AUSTAR ACE 60 User manual

Page 1

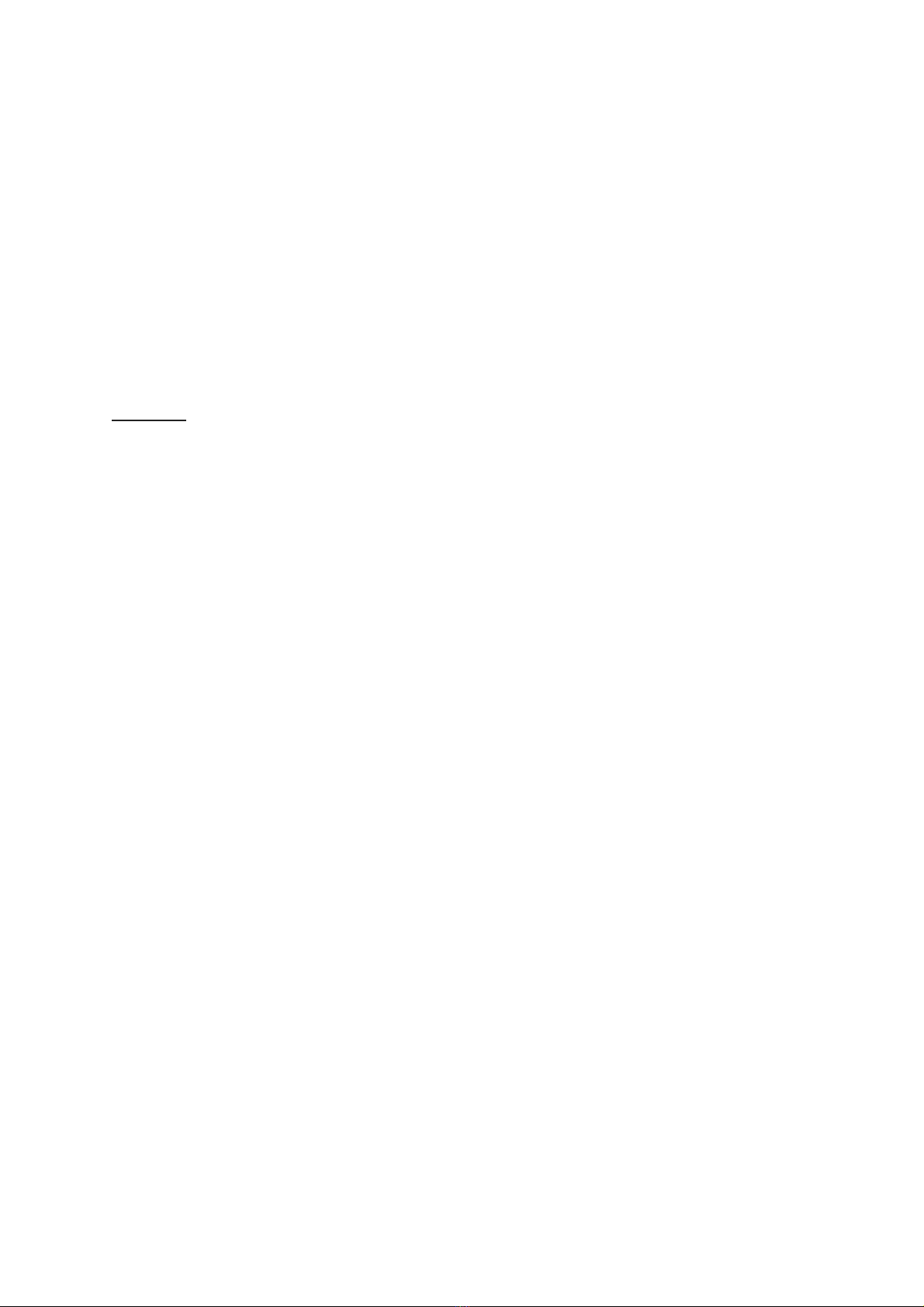

ACE 60/120 Turbine Engine

Manual v1

21 Oct 2016

Page 2

Engine Specifications

Engine: ACE 120

Diameter: 100mm

Length: 262mm

Weight: 1400g

RPM Range: 36,000 - 125,000

Thru t: 12Kg

Maximum con umption: 320ml/min

Fuel Type: Kero ene/Die el/Jet A1

Lubrication: 5% Mobil Jet oil

Maintenance: 25Hr

Receiver Power: 5-8.4V (5S Nimh or 2S Life or 2S Lipo)

Power upply: 9.9-11.1V (3S Life or 3S Lipo)

Engine: ACE 60

Diameter: 84 mm

Length: 232 mm

Weight: 820 g

RPM Range: 50,000 - 160,000

Thru t: 6 Kg

Maximum con umption: 200 ml/min

Fuel Type: Kero ene/Die el/Jet A1

Lubrication: 5% Mobil Jet oil

Maintenance: 25Hr

Receiver Power: 5-8.4V (5S Nimh or 2S Life or 2S Lipo)

Power upply: 9.9-11.1V (3S Life or 3S Lipo)

Page 3

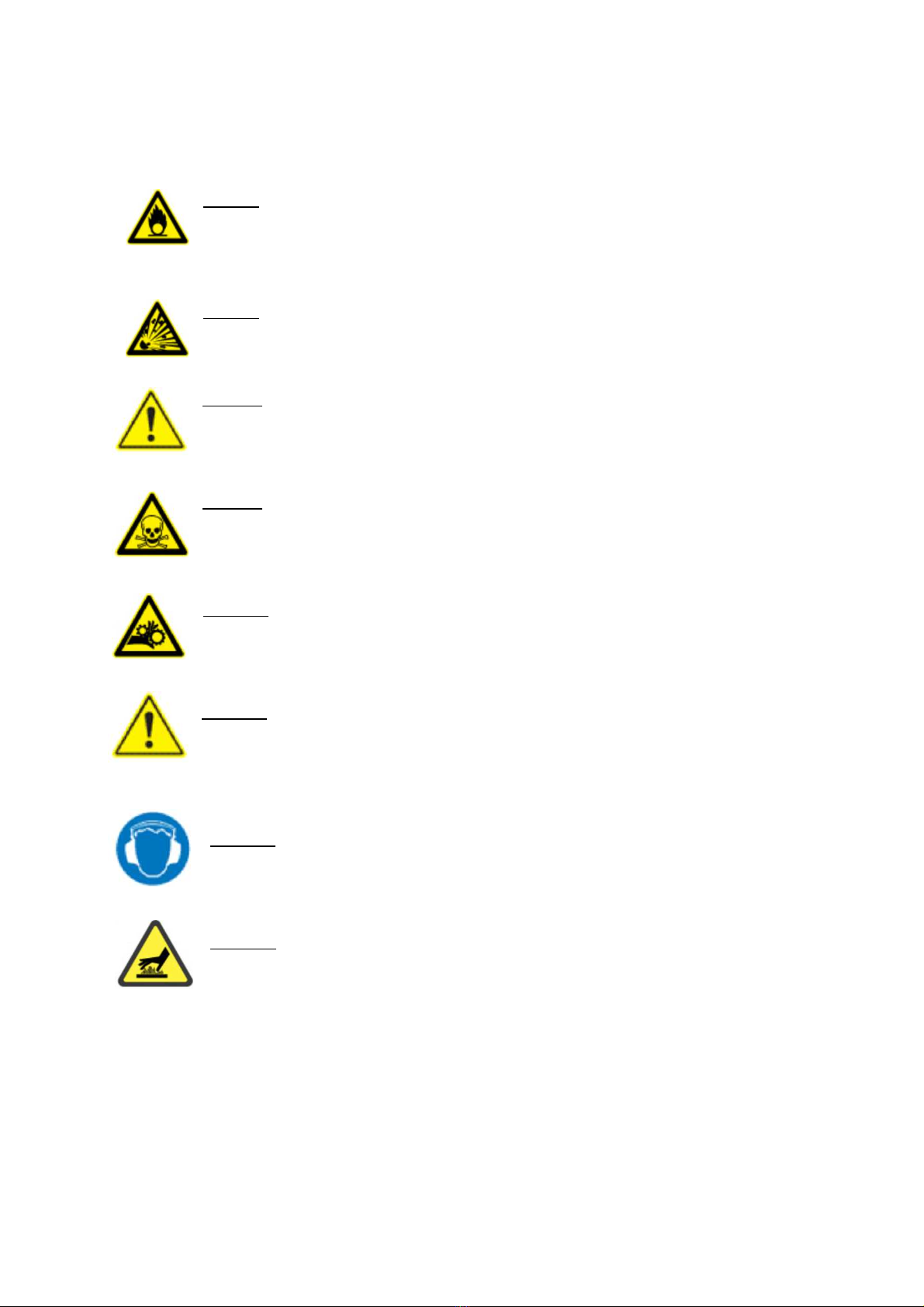

Safety – Rea before operating engine

Danger: Jet engine exhau t can et fire to flammable material uch a dry gra , fabric,

fuel, wood, etc. En ure your model i well protected from the jet exhau t and keep all

flammable material away from the exhau t of the engine. Do not u e the engine

where fire ban exi t.

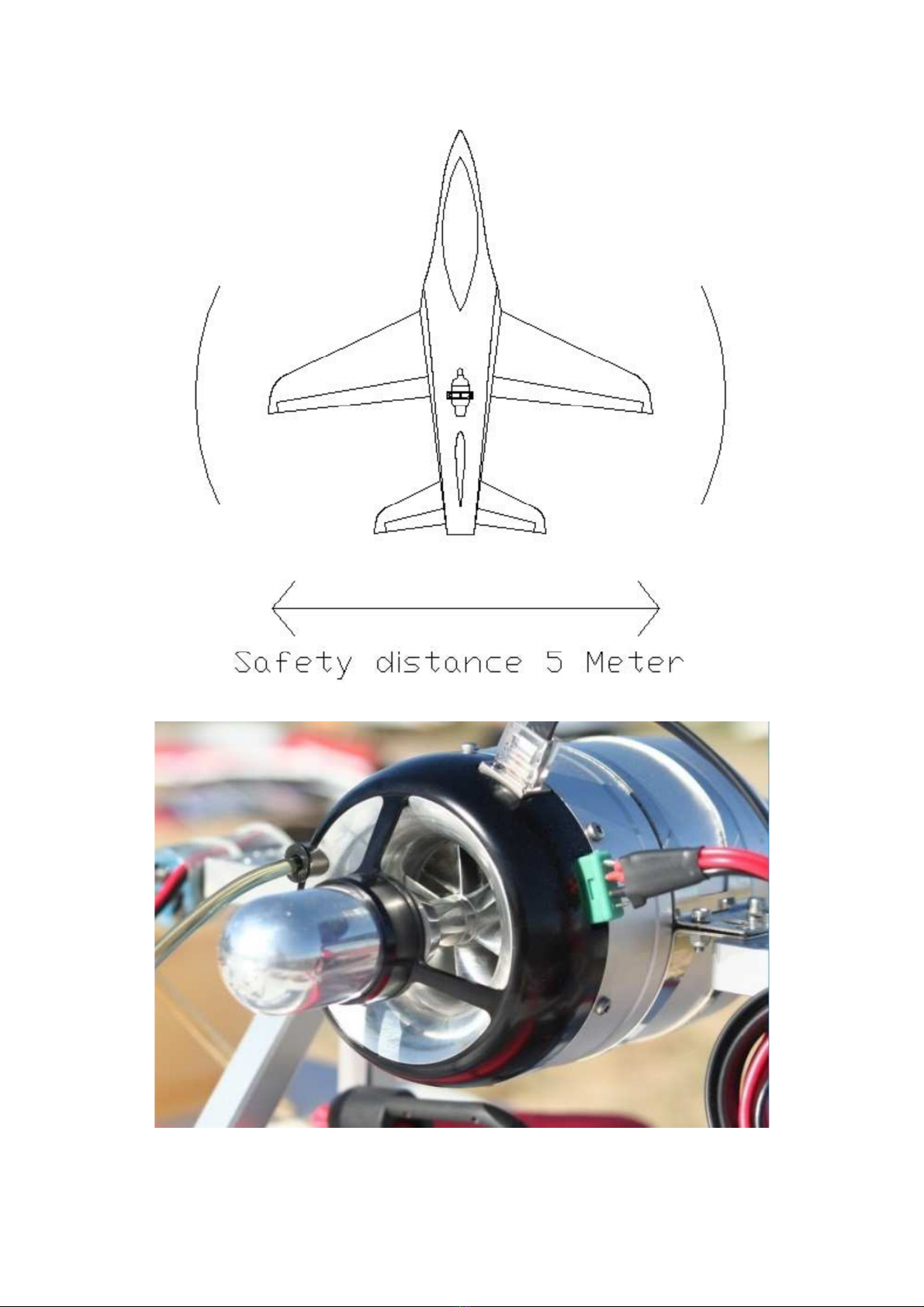

Danger: Turbine rotate at very high rpm. In ca e of failure or inge tion of foreign

object , part can be ejected from the engine, cau ing injury or death. DO NOT tand

directly be ide the engine while tarting or running.

Danger: Do NOT modify the engine in any way. Thi could lead to failure of the engine

rotor and injury or death.

Danger: Engine emit fume which are not breathable. Only run the engine in a well

ventilated pace.

Warning: Engine ha high peed rotating part . Keep finger well clear of engine inlet

and outlet while connected to power upply.

Warning: Jet engine inlet ha high uction. Loo e object can be drawn in leading to

failure of the engine. Keep hand clear of the engine inlet a finger can be ucked into

the engine. Protect your engine with a creen (FOD creen).

Warning: Jet engine are very noi y during operation. Wear hearing protection when

operating the engine.

Warning: Engine will be hot during and after operation. The rear part of the engine

and the exhau t can reach temperature up to 700 C. Keep clear.

Page 4

Page 5

Preparing the Engine for use

Connect the fuel supply to the engine as shown below. Use a hopper tank to prevent

bubbles reaching the engine. Use 4mm fuel hose (supplied) for connections. Make sure no

air can enter the fuel lines as this may cause a flame out.

Fuel pump connections. Ensure the Anti-bubble loop stays in place as shown.

Page 6

Connect the cable to the engine and ECU a hown below.

ECU (FADEC) and GSU (Data Terminal)

Engine connections to ECU Battery, Rx and GSU connections to ECU

Page 7

Cable identification

Engine to ECU cable (power) Engine to ECU cable (sensors)

Battery and Fuel Pump to ECU cable RX (throttle) to ECU cable

Use a 3S (9.9 to 11.1V) battery, either LiFe or LiPo. Capacity should be at least 2200mAH.

Page 8

Operation

If you are inexperienced with turbojet engines, it is recommended to install the engine on a

stable test platform, and perform a number of start-up operations to get used to and check

the equipment, turbojet engine, fuel circuit, fuel filter, anti-bubble tank. When happy, then

transfer to the model aircraft. This allows you to perform operations in a secure environment

and become familiar with the engine’s performance.

For the first start or any time the fuel tube to the engine is empty, use the “TEST PUMP”

function within the “TEST” menu on the GSU to prime the fuel lines up to the engine (see

part 6.1 of GSU section).

Warning: disconnect the fuel line from the engine and collect the fuel in a container.

Do not flood fuel into the engine or a “hot start” can occur with flames coming from

the exhaust.

Use the GSU to “teach” the ECU the radio signal from your system (See part 2 of the GSU

section).

Futaba remote control must be set to reverse throttle signal, JR & Spektrum throttle normal.

To start the engine:

1. Set trim to low, throttle to low.

2. Power up Tx then Rx.

3. Set trim to high.

4. Push throttle to high, then return to idle.

When the throttle is high, the starter motor will turn, then return the throttle to the minimum.

At this time, the engine will automatically enter the ignition starting procedure.

Once the engine has stabilised, the GSU will display “Running” and you will have throttle

control over the engine.

To Stop the engine, place throttle stick to low and trim to low. The engine will stop, and the

starter motor will turn the engine to cool it down below 80 C. This is to protect the bearings

from excessive heat soak. The cooldown sequence will stop automatically and may take a

couple minutes. Do not switch off the Rx until the cooldown sequence is finished.

If the trim is in the minimum position and the throttle stick is pushed the maximum, the motor

will also rotate, but the throttle will not enter the start sequence when the throttle is at

minimum. This feature can be used to manually cool the engine or clear excess fuel from

the engine if it becomes flooded.

Page 9

In cold weather, the diesel or kerosene becomes viscous. If ignition is not prompt, or

temperature rise after ignition is slow, slightly increase "pump voltage" (see section on

GSU).

The first time the engine is started when new or new installation, you must slowly increase

the throttle after the start to the maximum speed so, the ECU can learn the maximum speed

of the pump power value.

Page 10

Engine Care an Maintenance

After 25 hours of use, the engine needs to be returned to the factory for maintenance. The

main tasks are replacement of bearings, inspection of parts, cleaning of oil lines,

replacement of internal filter elements, removal of carbon deposits, re-balancing, re-

commissioning, ECU data reset. When returning to factory for maintenance, include the

entire electronic system with the engine.

In case of crash damage, return the engine to the factory for repair.

When removing the engine or the fuel pump, it is necessary to connect the fuel nozzle with a

small section of tubing and close the fuel pipe to avoid any impurity entering the engine or

the fuel pump. If even a very small impurity enters the engine it may cause the fuel line to

block up or make the pump gear failure, or a flameout.

On any new installation, you must carefully clean the fuel tank, fuel pump outlet must be

installed oil filter, make sure the fuel lines are clear of any dust or metal particles.

Ensure the power connection to the ECU is not reversed. If any electrical plug is found to be

bad, replace immediately - intermittent power supply is also likely to cause ECU failure.

Engine cooling after the flight directly affects the life of the bearing, allow the engine to

complete its cool down sequence after every flight before removing power.

The keys to affect the life of the turbojet: overheating, heavy fall, ultra-extreme use. After

any accidental flameout, run the cooling manually - set trim low and throttle high to run the

starter motor.

If the engine suffers a heavy fall, return engine to the factory to re-balance. If any foreign

body is sucked in, resulting in blade damage, it is recommended to return to the factory to

re-balance, otherwise the bearing life will be seriously shortened.

Regularly check and clean the fuel filter.

After starting the engine, push the throttle to maximum to check for any air bubbles, as these

can cause a flameout in flight.

The engine should not expel any flames during startup. In the case that the fuel solenoid

valves become damaged or worn (eg by grit in the fuel) then fuel may pool in the engine

while refueling and cause a fire on startup.

Always close the manual ball valve in the fuel line when refueling, to avoid this possibility.

Do not attempt to start the engine if it becomes flooded with fuel, as this will cause a fire.

Page 11

Ensure the inside of the model plane is clear of any foreign or loose objects that could be

sucked into the engine – this will damage or destroy the engine.

Install a mesh cover (FOD guard) over the inlet of the engine to protect it from loose items.

Always range check your model with the engine running before flying. Do not fly if there is

any interference.

Do not use screws to plug the fuel lines on the anti-bubble tank as these can leak air into the

system. Use a proper fuel tube plug.

This manual suits for next models

1

Table of contents

Popular Engine manuals by other brands

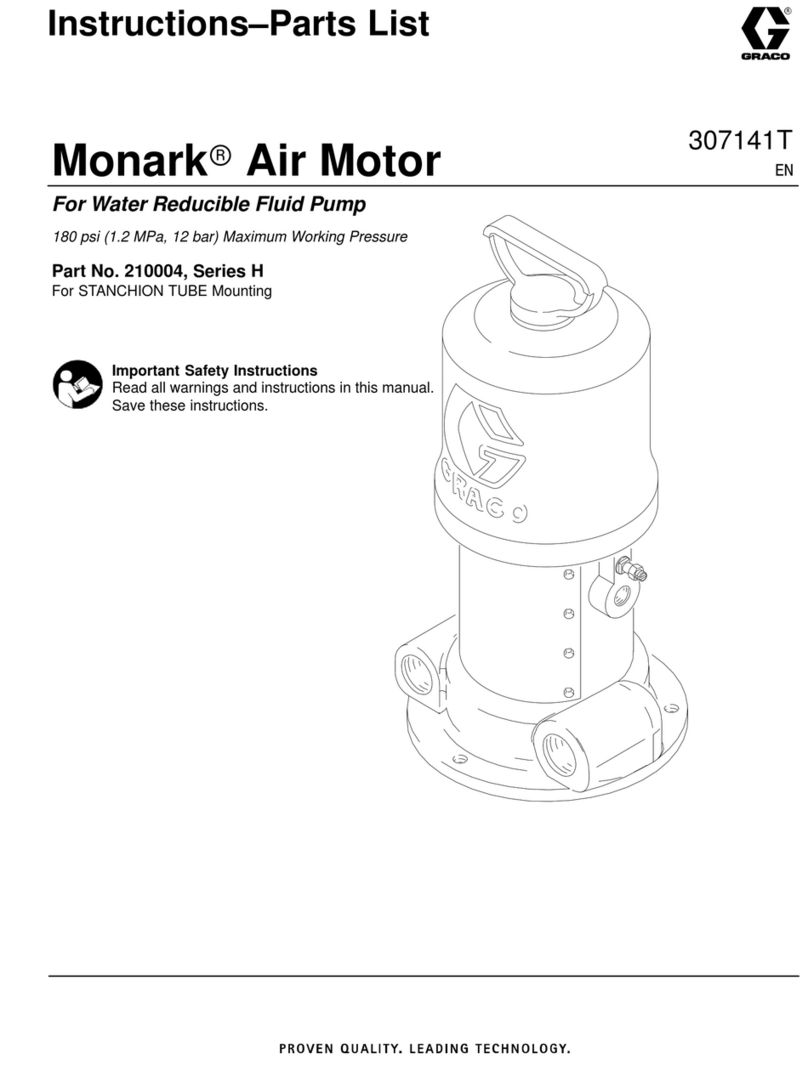

Graco

Graco Monark Instructions-parts list

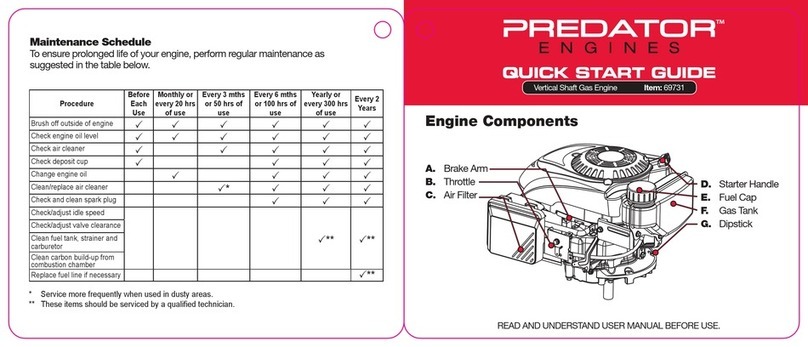

Predator Engines

Predator Engines 69731 quick start guide

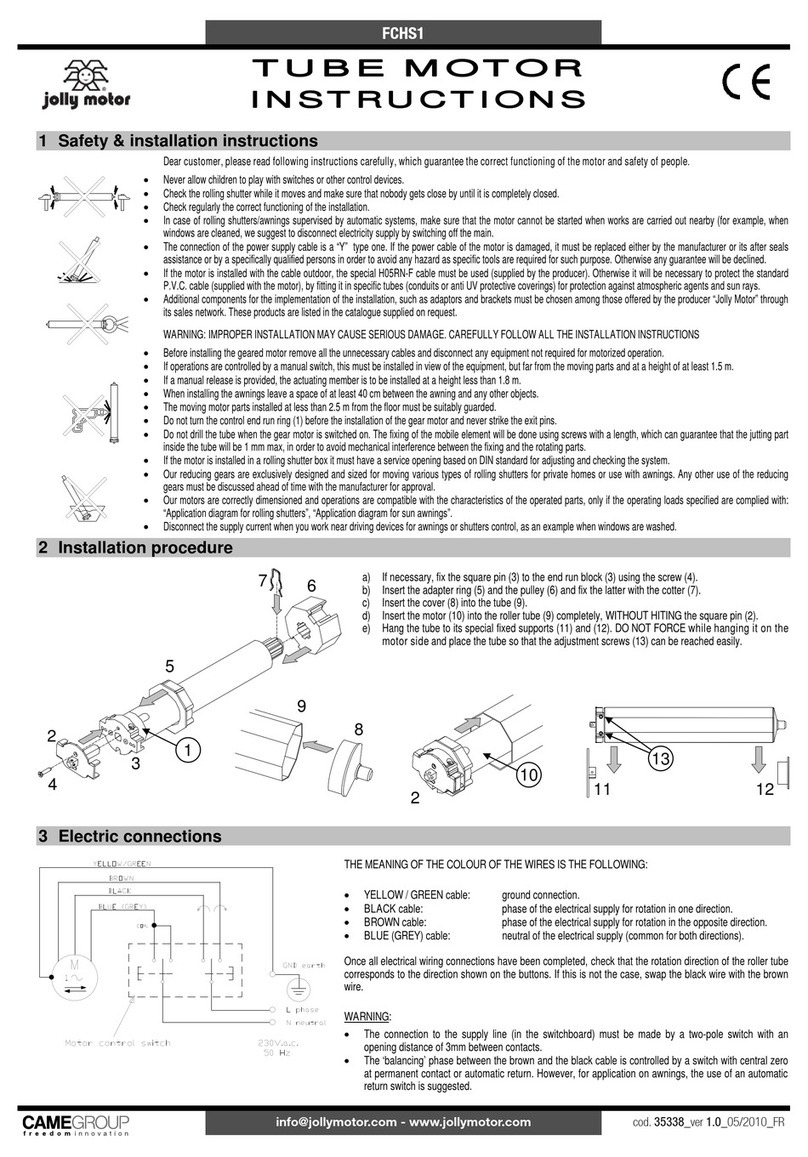

jolly motor

jolly motor FCHS1 instructions

Briggs & Stratton

Briggs & Stratton 400000 Professional Series Operator's manual

Siemens

Siemens SIMOTICS GP series operating instructions

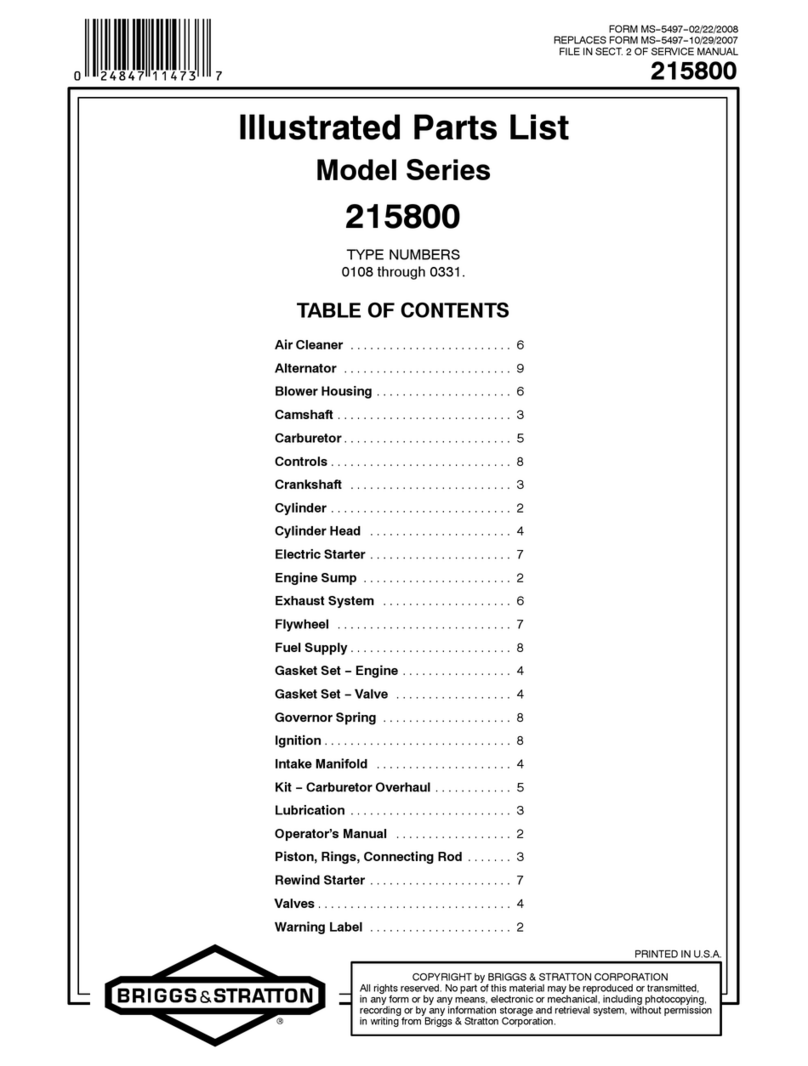

Briggs & Stratton

Briggs & Stratton 215800 Series Illustrated parts list

Volvo Penta

Volvo Penta IPS 350 Operator's manual

Generac Power Systems

Generac Power Systems GTV-990 Engine parts manual

wsm

wsm V3307-DI-T-E2B Workshop manual

Northern Lights

Northern Lights OL1276 Operator's manual

Siemens

Siemens Geared motors-Planetary gear instructions

Kohler

Kohler Courage SH265 Service manual