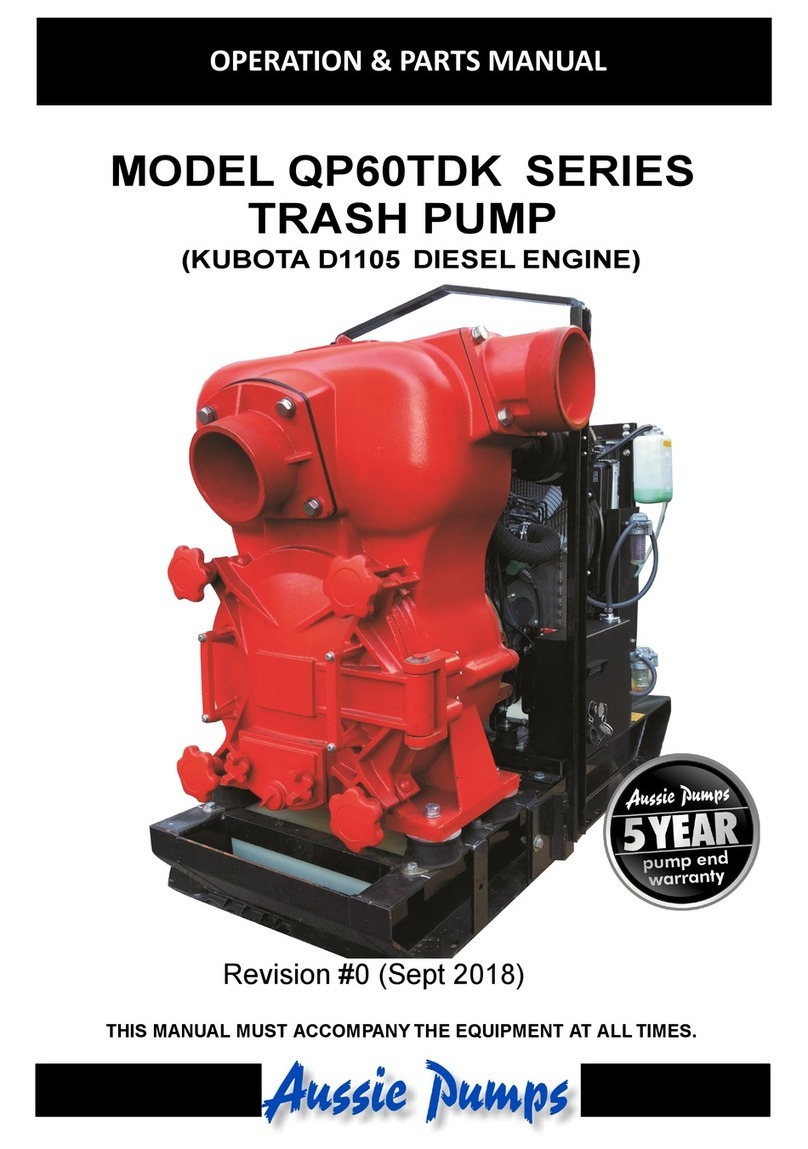

Aussie Pumps QP User manual

Table of contents

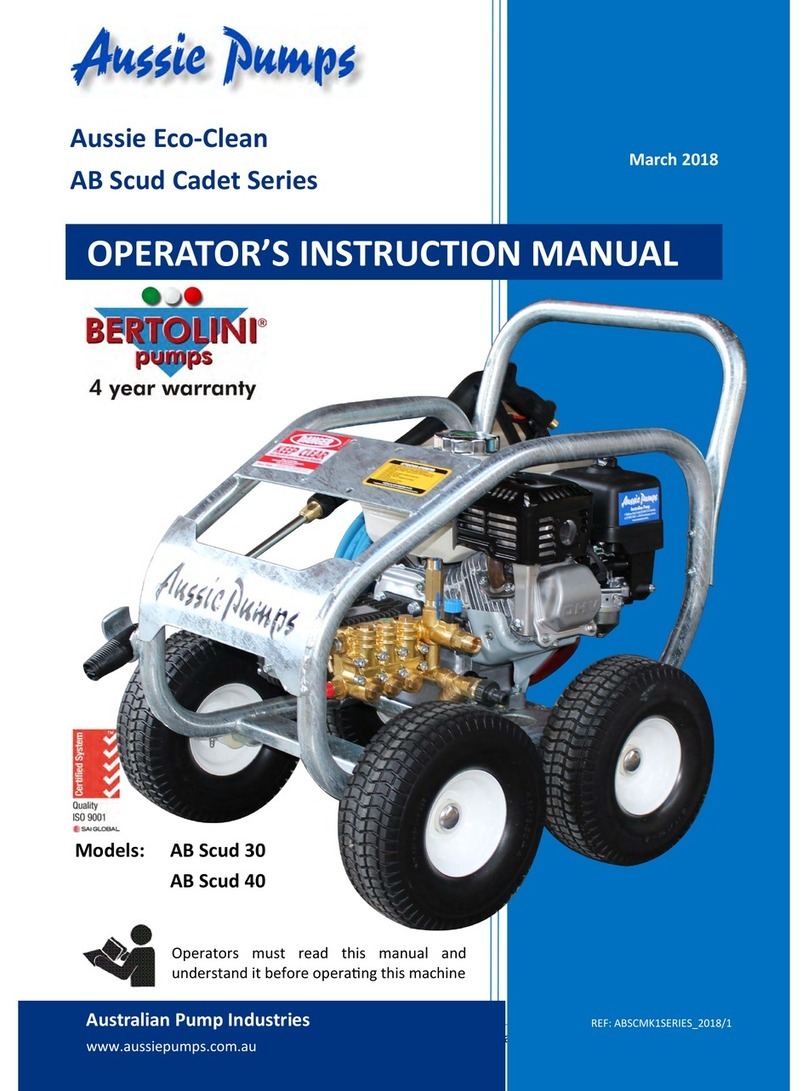

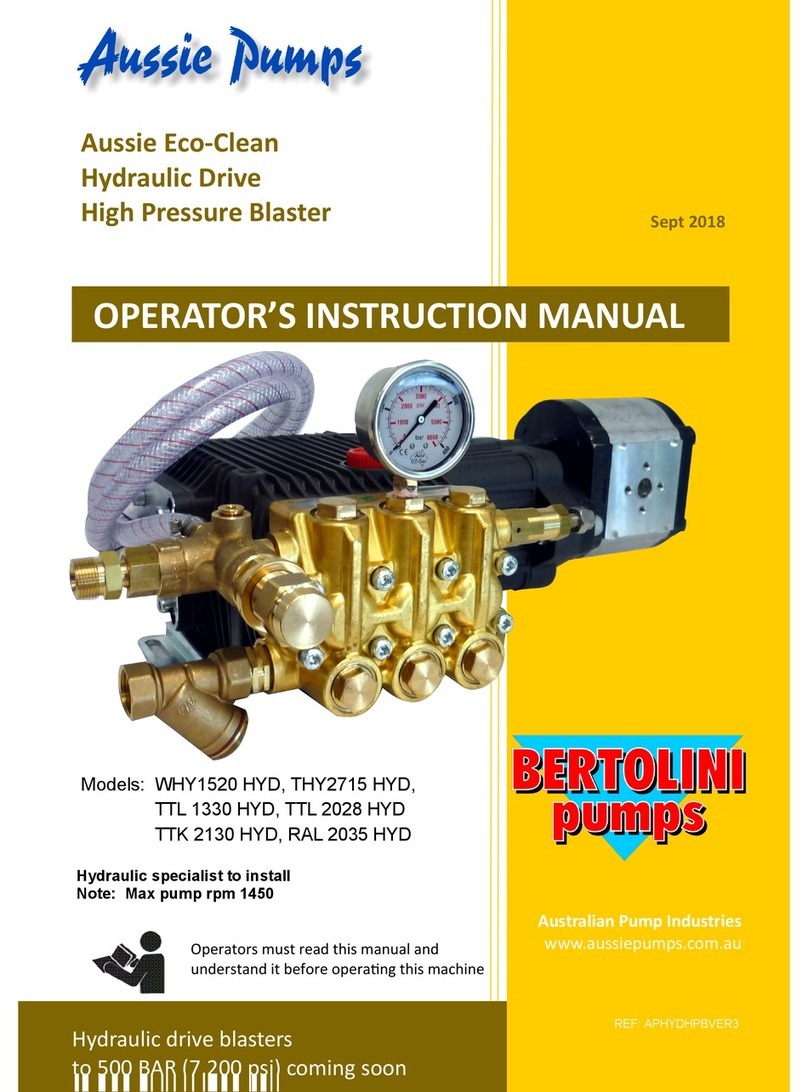

Other Aussie Pumps Water Pump manuals

Popular Water Pump manuals by other brands

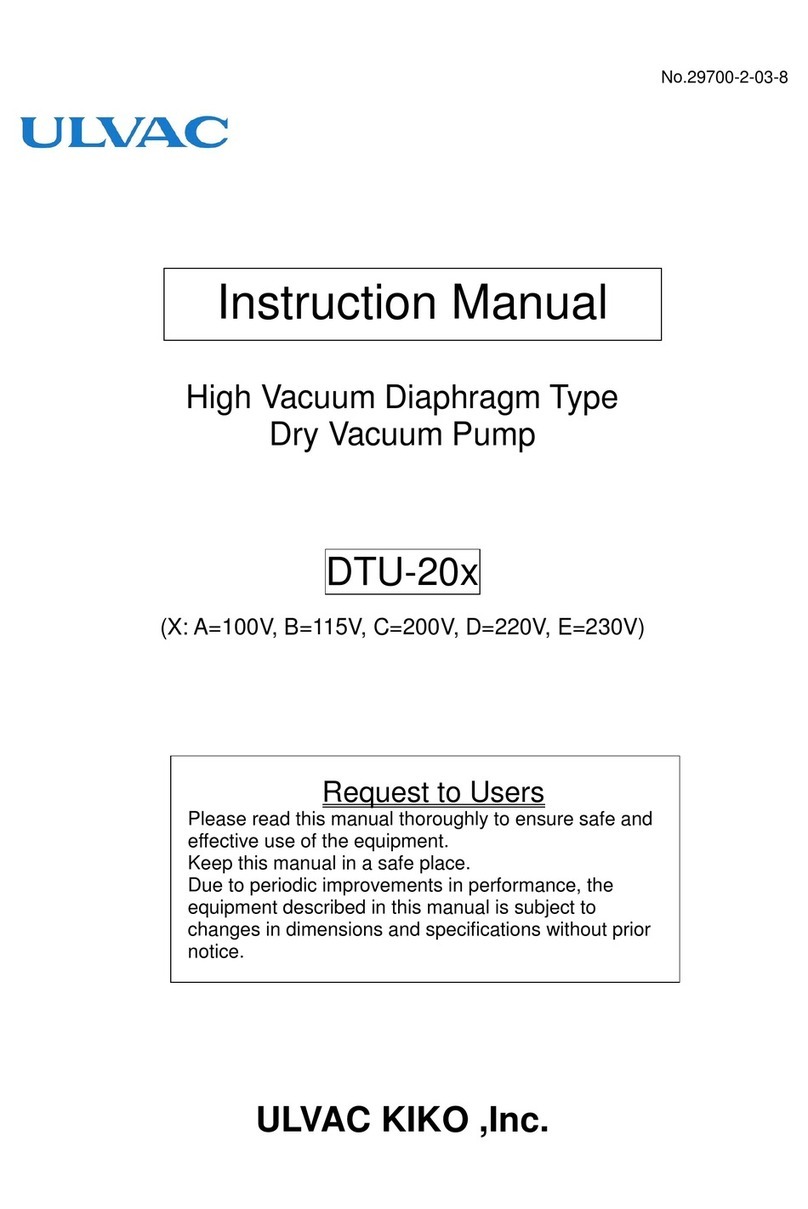

Ulvac

Ulvac DTU-20 Series instruction manual

Intex

Intex Krystal Clear 604 owner's manual

RIDGID

RIDGID DP-24 operating instructions

Intex

Intex Quick-Fill AP640 owner's manual

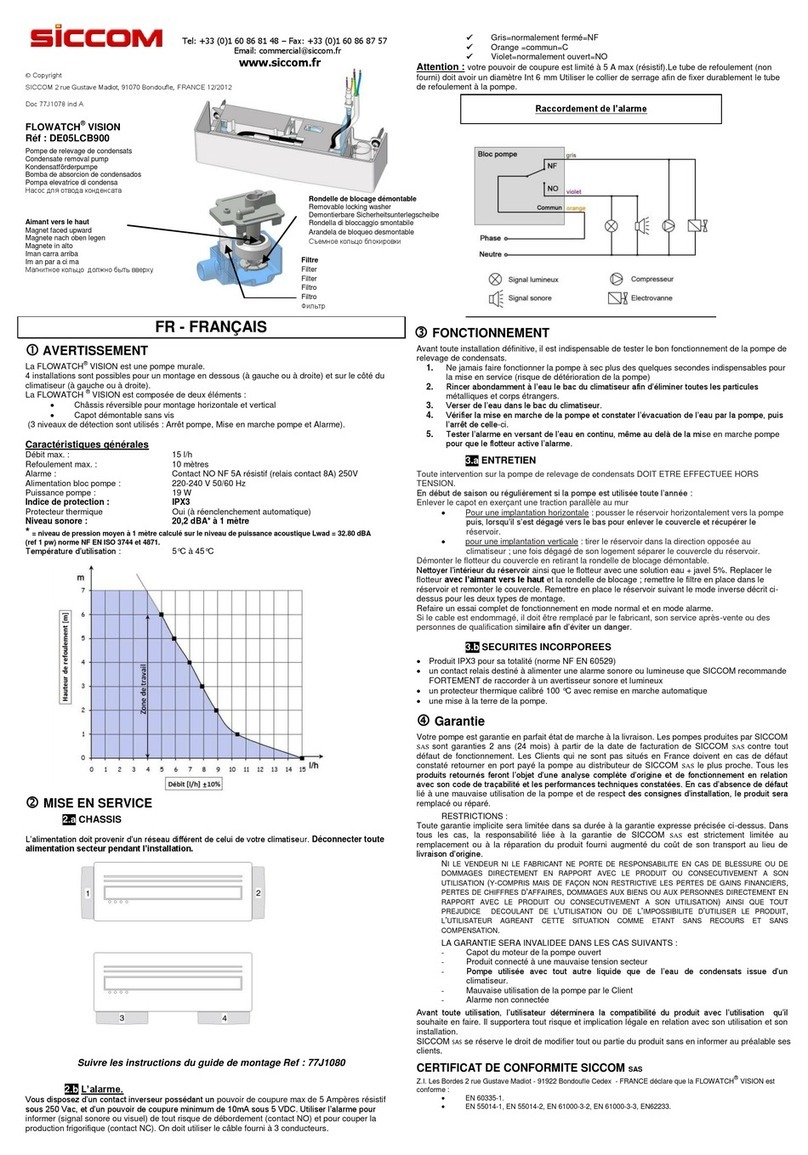

Siccom

Siccom FLOWATCH VISION manual

Stuart Turner

Stuart Turner Monsoon Extra U1.4 bar Installation, operation & maintenance instructions

Pentair

Pentair Berkeley BVMI1 Installation, Operation & Parts Manual

XPOtool

XPOtool 62543 Operation manual

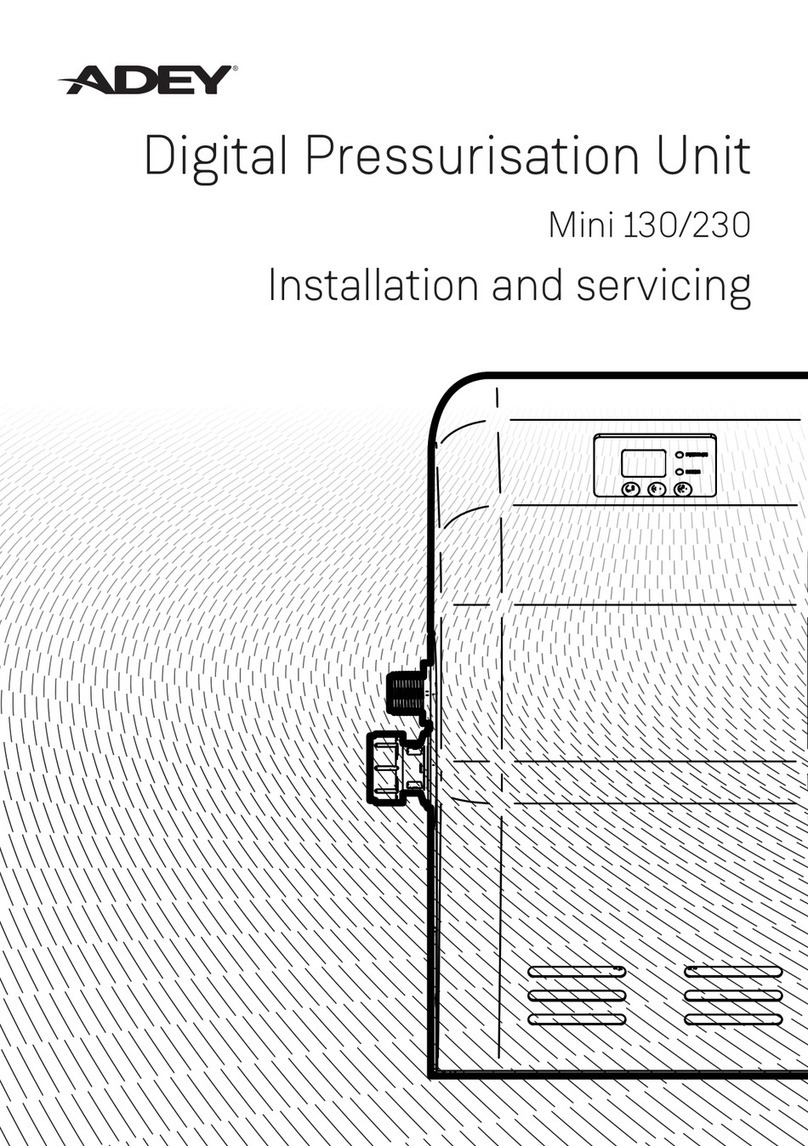

Adey

Adey Mini 130 Installation and servicing

T.I.P.

T.I.P. FlatOne 6000 INOX Translation of original operating instructions

Tuthill

Tuthill GlobalGear GG250 maintenance

Lincoln

Lincoln PMA - 2 user manual

Blue Angel

Blue Angel 400GT Operating instructions and replacement parts list

Stuart Turner

Stuart Turner Wasteflo Installation & maintenance instructions

Fuelworks

Fuelworks 17530572 instruction manual

HNP Mikrosysteme

HNP Mikrosysteme mzr-7208 operating manual

Agilent Technologies

Agilent Technologies 1200 series manual

SPX

SPX FIP - series instruction manual