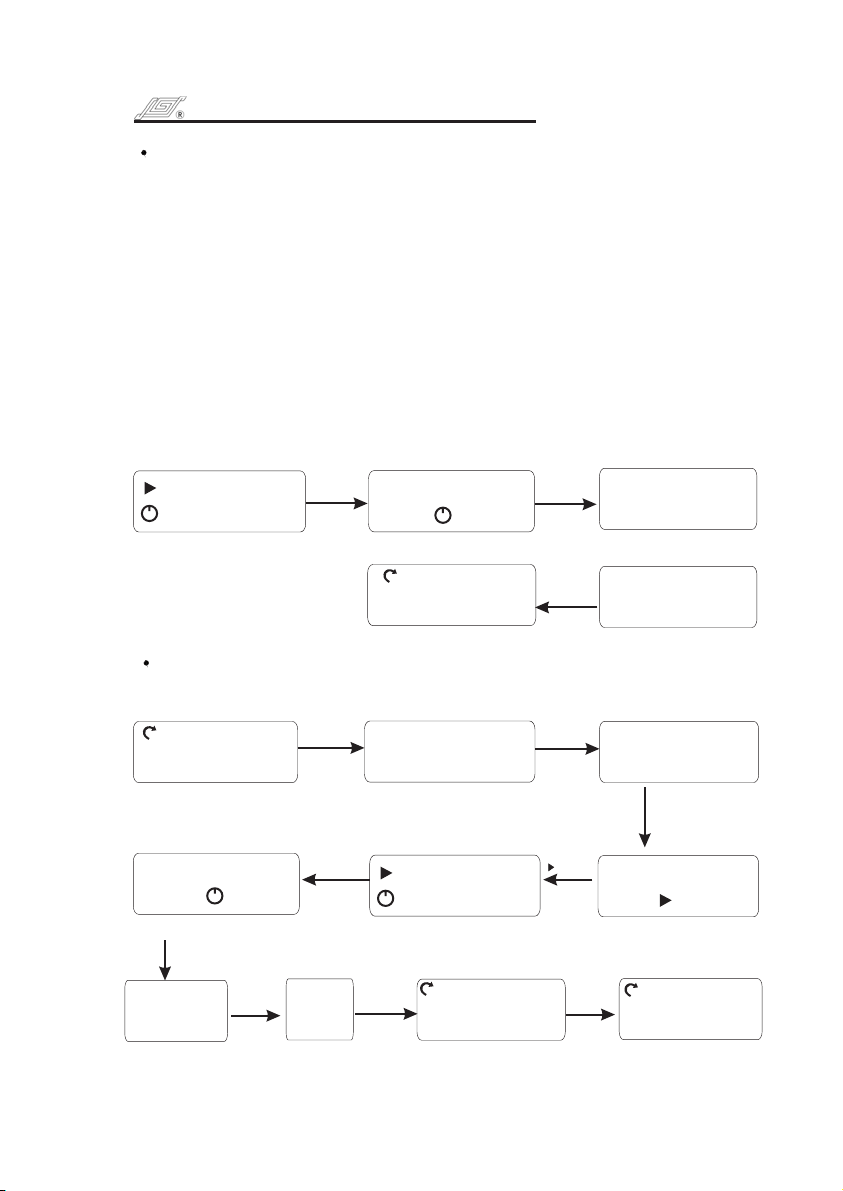

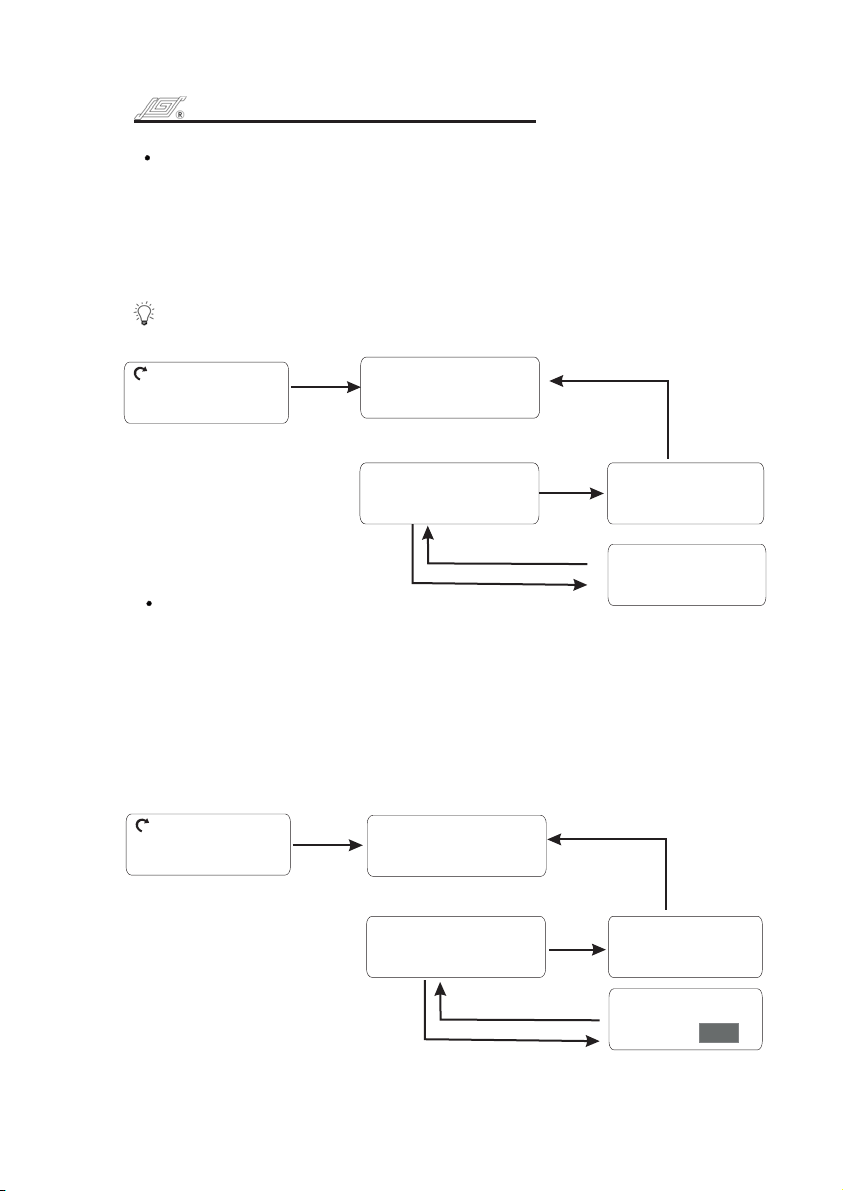

c. Remote control

Set remote control function.

On: Remote control is permitted.

Off: Remote control is forbidden.

In “System Setting” interface, press and then turn the

to enter “c. Remote Control” interface. Press the

to enter remote control selection interface. Turn the

to select the remote control state. Press the

to save and return back to “c. Remote Control”

interface.

Adjusting

Knob Adjusting

Knob

Adjusting Knob

Adjusting Knob

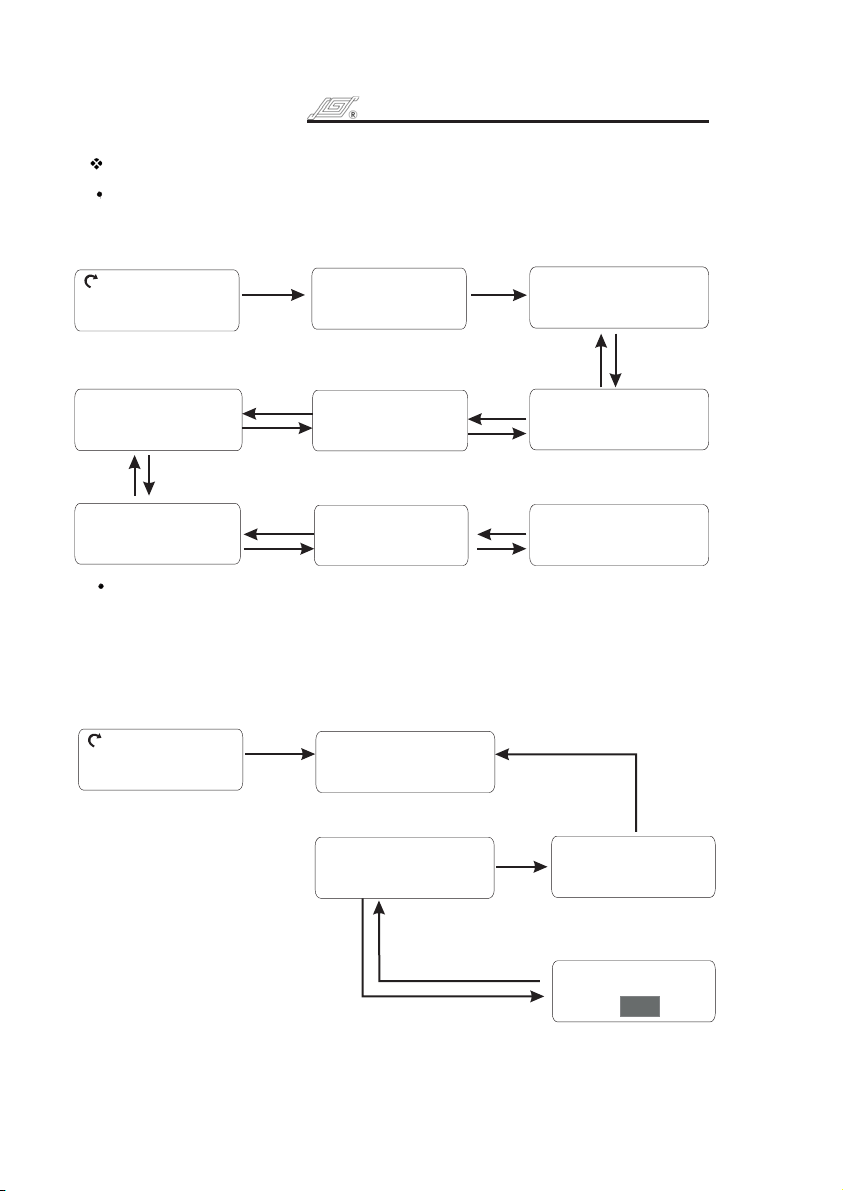

d.Pump I.D.

When control computer controls many pumps through RS485

interface, it must identify each pump's I.D.. This pump I.D. should

be unique. It's the identification of this pump.

In “System Setting” interface, press and then turn the

to enter “d. Pump I.D.” interface. Press the

to enter pump I.D. setting interface. Turn the

to set the pump I.D. # (1 -30). Press the

to save and return back to “d. Pump I.D.” interface.

Adjusting

Knob Adjusting

Knob Adjusting

Knob Adjusting Knob

Remote Control

On Off

↑

Set ump I.D.#.P

1

↑

b. Test time

The test time is the required time for one time flow rate

calibration.

In “System Setting” interface, press and then turn the

to enter “b. Test time” interface. Press the

to enter “Set test time” interface. Turn the to set

the test time. Press the to save and return back

to “b. Test time” interface.

Note: The time range is 0.5 25 min. The increment is 0.5 min.

Adjusting

Knob Adjusting Knob

Adjusting Knob

Adjusting Knob

Set test time:

0.5 min

↑

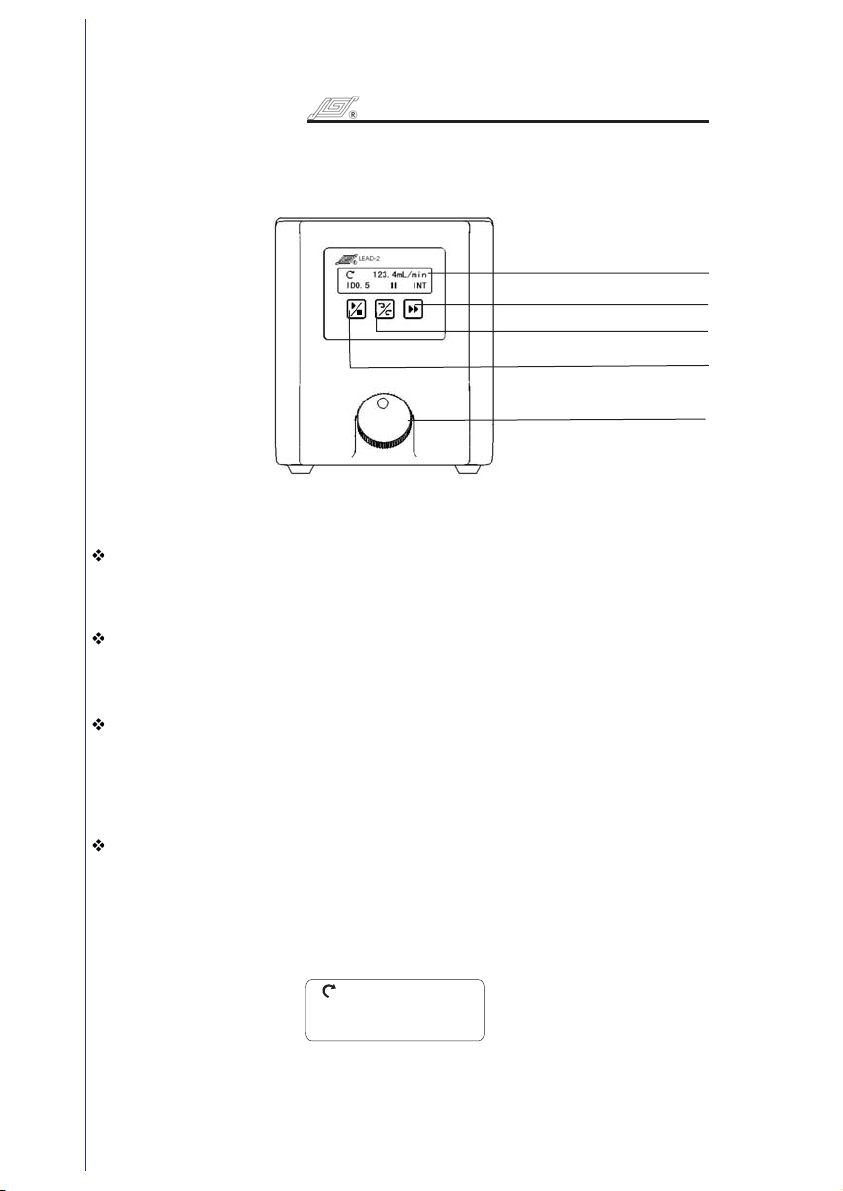

ID 0.5 INT■

123.4mL/min

ID 0.5 INT■

123.4mL/min

ID 0.5 INT■

123.4mL/min

e. Footswitch

Set footswitch working mode.

In “System Setting” interface, press and then turn the

to enter “e. Footswitch” interface. Press the

to enter footswitch setting interface. Turn the

to select footswitch working mode. Press the

to save and return back to “e. Footswitch” interface.

Trigger: Press footswitch, the pump starts running; Press

footswitch again, the pump stops.

Gated: The pump runs as long as the footswitch is pressed.

Adjusting

Knob Adjusting

Knob Adjusting

Knob Adjusting

Knob

Footswitch

Gated Trigger

↑

ID 0.5 INT■

123.4mL/min

78

LEAD-2OPERATINGMANUAL LEAD-2OPERATINGMANUAL

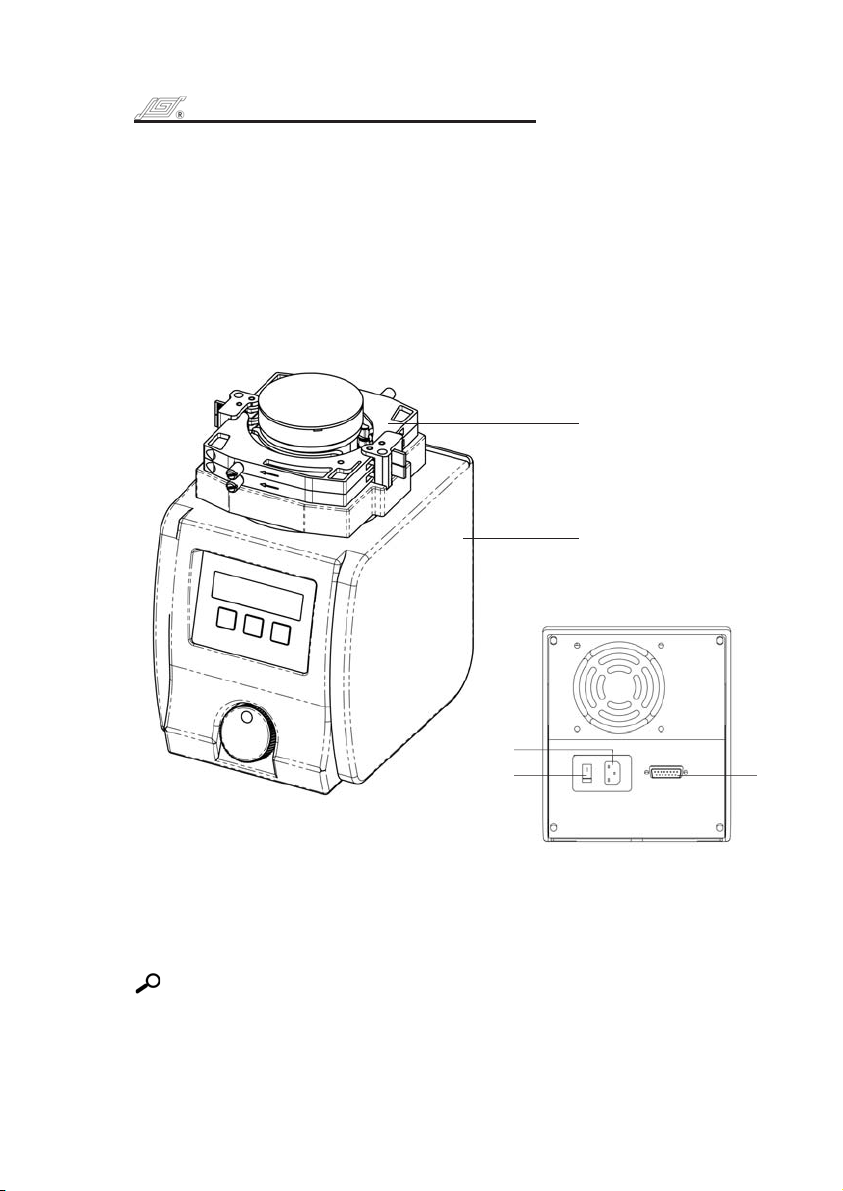

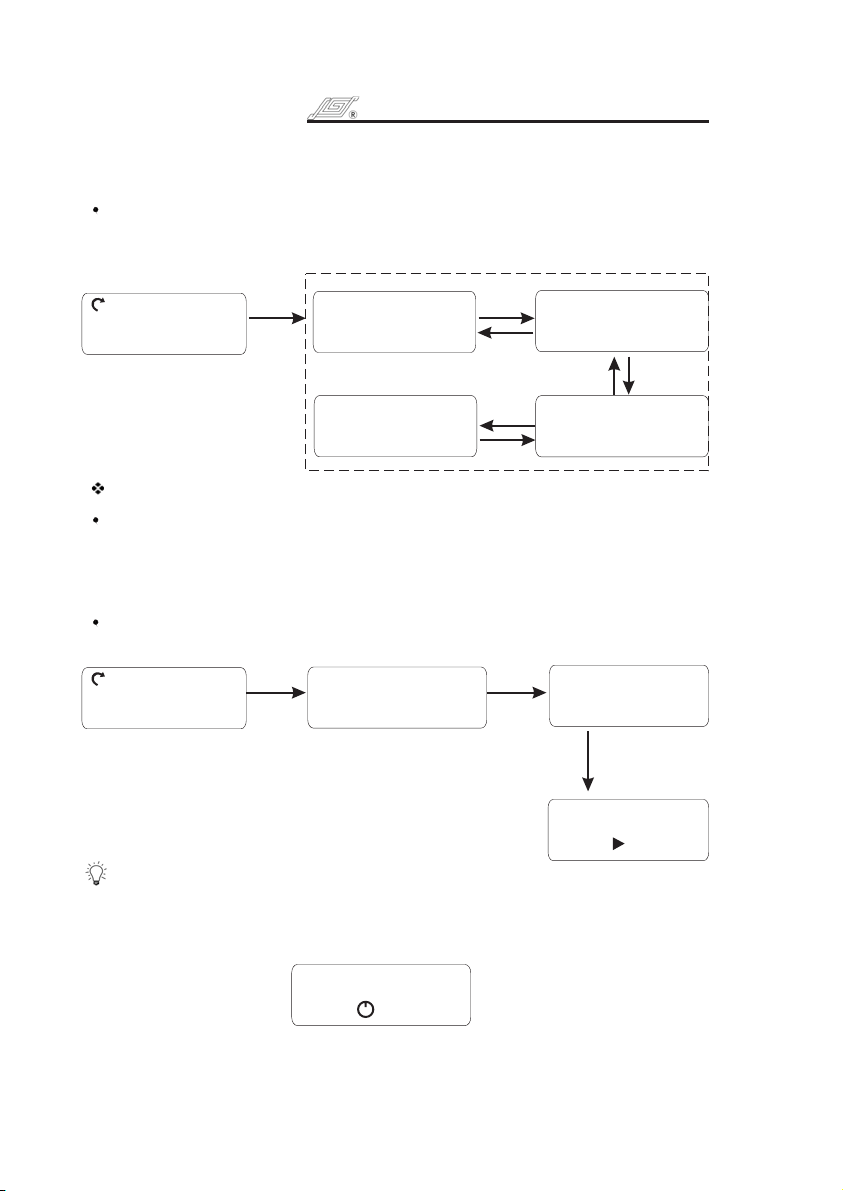

2. ystem SettingS

2. ystem SettingS

2. ystem SettingS

2. ystem SettingS

b.Test time

0.5min

:

f. ackB

f. ackBf. ackB

f. ackB

c.Remote

Control:on

d. ump I.D.#.P

1

e.Footswitch

Gated

:

Press

the Knob

Press the Knob

Press

the Knob

Press the Knob

Press

the Knob

Press the Knob

Press

the Knob

Press the Knob

Turn the

Knob

Turn the

Knob

Turn the

Knob

Turn the Knob to select

Turn the

Knob

TurntheKnobtoselect

Press the knob

andthenturn

the knob

Press the knob

andthenturn

the knob

Press the knob

and then turn

the knob

Press the knob

andthenturn

the knob

Press the knob

andthenturn

the knob

Press the knob

andthenturn

the knob

Press the knob

andthenturn

the knob

Press the knob

andthenturn

the knob

TurntheKnobtoselect

Running interface

To switch to “Speed Display”

please see page 9 “Control

Mode” for setting method

Running interface

To switch to “Speed Display”

please see page 9 “Control

Mode” for setting method

Running interface

To switch to “Speed Display”

please see page 9 “Control

Mode” for setting method

Running interface

To switch to “Speed Display”

please see page 9 “Control

Mode” for setting method

Turn the knob

To set the tim e