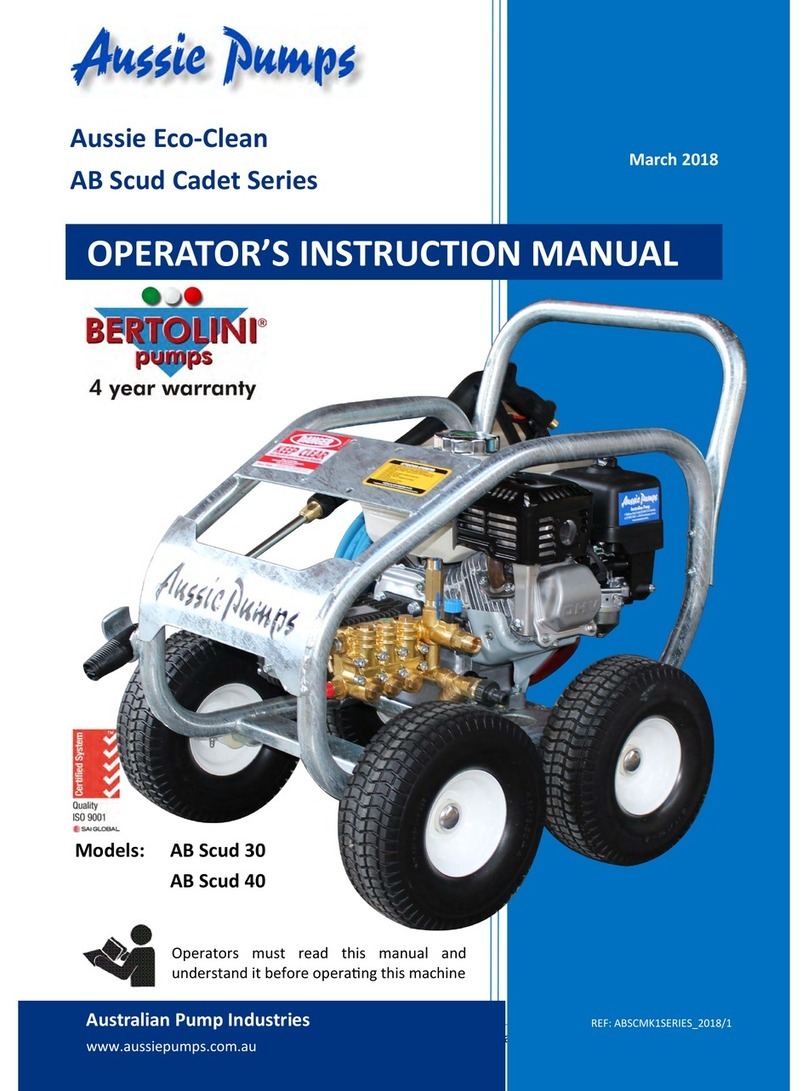

Aussie Hydraulic Drive Blaster … Operation & Maintenance Manual 9

Sept 2018

WATER SUPPLY HOSE:

Use a good quality supply hose (not supplied) of 19mm

diameter minimum on TTL & TTK versions, 25mm on

RAL version.

Fasten the one end of the hose to the inlet hose

connector securing using a worm drive clamp. This

connecon MUST be ght to avoid leaks. (19mm hose

tail provided TTL & TTK versions, 25mm hose tail on

RAL version. )

Water supply can be by means of either:

$ Mains Supply

Secure the free end of the hose to your tap using a

suitable tap adaptor (not supplied - available

through all good hardware and garden supply

stores).

$ Syphon Fed Supply

Place the free end of the hose into a water tank or

container and the pump will draw water itself.

Use a larger diameter sucon hose, at least 3/4"

diameter and no more than 2 metres long. Water

supply must be above or level with pump.

NOTE: The unit is ed with a Y strainer inlet lter.

Ensure this is removed and rinsed to clear debris

before each use.

OPERATION:

Turn on water supply if applicable. Note: Tap

should be full on.

Pull the trigger to expel air from the system.

Water will trickle from the end of the lance

when air is expelled.

Engage hydraulic to power to blaster.

Check that there are no leaks in the line

connecons, gun or power lance. Pressure

begins when the pistol trigger is squeezed.

SHUT DOWN

Turn o water supply if applicable.

Disengage hydraulic to power to blaster.

Pull the trigger release pressure from the

system. Gun trigger should be locked to prevent

accidental acvaon.

Hose and gun/lance assembly can now be

stowed or detached.

NOTE: Failure to release pressure before

disconnecng the hose quick coupler will result in the

quick coupler o-ring seal blowing out. This o-ring

must be replaced before operang machine.

ACCESSORIES:

(CONSULT AUSSIE BLASTER BLITZ FOR DETAILS)

Your Aussie water blaster can be used with a wide

variety of oponal extras to enhance performance.

To use the accessories you must rst disassemble the

lance. Unscrew quick coupler to unlock the lance.

The accessories can then be connected to the end of

the lance assembly. If quick coupler is not supplied it

can be purchased from your local Aussie Eco-Clean

Distributor.

TURBO LANCE - A correctly selected heavy

duty turbo lance can cut pressure cleaning me

in half and is a very important accessory.

SANDBLAST HEAD - Wet grit-blasng is safe

and tremendously eecve. Ideal for rust

removal, paint stripping and gra removal.

OPTIONAL LANCES - A range of oponal lances

in stainless steel or zinc plated steel are

available in lengths of up to 2 metres.

ROTARY CLEANER - The Aussie Eco-Clean rotary

cleaner allows at surfaces to be cleaned in a

fracon of the me normally taken. Ideal for

contractors and professional users.