc.

2-2

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

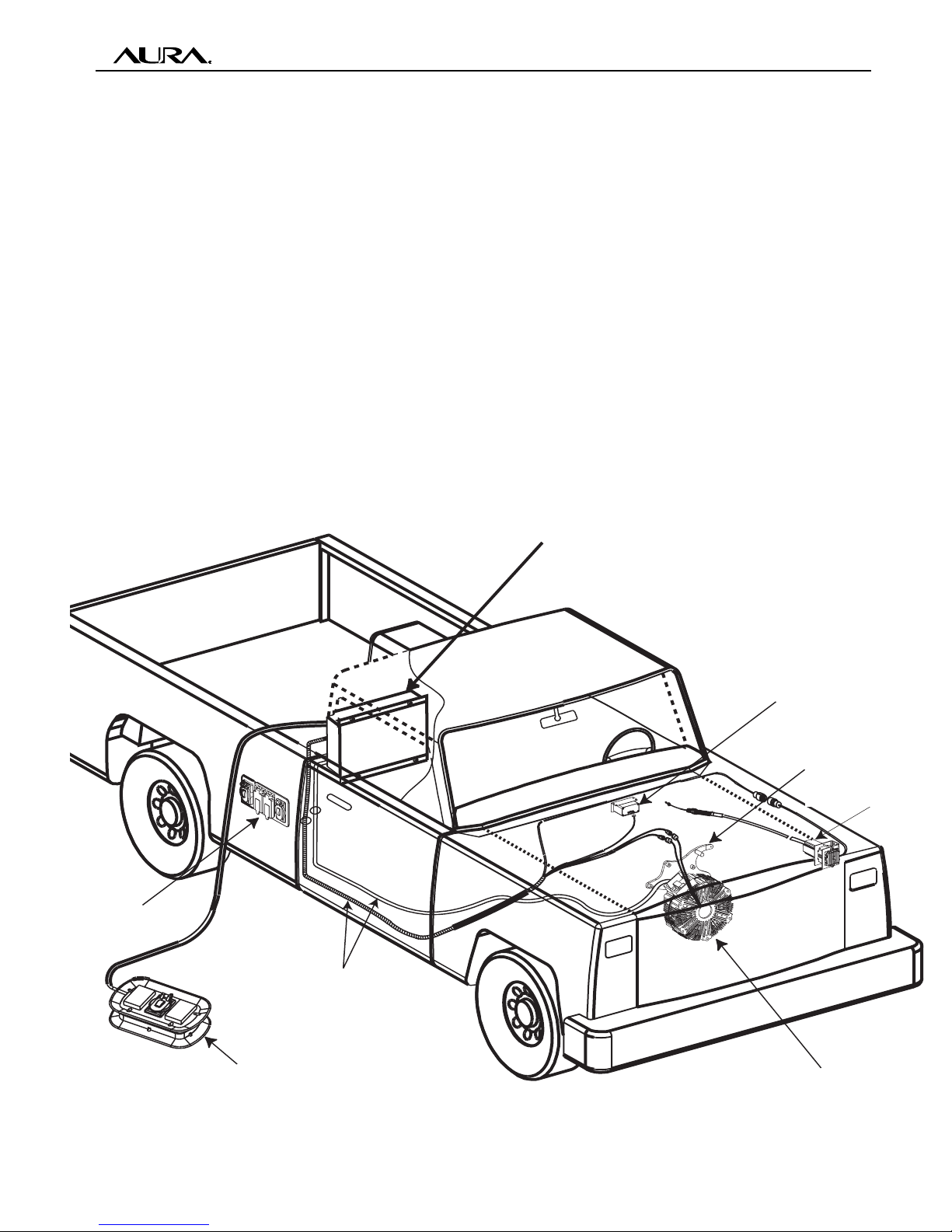

Cable Routing

The AuraGen Signal Harness connects the ECU

to the Throttle Control, Control Panel, and the

AuraGen’s Temperature and RPM sensors. All

of the system connectors are brought together

into a common cable under the hood. The Power

Cable and the Signal Harness should be

separated by roughly 5 inches, and routed to

the Electronic Control Unit (ECU). Some parts

of the Signal Harness may require routing into

the driver’s compartment or dashboard. See

Figures 3-1 through 3-3 for guidelines on routing

cables under the vehicle.

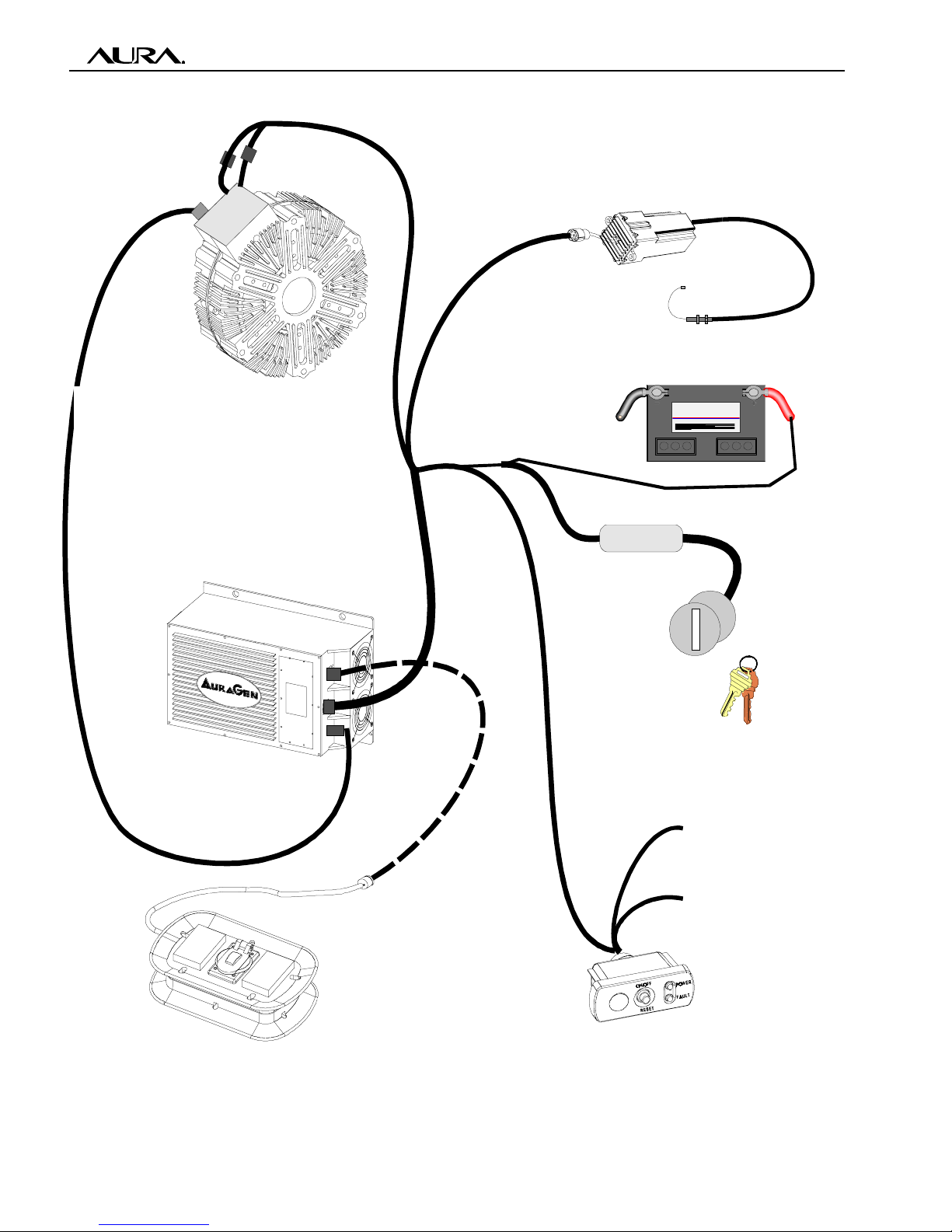

See Figure 3-5 for a general pictorial wiring

diagram. See Figure 3-4 for a component

interconnect diagram.

Specific routing methods are left to the

discretion and judgment of the installer and the

wishes of the individual vehicle owner.

However the following guidelines must be

strictly followed to prevent damage to equipment

or injury to personnel.

♦Do not route any cable near movingparts or

where it will be subject to friction or exces-

sive vibration.

♦Place all wiring in wire loom to provide pro-

tection from environment and abrasion.

♦Secure wire bundles to the vehicle every 12

to 18 inches.

♦Do not leave any bare wires exposed.

♦Maintain roughly 5 inches between the Power

Cable and the Signal Harness.

Figure 3-1: Signal Harness and Power

Cables are routed under the vehicle. Take

care to keep cables at least 6" away from

exhaust components, as shown.

♦ If too close to the exhaust system/compo-

nent, wrap heat tape on the Signal Harness

and/or Power Cable to protect them from

damage.

3-1

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

Figure 3-2: Route cables to rear area of

vehicle, keeping them clear of anything that

might subject them to damage by abrasion,

flexing or heat.

Do not route any cable near sharp or hot parts.

In particular, keep cables at least 6" away from

exhaust manifolds, mufflers or other exhaust

components.

Figure 3-3: Drill a hole in the underside of the

vehicle near the place where the ECU is to be

located and route the Signal Harness and Power

Cable through it, as shown. Seal hole(s) with

grommets or clear silicone after the cables are

secured.

3-2

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

3-3

Figure 3-4: Interconnection Diagram of the AuraGen Systems

Duke

Parkin

g

Brake/

Neutral Switch

Remote Start

Fused

+12 VDC

Switched

RPM

Te m p

Power

Conduit

AuraGen

Generator

Electronic

Control Unit

(ECU)

Power Strip

(optional)

Control Panel

Throttle Control Unit

Hook to

Throttle

Linkage

+

-

-

+

(Yellow Wire)

(Purple Wire)

Power Cable

Output Power

• Hardware

• Power Strip (Optional)

Mechanical or Electronic

IdleControl Unit

Induction Power

Source

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page 3-4

CONTROL AND POWER

CABLES ROUTED UNDER

VEHICLE TO REAR-MOUNTED

ELECTRONIC CONTROL UNIT

REMOTE POWER STRIP

(OPTIONAL)

RECEPTACLE

OUTLET BOX

AURAGEN MOBILE

GENERATOR

THROTTLE CONTROL

(LOCATION MAY VARY)

MOUNTING BRACKET

(ENGINE AND VEHICLE

SPECIFIC)

CONTROL UNIT

ON/OFF - STATUS LEDs

(USUALLY LOCATED UNDER DASH)

ELECTRONIC CONTROL UNIT

Figure 3-5: Pictorial Wiring Diagram of a “Typical Installation”

IDLE CONTROL

(LOCATION MAY VARY)

AURAGEN INDUCTION POWER SOURCE

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

Connecting Power Output Cable

to the AuraGen

Note: Use only high quality #10 AWG multi-

strand copper wire (with THNN or equivalent

insulation) to connect the ECU to the AuraGen.

Solid wire will fatigue and eventually break. Do

not attempt to connect short pieces of wires to-

gether, use a one piece length of cable (cut to

size).

To connect the four-wire power output cable to

the AuraGen, perform the following steps:

1. Use a straight edge to mark the circumfer-

ence of the flexible conduit.

2. Using a hacksaw,cut approximately six

inches of the conduit off to expose the four

wires inside. Note: When sawing the con-

duit, take care not to cut or damage the wire

insulation encased inside.

3. Slide the nut (B) of the liquid tight connector

over the four wires and onto the flexible con-

duit.

4. Slide seal ring (C) of the liquid tight connec-

tor over the four wires and screw it into the

flexible conduit.

5. Mount the coupler (D) into the hole on the

side of the AuraGen terminal box.

6. Secure the coupler (D) to terminal box with

the serrated nut (E) with o-ring, as shown in

Figure 3-6 and 3-7.

7. Slide the wires extending from the conduit

into the AuraGen terminal by passing the

wires through the coupler (D).

8. Connect the conduit to the AuraGen by

threading the nut (B) on the conduit to the

coupler (D) on the AuraGen.

Note: Use care when tightening conduit nut

(E). Do not pinch or nick temperature sen-

sor wire the AuraGen will not be operational

if sensor wire is damaged.

9. Route the wires to their respective terminals

while ensuring a maximum amount of ex-

cess wire while allowing for proper closure

of the terminal box. Strip one-fourth (1/4") of

insulation from ends of all four wires; apply

#10 flanged spade terminals (Thomas Betts

RC10-6FL) to each end of wire using a

crimping tool.

10. For the model G5000 and G6000 series,

connect all four wire terminal lugs to termi-

nal strip inside terminal box according to the

colors shown in Figure 3-7.

11. Torque the screws to 15 in-lbs.

12. Reinstall terminal box cover to top of the

AuraGen.

3-5

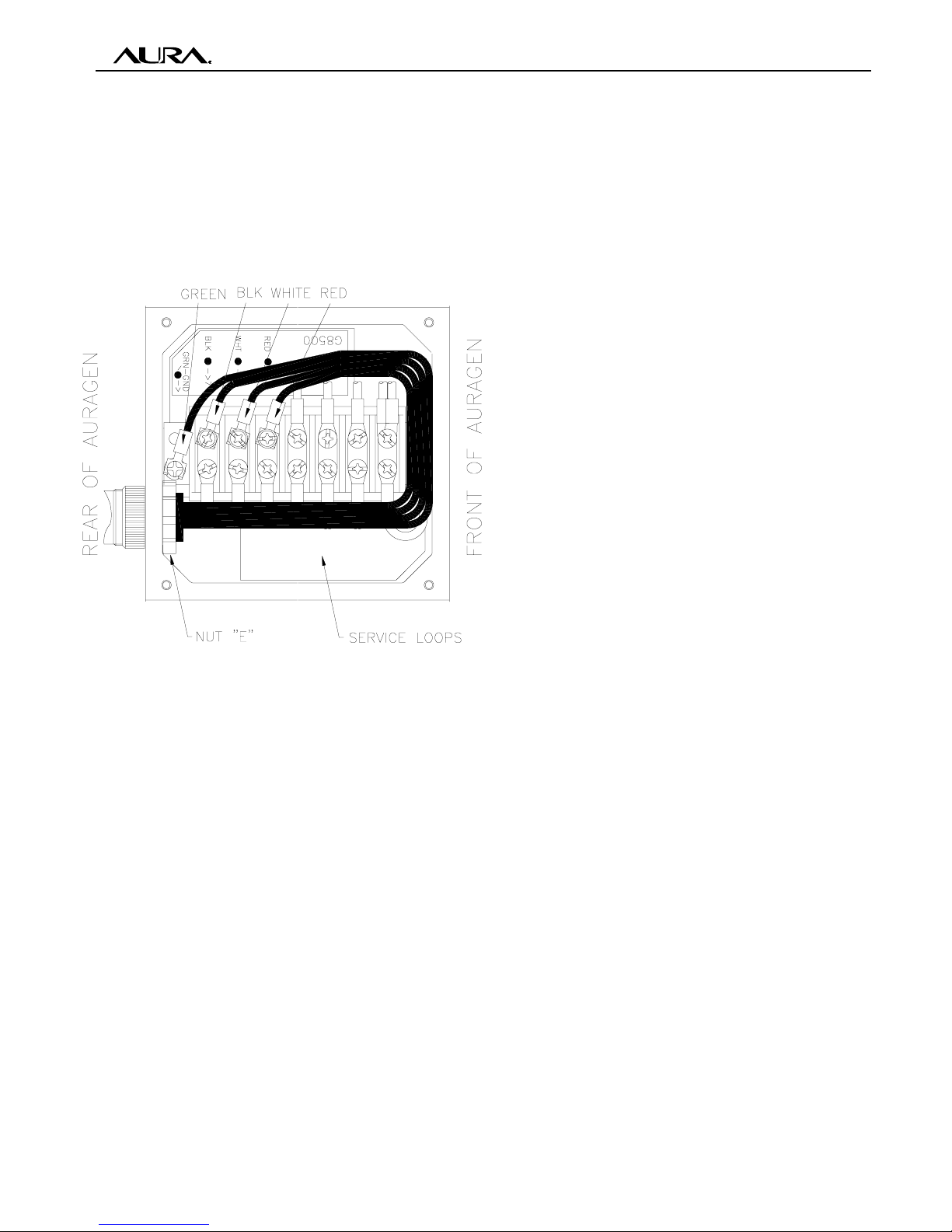

Figure 3-6: Liquid Tight Conduit Fitting

ECA

BD

Figure 3-7: G5000 and G6000 Series

Terminal Box Connections

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

13. For the G8500 model, connect all four wire

terminal lugs to terminal strip inside termi-

nal box according to the colors shown in Fig-

ure 3-8.

14. Torque the screws to 15 in-lbs.

15. Reinstall terminal box cover to top of Au-

raGen.

3-6

Figure 3-8: G8500 Series Terminal Box

Connections

Electronic Control Unit (ECU)

Mounting - All

Caution! If the ECU requires any field modi-

fications, perform those modifications prior

to mounting.

The ECU must be mounted in a location that

will provide adequate ambient air ventilation for

cooling. If the ECU is not adequately ventilated,

the unit will overheat, produce less than full rated

power, andeventually will shut down. The

maxmum ambient air temperature, whether the

ECU is enclosed or in the shade, is 120ºF,

measured at the ECU cooling fan inlet.

Always locate the ECU where it will not be sub-

ject to excessive heat, physical damage, or

road debris/splash.

Note: The ECU requires a minimum of 6 inches

of clearance on the air intake and exhaust. Many

mounting locations are possible, such as in the

rear of a van or the bed of a pickup. When

mounted in the bed of a pickup, it is recom-

mended that the ECU be installed on the wall of

the bed just behind the cab. However, this is

not an absolute requirement.

The following are rules for ECU installation that

regard operating temperature and environmen-

tal protection. These instructional rules are rec-

ommended to prevent ECU shut down due to

overheating.

1. The ECU has to operate at an ambient tem-

perature not to exceed 120ºF, measured

at the ECU cooling fan air inlet, whether in-

stalled in an enclosure or in the open air.

2. The preferred location of the compartment

is in a shaded area. Exposure to sun ra-

diation can add hundreds of Watts to the

total heat balance of the unit.

3. The compartment must be ventilated.

4. Locate the ECU in the shaded part of the

enclosure away from any heat source.

5. If possible, mount the ECU on a vertical

panel of the compartment See Figure 3-9.

6. Do not mount the ECU with the air exhaust

facing the forward motion of the vehicle.

This causes backpressure of airflow.

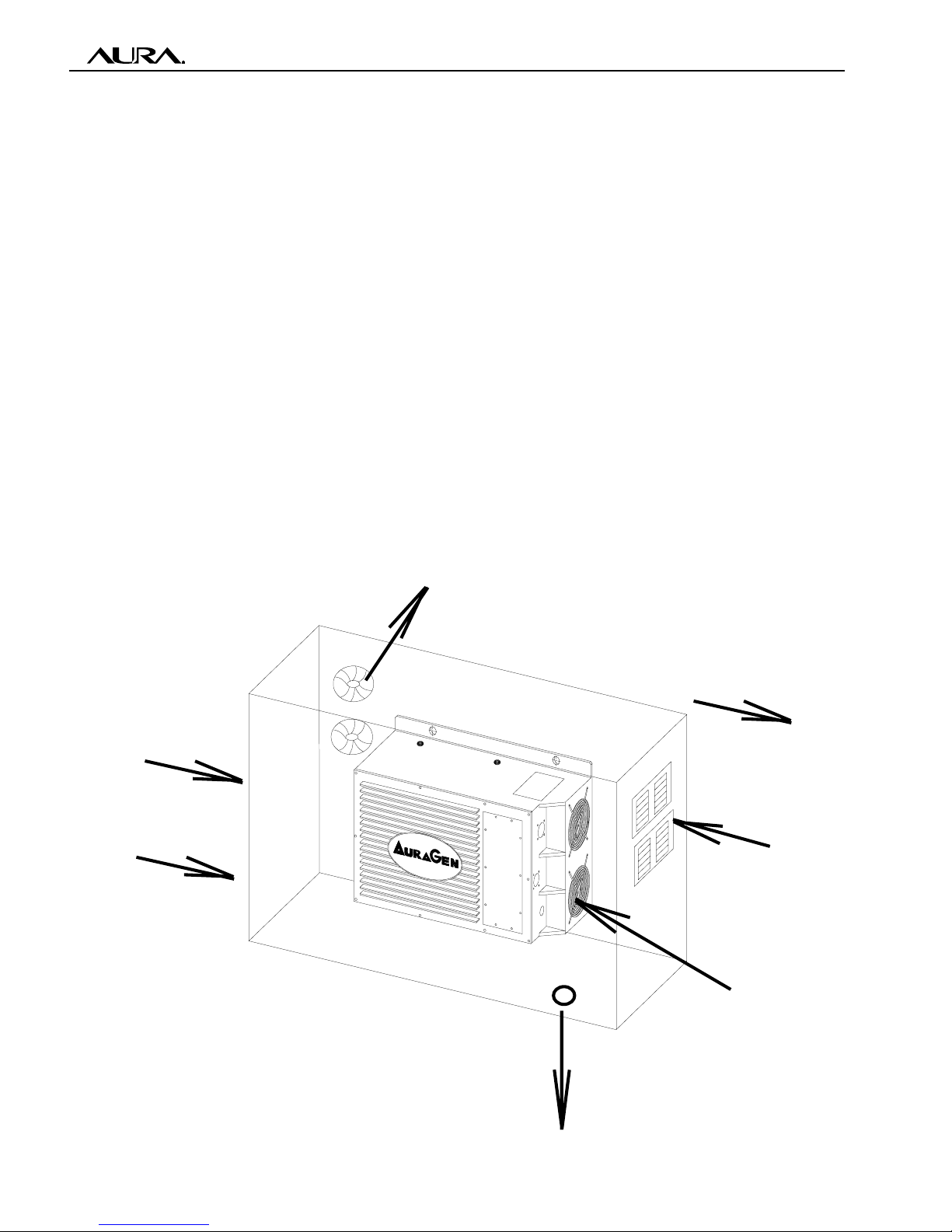

7. Enclosure Inlet Air Panel:

Install louvers (or perforated plate) in the

suction air panel of the enclosure. This

panel faces the two ECU cooling fans. The

airflow area of the louvers have to have a

surface area of around 30 square inches.

This will allow cool air to enter the ECU fans

to ventilate the compartment. “Louvered

Vent”Model 282387, supplied by Sea-Fit,

are suggested. Two of these louvers are

needed (one on top of the other) as each

has about a 13.3 square inch vent area.

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

3-7

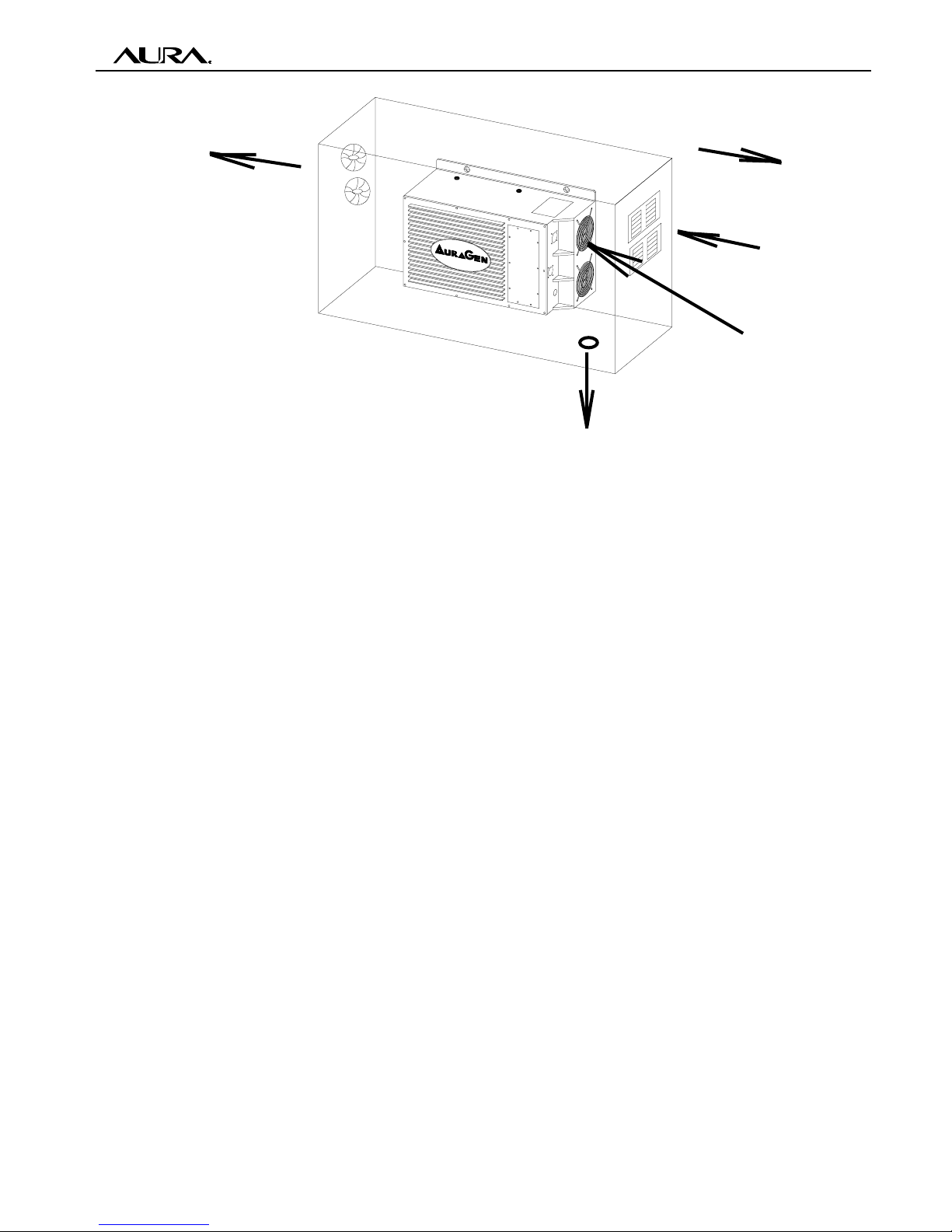

8. Ensure that the louvers are not positioned

such that water/mud splash from the wheels

would cause moisture to enter the compart-

ment. When splashing of water is sus-

pected, position the ECU as in Figure 3-9,

otherwise install it as in Figure 3-10.

9. Compartment Air Outlet Panel:

9.1. Two fans, 100 C.F.M. each, are nec-

essary for proper ventilation of the en-

closure. An A/C or D/C voltage fan can

be utilized for this purpose.

9.2. In moderate climates not exceeding

100ºF ambient temperature, two lou-

vers (similar to the inlet air) instead of

the fans may be used.

10. Locate the fans as close as possible to the

ECU exhaust air area. This will ensure ef-

ficient removal of hot air from the compart-

ment.

11. Do not mount the exhaust fans facing the

forward motion of the vehicle. This causes

backpressure of airflow. See Figures 3-9

and 3-10.

12. Ensure that the fans are not located such

that water/mud splash from the wheels

would cause moisture to enter the compart-

ment.

13. Additional benefit can be achieved by re-

ducing the heat radiation from the asphalt

to the lower compartment panel. This can

be accomplished by either of the following

methods.

13.1. Installing an insulation material on the

floor of the compartment.

13.2. Using a heat shield (reflect foil) on

the external lower panel. On the bot-

tom of the compartment, find the low

point and drill a hole for L.P.D (Low

Point Drain) to prevent water accumu-

lation. The size of the hole (or holes)

should be approximately 1/2".

SPLASH WATER

FORWARD DIRECTION

AIR IN

AIR OUT

L.P.D.

120°F MAX. OPERATING

AIR TEMPERATURE MEA-

SURED AT ECU INLET

Figure 3-9: ECU Compartment - Spash Water Environment

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

ECU Installation - Commercial

(See the following section for

military and offroad mounting)

Note: Before drilling any holes, be sure that the

area immediately behind the panel you are drill-

ing into is clear of any obstructions (fuel tank,

fuel lines, brake lines or wiring).

Note: The ECU mounting hardware is pack-

aged inside the ECU.

Note: The location within a vehicle into which

the ECU is to be mounted may vary, even among

the same make and model. For these reasons,

most of the details regarding mounting and lo-

cating the ECU are left to the judgment of the

installer and the wishes of the vehicle owner.

As a typical example, the guidelines shown in

this section illustrate the installation of the ECU

into the bed of a pickup truck. The same steps

will apply to any ECU installation, only the spe-

cific location will vary.

To gain access to the mounting hardware, re-

move the access cover from the ECU.

1. Place the ECU squarely against the flat in-

side bed of the pickup, and using a scribe

or sharp pencil, mark the locations of the

four mounting holes.

2. Move the ECU out of the way, and using a

scribe or sharp pencil, mark the locations

of the two cable access holes (in the floor of

the pickup bed or bed wall). Ensure there is

access for both cables to route to ECU with-

out binding or interfering with vehicle move-

ment.

3. Center punch and drill the two 1 to 1 1/4 inch

diameter access holes into the bed wall (or

bed floor) for the power cable and signal

Harness.

4. From underneath the vehicle, feed one end

of the power cable (1/2”conduit) through

one hole.

5. Route the signal harness cable through the

second hole in the pickup bed and route to

ECU area.

6. Reposition ECU over previously marked

mounting location and ensure adequate

room for routing of the signal harness and

power cable. Move ECU out of the way.

7. For Rivnuts; center punch, and with a 17/

32”(.5312) drill bit, drill four mounting holes

into the bed wall as shown in Figure 3-11.

8. For 3/8" bolts and nuts; center punch, and

with a 0.406" drill bit, drill four mounting holes

into the bed wall as shown in Figure 3-11.

3-8

Figure 3-10: ECU Compartment - Without Spash Water Environment

AIR OUT

L.P.D.

AIR IN

FORWARD DIRECTION

120°F MAX. OPERATING

AIR TEMPERATURE MEA-

SURED AT ECU INLET

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

Note: Proper function of the AuraGen sys-

tem requires the ECU case to be grounded

to the chassis. Whether mounting the ECU

with Rivnuts, or nuts and washers, removal

of debris, paint, or other coatings from

around both sides of the mounting holes is

required.

9. Place a Rivnut (F/N 4) onto the insertion tool

and insert the Rivnut into one of the four holes

that were drilled in the pickup bed. It may be

necessary to add a 1/2" washer between

the Rivnut and the wall to provide sufficient

area for the Rivnut to grasp. See Figures 3-

12 and 3-13.

10. Swage the Rivnut into the hole by applying

firm pressure to the installation tool.

11. Repeat steps 8 and 9 until all four (4) mount-

ing holes have Rivnuts installed.

Note: Adequate pressure must be used to

prevent the Rivnuts from loosening and spin-

ning inside the holes. See Figure 3-13.

Some ECU’s are supplied with 3/8" bolts,

3/8" washers, and Ny-lock nuts in place of

the Rivnuts and shoulder bolts.

Figure 3-11: Drill hole for Rivnut™

Figure 3-12: Installing Rivnut Onto Tool Figure 3-13: Installing Rivnut

3-9

AUTOMOTIVE AURAGEN®MAIN INSTALLATION MANUAL

020530E MAN-050-200, MAIN INSTALLATION MANUAL Page

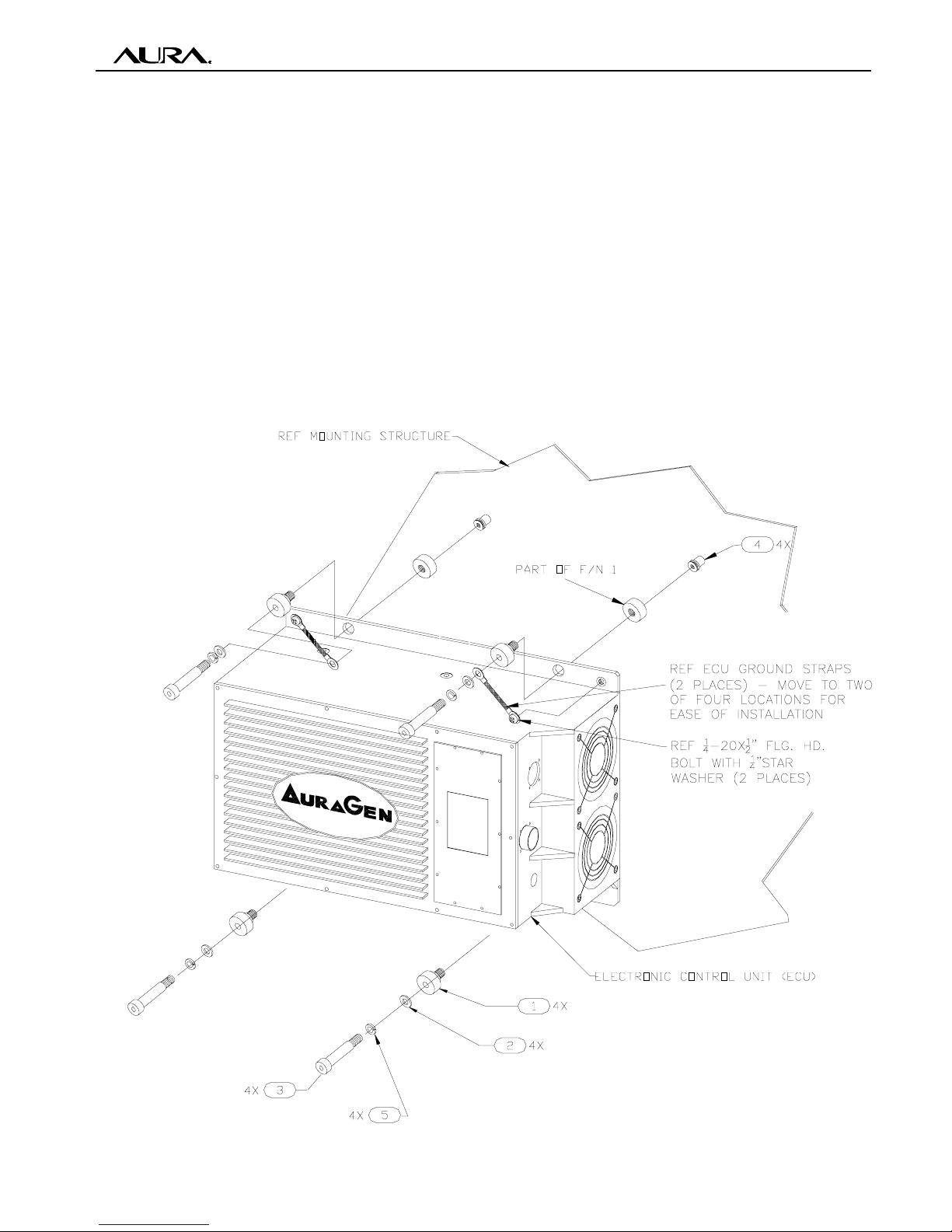

12. Install the four rubber shock mounts

(F/N 1) on the ECU. See Figure 3-14.

13. Place ECU over the mounting holes and

secure to the pickup bed using four (4) 3/

8x1 1/2" shoulder bolts (F/N 3), with 3/8"

lock washers (F/N 5), and 3/8" flat washers

(F/N 2). See Figure 3-14.

Note: The ECU has two ground straps at-

tached to it that must be added to the two

adjacent ECU mount bolts. To provide

3-10

Figure 3-14: ECU Mounting - Commercial

ease of installation, move the straps to any

of four attachment locations on the ECU

case. If the straps are relocated, torque the

1/4-20 bolts to 49-55 in-lbs.

CAUTION! Failure to ground the ECU case

to the chassis can cause system failures.

14. Add the ground strap lugs to the selected

ECU mount bolts .

15. Torque all of the 1/4" ECU mount bolts to

9-11 ft-lbs.

This manual suits for next models

4

Table of contents

Popular Portable Generator manuals by other brands

Briggs & Stratton

Briggs & Stratton 40375 Operator's manual

DEVA Broadcast

DEVA Broadcast DB9000-STC Quick user guide

Master

Master MGH10000C OWNER'S OPERATION AND INSTALLATION MANUAL

Powermate

Powermate Coleman PMC606500 user manual

Accton Technology

Accton Technology RPU150W Quick installation guide

Generac Power Systems

Generac Power Systems 005723-0 GP Series owner's manual