Austin Motor Company Austin Seven User manual

l.

~

,

f

,~

I'

11

\;

1t

11

.

HANDBOOK

OF

PRICE 2/6

14th EDITION

THE

AUSTIN MOTOR CO. LTD.

LONGBRIDGE,Nr. BIRMINGHAM

"

T,I,g"ffi'

T']'phon" '

Cod,

, "SPEWILY, NORTHFIELD."

, CENTRAL 4140. KING'S NORTON 230.

, BENTLEY's.

LONDON SHOWROOMS, REPAIR DEPOT AND HIRE DEPT.:

479-483, Oxford Street, W.!.

(NEAR MARBLE ARCH)

T,I'g""" "AUSTINmE, LONDON:'

T.!,phon, " MAYFAIR6230

Also at 3, 5 and 7, RUE du' PARNASSE, BRUSSELS.

1

1. "fm~' " "" boo' 352 M

pi.", q.~' "', ..mb,',

The "AUSTIN

, ~II

j,

,

, i

.11

It 1

'1,1~1

r" ..1.

SEVEN" .

,

,

I I

\

~

I

".:

'.

it

,

2

iI.

...

CONTENTS

AMMETER READINGS

ATTENTIONS, D,ily

W"kly

Monthly

O""ion,I

BATTERY, The ...

BODYWORK, Care 01

BRAKES, Ad;",ting the,

BRAKE GEAR, Lnhri"tion of ...

BRAKES, R...lining ..,

CAR. Cont<ol of the ...

" Fe,tnre, 01 the ...

" The New

CARBURETTER, The

PAG'.

28

11

12

13

13

29

38

34

26

36

9-

5

7

14

15

15

15

25

33

20

28,

28

21

8

37

26

2!i

25

27

19

17

16

38

23

21

19

25

27

32

36

35

27

39

37

26

32

10

30

".

Adju,tment of

Slow Running 01

" Le,hge from

CLUTCH, Luhri"tioh of ...

COMBUSTION CHAMBER, CI..ning ...

COOLING SYSTEM

DYNAMO, The ...

ELECTRICAL EQUIPMENT. The

ENGINE,Luhri"tionof .

St"ting the

...

FAN

FRONT AXLE, Luhrication of ...

FUSE, Action of the ... '1:

GEARBOX, Luhri"tion of ..'

HUBS (Front ,nd Re,r), Luhri"tion 01

'IGNITION, F,ult, in

Re-timing

Sy,tem, The

LAMPS, Care of ,..

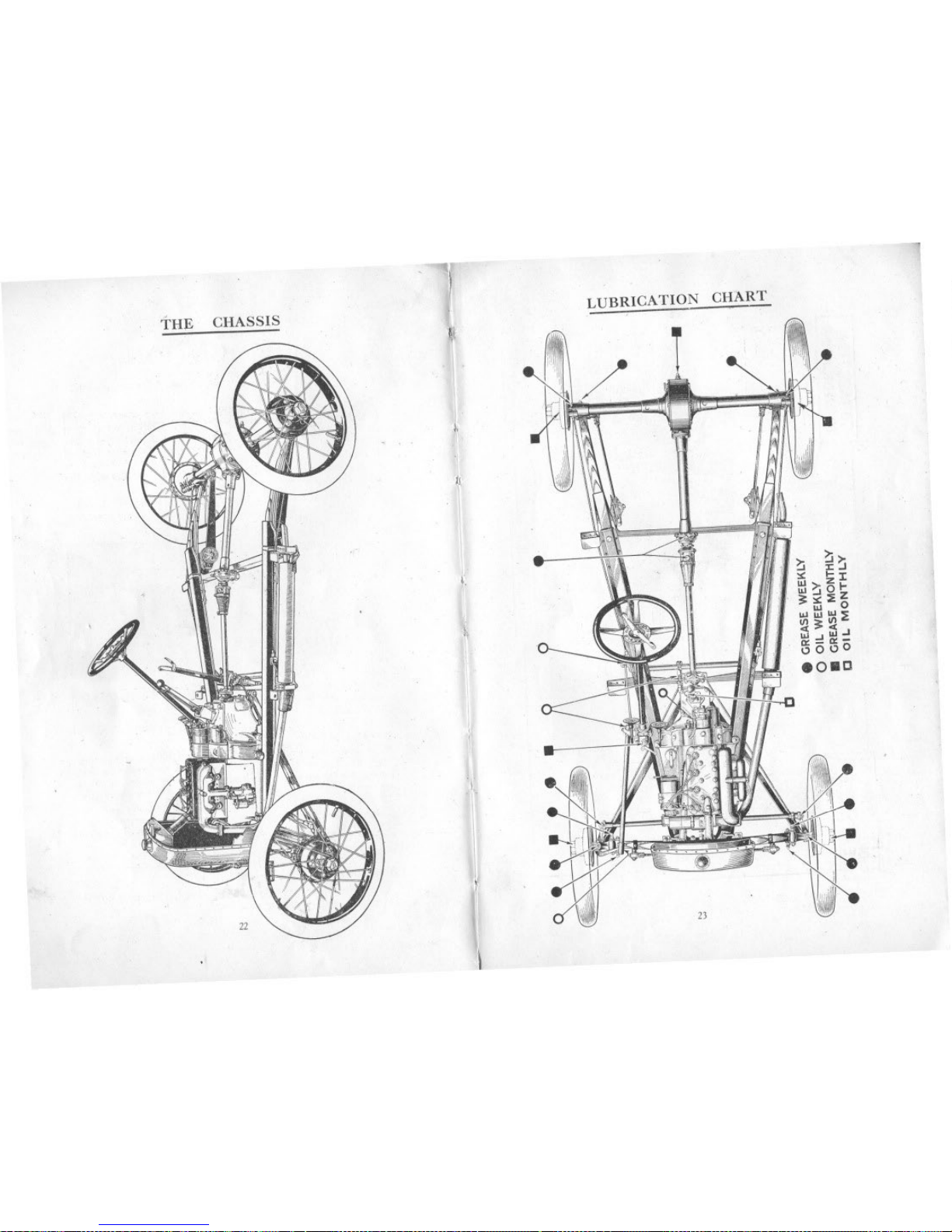

LUBRICATION CHART

LUBRICANTS ""'mmended

MAGNETO, Lubric,tion of

REAR AXLE, LubriCAtion01 ...

ROAD SPRINGS, Luh,ic"ion of

RUNNING ADJUSTMENTS .'..

SHOCK ABSORBERS, Adju,tment 01

STEERING. Adju,tmcnt 01 ...

STEERING GEAR. Luhri"tion 01

TOOLS, Supplied

TYRES ...

UNIVERSALJOINTS, Lubri"tion of

VALVE TAPPETS. Adju.tment 01

WHEEL, How to Ch,nge ,

WIRING, lItu,tr,tion of 3

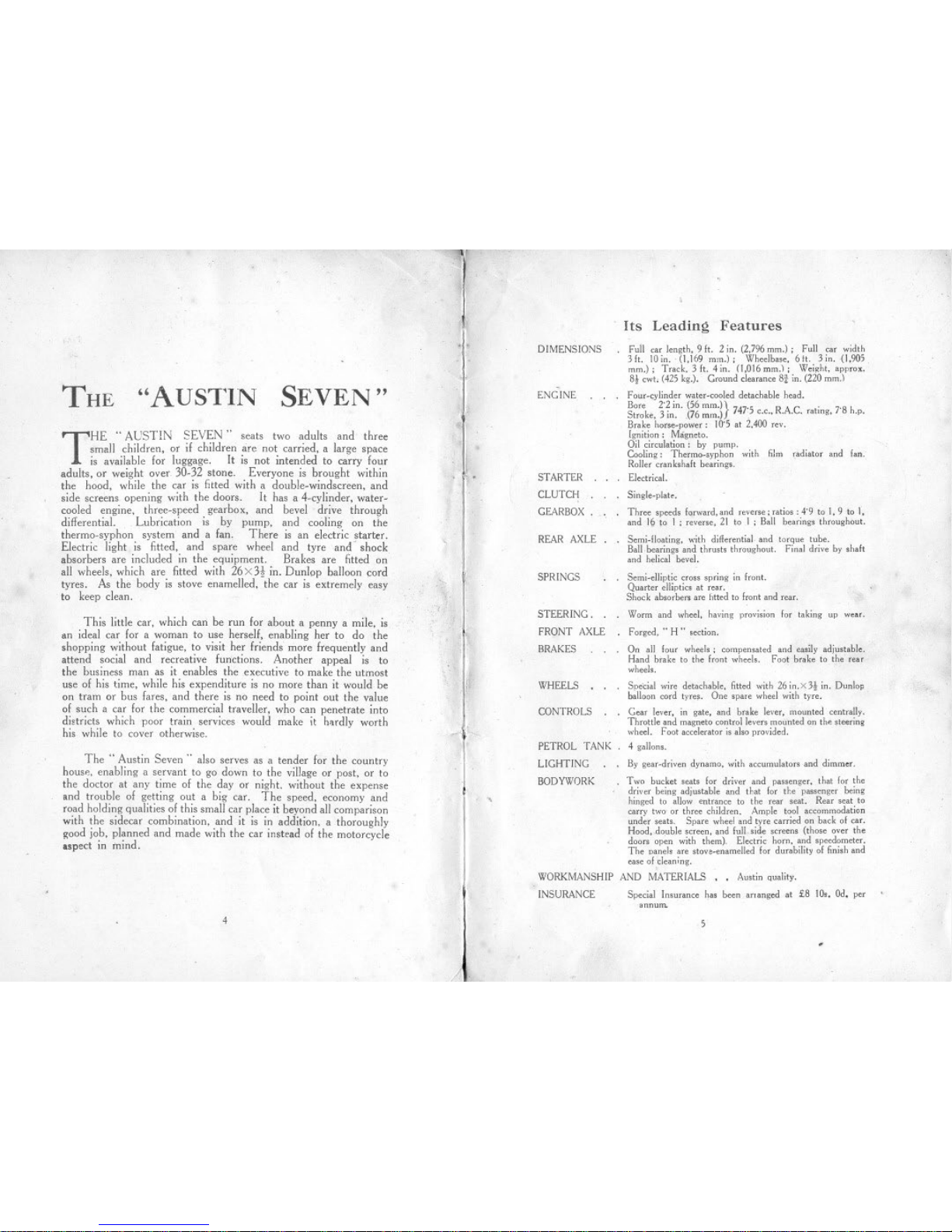

THE "AUSTIN SEVEN"

THE" AUSTIN SEVEN" seats two adults and three

smal! children, or if children are not carried, a large space

is availahle for luggage. It is not intended to carry four

adults, or weight over 30-32 stone. Everyone is brought within

the hood, while the car is fitted with a double-windscreen, and

side screens opening with the doors. It has a 4-cylinder, water-

cooled engine, three-speed gearhox, and hevel drive through

differential. Lubrication is by pump, and cooling on the

thermo-syphon system and a fan. There is an electric starter.

Electric light is fitted, and spare wheel and tyre and' shock

absorbers are included in the equipment. Brakes are fitted on

al! wheels, which are fitted with 26 X3t in. Dunlop bal!oon cord

tyres. As the body is stove enamel!ed, the car is extremely easy

to keep clean.

This little car, which can he run for about a penny a mile, is

an ideal car for a woman to use herself, enabling her to do the

shopping without fatigue, to visit her friends more frequently and

attend social and recreative functions. Another appeal is to

the business man as it enables the executive to make the utmost

use of his time, while his expenditure is no more than it would be

on tram or bus fares, and there is no need to point out the value

of such a car for the commercial travel!er, who can penetrate into

districts which poor train services would make it hardly worth

his while to cover otherwise.

The" Austin Seven" also serves as a tender for the country

house. enabling a servant to go down to the village or post, or to

the doctor at any time of the day or night. without the expense

and trouhle of getting out a hig car. The speed, economy and

road holding qualities of this small car place it beyond all comparison

with the sidecar combination, and it is in addition, a thoroughly

Koodjob, planned and made with the car instead of the motorcycle

aspect in mind.

4

,

,

..,.

r

11;

'0.'

';1

.

'

I

'

'I

11

'"

;I~

,

,

"';t,

DIMENSIONS

ENGINE

STARTER

CLUTCH

GEARBOX.

REAR AXLE.

SPRINGS

STEERING.

FRONT AXLE

BRAKES

WHEELS

CONTROLS

PETROL TANK

LIGHTING

BODYWORK

,

Its Leading Features

. Full m leng,h, 9 It. 2 in. (2,796mm.); Full m width

3 It. 10in. (1.169 mm.); Wheelb"e, 6 tt. 3 in. (1,905

mm.); T"ck. 3 ft. 4 in. (1,016mm.); We;.ht. appcoX.

8! cwt. (425kg.). Ground clmance 8i in. (220 mm.!

. Four-cyl;nder water-cooled detachable head.

Bore 2'2 in. (56 mm.)}. '.

Stcoke. 3in. (76 mm,) 7475 C.c"RAC. "tmg, 7 8 h.p.

B"ke hom-power; 10'5 at 2,400 rev.

Ign;tion: Magneto.

Oil cireulation: by pump.

Cooling: Thermo-,yphon with film "diator and fan.

Roller ",nbhalt bming,.

. Eledrical.

. S;ngIe-plate.

. Three ,peed, forward,and mer,,; "t;ca :4'9 '0 I, 9 to I,

and 16 to I; rovem, 21 to.f ; Ball b",;ng, throughout.

. Semi-IIeating. with diflerentiaI and torque tube.

Ball.bearing' and thm,t, thcoughout. F;nal drive by ,halt

and helical bevel.

Semi-elliptic crca, ,pr;ng m hont.

Quarter ellipt;" at rear.

Shock ab,orben; are httd 10 front and r"'.

Worm and wheel, having pcovi,;on for taking up wm,

Forgd. .. H" "dion.

On all four wheel,; compemated and ea,ily adiu,tabIe.

Hand brake to the fcont wheela. Foot b"k, to the re"

wheel,.

Spe,;al wire detachable. fitted with 26 ;n.X 3t in. Dunlop

balloon cord tyre,. One 'pare wheel with tyre.

G", lever, ;n gate, and b"ke lever. mounted eentcally.

Throttle and magnetocon'colleve" mounted on th, 'teer;ng

wheel. Foot accelerator ;, a"o provided.

4 gallon"

By ",,-dr;ven dynamo, with accumulato" and dimmer.

. Two bucket "at, for driver aod pa..enger, that for ,he

driver being adiu,'able and that for the p""o,er being

h;o,ed to allow entranee to the rear ,eat. Rear "at to

carry two or three children. Ample '001 accommoda,ion

under "at" Spare wheel and tyre c",ied on back of car.

Hood, double "'eeo, aod full,ide "reem (thoa< over ,he

doo" open with them), Electr;c horn. and ,peedometer.

The Daoeb are ,'ove-enamelld for durability of fini,h and

ea" ofcI"ning.

WORKMANSHIPAND MATERIALS, , Au,tin qu,Iity.

INSURANCE Special In,mance h" beeo anaoged at £8 IQ,. Od. per

,noum.

5.

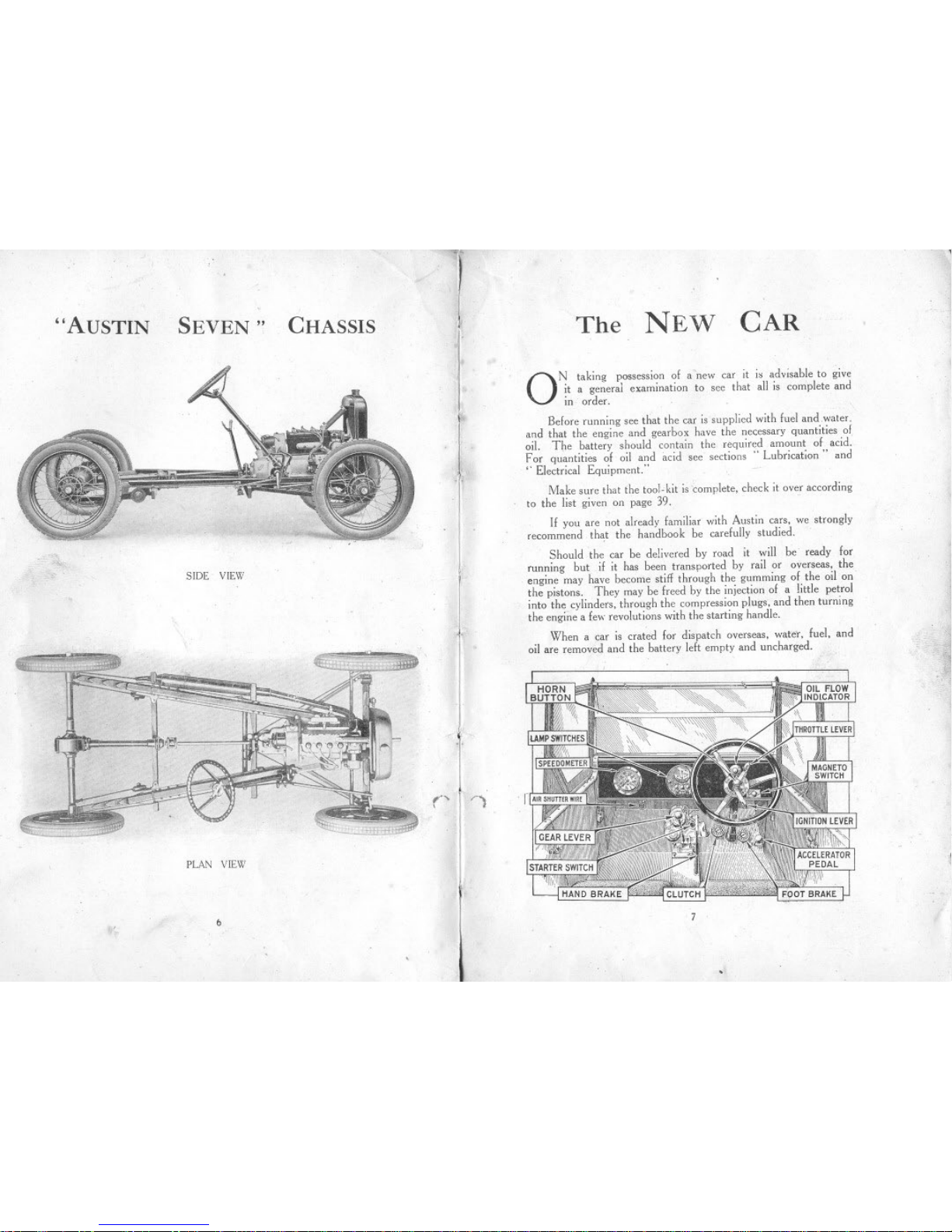

"AUSTIN SEVEN" CHASSIS

SIDE VIEW

PLAN VIEW

"b

("

;1

,It

i

'I

f

J,

~

if!

'1

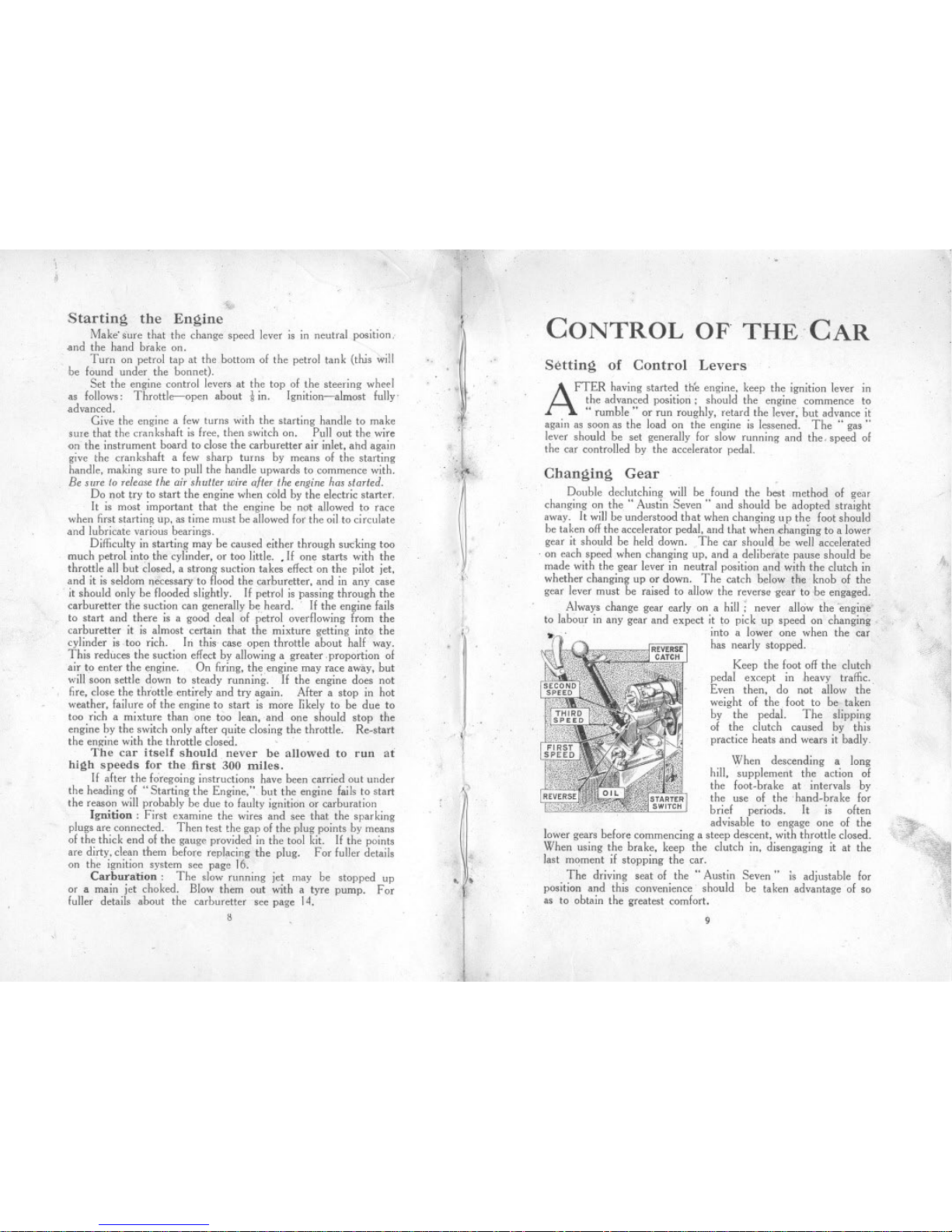

The NEW CAR

ON taking possession of a new car it i, advisable to give

it a general examination to see that all is complete and

in order. .

Before running see that the car is supplied with fuel and water,

and that the engine and gearbox have the necessary quantities 01

oil. The battery should contain the required amount of acid.

For quantities of oil and acid see sections" Lubrication" and

,. Electrical Equipment."

Make sure that the tool. kit is complete, check it over according

to the list given on page 39.

If you are not already familiar with Austin cars, we strongly

recommend th~t the handbook be carefully studied.

Should the car be delivered by road it will be ready for

running but if it has been transported by rail or overseas, the

engine may have become stiff through the gumming of the oil on

the pistons. They may be freed by the injection of a little petrol

into the cylinders, through the compression plugs, and then turning

the engine a few revolutions with the starting handle.

When a car is crated for dispatch overseas, water, fuel, and

oil are removed and the battery left empty and uncharged. '"

7

.

,!

*

'~

Starting the Engine

Make'sure that the change speed lever is in neutral position.

and the hand brake on.

Turn on petrol tap at the bottom of the petrol tank (this will

be found under the bonnet).

Set the engine controJlevers at the top of the steering wheel

as follows: Throttle-open about iin. Ignition-almost fully'

advanced.

Give the engine a few turns with the starting handle to make

sure that the crankshaft is free, then switch on. Pull out the wire

on the instrument board to close the carburetter air inlet, ahd again

give the crankshaft a few sharp turns by means of the starting

handle, making sure to pull the handle upwards to commence with.

Be sure to release the air shutter wire after the engine has started.

Do not try to start the engine when cold by the electric starter,

It is most important that the engine be not allowed to race

when first starting liP, as time must be allowed for the oil to circulate

and lubricaie various bearings.

Difficulty in starting may be caused either through suc'king too

much petrol into the cylinder, or too little. ,I! one starts with the

throttle all but closed, a strong suction takes effect on the pilot jet,

and it is seldom necessary to flood the carburetter, and in any case

it should only be flooded slightly. I! petrol is passing through the

carburetter the suction can generally be heard. ' I! the engine fail.

to start and there is a good deal ofp'etrol overflowing from the

carburetter it is almost certain that the mixture getting into the

cylinder is too rich. In this' case open throttle about half way.

This reduces the suction effect by allowing a greater. proportion of

air to enter the engine. On firing, the engine may race away, but

will soon settle down to steady running. I! the engine does not

fire, close the thiottle entirely and try again. After a stop in hot

weather, failure of the engine to start is more likely to be due to

too rich a mixture than one too lean, and one should stop the

engine by the switch only after quite closing the throttle. Re.start

the enginewith the throttle closed. '

The car itself should never be allowed to run at

high speeds for the first 300 miles.

I! after the foregoing instructions have been carried out under

the heading of .. Starting the Engine," but the engine fails to start

the reason will probably be due to faulty ignition or carburation

Ignition: First examine the wires and see that the sparking

plugs are connected. Then test the gap of the plug points by means

of the thick end of the gauge provided in the tool kit. I! the points

are dirty, clean them before replacing the plug. For fuller details

on the ignition system see page 16.

Carburation: The slow running jet may be stopped up

or a main jet choked. Blow them out with a tyre pump. For

fuller details ahout the carburetter see page 14.

8

J

CONTROL OF THE' CAR

Setting of Control Levers

.. ~FTER having started th'e engine, keep the ignition lever in

the advanced positiori; should the engine commence to

.. rumhle " or run roughly, retard the lever, hut advance it

again as soon as the load on the engine is lessened. The" gas ..

lever should he set generally for slow running and the. speed of

the car controlled by the accelerator pedal.

'.1',

>Changing Gear

Double declutching will be found the best method of gear

changing on the" Austin Seven" and shonld be adopted straight

away. It will be understood that when changing np the foot should

be taken off the accelerator pedal, and that when changing to a lower

gear it should be held down. The car should be well accelerated

,on each speed when changing up, and a deliberate pause should be

made with the gear lever in neutral position and with the clutch in

whether changing up or down. The catch below the knob of the

gear lever must be raised to allow the reverse gear to be engaged.

Always change gear early on a hill: never allow the 'engirie" ,

to labour in any gear and expect it to pick up speed on changing,

.~' into a lower one when the car

has nearly stopped.

Keep the foot off the clutch

pedal except in heavy traffic.,

Even then, do not allow the

weight of the. foot to be taken

by the pedal. The slipping

of the clutch caused by this

practice heats and wears it badly

When descending a long

hill, 'supplement the action of

the foot.brake at intervals by

the use of thehand.brake for

brief periods. It is often

advisable to engage one of the

lower gears before commencing a steep descent, with throttle closed.

When using the brake, keep the clutch in, disengaging it at the

last moment if stopping the car.

The driving seat of the" Austin

position and this convenience should

as to obtain the greatest comfort. >

/

4,

f.'

11

. ,D '.

(I

.

"$

",,'~'

.' ."'.

. ~F'

*

,I~). Seven" is adjustable for

be taken advantage of so

'"

.~

"

,

9

.How TO

CHANGE A WHEEL

WHEN it becomes necessary to change a wheel because

of a puncture or for any other cause. it will be necessary

first to remove the number plate. The spare wheel is

fastened on a bracket with three screws. in a sim;lar manner to

its fixing on the hub.

To detach a road wheel from the hub loosen the three right-hand

threaded nuts A which are in the hub of the wheel. by means of

the brace; it is not. necessary to remove them entirely. Now pull

the wheel outwards about Jrin. .and turn it so that the large hole

will pass over the nut. THe wheel can now he pulled 011the .bub.

When replacing make sure that the large pole in tbe hub is properly

fitted over its peg. <'.'

Should difficulty be experienced upon the first occasion of

removing the wheel from the hub, the wheel nuts may be screwed

right of!, The brake drum will then come away with the wheel.

To free this from the wheel. insert a screwdriver between the two

flanges, Before replacing, wipe the outside of the brake drum

and the inside of the hub with an oily rag. Great care is

necessary in order that no damage is done to the flanges. .

IQ

>PERIODICAL

ATTENTIONS

THE importance of giving careful attention

and regular inspection to the modern auto-

mobile cannot be over-estimated. If this is

done systematically considerably greater pleasure

will be derived from motoring as the car will always

be kept in tune and will not require adjusting at

inopportune moments.

Further, by following out the instructions given

in this book, expensive repairs may even be avoided,

as much of the trouble experienced by motorists

could have been avoided if attention had been given

.to details at the proper time.

The fol1owing instructions are arranged on a daily.

weekly, or monthly basis. The estimated needs

of the car for such periodical attention is based. on

the assumption that the maximum mileage for a

week wi1l not exceed 300 miles.

,

Daily Attentions-See also Lubrication

Chart, page 23.

1. Examine water level in radiator and

fill np to within 2 in. of the top. Always

use the strainer when re-filling as

dirty water will cause the radiator

film to become choked.

2. Examine oil level in the crankcase

and add more oil if necessary. The

teJJ-tale dipper rod indicates the level

of the oH (see illustration, page 21).

Fill up the petrol tank if necessary.

Care should be exercised when filling

the tank not to spill the petrol over

the engine.

3.

11

';

Monthly Attentions

Weekly 1. Examine the oil level in the gearbox

which should contain two-thirds of

a pint, or measure 2-2! in. deep.

Attentions

1. With the grease gun charge-,

Front spring shackle pins (4).

Rear spring pins (2).

Front wheel swivel pins (2).

Steering cross tube (2).

Fan bearing.

as'

2. Charge the back axle case with a gunfull

of grease and oil mixed half and half.

/. 3.

2. Oil the following-

Handbrake gear.

Pedal gear and jaw joints.

Engine control. and ball joints.

Clutch release ring.

Rear Brake cam spindles (2).

-" 4.

Fill all the hubs with

instru'cted on page 27.

Charge with grease the steering worm

case through the connection.

grease,

Examine the battery and see that the

connections are tigh~.

6. Give a cbarge of grease to the nipple

.on the fan spindle.

5.

3. Examine both sets of brakes, and adjust

if necessary. For method of doing this

see page 34. Occasionally

4. Examine all bolts and nuts, and any other parts such as

steering connections, neglect of which might lead to failure and

breakdown which would be followed by an expensive repair and

the inability to use the car for a lengthy period.

Inject high speed grease such as

Messrs. Stern's" Diathol" into the

universal joint at the rear end of the

propeller shaft, !md yellow grease into

the front end of the torque tube.

Oil the joints of the steering side tube. Spring clips and cylinder head nuts should be tightened

up occasionally when the car is new. and the nuts whenever the

cylinder head has been recently replaced.

It is advisable occasionally to remove all the road wheels and

clean inside the hub and wipe with an oily rag.

This emures the rapid removal of a wheel in case of a

puncture when on the road.

5.

"Utile, but often" should be the motto in lubrication.

12 13

.

}

I

The

CARBURETTER

,Method of Adjustment

Before altering the carburetter setting, turn off the petrol

bY'means of the tap underneath the tank. A jet key is sent out

with each car for the purpose of taking out the main and com-

pensating jets. The caps below the jets must be removed by

means of the adjustable spanner, when the 'jets can be unscrewed

with the special key. When replacing either, make sure that they

have washers on them, and are well down on the shoulder.

THE. following instructions have reference to the Zenith

c",buretter, adjusted by determining ihe correct sizes of

the choke tube, main jet and compensator, The purpose

of the choke tube is to obtain the correct velocity of air around the

jet in order to get the best mixture at all speeds. The main jet

I

\I

ij

jl

Slow Running

Too much petrol for slow running causes cho king and hesita-

tion in the pick-up. Although the engine may start easily and keep

running, it commences to run jerkily. A want of petrol, on the

other hand, causes a loss of power and misfiring at the same time.

It is, therefore, necessary to regulate the slow. running as carefully

as possible. First release the small locking screw A and then with-

draw the tube B, as illustrated. To reduce the quantity of petrol

unscrew the lower part C of the tube B, one notch at a time.

Reverse the operation to increase the flow of petrol. The jet

can be unscrewed from the lower part of the tube. There are

other factors quite apart from the carburetter which have a great

influence on slow running (slow running when the engine is oul

of gear and the car is stationary). These factors are:-

Cylinder head ,and induction pipe joints not air-tight.

Valve guides worn. Valves not gas tight.

Ignition too much advanced.

These points must always be taken into consideration, and

one should not blame the carburetter only if slow running is not

satisfactory,

i

.

has most influence at high speeds, The compensator, which

corrects the irregularities of the ,main jet flow due to differences

in engine speed, has Ihe greatest influence at slow speeds. Besides

these three parts there is a special device to provide for slow

running. The carburetter is tuned and set at the works to give

the best results under ordinary conditions; should the car be taken

to districts where the atmospheric conditions vary considerably, or

a different fuel be used, it may be advisable to adjust the

carburetter accordingly. Before making alterations to the carburetter,

make qtlite sure that the engine is in good running order.

particularly the ignition. The standard carburetter setting is:-

Choke ... .., 15mm,

MainJet ... ,.. '70mm,

CompensatingJet ..' '75mm.

14

. Leakage from the Carburetter

The cause is that the flo~t control is out of adjustment-the

floatperforated-or there isdirt on the needleseating,wh,ichshoul~

be cleaned. The two defects first mentioned should be remedien

by an expert:

1

--.-

t;

"'/

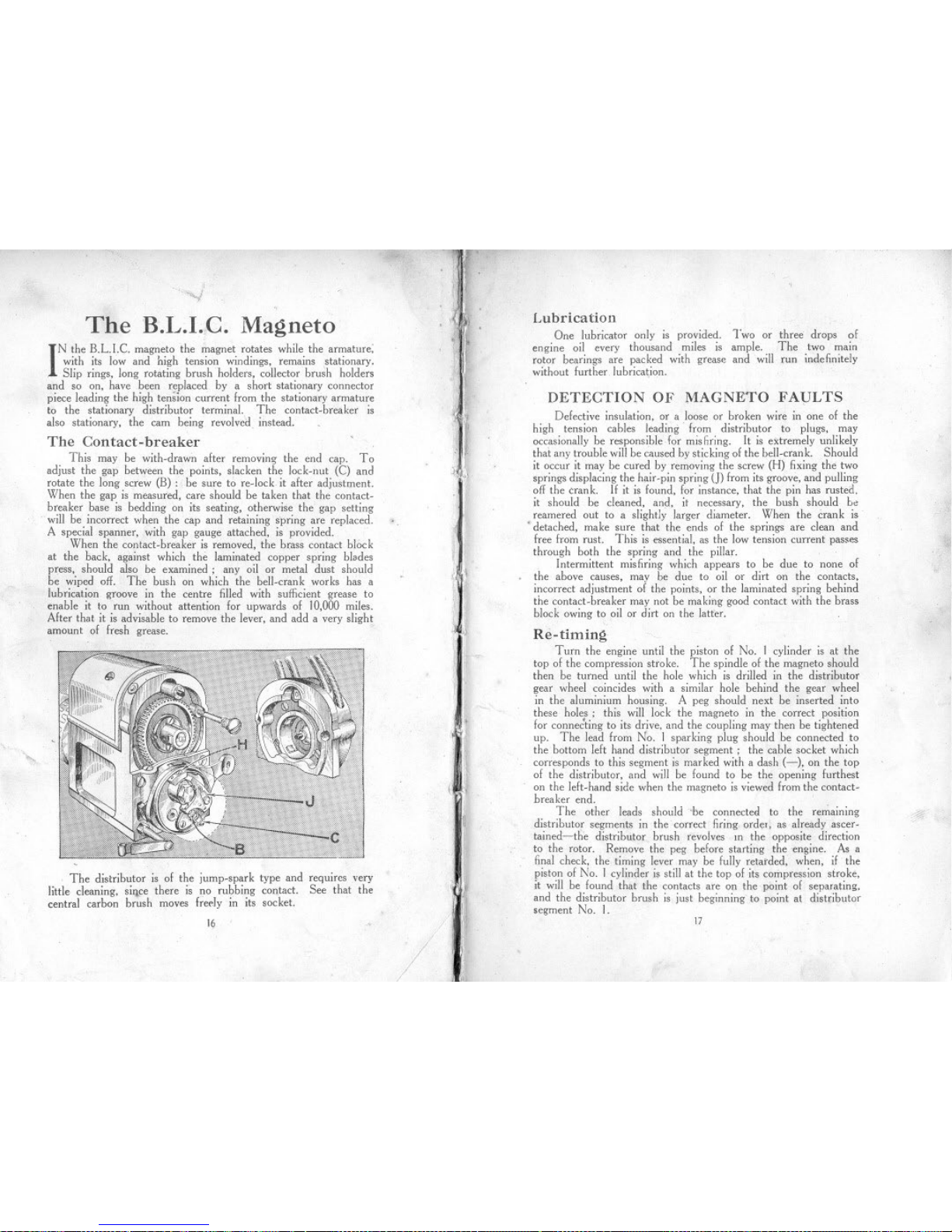

The B.L.I..G. Magneto

INthe B.L.LC. magneto the magnet rotates while the armatnre;

with its Iow and high tension windings, remains stationary.

. Slip rings, long rotating brush holders, collector brush holders

and so on, have been replaced by a short stationary connector

piece leading the high tension current from the stationary armature

to the stationary distributor terminal. The contact.breaker is

also stationary, the cam being revolved instead.

The Contact-breaker

This may be with.drawn after removing the end cap. To

adjust the gap between the points, slacken the lock.nut (C) and

rotate the long screw (B): be sure to re.lock it after adjustment.

When the gap is measured, care should be taken that the contact-

breaker base is bedding on its seating, otherwise the gap setting

will be incorrect when the cap and retaining spring are replaced.

A special spanner, with gap gauge attached, is provided.

When the contact-breaker is removed, the brass contact block

at the hack, against which the laminated copper spring blades

press, should also be examined; any oil or metal dust should

be wiped off. The bush on which the bell.crank works has a

lubrication groove in the centre filled with sufficient grease to

enable it to run without attention for upwards of 10,000 miles.

After that it is advisable to remove the lever, and add a very slight

amount of fresh grease.

...

The distributor is of the jump.spark type and reqUIres very

little cleaning, si'1ce there is no rubbing contact. See that the

central carbon brush moves ifeely in its socket.

16

/

J

.II~j

t

~

"1

It

~i

k i

Ii

'.

11~ ~

.,

1:."

I

!

"ti'J

I

I

(I:

.

,

/

/

Lubrication

One lubricator only is provided. Two or three drops of

engine oil every thousand miles is ample. The two main

rotor bearings are packed with grease and will run indefinitely

without further lubrication.

DETECTION OF MAGNETO FAVLTS

Defective insulation, or a loose or broken wire in one of the

high tension cables leading from distributor to plugs, may

occasionally be responsible for mis hring. [t is extremely unlikely

thai any trouble will be caused by sticking of the bell.crank. Should

it occur it may be cured by removing the screw (H) fixing the two

springs displacing the hair.pin spring (]) from its groove, and pulling

off the crank. If it is found, for instance, that the pin has rusted,

it should be cleaned, and, it necessary, the bush should be

reamered out to a slightly larger diameter. When the crank is

. detached, make sure that the ends of the springs are clean and

free from rust. This is essential, as the Iow tension current passes

through both the spring and the pillar.

Intermittent misfiring which appears to be due to none of

the above causes, mav be due to oil or dirt on the contacts,

incorrect adjustment 01 the points, or the laminated spring behind

the contact.breaker may not be making good contact with the brass

block owing to oil or dirt on the latter.

Re-timing

Turn the engine until the piston of No. 1 cylinder is at the

top of the compression stroke. The spindle of the magneto should

then be turned until the hole whicb is drilled in the distributor

gear wheel coincides with a similar hole behind the gear wheel

in the aluminium housing. A peg should next be inserted into

these holes: this will lock the magneto in the correct position

for conne~ting to its drive, and the coupling may then be tightened

up. The lead from N~. 1 sparking plug should be connected to

the bottom left hand distributor segment; the cable socket which

corresponds to this segment is marked with a dash (-), on the top

of the distributor, and will be found to be the opening furthest

on the left. hand side when the magneto is viewed from the contact-

breaker end.

The other leads should 'be connected to the re';'aining

distributor segments in the correct firing orde" as already ascer.

tained-the distributor brush revolves In the opposite direction

to the rotor. Remove the peg before starting the engine. As a

final check, the timing lever may be fully retarded, when, if the

piston of No. I cylinder is still at the top of its compression stroke,

it will be found that the contacts are on the point of separating,

and the distributor brush is just beginning to point at distributor

segment No. I.

#.

17

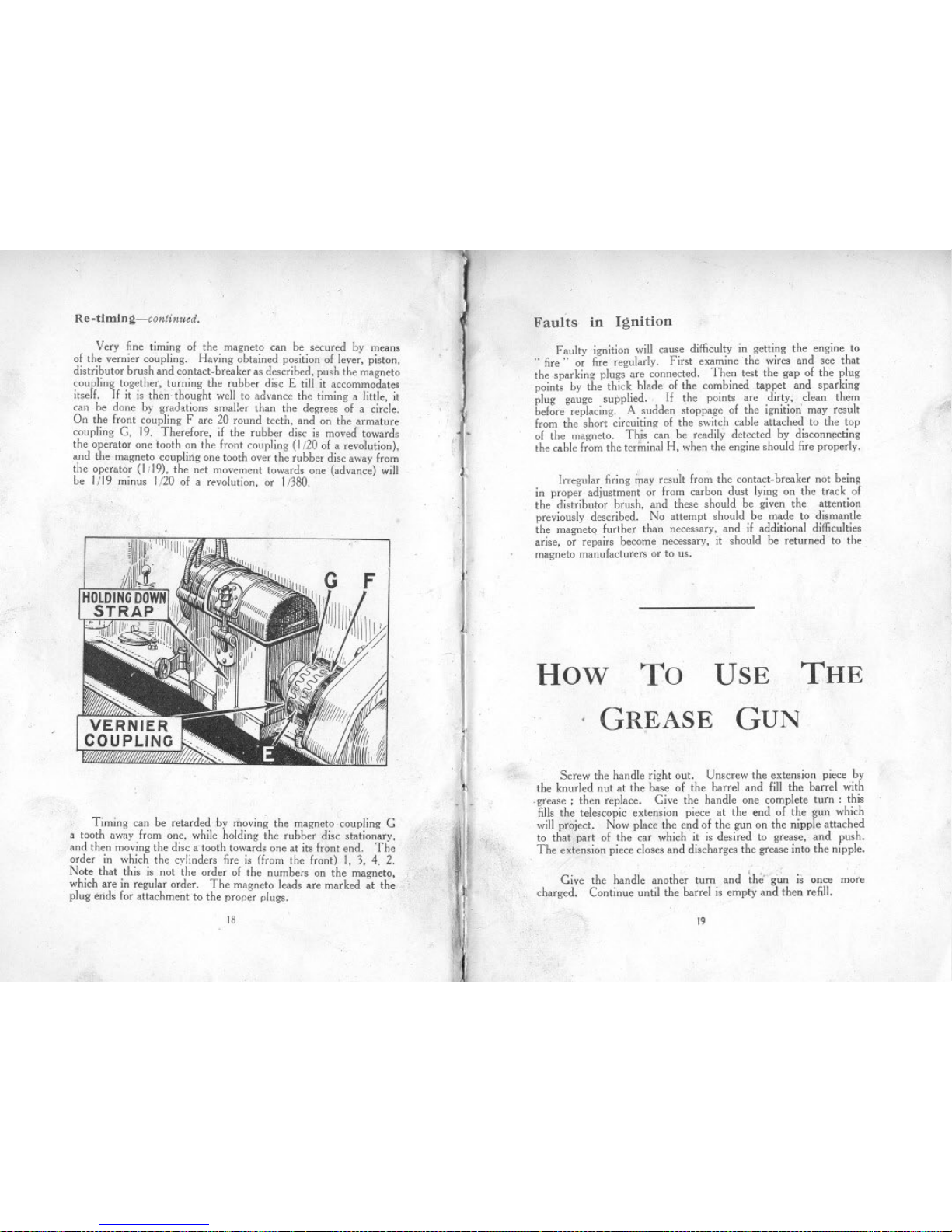

Re-timing-continued.

Very fine timing 01 the magneto can be secured by means

01 the vernier coupling. Having obtained position 01 lever, piston,

distributor brush and contact-breaker as described, push the magneto

coupling together, turning the rubber disc E till it accommodate,

itsell. If it is then thought well to advance the timing a little, it

can he done by grad,tions smaller than the degrees 01 a circle.

On the Iront coupling Fare 20 round teeth, and on the armature

coupling G, 19. Therelore, il the rubber disc is moved towards

the operator one tooth on the Iront coupling (1/20 01 a revolution),

and the magneto coupling one tooth over the rubber disc away Irom

the operator (I ;19), the net movement towards one (advance) will

be 1/19 minus 1/20 01 a revolution, or 1/380.

Timing can be retarded by moving the magneto .coupling G

a tooth away Irom one, while holding the rubber disc stationary,

and then moving the disc a tooth towards one at its Iront end. Thc

order in which the cylinders fire is (from the Iront) I, 3, 4. 2.

Note that this is not 'the order 01 the numbers on the magneto,

which are in regular order. The magneto leads are marked at the

plug ends lor attachment to the proper plugs.

18

, .ij

'f

.,,:1.

t

.

or,

(

~

Faults in Ignition

Faulty ignition will cause difficulty in getting the engine to

..fire" or fire regularly. First examine the wires and see that

the sparking plugs are connected. Then test the gap 01 the plug

points by the thick blade 01the combined t;lppet and sparking

plug gauge supplied. If the points are dirty; clean them

belore replacing. A sudden stoppage 01 the ignition' may result

Irom the short circuiting 01 the switch cable attached to the top

01 the magneto. Thjs can be readily detected by disconnecting

the cable Irom the terminal H, when the engine should fire properly.

Irregular firing <ray result Irom the contact-breaker not being

in proper adjustment or Irom carbon dust lying on the track 01

the distributor brush, and these should be given the attention

previously described. No attempt should be made to dismantle

the magneto lurther than necessary, and il additional difficulties

arise, or repairs become necessary, it should be returned to the

magneto manulacturers or to us.

How To THE

USE

GREASE

.GUN

,

Screw the handle right out. Unscrew the extension piece by

the knurled nut at the base 01 the barrel and lill the barrel with

.grease ; then replace. Give the handle one complete turn: this

fills the telescopic extension piece at the end 01 the gun which

will project. Now place the end 01 the gun on the nipple attached

to that part 01 the car which it is desired to grease, and push.

The extension piece closes and discharges the grease into the nipple.

Give the handle another turn and the- g~ is once more

charged. Continue until the barrel is empty and then refill.

19

The

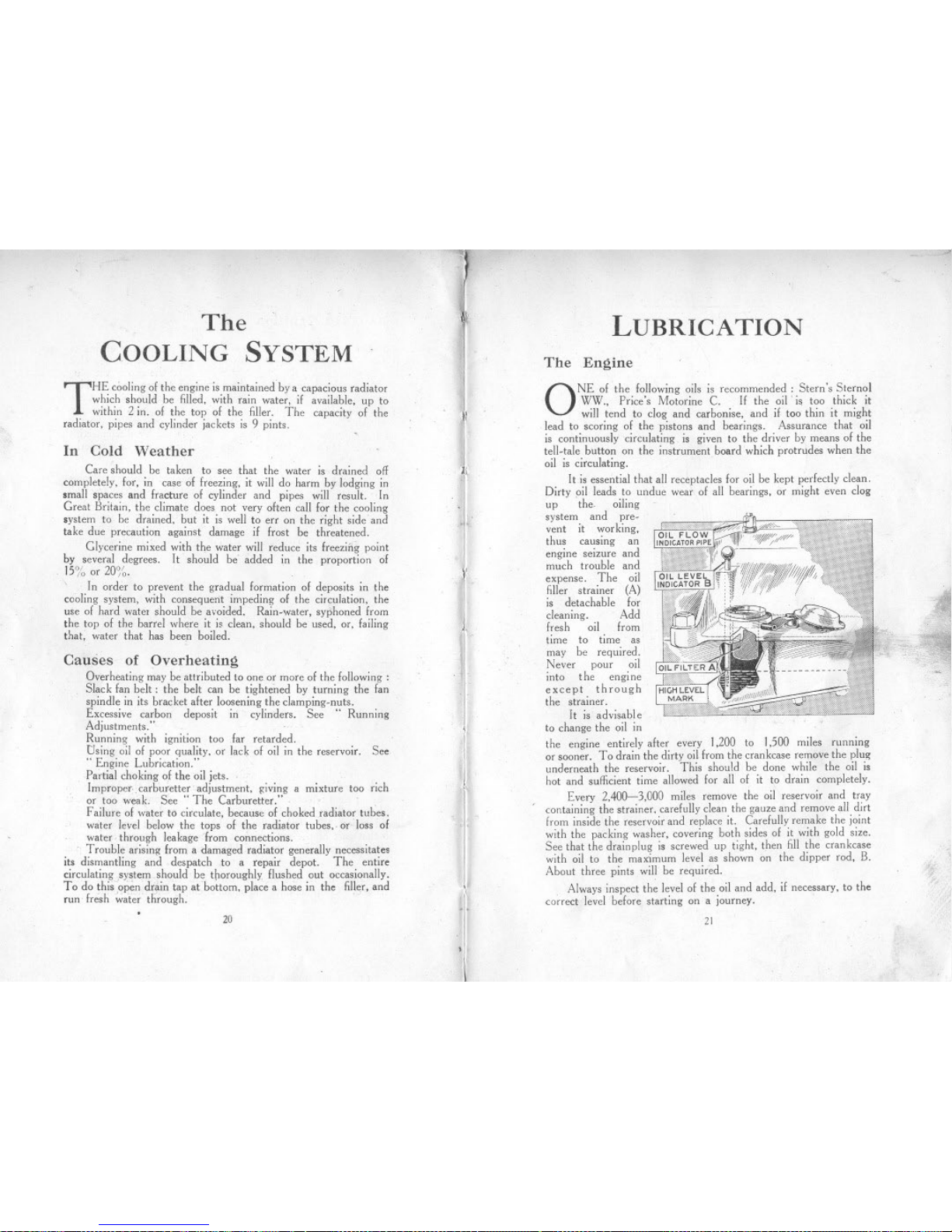

COOLING SYSTEM LUBRICATION

ONE of the following oils is recommended: Stern's Sterna I

WW.. Price's Motorine C. If the oil' is too thick it

will tend to clog and carbonise, and if too thin it might

lead to scoring of the pistons and bearings. Assurance that oil

is continuously circulating is given to the driver by means of the

tell-tale button on the instrument board which protrudes when the

oil is circulating.

ltis essential that all receptacles for oil be kept perfectly clean.

Dirty pil leads to undue wear of all bearings, or might even clog

up the. oiling

system and pre-

vent it war king,

thus causing an

engine seizure and

much trouble and

expense. The oil

filler strainer (A)

is detachable for

cleaning. Add

fresh oil from

time to time as

may be required.

Never pour oil

into the engi ne

except through

the strainer.

It is advisable

to change the oil in

the engine entirely after every 1,200 to 1,500 miles running

or sooner .To drain the dirty oil from the crankcase remove the plug

underneath the reservoir. This should be done while the oil is

hot and sufficient time allowed for all of it to drain completely.

Every 2,400-3,000 miles remove the oil reservoir and tray

containing the strainer, carefully clean the gauze and remove all dirt

from inside the reservoir and replace it. Carefully remake the joint

with the packing washer, covering both sides of it with gold size.

See that the drain plug is screwed up tight, then fill the crankcase

with oil to the maximum level as shown on the dipper rod, B.

About three pints will be required.

Always inspect the level of the oil and add, if necessary, to the

correct level before starting on a journey. .

The Engine

THE cooling of the engine is maintained by a capacious radiator

which should be filled, with rain water, if available, up to

within 2 in. of the top of the filler. The capacity of the

radiator, pipes and cylinder jackets is 9 pints.

In Cold Weather

Care should be taken to see that the water is drained of!

completely, for, in case of freezing, it will do harm by lodging in

small spaces and fracture of cylinder and pipes will result. In

Great Britain, the climate does not very often call for the cooling

system to be drained. bnt it is well to err on the right side and

take due precaution against damage if frost be threatened.

Glycerine mixed with the water will reduce its freezing point

by several degrees. It should be' added in the proportion of

15% or 20%. .

In order to prevent the gradual formation of deposits in the

cooling system, with consequerit impeding of the circulation, the

use of hard water should be avoided. Rain-water, syphoned from

the top of the barrel where it is clean, should be used, or, failing

that, water that has been boiled.

Causes of Overheating

Overheating may be attributed to one or more of the following:

Slack fan belt: the belt can be tightened by turning the fan

spindle in its bracket after loosening the clamping-nuts.

Excessive carbon deposit in cylinders. See" Running

Adjustments."

Running with ignition too far retarded.

Using oil of poor quality, or lack of oil in the reservoir. See

.. Engine Lubrication."

Partial choking of the oil jets.

Improper.. carburetter' adjustment, pvmg a mixture too rich

or too weab See" The Carburetter."

Failure of water to circulate, because of choked radiator tubes,

water level below the tops of the radiator tubes,. or loss of

water through leakage from connettions.

Trouble arising from a damaged radiator generally necessitates

its dismantling and despatch to a repair depot. The entire

circulating system should be tllOroughly flushed out occasionally.

To do thisJopen drain tap at bottom, place a hose in the filler, and

run fresh;';ater through.

1

,l

f

I

"

,

I

-11

It~

III

20

ill

,~

,',

~~

-.

2t

--

-

Eo<

~

.(

:I:

0

Z

0

.....

Eo<

<

0

.....

~.

~

::>

~

A'H.1.NOW 110 Cl

A1W.LNOW3S'9'3!1~ .

A1)t33M 110 0

A1)t33M 3S'9'3!1~ .

~

N

r

"- :: =-~-=~ c- ~,""---=---. ~. :;. :=.0- .--'.-- -- CO"= ..

=.. ---=~

~.

:I:

'Eo<

N

N

<fJ

.....

<fJ

<fJ

<

:I:

0

zO:

00

-I-

I-<t

(.)U

I.IJ-

ZC

Z~

00

(.)1-

01-

I-~

L&JXC)

C1(1) Z

<t:E

V)«-

V)UQ::

if~«

-,oLIJ

-a::fXI

0....

... a.

~'

::J

Q.

>

.'«

24

.

.,

~Tbe main bearings 01 tbe engine are 01 tbe roller type, and

tbe oily vapour in tbe crankcase is quite sufficient to lubricate tbese,

Tbe pistons are also. lubricated by tbe oily vapour.

Lubrication 01tbe big-ends is ellected by catcbing oillrom tbe

pump-led jets in pockets on tbe cranksbalt webs.

It is advisable to make sure tbese jets are always clear a"d' to

do so tbe plugs over tbe jets (see illustration 0" page 24) sbould

be occasionally removed and. a piece 01 stiff wire i"serted tbrougb

tbe jets, Tbis prevents loreign matter accumulati"g in tbe

jets a"d cboki"g tbem.

Gearbox

A suitable oil for tbe gearbox is tbe same as that used in tbe

engine; but illor a"y reason a"otber brand 01oil is used it sbould

be 01 about tbe same consistency and no tbicker, otberwise it will

not reacb all tbe bearings. Tbe deptb 01 tbe oil should "ever

be less tha" I i", or. more tban 2,\ in. It can be measured by a

rod i"serted through the filler plug hole. The maximum qua"tity

is approximately ""'".pi"t. Tbe correct oil level should be

maintained; excess of oil will leak Irom tbe bearings and seriously

.ffect the clutch. causing it to slip; on tbe otber band there must

be sufficient oil to prevent wear,

The gearbox sbould be drai"ed entirely alter the /irst 500.800

miles, and then alter every 4,000 or 5,000 miles, when any grit,

etc., which may bave collected will drain away through tbe plug

hole in the sump.

Clutch

The clutch

surlaces being

01 a labric ma-

terial must be

kept Iree from

oil and grease,

or the clutch

willlail to grip.

It is necessary

to lubricate the

operating ring

at point A, as

show" on tbe

sketch, o"ce a

week.

Rear Axle

For tbe rear axle attention: every 1,200 to 1,500miles sbould be

sufficient. A mixture 01 yellow grease a"d engine oil 01 equal parts

sbould be used and injected witb tbe grease gun supplied witb tbe car.

Do not inject too mucb grease at anyone time as tbe Ielt rings will

lail to bold tbis grease in tbe axle case, and it will tben leak through

0" to tbe brake drums and preve"t tbem I.rom being effective.

25

i

,I.

"

.,.

'I

I;<-

"

i)

,.

\

The makers recommend that a good quality" high-speed"

grease be used. This is of a dark brown colour. and will remain in

the joint longer than the ordinary yellow grease.

The. rear universal joint being ot mctal, must be kept well

lubricated at A on account of the movement of the rear axle.

It should be one of the points to have strict attention. Access for

greasing this, together with the grease connection B on the end

of the torque tube,

is obtained through

a cover C in the floor

of the body, asshown

on the illustration

adjoining.

Rear Universal Joint Hubs (front)-continued.

Fill the hub with grease

until it is seen to exude from

the flutes, or slots, at the

base of the adaptor. It is

important that the hubs are

not given too much grease,

otherwise the brakes will

not be effective.

Hubs (rear)

,

Remove the road

wheel. Turn the wheel

until the nipple" A" is at

the top. Inject grease into

the hub; one push down of-

the telescopic extension

piece is sufficient for or-

dinary maintenance pur-

poses, but when it is desired to give extra attention to the lubrication

of the rear hubs the nipple can be extracted and the adaptor already

referred to, inserted in its stead, the same procedure being adopted

as that described for the front.

Brake Gear

On each of the

rear brakes there is a

.Iubricator for oiling

the cam spindle

bearing. These and

all other joints, etc., should be oiled once a week.

,The front brake cam spindle is lubricated from the swivel

pin as shown at E, on illustration.

Front Axle

The swivel pins are lubricated with the grease gun.

Hubs (front)

Remove the road wheel. Turn the hub until the plug HA"

is at the top. Screw out the plug and screw in the adaptor illustrated

which is provided in the kit.

Steering Gear

To obtain easy steering it is important to give it regular

attention as regards lubrication. The grease gun connection is

on the top of the worm case, and if a charge is given once a month

it is sufficient to lubricate the bearings of the worm and worm wheel.

and also lubricate the worm itself. The bearing at the top of the

column, just under the steering wheel. can be given a little oil from

the oil-can. The steering connections on the side rod and the

nipples at the end of the cross rod given a charge of gr~ase once

a week.

Road Springs

The ends of the road springs where they are attached to the

axles are provided with grease gun connections, and should be

given a charge once a week if the car is continually used. After

a long period of use it is advisable to lubricate the leaves of the

spring with a warm mixture of white lead and tallow in equal parts.

This can best be applied with a stiff br~sh, the leaves being eased

apart by a screwdriver; first jack up the car (not under the axles)

to take the weight off the springs.

27

26

ELECTRICAL EQUIPMENT

THE lighting equipment is a CAV. 6-volt system. Very

little attention is required to keep this in satisfactory working

order. .

Should difficulties arise that cannot be understood or remedied

from the information given below, the difficulty should at once

be referred to the Austin Service Department or the nearest depot.

Dynamo

The dynamo should be kept" on " as a rule. It is designed

to be self-regulating, and the only parts which call for any

attention are the commutator and brushes. To examine the

commutator and brushes all that is necessary is to remove the

cover. The commutator should be kept dean using a piece of

ordinary soft rag. To dean a dirtv or neglected commutator, use

very hne glass paper, but this should only be done in extreme cases.

Blow away any

carbon dust, see

that the carbon

brushes are wear-

ing evenly, and that

they run freely in

their slots. also that

the flexible leads

to the brushes

are not .caught

in any part of

the brush gear.

There is a

lubricator at each

end of the machine. A drop or two of engine oil in each, every

thousand miles or so, is sufficient. The best oil to use is ordinary

engine oil. When the machines are hrst assembled the bearings

are packed with grease which lasts for a long time.

Ammeter Readings

When the engine is running fairly fast and no lamps are in use,

the ammeter pointer should give a "charge" reading of 7 or

8 amp., or with the lamps full on a small reading, to right or left

of .. 0," but when the engine is stopped and lamps are on, the

ammeter will indicate" discharge" 4-5 amp. The dimmer switch

should be used when the car is standing, even fora short time. It

reduces the discharge to a negligible figure.

If the ammeter pointer remains at 0 when the engine is

running and no lamps are on, see that all connections are tight,

particularly those on the dynamo, switchboard (F, 0, CB and CD),

and cut.out, that the fuse is intact, and that the battery connections

to switchboard are tight at both ends and unbroken. Should the

reading be but a small one, see if it is necessary to dean the

commutator of the dynamo.

\-

28

'-

Action of the Fuse

A fuse is fitted in the switch to protect the dynam~ in the 'event

of its battery connection being broken or the battery removed.

If this fuse melts

look carefully over

all the battery

connections, in-

cluding those

between the cells,

and see that no

terminal is loose.

Don't replace the

fuse wire until

you have found

the fault which

caused it to .. blow"

and remedied it.

Always replace with the proper fuse wire, never using any makeshift.

Reserve fuses are carried inside the cavity in the fuse cover.

Starting Motor.

This unit should never require any adjustment or attention. If

for any reason it should fail to function when the battery is well

charged, it will be necessary to remove it from the engine and send

it to the works. The armature shaft rllns in self-lubricating bushes

and therefore does not require any further lubrication.

THE BATTERY

The battery is an item of the equipment that is often neglected

or receives insufficient attention. It is most important that it be

kept in the best condition and the following instructions should be

carefully noted.

During the winter 'months, when the periods of discharge are

long and heavy the switch on the switchboard should always be in

the out, or charging position, especially when the lights are on, and

the car is running. .

During the summer months, however, when the periods of

discharge are comparatively light, over-charging the battery must be

guarded against, as harm will result. If the car is used every day,

charging for about an hour should be sufficient to compensate for

the discharge requited to operate the horn and occasionally the self-

starter. It is desirable to test the specific gravity of the liquid,

known as electrolyte monthly, and we strongly advise .11owners to

procure a suitable hydrometer, which can be obtained from practi-

cally all good .accessory dealers-and pay particular attention to the

battery to obviate the possibility of bad results from over-charging.

Should the state of the battery be continually bad, see that all its

connections to the switchboard are tight and unbroken, and that no

wire has a chafed covering allowing leakage of current to frame.

During periods when the car is unused inspect ihe battery

occasionally and, give it a charge if required.

29

SIDE LAMP

DYNAMO

(EARTHED)

FIELI>

(BLACK)

CUT OUT POSITIVE

(RED)

Q

DIMMER SWITCH

WITH KNOB OUTGIVES

LIGHTSI>IMANDWITH

KNOBIN LIGHTSfULL ON

STARTER

F.E. Frameearllred.

TAIL LAMP

F.E.

-

ILLUSTRATIONOF WIRING

30

3IDELAMP

HORN

,.

Battery-continued.

When the battery arrives

empty (as in the case of cars sent

.abroad) the first thing to do is

to fill and charge it.

'-..

The best indication of the

state of the battery is the density

of the liquid (known as the

electrolyt~). Its specific gravity

should be 1'275 when the battery

is fully charged and should never

be discharged so as to bring the

speci fic gravity below 1'170,

otherwise sulphating will result

and the life of the battery be

shortened.

When the specific gravity is

too high, that is to say 'Yhen it.

exceeds 1'275, diluted acid or

distilled water must be added.

When the specific gravity falls

appreciably below n75, add. a little

part to three of water. sulphuric acid diluted, one

If, after being in use for some time, the battery does not seem

to hold its charge properly, and the lights go dim quickly when left

on for awhile without the dynamo charging, test the acid. Should

it be found too weak do not attempt to correct this by adding acid

or water, but give a good charge and then refill with 1.275 solution

as before. The tops of the cells should be kept clean and dry,

and the terminals shewed up tightly.

-.-

31

RUNNING

ADJUSTMENTS

THE adjustments set out below are all that the amateur owner

will find -necessary to make to keep the car in good running

order, and are fully described in the following pages.

To keep correct clearance between

To remove and clean the cylinder

pistons, and grind in the valves.

To adjust and re-line the brakes.

To adjust steering.

To adjust shock absorbers.

tappets and valves.

head, dean tops of the

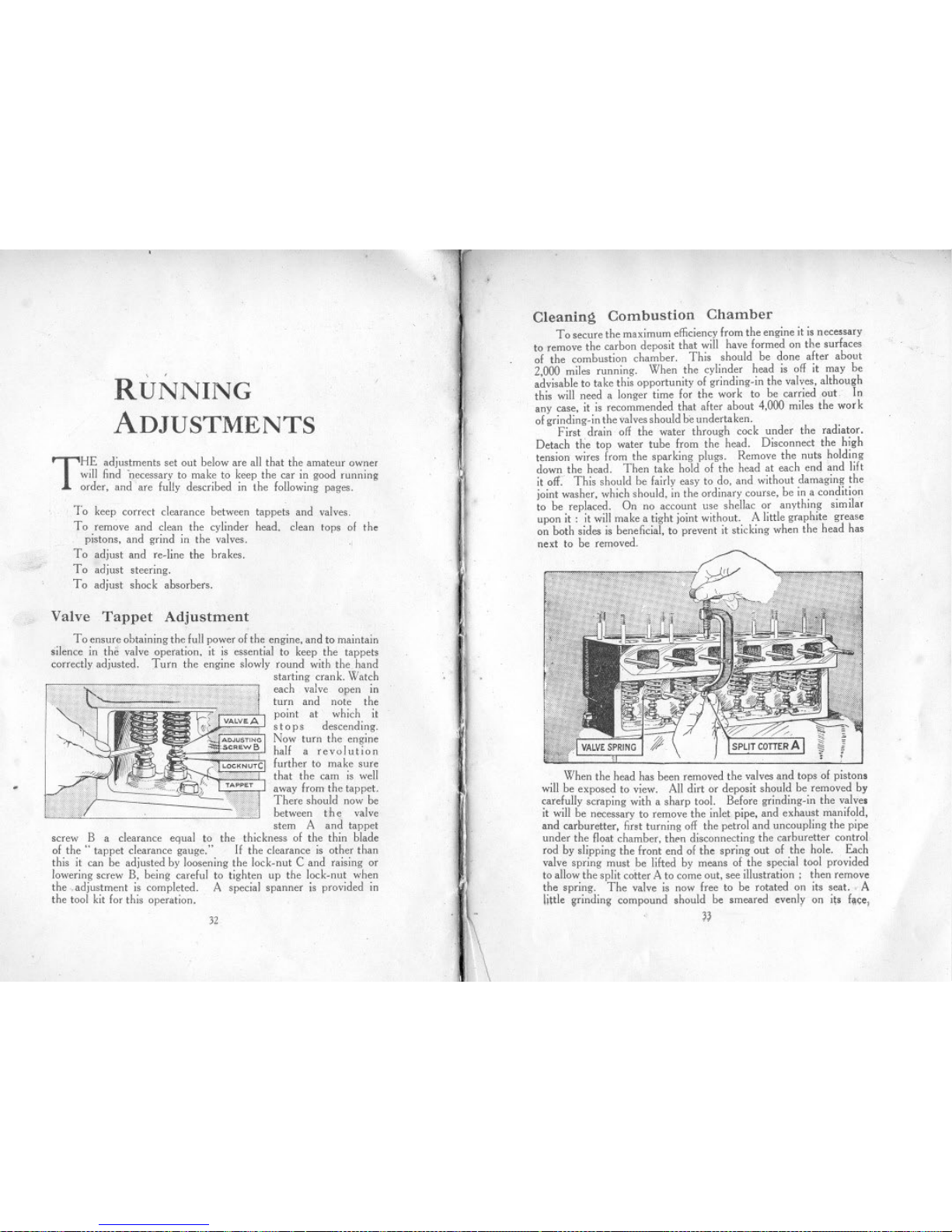

~Valve AdjustmentTappet

To ensure obtaining the full power of the engine, and to maintain

silence in the valve operation, it is essential to keep the tappets

correctly adjusted. Turn the engine slowly round with the hand

starting crank. Watch

each valve open in

turn and note the

point at which it

stop s descending,

Now turn the engine

half a revolution

further to make sure

that the cam is well

away from the tappet.

There should now be

between the valve

stem A and tappet

screw B a clearance equal to the thickness of the thin blade

of the" tappet clearance gauge," 11the clearance is other than

this it can be adjusted by loosening the lock-nut C and raising or

lowering screw B, being careful to tighten up the lock-nut when

the .,adjustment is completed. A special spanner is provided in

the tool kit for this operation-

32

I

Cleaning Combustion Chamber

To secure the maximum efficiency from the engine it is necessary

to .remove the carbon deposit that will have formed on the surfaces

of the combustion chamber. This should be done after about

2,000 miles running. When the cylinder head is off it may be

advisable to take this opportunity of grinding-in the valves, although

this will need a longer time for the work to be carried out In

any case, it is recommended that after about 4,000 miles the war k

of grinding-in the valves should be undertaken.

First drain off the water through cock under the radiator,

Detach the top water tube from the head. Disconnect the high

tension wires from the sparking plugs. Remove the nuts holding

down the head. Then take hold of the head at each end and lift

it off: This should be fairly easy to do, and without damaging the

joint washer, which should, in the ordinary course, be in a condition

to be replaced. On no account use shellac or anything similar

upon it: it will make a tight joint without. A little graphite grease

on both sides is beneficial, to prevent it sticking when the head has

next to be removed.

When the head has been removed the valves and tops of pistons

will be exposed to view. All dirt or deposit should be removed by

carefully scraping with a sharp tool. Before grinding-in the valves

it will be necessary to remove the inlet pipe, and exhaust manifold,

and carburetter, first turning off the petrol and uncoupling the pipe

under the float chamber, then disconnecting the carburetter control

rod by slipping the front end of the spring out of the hole. Each

valve spring must be lifted by means of the special tool provided

to allow the split cotter A to come out, see illustration; then remove

the spring. The valve is now free to be rotated on its seat. " A

little ~rinding compound should be smeared evenly on its f~ce,

II

~

RUNNING

ADJUSTMENTS

THE adjustments set out below are all that the amateur owner

will find -necessary to make to keep the car in good running

order, and are fully described in the following pages.

To keep correct clearance between

To remove and clean the cylinder

pistons, and grind in the valves.

To adjust and re-line the brakes.

To adjust steering.

To adjust shock absorbers.

tappets and valves.

head, dean tops of the

~Valve AdjustmentTappet

To ensure obtaining the full power of the engine, and to maintain

silence in the valve operation, it is essential to keep the tappets

correctly adjusted. Turn the engine slowly round with the hand

starting crank. Watch

each valve open in

turn and note the

point at which it

stops descending,

Now turn the engine

half a revolution

further to make sure

that the cam is well

away from the tappet.

There should uow be

between the valve

stem A and tappet

screw B a clearance equal to the thickness of the thin blade

of the" tappet clearance gauge," 11the clearance is other than

this it can be adjusted by loosening the lock-nut C and raising or

lowering screw B, being careful to tighten up the lock-nut when

the ..adjustment is completed. A special spanner is provided in

the tool kit for this operation-

32

Cleaning Combustion Chamber

To secure the maximum efficiency from the engine it is necessary

to remove the carbon deposit that will have formed on the surfaces

of the combustion chamber. This should be done after about

2,000 miles running. When the cylinder head is off it may be

advisable to take this opportunity of grinding-in the valves, although

this will need a longer time for the work to be carried out In

any case, it is recommended that after about 4,000 miles the wor k

of grinding-in the valves should be undertaken.

First drain off the water through cock under the radiator,

Detach the top water tube from the head. Disconnect the high

tension wires from the sparking plugs. Remove the nuts holding

down the head. Then take hold of the head at each end and lift

it oft. This should be fairly easy to do, and without damaging the

joint washer, which should, in the ordinary course, be in a condition

to be replaced. On no account use shellac or anything similar

upon it: it will make a tight joint without. A little graphite grease

on both sides is beneficial, to prevent it sticking when the head has

next to be removed.

When the head has been removed the valves and tops of pistons

will be exposed to view. All dirt or deposit should be removed by

carefully scraping with a sharp tool. Before grinding-in the valves

it will be necessary to remove the inlet pipe, and exhaust manifold,

and carburetter, first turning off the petrol and uncoupling the pipe

under the float chamber, then disconnecting the carburetter control

rod by slipping the front end of the spring out of the hole. Each

valve spring must be lifted by means of the special tool provided

to allow the split cotter A to come out, see illustration; then remove

the spring. The valve is now free to be rotated on its seal..' A

little ~rinding compound should be smeared evenly on its f~ce,

II

Cleaning Combustion Chamber-continued.

and the valve rotated hackwards and forwards, advancing it a step

at short intervals until the pitting is removed. Care should he

taken that none of the compound enters the cylinders, and the

valve and seating should he wiped clean after the operation.

When replacing the head take care to tighten the nuts evenly.

Don't forget, after replacing the head, to refill the radiator.

Adjusting the Brakes

The hand hrake operates on the front wheels and the bot

hrake'on the rear wheels. They require adjusting when the hand

lever can he pulled right hack to the full travel on the'rack, and

when the pedal can he pushed nearly to the floorhoard without

either hrake holding the wheels. The car should never he taken

out when in this condition

hut attended to at once. .

To adjust the hand hrake

pull the lever on ahout o;'e-third

(or to suit driver's reach) of

the total travel provided hy

the rack. Now unlock the

nut B and screw up the

hrake adjusting handle A untiI

the shoes are hard on, the

drum. If the hrake sho~s do

not then ruh on the drum when

the lever is right forward. the

adjustment is correct. See

that the handle is locked again

hy nut B.

To adjust the foot hrake: Under

the car and approximately under

the fuot controls is a wing nut

C. This must he

screwed towards the

front of the engine

until the brakes

go full on when

the pedal is de-

pressed ahout 2 in.

When the pedal is

up, the hrake shoes

should not rub

the rear wheel

drums in which

they operate.

Adjustment of Steering

If after continual use slackness should be felt in the steering.

two adjustments are availahle :-1'0 take up the play in the

column, loosen the nut which tightens the bracket supporting the

steering outer column to the instrument board, unscrew locking peg

" A" and clamping holt .. B." then turn the sleeve" C" with

the special spanner provided for the purpose, until the play has

heen removed. Do not screW the sleeve in t06 tight or the

steering will then become stiff. Having adjusted the sleeve

correctly, 'screw in the locking pcg so that it enters one of the slots

of the sleeve, tighten up the clamping halt, and the supporting

hracket to the instrument hoard. '

,.,'

34

To take up the clearance hetween the worm and worm wheel,

due to wear, slacken the three nuts" 0" holding the cover" E "

to the worm casing, then turn adjusting screw" F .. so as to slightly

draw the cover in the direction of the worm, Care must he taken

that the worm wheel is not hrought too tight into mesh with the

worm or it will make the steering exceedingly hard and stiff. Having

made the adjustment he sure and tighten up the three nuts" D."

Should it he desirahle to remove the steering worm wheel

from the casing, it is only necessary to slacken the "djusting screw

F and remove the three nuts 0 when the cover E can he withdrawn

together with the worm wheel and steering arm, The steering

column H with control rods can he withdrawn hy first removing

control levers K and nut L, then slacken lockiIl~ peg A and

clamping halt B and, unscrew the sleeve C.

35

~

Other manuals for Austin Seven

1

Other Austin Motor Company Automobile manuals

Austin Motor Company

Austin Motor Company FX4R User manual

Austin Motor Company

Austin Motor Company A40 Somerset Sedan Technical specifications

Austin Motor Company

Austin Motor Company A40 Somerset Sedan User guide

Austin Motor Company

Austin Motor Company LANDCRAB 1993 User manual

Austin Motor Company

Austin Motor Company Austin Seven User manual