Austin Motor Company Austin Seven User manual

~~:!fi~'"

r}~

"" ¥'

" '

"" 'C>,,'

,i,

'iIII""'- '"

,

r~..:,

"if'

J

t

I'

'ill

~~~

.

t

~<,

L:p. I

~'" '6,

;"r

( "

. . ~'

"'.

, ,

.~

9h.

;1;;,

.£."

eft

1= =,'"

'" I!!?t ii,~

f"IiIi ~

~:

e~-

~7.

1\1'

k 'i!"

iiI;i """ "f. '" i!"fiB"

HANDBOOK "

"

"

..

~

..

";;p \'oJ.~

!.. .,'.

" "

..

,""" !::'

""" I>-

" PubuCauorr 619

'" i;i

z iIij

'=

'",

~~

11

,rf ~

,

-,' ~

,

'

,

\,,

_

,(:i~STIN MOTOR C<J.L+,

''

~'" '-, c ~l.

LQliGBRIDGE. nearBJRMINGHAM

."",

f

'f.. ..

i

"..

""

.. .,

;~\ '

""... "'"

""""=

. 01 'fitM'

~ '. ",

'1> """"~""!,,

~. "

...'

~7f

~' ..'

..

"11 "

"'

41t

<, "

"" j

"[

"

..,.

,t!'

".

I

<

#\

'.

i!.f

~

,

""'j

>',

;.j

.\

i

,~I

t

~

)!' f

i1!I

"

11,

,',

"'..,

"'A',i>

-::Ai.

..

~., <'i

~

-

'" ~

~

."

..~ '

t",-,

~, " "f

~~'f!f.' V

'*~

~e .,

I!" , .

a

n

/lS,l;e

!1,~

\

!~i

'\lI.

~"

!~

\J' w

"0

,I,

-

\j;

\~ .\'"

""

~i

.

.,

.

!fj

\

"

\fil

,I,

m ~

"

.,

HANDBOOK

r'

.

.

PRICE 2/6

17th EDITION

m

THE AUSTIN MOTOR CO. LTD;

LONGBRIDGE, Nr. BIRMINGHAM

T,l,phone> CENTRAL4140, KING'SNORTON541

Td,gmm" '" SPEEDILY,NORTHFIELD." Cod" BENTLEy'S

LONDON SHOWROOMS, REPAIR DEPOT AND HIRE DEPT, :

479-483, Oxford W./

Street,

(NEAR M<RBLE ARCH)

Td,phon" MAYFAIR6230, T,/,gm=, "AUSTlNETTE,LONDON,"

I

fU "f"ro" to thi, boo' 6

--

1

m-

9I

pl"" quo" "" uum'" ...

"~

CONTENTS

AForeword. AMMETER READINGS

ATTENTIONS, Da;!y ..

Weekly

Monthly

Ocea,ional

PAGE

34

12

12

13

13

35

49

41-42

30

44.45

10

6

8.9

15-19

15

17

18.

29

39.40.

25

33

33.37

27-29

8

25,47

31

35

29

26

31.32

22

23.24

20.24

38

14

27

20.21

30

31

39.47

46

42-43

29

51

50

30

39

11

37

THE information coniained in this Handbook is intended

only to guide 'and assist owners or drivers of "Austin

Seven" cars to preserve the car in its proper satisfactory

running condition. This must not be considered as

.

exhaustive or as varying or extending the liability of the

company,' which is limited to the Warranty issued with the

car. Where no information is given for a particular

adjustment, it may be regarded as one which the average

owner would entrust to a garage. When the occasion for

. adjustments of this character arises, the owner should" seek the

aid of an Austin agent. Both owner and agent are encouraged

to call upon the Service Department of the Company for

advice, whether upon management of the car, the effecting

of adjustment, ot methods of repair. Owners need not

suppose that they will have to apply all t~e attentions given

in this book, but careful notice should be taken of the

chapters dealing with maintenance.

BATTERY, The

BODYWORK, CMe of ..

BRAKES, Ad;u,ting the .

BRAKE GEAR, Luh,ication of ..

BRAKES, Re.lining

CAR, Coutml of the

" FeaMe, of the

" The New

CARBURETTER, The..

" Adju",meut of. .

" Slow Runmug of

" " Leakage horn

CLUTCH, Luh,ication of

COMBUSTION CHAMBER, Geaning ..

COOLING SYSTEM

DYNAMO, The

ELECTRICAL EQUIPMENT, The

ENGINE. Lub,ication of

Sta,ting the. .

Two additional publications give hsts and illustrations of

~ll the parts, and their prices, respectively, and the owner should

find'these books helpful for reference.

FAN ..

FRONT AXLE, Lub,ication of ..

FUSE, Acrion of the

GEARBOX, Lub,icatiou of

GREASE GUN, How to u,e the

HUBS (Fmnt aud Rea,), Lubrication of

IGNITION, Fault, iu

" Timing

" Sy,tern, The

LAMPS. CMe of

LUBRICATION CHART

LUBRICANTS. Choice of

MAGNETO, Lubricariou of

REAR AXLE. Lub,ication of

ROAD SPRINGS, Lubrication of

RUNNiNG ADJUSTMENTS..

SHOCK ABSORBERS, Adju,trnent of ..

STEERING. Adju,tment of

STEERING GEAR, Lubrication of

TOOLS, Supplied

TYRES. The..

.UNIVERSALJOINT. Lub,ication of

VALVE TAPPETS. Adjmtrnent of

WHEEL. Cbanging a

WIRING. Illu,"ation of

Many of the adjustments and attentions described in the

following pages are included in the" . Austin Seven' Schedule

of Charges fot Repairs." The Company is confident that

owners will find it to their own benefit to make the fullest use

of this standard price repair and maintenance service, which it

is a function of all Austin Agents to offer (see page 19).

IMPORTANT.--See special note on page 52, with

reference to accessories and equipment not manufac-

tured by the Austin Motor Co. Ltd.

February. 1928.

23

j A

""l1li

The ';AUSTIN SEVEN"

Brakes are fitted to all four wheels which carry 26 X3t in.

Dunlop balloon reinforced cord tyres.

. The" Austin Seven" is particularly suitable for the woman

driver. It requires little physical effort to drive and control, and

for that reason its use enables. her to do shopping calls without

fatigue, visit her friends, attend social and other funciions., or

make excursions or trips in any direction in any weather. For

the same reasons business men find it an excellent vehicle, and

commercial travellers and others whose occupation compels

frequent calls over an exterided area, have in the little car an

embodiment of all they require. Calls can be made in places

where trains, trams and 'buses are infrequent.

In large establishments where the use of a big car for short

runs with messages, on shopping, emergency calls at short

notice, as in case of sudden illness, would be found costly and

inconvenient, the" Seven" has proved to be a splendid

.. tender," saving time and money.

As 45 to 50 miles per gallon is the average petrol consump-

tion, .the cost of transit is below the cost of fares on any

public conveyance, and in this particular the" Austin Seven"

has no rival.

Its speed, economy, reliability and road-holding qualities

have been admitted beyond dispute.

Thousands of motorists have had their first experiences on

a .. Seven," thousands more will follow them.

It has successfully passed through years of severe use and

trial, and emerged a really successful and popular favourite.

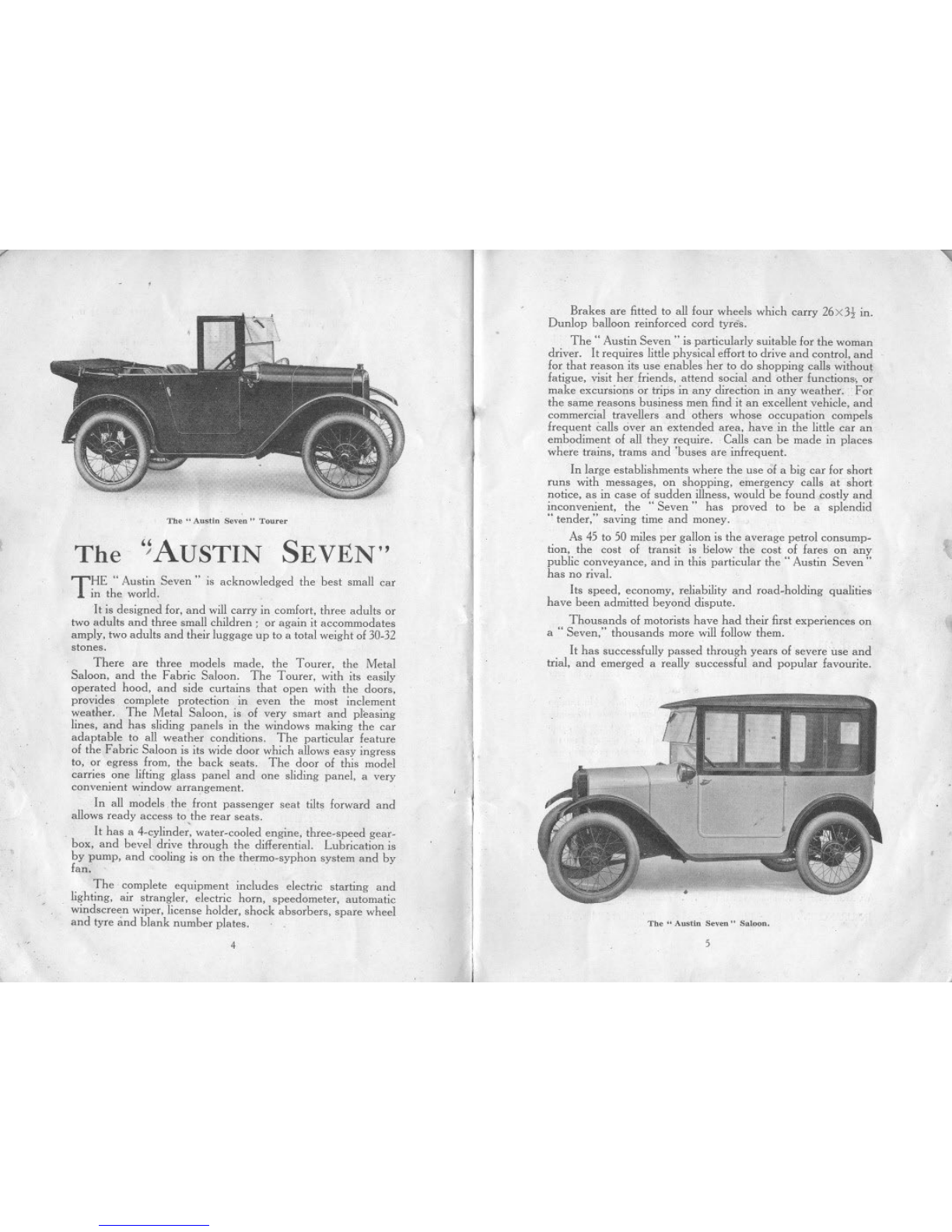

The" Au,tln Seven" Tourer

THE" Austin Seven" is acknowledged the best small car

in the world.

It is designed for, and will carry in comfort, three adults or

two adults and three small children; or again it accommodates

amply, two adults and their luggage up to a total weight of 30-32

stones.

There are three models made, the Tourer, the Metal

Saloon, and the Fabric Saloon. The Tourer, with its easily

operated hood, and side curtains that open with the doors,

provides complete protection in even the most inclement

weather. The Metal Saloon, is of very smart and pleasing

lines, and has sliding panels in the windows making the car

adaptable to all weather conditions. The particular feature

of the Fabric Saloon is its wide door which allows easy ingress

to, or egress from, the back seats. The door of this model

carries one lifting glass panel and one sliding panel, a very

convenient window arrangement.

In all models the front passenger seat tilts forward and

allows ready access to ,the rear seats.

It has a 4-cylinder, water-cooled engine, three-speed gear-

box, and bevel drive through the differential. Lubricationis

by pump, and cooling i. on the thermo-syphon system and by

fan.

The complete equipment includes electric starting and

lighting, air strangler, electric horn, speedometer, automatic

windscreen wiper, license holder, shock absorbers, spare wheel

and tyre and blank number plates.

4

The" A.-tin Seven" Satoon.

5

,

7'

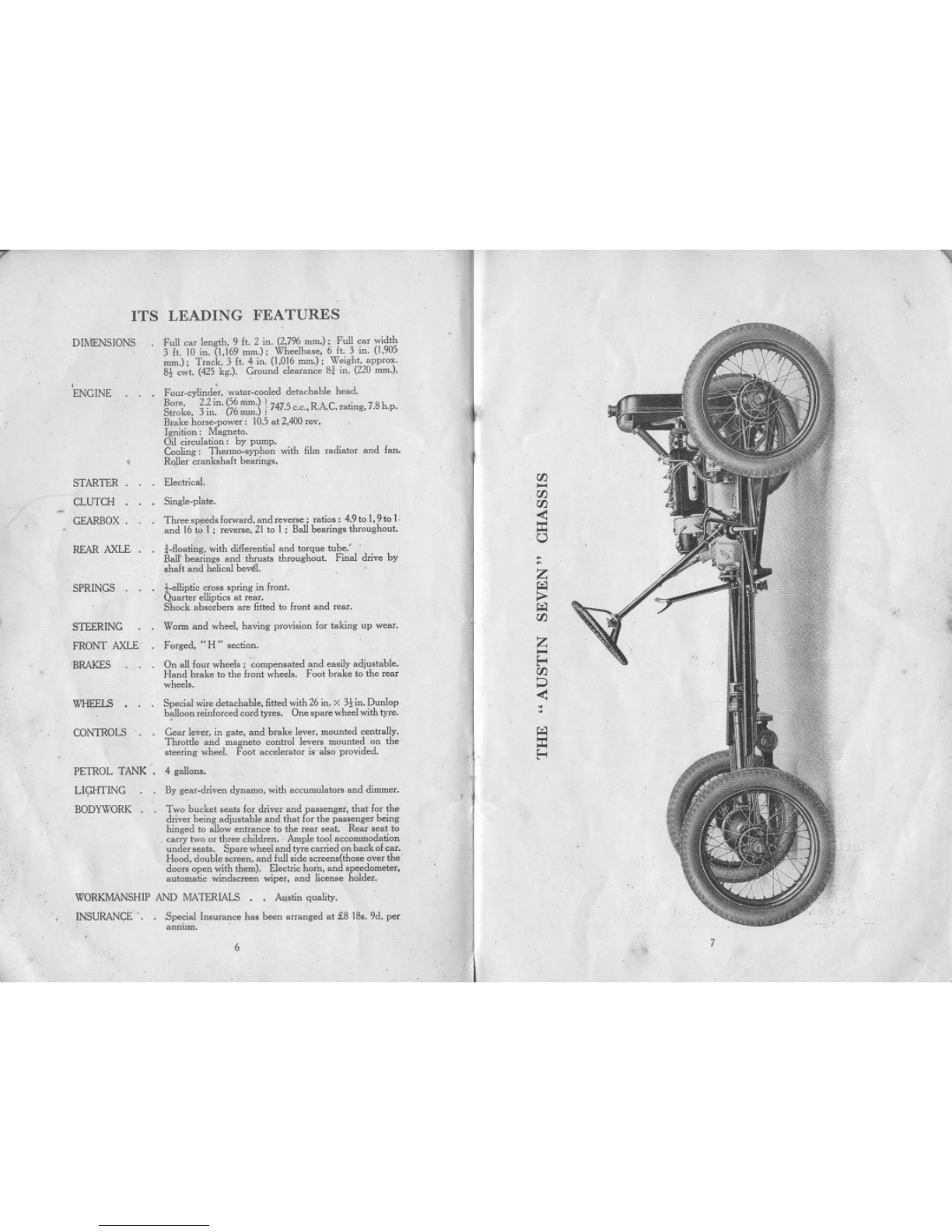

DIMENSIONS

,ENGINE

STARTER.

CLUTCH .

GEARBOX.

REARAXLE .

SPRINGS.

STEERING

FRONT AXLE'

BRAKES

WHEELS

CONTROLS

ITS LEADING FEATURES

.

. Full ca<length. 9 It. 2 ;u. (2,796 mm.); Full ca. ,,;dth

3 ft. ID ;u. (1.169 mm.); Wheelba,e, 6 ft. 3 ;u. (1,905

mm.); Tmck, 3 ft. 4 m. (1.016 mm.); We;ght, appmx.

8j; cwt. (425 kg.). G.ouud clea.auce S. iu. (220 mm.),

. Fom.cylinde~, wate..cooled detachahIe head.

Bo.e, 2.2 in. (56mm.) 17475 RAC '7Sh

Stmke, 3 in. (76mm.) f. C.C., . . . mtmg,. .p.

Bmke hom.powe.: 10.5at 2,400 .ev.

Ignihon: Magneto.

Oil cimulahon: by pump.

Coohng: Tbenno.,ypbon ,,;th film mdiato. and lau,

Roller cmnk,halt bearing',

. Electrical.

. Single.plate.

. Tb.ee,peed,fm"Wa.d,and.evem; mho" 4.9to1,9to 1.

and 16to I ; .eve..e, 21to I ; Ballbearing, thwughout.

. ..floahng, ,,;th diffe.enhaland to.que tube:

Ballbeariug, aud tbm,t, tb.oughout. Fmal drive by

,halt aud hehcalb~.

,.eIhPhc cm" 'pring in fwnt.

. Qua.te. eIhPh'" at .ea..

Shock ab,o.be" a.e fitted to [mnt and .ea..

Wonn aud wheel, having pwvi,ion 1o. taking up wea..

Fo.ged, .. H" ,echon.

. I

. On all lom wheel,; compen,ated and ea,ily adju,table.

Hand hmke to the Imnt wheel,. Foot bmke to the .ea'

whee]"

Special ,,;.e detachahle, fitted ,,;th 26 m. X 3, ;n. Dunlop

b~oon .einfo.ced co.d ""e,. One 'pa.. wheel ,,;th ty.e.

Gea. leve., in gate, aud bmke leve., mounted cen"ally.

Thmttle and magneto con"ol lev.., mounted on the

"eering wheel. Foot accelemto. i,' aI,o pmvided.

PETROL TANK. 4 gallon,.

LIGHTING

BODYWORK.

By gea..driven dynamo, ,,;thaccumnlato.. and dimm...

Two bucket ,eat, 1o. drive. and pa"engei, that £0. the

drive. being adju,tahle and that 1o. the pa"enge. bemg

hinged to allow en"auce to the .ea. ,eat. Rea. ,eat to

. ca"y two°, th.ee child..n. . Ample tool accommodahon

unde. ,ea". Spa.e wheel and ty.. "",ried onback ofea..

Hood, double ,aeen, aud lull side ween,(tho,e ove. the

doo.. open ,,;th them). Electric horn, and ,peedomete.,

automahc ,,;nd,«een ,,;pe., and hceme holde.,

WORKMANSHIP AND MATERIALS, , AU'hnquahty.

INSURANCE' . . Special Imu.ance has been a"anged at £8 IS,. 9d. p..

annum. .

6

"

r/]

~

r/]

r/]

<:

::.:

0

"

~

z

f;I;1

;>

f;I;1

r/]

z

...

Eo<

r/]

~

<:

~

f;I;1

::.:

Eo<

,7

7' ,),

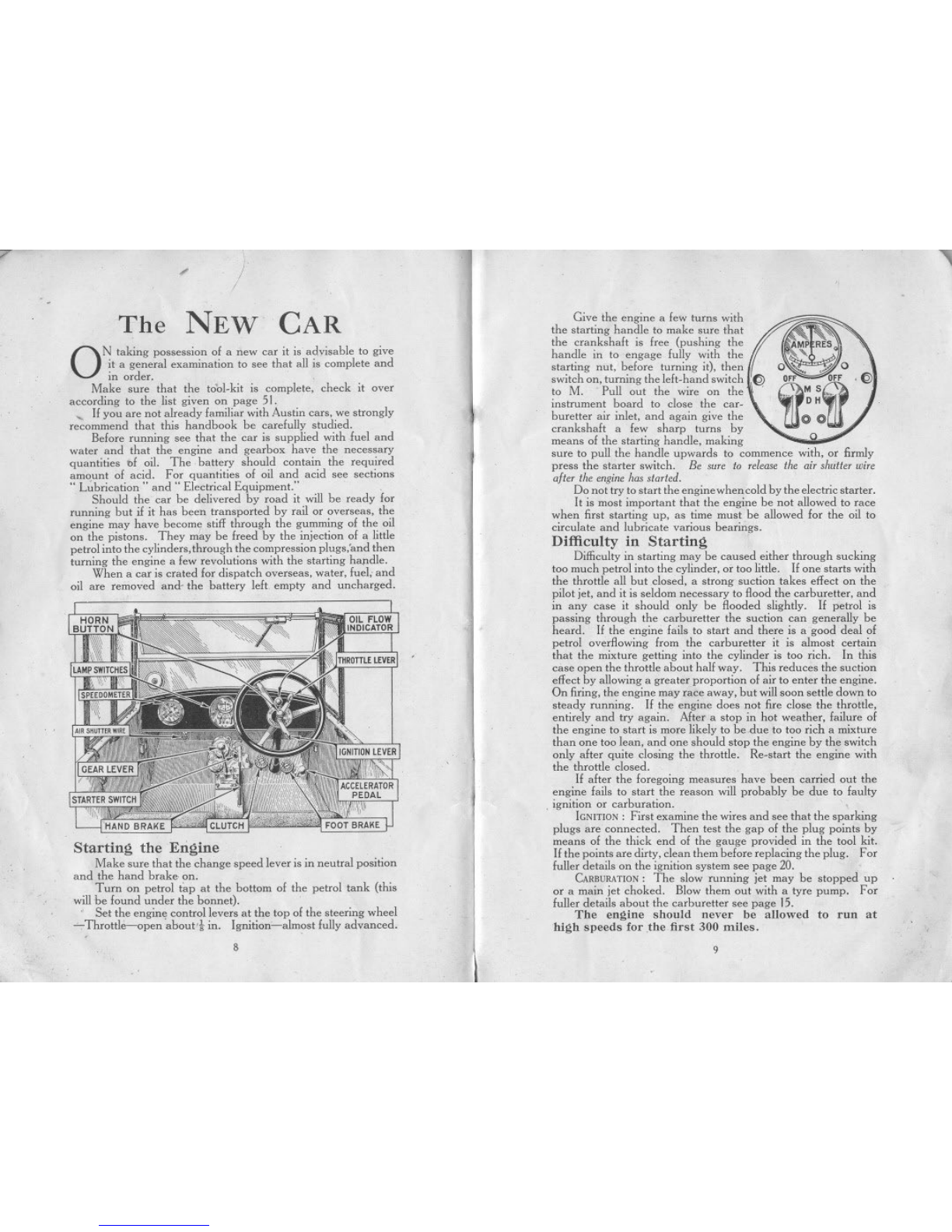

TheNEW CAR Give the engine a few turns with

the starting handle to make sure that

the crankshaft is free (pushing the

handle in to engage fully with the

starting nut, before turning it), then

switch on, turning the left-hand switch I:~

to M. Pull out the wire on the'

instrument board to close the car-

buretter air inlet, and again give the

crankshaft a few sharp turns by

means of the starting handle, making

sure to pull the handle upwards to commence with, or firmly

press the starter switch. Be sure to release the air shutter wire

after the engine has started.

Do not try to start the engine when cold by the electric starter.

It is most important that the engine be not allowed to race

when first starting up, as time must be allowed for the oil to

circulate and lubricate various bearings.

Difficulty in Starting

Difficulty in starting may be caused either through sucking

too much petrol into the cylinder, or too little. If one starts with

the throttle all but closed, a strong suction takes effect on the

pilot jet, and it is seldom necessary to flood the carburetter, and

in any case it should only be flooded slightly. If petrol is

passing through the carburetter the suction can generally be

heard. If the engine fails to start and there is a good deal of

petrol overflowing from the carburetter it is almost certain

that the mixture getting into the cylinder is too rich. In this

case open the throttle about half way. This reduces the suction

effect by allowing a greater proportion of air to enter the engine.

On firing, the engine may race away, but will soon settle down to

steady running. If the engine does not fire close the throttle,

entirely and try again. After a stop in hot weather, failure of

the engine to start is more likely to be due to too rich a mixture

than one too lean, and one should stop the engine by the switch

only after quite closing the throttle. Re-start the engine with

the throttle closed.

If after the foregoing measures have been carried out the

engine fails to start the reason will probably be due to faulty

.ignition or carburation.

iGNITION: First examine the wires and see that the sparking

plugs are connected. Then test the gap of the plug points by

means of the thick end of the gauge provided in the tool kit,

If the points are dirty, clean them before replacing the plug. For

fuller details on the ignition system see page 20.

CARBURATION:The slow running jet may be stopped up

or a main jet choked. Blow them out with a tyre pump. For

fuller details about the carburetter see page 15.

The engine should uever he allowed to run at

high speeds for the. first 300 miles.

9

ON taking possession of a new car it is advisable to give

it a general examination to see that all is complete and

in order. .

Make sure that the tool-kit is complete, check it over

according to the list given on page 51.

, Ifyou are not already familiar with Austin cars, we strongly

recommend that this handbook be carefully studied.

Before running see that the car is supplied with fuel and

water and that the engine and gearbox have the necessary

quantities bf oil. The battery should contain the required

amount of acid. For quantities of oil and acid see sections

.. L~brication .. and" Electrical Equipment." .

Should the car be delivered by road it will be ready for

running but if it has been transported by rail or overseas, the

engine may have become stiff through the gumming of the oil

on the pistons. They may be freed by the injection of a little

petrol into the cylinders, through the compression plugs,'and then

turning the engine a few revolutions with the starting hapdle.

When a car is crated for dispatch overseas, water, fuel, and

oil are removed and- the battery left empty and uncharged.

Starting the Engine

Make sure that the change speed lever is in neutral position

and the hand brake. on.

Turn on petrol tap at the bottom of the petrol tank (this

will.be found under the bonnet). .

., Set the engin, control levers at the top of the steering wheel

~Throttle-open abou\'i in. Ignition-almost fully advanced.

8

'" ~

CONTROL OF THE CAR

".

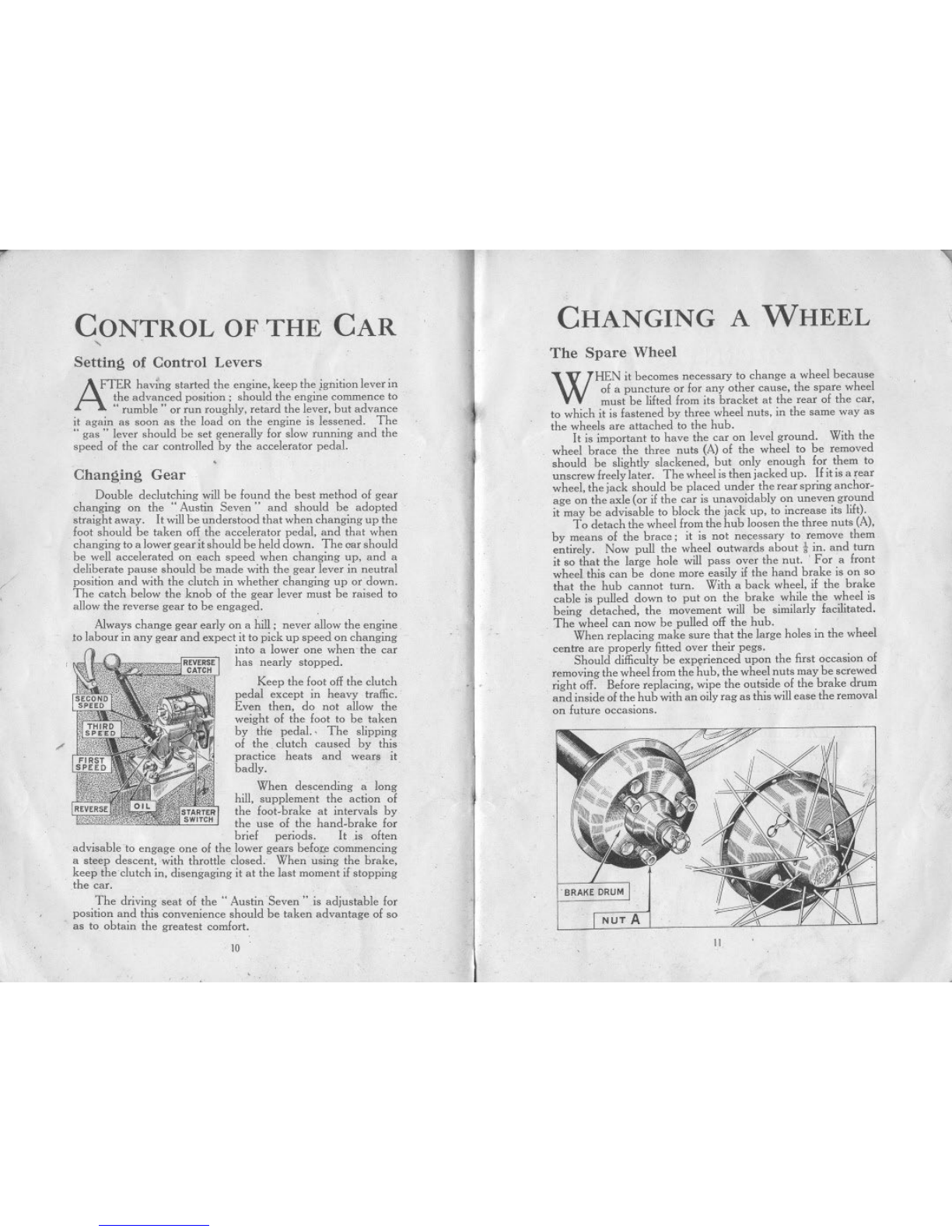

CHANGING A WHEEL

The Spare Wheel

Setting of Control Levers

AFTER hav:ng started the engine, keep the jgnition lever in

f-\. the advanced position; should the engine commence to

" rumble" or run roughly, retard the lever, but advance

it again as soon as the load on the engine is lessened. The

" gas" lever should be set generally for slow running and the

speed of the car controlled by the accelerator pedal.

Changing Gear

Double declutching will be found the best method of gear

changing on the" Austin Seven" and should be adopted

straight away. It will be understood that when changing up the

foot should be taken off the accelerator pedal, and that when

changing to a lower gear it should be held down. The car should

be well accelerated on each speed when changing up. and a

deliberate pause should be made with the gear lever in neutral

position and with the clutch in whether chang;ng up or down.

The catch below the knob of the gear lever must be raised to

allow the reverse gear to be engaged. ,

Always change gear early on a hill; never allow the eng;ne

to labour in any gear and expect it to pick up speed on changing

into a lower one when the car

has nearly stopped.

Keep the foot off the clutch

pedal except in heavy traffic.

Even then, do not allow the

weight of the foot to be taken

by the pedal.. The slipping

of the, clutch caused by this

practice heats and wears it

badly. '

When descending a long

hill, supplement the action of

the foot-brake at intervals by

the use of the hand-brake for

brief periods. It ,is often

advisable to engage one of the lower gears befo):.e commencing

a steep descent, with throttle closed. When using the brake,

keep the clutch in, disengaging it at the last moment if stopping

,the car.

The driving seat of the" Austin Seven .. is adjustable for

position and tlUs convenience should be taken advantage of so

as to obtain the greatest comfort.

"..

WHEN it becomes necessary to change a wheel because

of a puncture or for any other cause, the spare wheel

must be lifted from its bracket at the rear of the car,

to which it is fastened by three wheel nuts, in the same way as

the wheels are attached to the hub.

It is important to have the car on level ground. With the

wheel brace the three nuts (A) of the wheel to be removed

should be slightly slackened, but only enough for them to

unscrew freely later. The wheel is then jacked up. If it is a rear

wheel, the jack should be placed under the rear spring anchor-

age on the axle (or if the car is unavoidably on uneven ground

it may be advisable to block the jack up, to increase its lift).

To detach the wheel from the hub loosen the three nuts (A),

by means of the brace; it is not necessary to remove them

entirely. Now pull the wheel outwards about iin. and turn

it so that the large hole will pass over the nut. ' For a front

wheel this can be done more easily if the hand brake is on so

that the hub cannot turn. With a back wheel, if the brake

cable is pulled down to put on the brake while the wheel is

being detached, the movement will be similarly facilitated,

The wheel can now be pulled off the hub.

When replacing make sure that the large holes in the wheel

centre are properly fitted over their pegs.

Should difficulty be exp~rienced upon the first occasion of

removing the wheel from the hub, the wheel nuts may be screwed

right off. Before replacing, wipe the outside of the brake drum

and inside of the hub with an oily rag as this will ease the removal

on future occasions.

~;

NUT A

10 11.

Daily Attentions

I. Examine water level in radiator and

fill up to' within 2 in. of the top. Always

use the strainer when re-filling as

dirty water will cause the radiator

film to become choked.

2. Examine oil level in the crankcase

and add more oil if necessary. The

tell-tale dipper rod indicates the level

of the oil (see illustration, page 27).

3. Fill up the petrol tank if necessary.

Care should be exercised when filling

the tank not to spill the. petrol over

the engine.

r

~.

,~

.

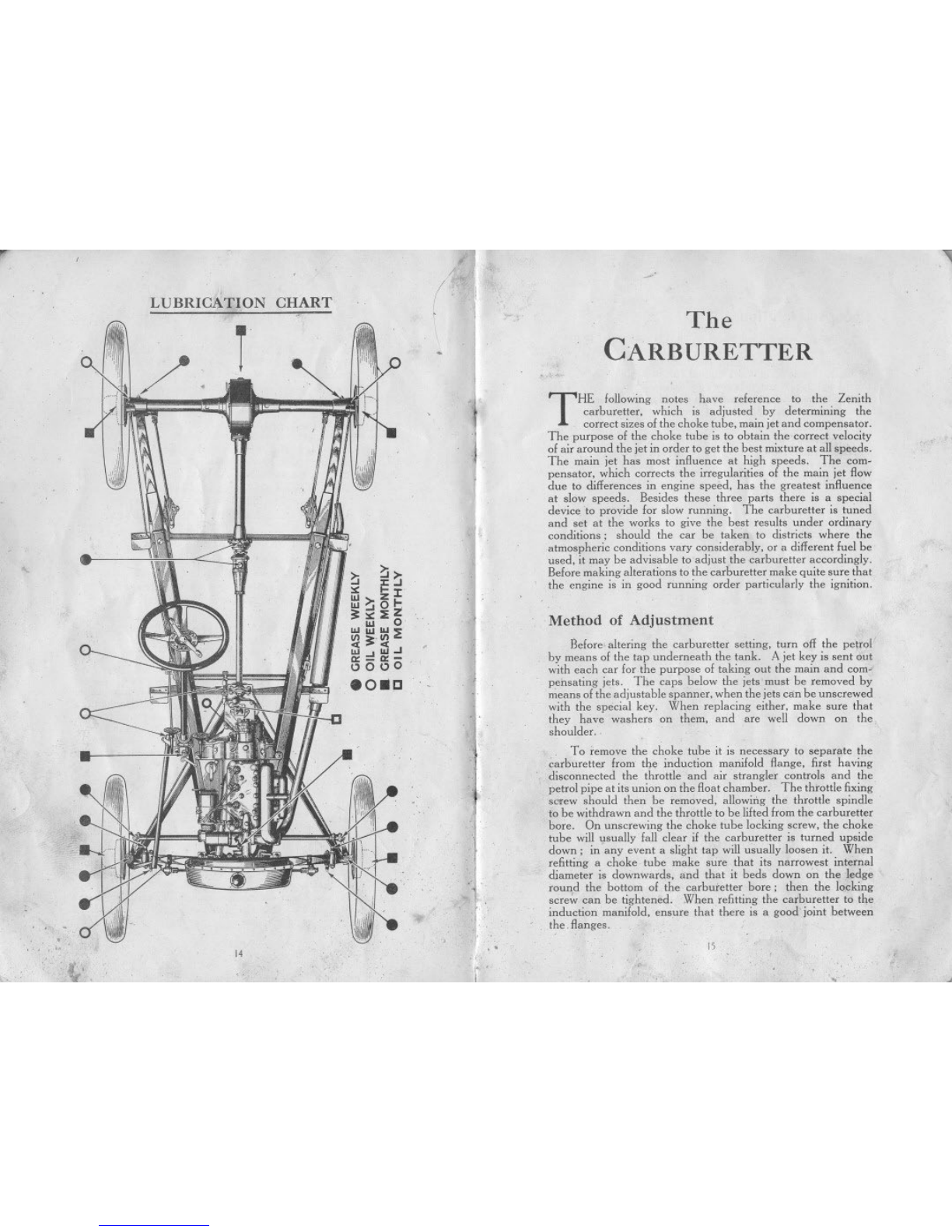

ON this and the opposite page is a handy

summary 01 all the attentions described in

this handbook. The attentions under.. the

daiIY, weekly, and monthly headings are based on

the assumption that the maximum mileage per

week does not exceed 300. .

The occasional attentions should not be neglected

if the car is to continue to run efficiently. When

relerring to the attentions below, see the lubrica-

tion chart on page 14.

PERIODICAL

ATTENTIONS

Weekly Attentions

I. With the grease. gun charge-

Front spring shackle pins (4).

Rear spring pins (2).

Front wheel swivel pins (2).

Steering cross tube (2):

2. Oil the following-

Handbrake gear.

Pedal gear and jaw joints.

Engine control and ball joints.

Clutch release ring.

Rear brake cam spindles (2).

Steering side tube joints (2).

3. Examine both sets of brakes, and

if necessary.

12

,

4. Inject high speed grease (such as

Messrs. Stern's" Diamol ") into the

universal joint at the rear end of the

propeller shaft using the special adapter

on the grease gun, and yellow grease into

the front end of the torque tube.

5. Test the tyres for correct pressure and

examine them for cuts (see page 50).

Monthly Attentions

I. Examine the oil level in the gearbox

which should contain two-thirds of

a pint, or measure 2-2t in. deep.

2. Charge the back axle case with a gunful

of grease and oil mixed half and half,

using the special adapter on the grease gun.

3. Fill all the hubs with grease, as

described on pages 3I and 32.

4. Charge with grease the steering worm

case through the nipple.

5. Examine the battery and see that the

connections are tight. For details see

page 35.

6. Give a charge of grease to the nipple

on the fan spindle.

J

1

'" ..

Occasional Attentions

adjust

Examine all bolts and nuts. such ris road spring clips,

cylinder head nuts, wheel nuts (these three especially when the

car is new), examine other parts such as steering connections,

the radius rod anchorage below the gearbox, and the torque

tube socket, neglect 01 which points might be lollowed by an

expensive repair, and the inability to use the car lor a lengthy

period.

Occasionally clean the petrol filler and float chamber

strainers, the radiator filler strainer, the oil filler strainer, and the

oil reservoir gauze (when the engine oil can be changed); also

ensure that the oil jets, under the plugs on the crankcase, are

clean. Drain the gearbox and refill with fresh oil (i pint).

Flush the. radiator through. Clean the magneio dis-

tributor, and the contact breaker points (adjust the latter),

the dynamo and starter commutators. Clean and lubricate

the shock absorbers, adjust the tappets, and the fan belt,

decarbonize the engine and grind-in the valves. Check the

alignment of the Iront wheels. For details 01 these attentions

refer to the pages tha t follow. .

13

"'"

..

LUBRICATION CHART

.

;,

~ ~~

i5 z:I

...~ol-

~:.:::i:Z

... 0

"""

U1 :>. U1 0:;

«:>«

"' "'...1

~-~-

0000

808C

14

/!

(

,

,

,.,

,"

"";.

~'

"

-

The

CARBURETTER

,THE following notes have reference to the Zenith

carburetler, which is adjusted by determining the

correct sizes of the choke tube, main jet and compensator.

The purpose of the choke tube is to obtain the correct velocity

of air around the jet in order to get the best mixture at all speeds.

The main jet has most influence at high speeds. The com-

pensator, which corrects the irregularities of the main jet flow

due to differences in engine speed, has the greatest influence

at slow speeds. Besides these three parts there is a special

device to provide for slow running. The carburetler is tuned

and set at the works to give the best results under ordinary

conditions; should the car be taken to districts where the

atmospheric conditions vary considerably, or a different fuel be

used, it may be advisable to adjustthe carburetter accordingly.

Before making alterations to the carburetler make quite sure that

the engine is in good running order particularly the ignition.

Method of Adjustment

Before- altering the carburetter setting, turn off the petrol

by means of the tap underneath the tank. A jet key is sent out

with each car for the purpose of taking out the main and corn'

pensating jets. The caps below the jets must be removed by

means of the adjustable spanner, when the jets can be unscrewed

with the special key. When replacing either, make sure that

they have washers on them, and are well down on the

shoulder. . .

To remove the choke tube it is necessary to separate the

carburetter from the induction manifold flange, first having

disconnected the throttle and air strangler controls and the

petrol pipe at its union on the float chamber. The throttle fixing

screw should then be removed, allowing the throtlle spindle

to be withdrawn and the throttle to be lifted from the carburetler

bore. On unscrewing the choke tube locking screw, the choke

tube will usually fall clear if the carburetter is turned upside

down; in any event a slight tap will usually loosen it. When

refitting a choke tube make sure that its narrowest internal

diameter is downwards, and that it beds down on the ledge

round the bottom of the carbutetler bore; then the locking

scre~ can be tightened. When refitting the carburetter to the

induction manifold, ensure thal there is a good' joint between

the. flanges.

15 ,

~ ,

r

{

Poor Acceleration

When picking up is bad, or when it is impossible to obtain

a sharp acceleration no matter what size of compensator is used,

the choke tube is too large. The tests for" pick-up" should

be made on the level. Let the car run at a good .speed, slow

down slightly; then press the accelerator down sharply as far

as it will go. The car should then quickly pick up its previous

speed without hesitation.

If, instead of accelerating, the engine stops, try larger

compensators. If, in spite of this, the picking up is not good,

the choke tube is too large, in which case fit another, one or two

millimetres smaller, and try again until the acceleration is perfect.

AI. HOLE

CHOKE

TUBE

MAINJET

COMPENSATING JET

CAPS

Tb. Z.nUh ca,bu,""", type 2>F. Th. ~tand..d .e"lng I.,

choke tnb. 15, main Jet 70, camp.n.atlng Jet 75, .Inw ,unnlng

tnbe 26.35.

Lack of Speed

With too small a choke tube the pick-up is excellent but

the speed attained on the level with the accelerator right down

is insu/ficient-a larger choke tube is then fitted, and the jet

altered proportionally, when the tests are continued until a

satisfactory maximum speed is attained.

Choking and" Hunting"

To ascertain the correct size of the main jet, the test is also

made on the level at high speed. A jet ",hich is much too large

causes choking, and the engine often runs jerkily and hunts.

The petrol consumption is also excessive. The jet that gives the

greatest speed on the level is chosen. If two jets give an equal

speed, choose the smaller on the score of economy.

16

.

~

No Power

When the car gets away badly, and popping.back occurs

in the carburetter when accelerating, the main jet is too small.

This popping.back occurs at irregular intervals, and the engine

has little power and cannot drive the car at a high speed. Fit

larger jets until these explosions in the inlet pipe disappear and

then fest until the right jet has been found, as indicated in

previous paragraph. .

The popping-back may also be due to air leaking into the

induction pipe through joints which are not air-tight, to-leakage

at the extra air valve, or to'thevalves not closing properly. Test

the tappet clearances by the thin blade of the sparking plug

and tappet clearance gauge. In some cases popping back is

due to the engine being cold, and will cease when it has been

running for a little time. .

I

i

Irregular Firing

The trials of different compensators ~hould take place

up an incline, with the engine driving the car at a speed it can

scarcely maintain, say 300 to 500 Lp.m. The compensat~r is

too large when the engine at this speed runs with an irr~gular,

jerky motion; the hunting which takes place at high speed in

the case of too large a main jet is found at low speeds with too

large a compensator. The size of the compensator is decreased'

until all the cylinders fire evenly and the exhaust is quite regular.

As in the case of the main jet, if two compensators gi):'e equal

results. choose the smaller on the score of economy. The

compensator plays a great part in the picking-up, but when the

size of the former is determined according to the above method,

it is generally suitable for an excellent acceleration.

w

I

Slow Running Device

Nofe that too much petrol for slow running causes choking

and hesitation in pick-up. A want of petrol, on the other hand,

causes a loss of power and misfiring at the same time. It i.

therefore necessary to regulate the slow running as carefully ';S

possible. By first releasing the lock nut and then turning the

knurled screw B to the right a gre...ter flow of petrol.is obtained,

while it can be cut down by'furning the screw to the left.

This device can be drawn out after releasing the lock.nut ,

and slackening the round. headed screw A on the side. It is

possible to unscrew the lower half C, from the upper with a pair

of pliers. in order to see if it is clear.

17

--., I

"

There are other factors quite apart from the carburetter

which have great influence on slow running (slow running when

the engine is out'of gear and the car is stationary).

These factors are:-

Joints not air-tight. Valve guides worn. Valves not

seating. 19nition too much advanced.

Engine Misfires and Stops

In tests made as in the last instance. the engine misses fire

now and again, the transmission receives jerks, ami the engine

finally stops. In this case fit a larger compensator until the

engine runs regularly. '

,I

The Float Chamber

Petrol leakage from the float chamber may be due to the caps

under the jets not being tight..or a leaking petrol pipe union.

If no leakage seems possible' at these points, suspect float

chamber derangement, which is causing petrol to overflow, tbe

jets. It may be that the float control is out of adjustment, the

float may be perforated, or the needle not seating properly

owing to dirt on the needle seating. The remedy for the last

mentioned defect is obvious; the first two defects should be

left to an expert to remedy. When replacing the float chamber

cover, ensure that the needle has entered its seating, and is free

to be moved by the float; also that the cover beds down

properly, then secure it with the clip.

w..."

Petrol Flow

If the petrol supply from the Autovac is unrestricted yet

difficult starting points to insufficient petrol. there is a restridion

somewhere in the carburetter. First, see that the air vent in the

float chamber cover, under the retaining chp, is clear. Should

it be so, the next point to examine is,the filter below the float

chamber, and the passage from it to the needle seating. Access

to this filter is given by removing the petrol pipe union and un-

screwing the petrol inlet nut, on the bottom of the float chamber.

,The slowrunning tube and jet maybe stopped up. Remove

the slow running tube bodily, having loosened its locking screw.

In the bottom of the tube is a small filter which can be prised out

and cleaned. The bottom portion of the tube, comprising the

jet, may be then unscrewed from the top portion, and the jet

cleaned if stopped up; two flats on the jet allow a small spanner

to be used to unscrew it. Lastly the compensating or main

jets may be choked. Remove them and clear them. Never

insert anything in any of the jets; always blow through to clear

them; a tyre pump can be used if desired. When refitting the

slow running tube ensure that it beds down to its collar at the

top, with the small projection under the collar fitting the groove

in the carburetter casting; then tighten the locking screw.

18

"

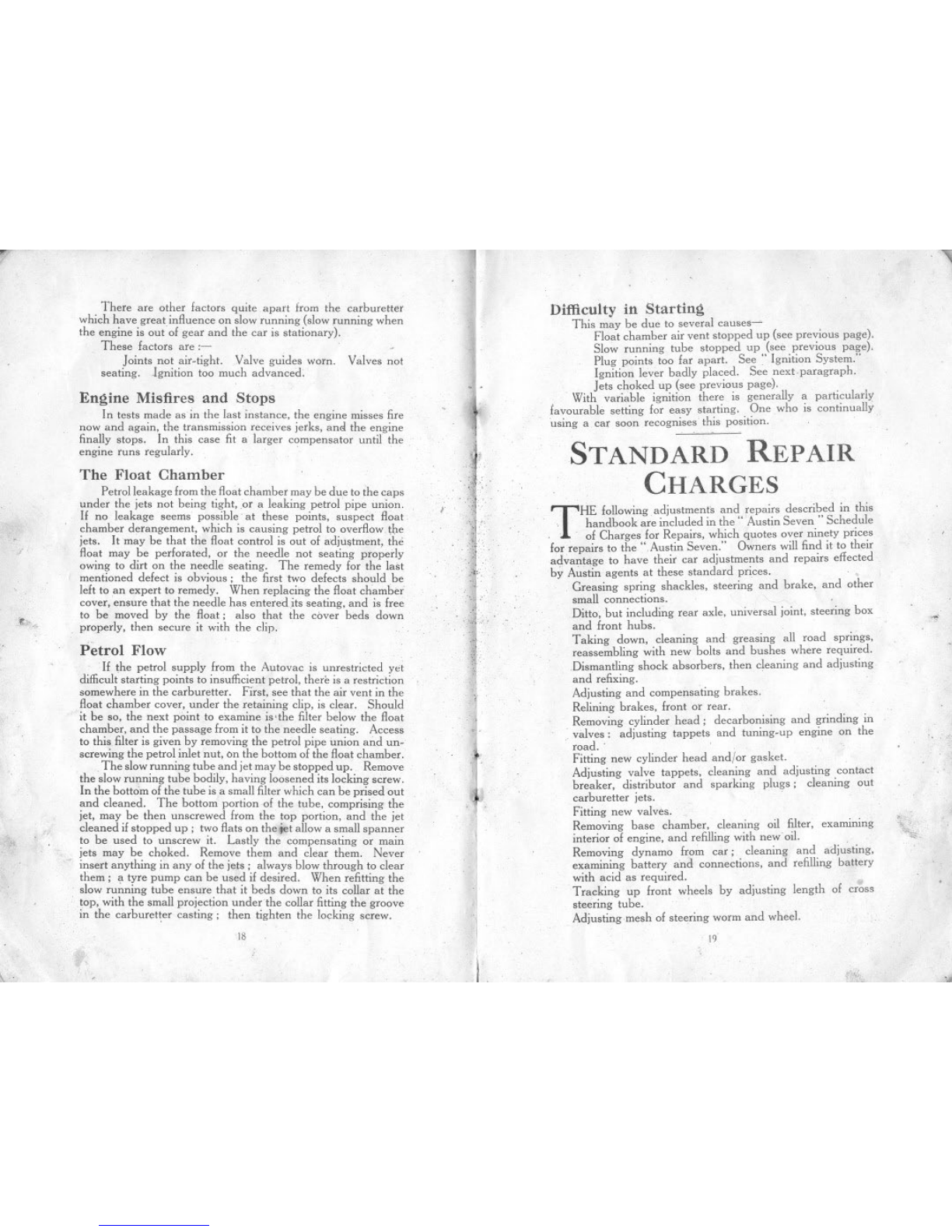

Difficulty in Starting

This may be due to several cause'~

Float chamber air vent stopped up (see previous page),

Slow running tube stopped up (see previous page).

Plug points too far apart. See" Ignition System."

Ignition lever badly placed. See next.paragraph.

Jets choked up (see previous page),

,With variable ignition there is generally" particularly

favourable setting for easy starting. One who is continually

using a car soon recognises this position.

,.

STANDARD REPAIR

CHARGES

THE following adjustments and repairs described in this

,handbook are included in the" Austin Seven" Schedule

, ' 'of Charges for Repairs, which quotes over ninety prices

for repairs to the ".Austin Seven." Owners will find it to their

advantage to have their car adjustments and repairs e!fected

by Austin agents at these standard prices.

Creasing spring shackles, steering and brake, and other

small connections. .

,Ditto, but including rear axle, universal joint, steering box

and front hubs.

Taking down, cleaning and greasing all road springs,

reassembling with new bolts and bushes where required.

Dismantling shock absorbers, then cleaning and adjusting

and refixing. "

Adjusting and compensating brakes.

Relining brakes, front or rear.

Removing cylinder head; decarbonising and grinding in

"valves: adjusting tappets and tuning-up engine on the

road.' ' ,

Fitting new cylinder head and/or gasket.

Adjusting valve tappets, cleaning and adjusting contact

breaker, distributor and sparking plugs; cleaning out

carburetter jets.

Fitting new valves.

Removing base chamber, cleaning oil filter, exarmnmg

interior of engine, and refilling with new oil.

Removing dynamo from car; cleaning and adjusting,

examining battery and connections, and refilling battery

with acid as required.

Tracking up front wheels by adjusting length of cr~ss

steering tube.

Adjusting mesh of steering worm and wheel.

19

~

.

"

..~

I

I

~

I '..

7'

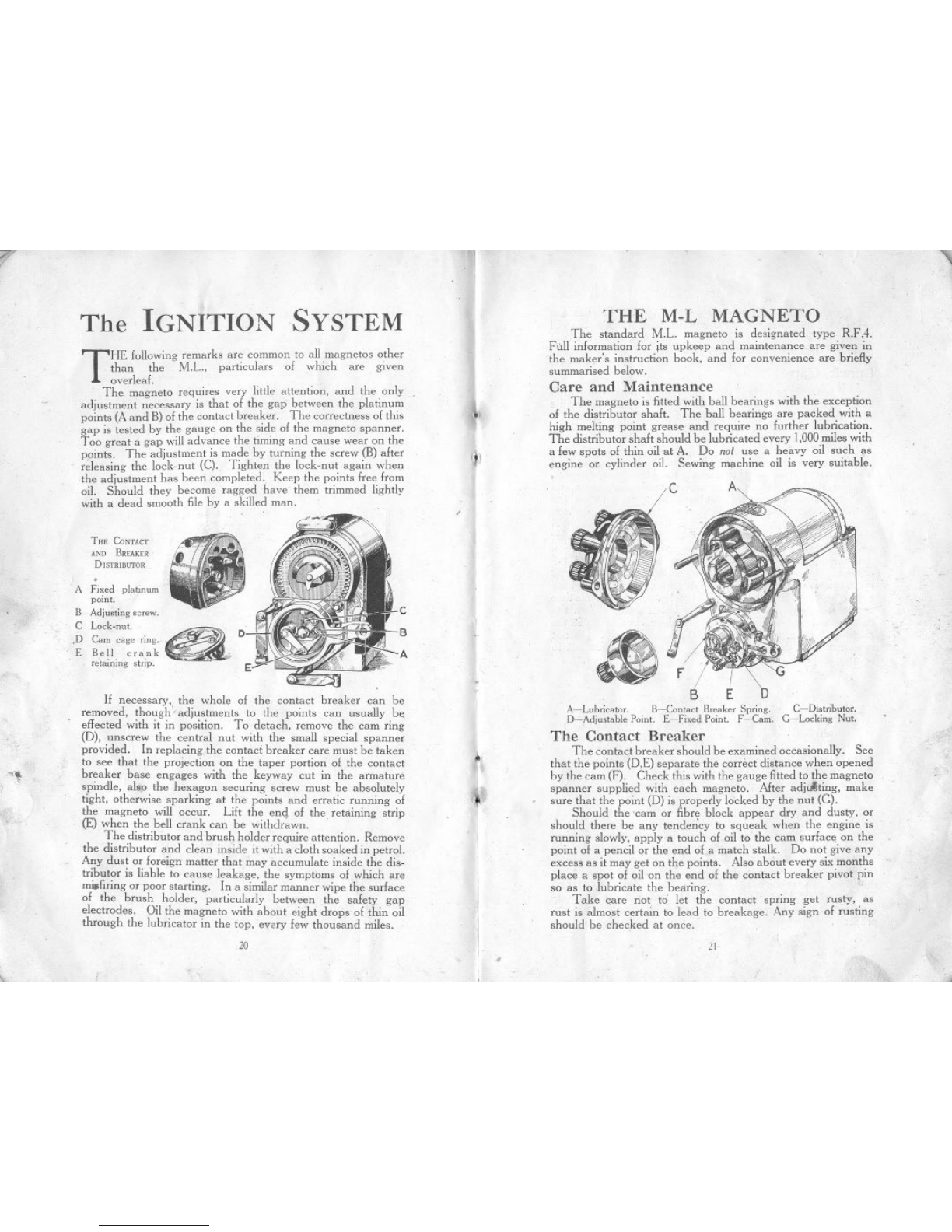

The IGNITION SYSTEM

THE following remarks are common to

.

all magnetos other

than the M.L., particulars of which are given

overleaf.

The magneto requires very little attention, and the only -

adjustment necessary is that of the gap between the platinum

points (A and B) of the contact breaker. The correctness of this

gap is tested by the gauge on the side of the magneto spanner.

Too great a gap will advance the timing and cause wear on the

p,oints. The adjustment is made by turning the screw (B) after

releasing the lock.nut (C). Tighten the lock-nut again when

the adjustment has been completed. Keep the points free from

oil. Should they become ragged have them trimmed lightly

with a dead smooth file by a skilled man.

THE CoNTACT

AND BREAKER

DISTRIBUTOR

.

A Fixed platinum

point.

B Adjusting mew,

C Lock.nut.

.D Cam cage ring.

E Bell crank

retaining ",ip. aB

A

E

.."

If necessary, the whole of the contact breaker can be

removed, though" adjustments to the points can usually be

.effected with it in position. To detach, remove the cam ring

(D), unscrew the central nut with the small special spanner

provided. In replacing the contaci breaker care must be taken

to see that the projection on the taper portion of the contact

breaker base engages with the keyway cut in the armature

spindle, also the hexagon securing screw must be absolutely

tight, otherwise sparking at the points and erratic running of

the magneto will occur. Lift the end of the retaining strip

(E) when the bell crank can be withdr~wn. .

The distributor and brush holder require attention. Remove

the distributor and clean inside it with a cloth soaked in petrol.

Any dust or foreign matter that may accumulate inside the dis.

tributor is liable to cause leakage, the symptoms of which are

m.firing or poor starting. In a similar manner wipe the surface

of the brush holder, particularly between the safety gap

electrodes. Oil the magneto with about eight drops of thin oil

through the lubricator in the top, .every few thousand miles.

20

..

1

I

4\

~)

..

.

~

I

"

THE MAGNETOM~L

The standard M.L. magneto is designated type R.FA.

Ftill information for jts upkeep and maintenance are given in

the maker's instruction book, and for convenience are briefly

summarised below.

Care and Maintenance

The magneto is fitted with ball bearings with the exception

of the distributor shaft. The ball bearings are packed with a

high melting point grease and require no further lubrication.

The distributor shaft should be lubricated every 1,000miles with

a few spots of thin oil at A. Do not use a heavy oil such as

engine or cylinder oil. Sewing machine oil is very suitable.

c

B

A~Lubricator. B-Contact B<eaker Spring. C-Di,tributor.

D-Adju,table Point. E-Fixed Point. F-Cam. G-Locking Nut.

The Contact Breaker

The contact breaker should be examined occasionally. See

that the points (O,E) separate the correct distance when opened

by the cam (F). Check this with the gauge fitted to the magneto

spanner supplied with each magneto. After adj,jting, make

sure that the point (D) is properly locked by the nut (G).

Should the 'cam or fibre block appear dry and dusty, or

should there be any tende,{cy to squeak when the engine is

running slowly, apply a touch of oil to the cam surface on the

point of a pencil or the end of a match stalk. Do not give any

excess as it may get on the points. Also about every si." months

place a spot of oil on the end of the contact breaker pivot pin

so as to lubricate the bearing.

Take care not to let the contact spring get rusty, as

rust is almost certain to lead to breakage. Any sign of rusting

should be checked at once.

21

.

r

Do not attempt io run with a very large gap between the

contact points. They wear more rapidly and the machine will

be less efficient. because the armature will not be in the best

position when the circuit is broken.

Spark Gap

Do not use any form of amplifier or spark gap in connection

with the magneto. No improvement will be obtained. and its

use may lead to high voltages and possible breakdown.

I

Insulating Surfaces

As wet and dirt on insulation will often cause leakage and

bad starting. it is advisable to keep the outside of the distributor.

to which the HT. cables are connected, reasonably clean and

free from accumulation of dirt and dust. In addition the

distributor should be removed about every 5,000 miles and the

interior wiped out with petrol and a soft rag. As the R.FA

magneto is of the revolving field type there is no br'lsh holder

and slip ring at the other end of the magneto to require attention

and the whole of the H.T. insulation is exposed when the

distributor block is removed. H the insulation of the distributor

rotor, or the insulating bush. passing through the centre of the

gear wheel. are dirty these should be cleaned. at the same time

care being taken not to damage or break them. When the

distributor cover is removed. examine the carhon brush in the

distributor rotor, making sure that it slides freely. Do not

remove it from its guide unnecessarily, and take care not to

strain the spring.

TROUBLES REMEDIESAND

IRREGULAR firing or faulty ignition may be traceable to

slight defects in the magneto or carburetter. Apartially

choked jet. or an incorrect petrol level, may be the fault.

Air leaks in the induction system are a possible cause of bad

starting and irregular running at low speeds.

For faulty ignition. First examine the sparking plugs and

test the gap of the plug points by means of the thick blade of the

sparking plug and tappet clearance gauge provided in the kit.

H the points are dirty, clean them before replacing. Asudden

failure of the ignition may result from the short circuiting of the

switch cable attached to the terminal on the inspection cover of

the contact-breaker. This can be readily detected by discon-

necting this cable from the terminal, when the en!!iI\~ ~!!Qu!dliie .

properly. .

22

~

--, ~

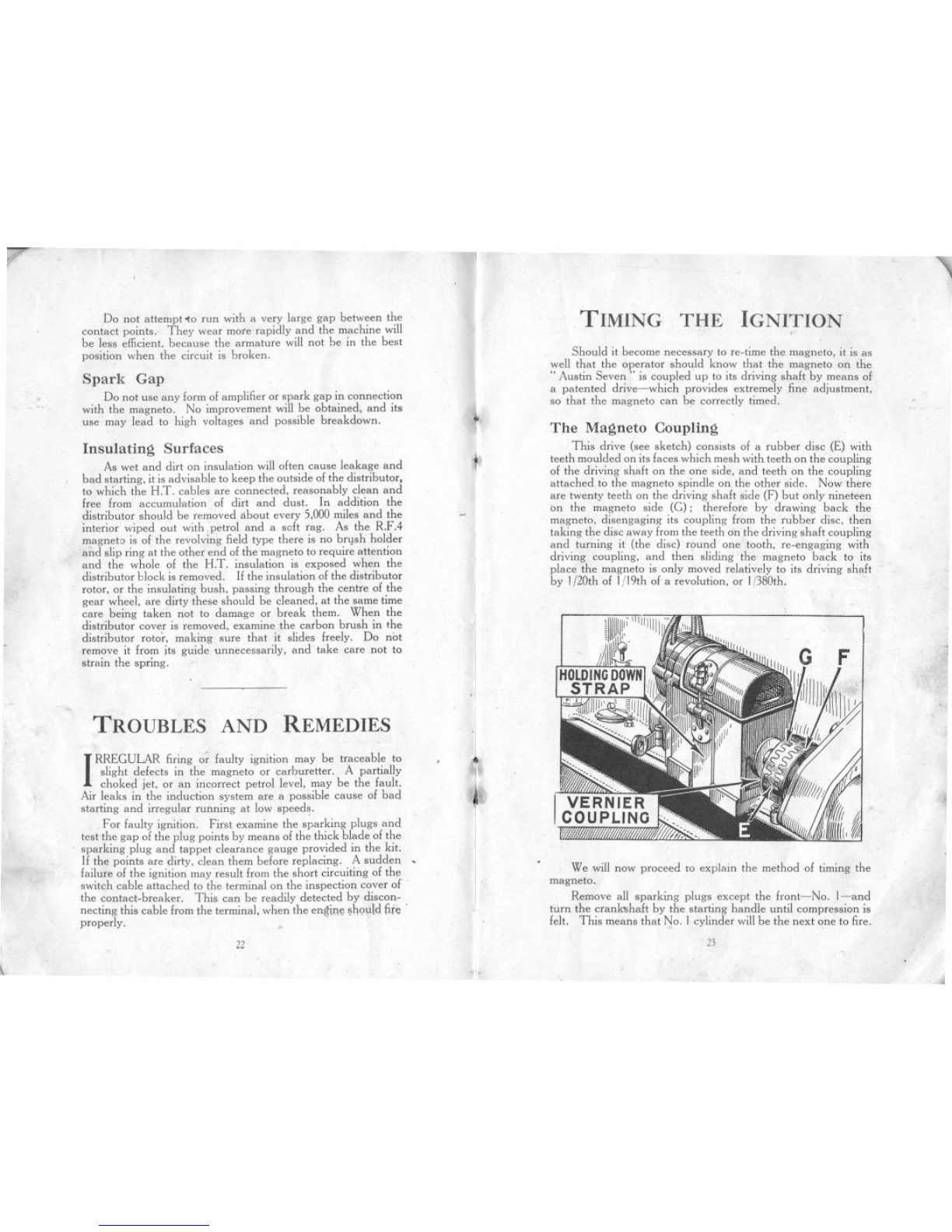

.TIMING THE IGNITION

t.

~

Should it become necessary to re-time the magneto, it is as

well that the operator should know that the magneto on the

.. Austin Seven" is coupled up to its driving shaft by means of

a patented drive-which provides extremely fine adjustment.

so that the magneto can be correctly timed.

The Magneto Coupling

This drive (see sketch) consists of a rubber disc (E) with

teeth moulded on its faces which mesh with teeth on the coupling

of the driving shaft on the one side, and teeth on the coupling

attached. to the magneto spindle on the other side. Now there

are twenty teeth on the driving shaft side (F) but only nineteen

on the magneto side (G); therefore by drawing back the

magneto. disengaging its cou,pling from the rubber disc. then

taking the disc away from the teeth on the driving shaft coupling

and turning it (the disc) round one tooth. re-engaging with

driving coupling, and then sliding the magneto back to its

place the magneto is only moved relatively to its driving shaft

by I{20th of I/19th ola revolution, or 1{380th.

~

.;

;~:

I

I

I

1

We will now proceed to explain the method of timing the

magneto.

Remove all sparking plugs except the front-,-No. I-and

turn the cranbhaft by the starting handle until compression is

felt. This means that No. 1 cylinder will be the next one to fire.

23

i

rI

Remove the starte~ motor with its casing by unscrewing the"

securing studs, one on each side of the casing, and. lifting the

assembly clear vertically off the locating dowel on the crank-

.case, A line willbe seen on the back of the flywheel, marked...

I and 4 (see illustration on page 29), This line is parallel to the

throws of the crankshaft, and when this line .is verticalitiOo

naturally follows that Nos, I and 4 pistons are at the top of

their stroke. In this case, however, we are only dealing with

No. J. Now turn the flywheel until this line is Iiin. to I! in.

before the top centre. This is the position at which the spark

should take place at the sparking plug, when the ignition is

fully advanced.

Now fully advance the ignition lever at the top of the

steering wheel. Disconnect the contact breaker control and

magneto strap, draw back magneto to disconnect the coupling.

Turn the spindle by hand until the carbon brush of the dis-

tributor is on the segment corresponding to the magneto I~ad of

No. I cylinder, and carefully leave it so that the points of the

contact breaker are just commencing to separate. Thi" is the

position where the spark takes place. .

Now hold the rubber disc in between the driving shaft and

magneto, and slide the magneto towards its place-'-Without

having turned the spindle-leaving just sufficient room for the

rubber disc to be turned round, without being in engagement

on either side. Turn the rubber disc until the teeth on each

side come exactly opposite those they mesh with. Then push

the magneto up into place.

Checking the Timing

If nothing has moved while this latter part of the operation

has been taking place, the magneto should be correctly timed,

but as it is extremely difficult, wiihout making use of the fine

adjustment, to do this, the timing should now be checked.

Turn the engine round two revolutions, bringing l\Jo. 'i

piston into its firing position again, and set the line o~ th';

flywheel. as before described. Check the contact breaker.

If it has not commenced to open, the timing is late. The

timing is advanced by drawing the magneto' back, without

revolving it; detaching the rubber disc from both sets of teeth

and turning it one tooth in the opposite direction to that in which

the magneto revolves-which in this case means turning the top

of the disc towards the operator as he stands at the offside of

the car. This, as before described, will advance the firing

point of the magneto, relative to the driving spindle, 1/380th

of a circle. Check and if still timed late, advance still furth~r.

To retard, the coupling will be turned one or more teelh,

as required, in the opposite direction.

The order in which the cylinders fire is, from the front, 1-3

-4-2. ..

24

....

.~

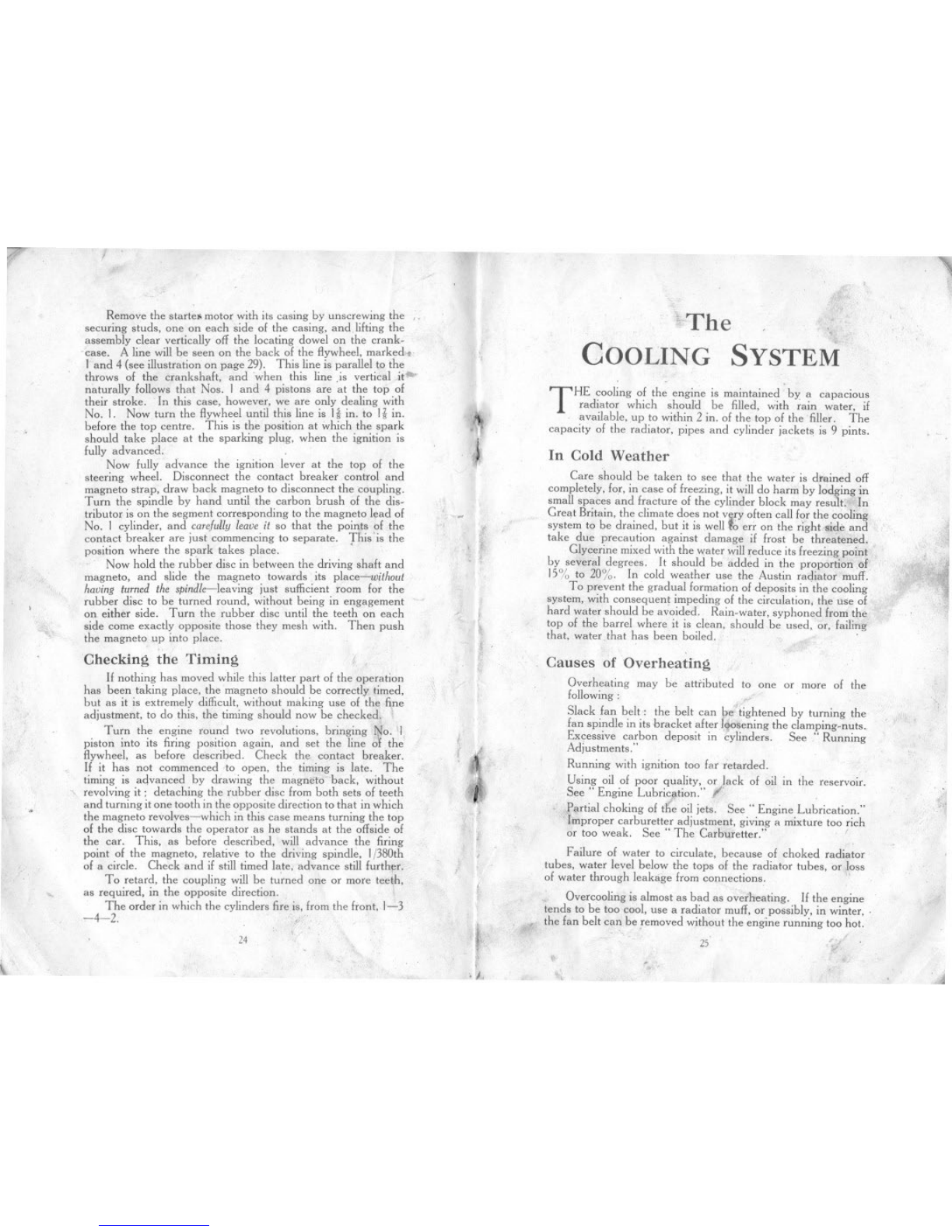

-The

COOLING SYSTEM

~

~.

THE cooling of the engine is maintained by a capacious

radiator which should be filled, with rain water, if

. available, up to within 2 in. of the top of the filler. The

capacity of the radiator, pipes and cylinder jackets is 9 pints.

In Cold Weather

Care should be taken to see that the water is drained off

completely, for, in case of freezing, it will do harm by lodsing in

small spaces and fracture of the cylinder block may result;. In

Great Britain, th~ climate d?e.s not v'J!Y often call f~r the .cooling

system to be dramed, but It ISwell fa err on the nght sIde and

take due precaution against damage if frost be threatened.

Glycerine mixed with the water will reduce its freezing point

by several degrees. It should be added in the proportion .of

15% to 20%. In cold weather use the Austin raqiator muff.

To prevent the gradual formation of deposits in the cooling

system, with consequent impeding of the circulation, the USe of

hard water should be avoided. Rain-water, syphoned from the

top of the barrel where it is clean, should be used, or, failing

that, water that has been boiled.

I

J

I

tiI

t

Causes of Overheating

Overheating may be attiibuted to one or more of the

following;

Slack fan belt: the belt can be' tightened by turning the

fan spindle in its bracket after /,4osening the clamping-nuts.

Excessive carbon deposit in cylinders. See" Running

Adjustments."

Running with ignition too far retarded.

Using oil of poor quality, or lack of oil in the reservoir.

See" Engine Lubrication." I' .

partial choking of tt;, oil jets. See" Engine Lubrication."

Improper carburetter adjustment, giving a mixture too rich

or too weak. See" The Carburetter." I

Failure of water to circulate, because of choked radiator

tubes, water level below the tops of the radiator tubes, or loss

of water through leakage from connections.

Overcooling is almost as bad as overheating. If the engine

tends to be too cool, use a radiator muff, or possibly, in winter,

the fan belt can be removed without the engine running too hot.

I

*

if

I

'J.

25 ,.

j

;'

The entire circula'ing system should be thoroughly flushed

out occasionally, To do this open the drain tap at the bottom,

place a hose in the filler, and run fresh water through. .

Trouble arising from a damaged radiator generally

necessitates its dismantlirig and despatch to a repair depot.

How To USE THE

GREASE GUN

Screw the handle right out. Unscrew the extension piece

by the knurled nut at the base of the barrel and fill the barrel

with grease; then replace. Give the handle one complete

turn: this fills the telescopic extension piece at the end of the

gun which will project. Now place the end of the gun on the

nipple attached to that part of the car which it is. desired to

grease, and push. The extension piece closes and discharges

the grease into the nipple.

Give the handle another turn and the gun is once more

charged. Continue until the barrel is empty and then refill.

For the rear universal joint and the back axle a special

adapter is used on the gun in place of the standard telescopic

end. This adapter screws into the part to be greased, in place

of the plug. When replacing the plug, do not omit its washer.

It is important not to let dirt get into the adapter which, when

not in use, is screwed onto the side of the gun.

'" /, DON'T!

Don't, pleasedon't-

Don't leave the car in gear with the handbrake off.

Don't make a fast run with the radiator muff down.

Don't fill the radiator with cold water when the engine is hot.

Don't try to turn the engine without first pushing the starting.

handle in to engage fully with the starting nut.

Don't be cruel to the starter if the engine will not fire.

Don't touch the reverse catch when changing gear.

D~n't put an excessive quantity of lubricant in the gear box.

Don't pour oil into the engine with the strainer removed.

Don't forget the ignition switch when starting up.

Don't run the engine in a closed garage. (The exhaust gases

are highly toxic and a very small amount in a restricted

atmosphere will produce grave, if not fatal, results.)

26

'"

";

...

-

i

"

'1.

.

i

~

LUBRICATION

Choice of Lubricants

FOR the engine or gear box use one of the followin.

g oils:-

Stern's" Sternol W.W:' Heavy; Price's" Motor-

ine C:'; Speedwell .. Sans Egal Zero"; .. Triple

Shell"; .. Mobiloil BB:'; .. Speedolene B. Heavy"; T exaco

.. Heavy"; Filtrate" Extra Heavy"; .. Royal Snowdrift 3 .. ;

Wakefield's .. Castrol XL"; and. Duckham's .. Adcol NP 3

and 4:'

Use ordinary" engine" oil in the small can,. and ordinary

yellow grease for greasing.

Both these lubricants can be obtained from any garage or

repair shop.

Use" High Speed" grease for the rear universal joint .of

the drive shaft,

The Engine

When the neW car is sent out the engine and gearbox i.

filled with" Sternol W.W. Heavy" to the proper level. On no

account must different brands of oil be used in the engine at the

same time or mixed in any way. If the oil is too thick it will

tend to clog and carbonise. and if too thin it might lead to

scoring of the pistons and bearings. Assurance that oil is

continuously circulating is given to the driver by means of

the tell.tale button on the instrument board, which protrudes

when the oil is circulating.

.It is essential that all receptacles foroil be kept perfectly

clean. Dirty oil

leads to undue

wear ofall bearings,

or might even clog

up the oiling

system and prevent

it ,,:orking, thus

causmg an engme

seizure and much

troyble and ex.

perise. The oil

filler strainer (A)

is detachable for

cleaning. After the

first 500.800miles

running, drain the

original oil from

/I

"

27

t-

I

the 1<eservairby remaving the plug in the battam, while the

engi~ is hat. Drain the reservair campletely. Never pqur

ail i~t" the engine except thraugh the strainer.

After the first re-filling it is advisable ta change the ail in the

engine entirely alter every 1,200ta 1,500 miles running ar saaner.

Every 2,400-3,000 miles remave the ail r",ervair. The

gauze oil tray will then be accessible lor remaval. Carelully

clean the gauze and remove all dirt Irom inside the reservoir.

and replace them, Carelully remake the jaint with the packing

washer, cavering bath sides '11it with grease. When tightening

up the nuts halding the ail reservoir to the crankcase, do not

pull up ane nut tight, but tighien each nut equally, a little at

a time. See that the draipplug is screwed up tight: then fill the

crankcase with oil to the maximum level as shawn an the

dipper rad, B. Abaut half a gallan will be enaugh ta fill.

Always inspect the level '11'the ail and add, enaugh ta fill,

ta the correct level belore starting an a lang journey.

The ail level shauld nat be allawed to go below'! inch an

the battam '11the.dipper rad. It is advisable ta wipe the dipper J

rod belare taking. the reading '11 the level, and the reading J

shauld anly be taken when the engine is nat running and the

car is an the level ground.

The main bearings '11the engine are '11the roller type, and

the aily vapaur in the crankcase is quite sufficient ta lubricate

these.

The pista';1i' are alsa lubricated by the aily vapour.

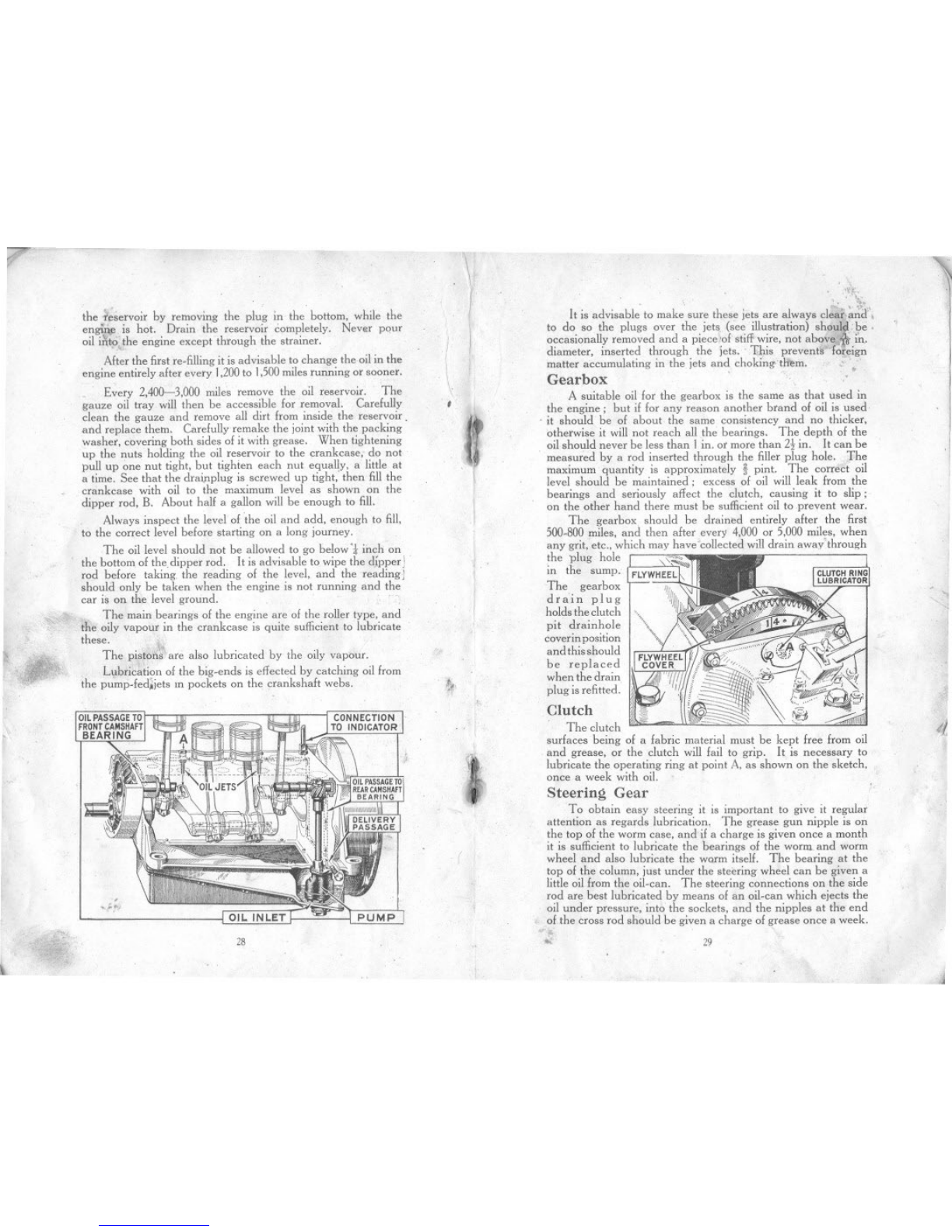

L",bricatian 01 the big-ends is effected by catching aillram

the pump-Iedjjets m pockets on the crankshalt webs.

.

.

.."." PUMP

28

~. .',

,. ,

':~~'.

'. "i.

It is advisable ta make sure these jets are always cle~,,~rit.

ta da sa the plugs over the jets (see illustratian) shau!~t pe .

a~casianall'yremavedand a piece:ol stiff wire, nat abo~e~in.

diameter, mserted through the Jets. 1;l)is prevent~ 'Im:elgn

matter accumulating in the jets and chaking.t~m.

Gearbox .'

A suitable aillar the gearbox is the same as that used in

the engine; but il lar any reasan anather brand 01ail is used,

. it should be '11abaut the same cansistency and na thicker,

atherwise it will nat reach all the bearings. The depth 01the

ail shauld never be less than I in. ar mare than 2t in. It can be

measured by a rad inserted through the filler plug hale. The

maximum quantity is appraximately !pint. The correct oil

level shauld be maintained; excess '11ail will leak Iram the

bearings and seriausly affect the clutch, causing it to slip;

an the ather hand there must be sufficient ail ta prevent wear.

The gearbax. shauld be drained entirely alter the lirst

500-800nilles. and then alter every 4.000 ar 5,000nilles. when

any grit, etc., which may have'collected willdrain away'through

the plug hale 's..

in the sump. FLYWHEEL

The gearbax T

drain plug 111/11

halds the clutch 1111<,.

pit drainhale

caverin pasitian

and this shauld

be replaced

when the drain

plug is relitted.'

Clutch

The clutch

surfaces being '11a labric material must be kept free Iram ail

and grease, ar the clutch will lail ta grip. It is necessary ta

lubricate the aperating ring at paint A. as shawn an the sketch,

once a week with ail.

.

J

I

I

I

I

It

Steering Gear

Ta abtain easy steering it is impartant ta give it regular

attentian as regards lubricatian, The grease gun nipple is an

the tap '11the worm case, and il a charge is given ance a manth

it is sufficient to lubricate the bearings '11the worm and warm

wheel and also lubricate the WQ1'mitself. The bearing at the

tap '11the calumn, just under the steering wheel can be given a

little ail Iram the ail.can. The steering connectians an the side

rad are best lubricated by means '11an oil-can which ejects the

ail under pressure, inta the sackets, and the nipples at the end

'11the crass rad shauld be given a charge '11grease ance a week.

.. 29

I

.\

J

I

\.

,,

-

r

I

the ".servair by remaving the plug in the battam, while the

engiro. is hat. Drain the reservair campletely. Never pqur

ail iX",the engine except thraugh the strainer.

After the first re-filling it is advisable ta change the ail in the

engine entirely after every 1,200ta 1,500 miles running ar saaner.

Every 2,400-3,000 miles remave the ail r""ervair. The

gauze oil tray will then be accessible for remaval. Carefully

clean the gauze and remove all dirt from inside the reservoir.

and replace them, Carefully remake the jaint with the packing

washer, covering both sides of it with grease. When tightening

up the nuts holding the oil reservoir to the crankcase, do not

pull up one nut tight, but tighien each nut equally, a little at

a time. See that the draipplug is screwed up tight: then fill the

crankcase with oil to the maximum level as shown on the

dipper rod, B. About half a gallon will be enough to fill.

Always inspect the level of 'the oil and add, enough to fill.

to the correct level before starting on a long journey.

The oil level should not be allowed to go below'! inch on

the bottom af the, dipper rad. It is advisable ta wipe the d,ipper J

rod befare taking, the reading of the level, and the reading J

shauld anly be taken when the engine is nat running and the

car is an the level ground.

The main bearings af the engine are of the roller type, and

the aily vapour in the crankcase is quite sufficient ta lubricate

these.

The pista';1?' are also lubricated by the aily vapour.

Lubricatian of the big-ends is effected by catching ail from

the pump-fediiets In pockets on the crankshaft webs.

.

.

';'."' PUMP

28

~"

"

",

.,

. ,'~~.

. .\'.,

It is advisable to make sure these jets are always cle~q~rit.

to da sa the plugs over the jets (see illustration) shaulj.. pe .

a~casianall'y removed and a piece,~of stiff wire, not abave~.'in.

diameter, mserted thraugh the Jets. 1;l)ls prevent~ 'fo~elgn

matter accumulating in the jets and chaking"t~m.

Gearbox .'

A suitable ail far the gearbax is the same as that used in

the engine; but if far any reasan another btand of oil is used,

. it shauld be of abaut the same consistency and no thicket,

atherwise it will not reach all the bearings. The depth af the

oil should never be less than I in. ot more than 2t in. It can be

measured by a rod inserted through the filler plug hole, The

maximum quantity is appraximately !pint. The correct oil

level shauld be maintained; excess of oil will leak from the

bearings and seriously affect the clutch, causing it ta slip;

on the ather hand there must be sufficient ail ta prevent wear.

The gearbox, shauld be drained entirely after the first

500-800miles, and then after every 4,000 ar 5,000miles, when

any grit, etc., which may have'collected willdrain away'thraugh

the plug hale 's..

in the sump. FLYWHEEL

The gearbox WI

drain plug I11111

holds the clutch JII

pit drainhale

coverin positian

and this shauld

be replaced

when the drain

plug is refitted.'

Clutch

The clutch

surfaces being of a fabric material must be kept free fram ail

and grease, ar the clutch will fail to grip. It is necessary ta

lubricate the aperating ring at point A. as shawn an the sketch,

once a week with oil.

.

J

I

I

I

I

4,

Steering Gear

Ta abtain easy steering it is impartant to give it regular

attentian as regards lubrication. The grease gun nipple is an

the tap af the worm case, and if a charge is given once a month

it is sufficient to lubricate the bearings of the worm and worm

wheel and also lubricate the wW'm itself. The bearing at the

top of the column, just under the steering wheel can be given a

little oil from the oil.can. The steering connections on the side

rod are best lubricated by means of an oil.can which ejects the

oil under pressure, into the sockets, and the nipples at the end

of the crass rod should be given a charge of grease once a week.

"

'" 29

I

,\

J

I)

I\,

,

(f

I

I ~

Rear Axle

For the rear axle, attention every 1,200 to 1.500 miles should

be sufficient. A mixture of yellow grease and engine oil of

equal parts should be used. It is injected into the axle, using

the special adapter on the grease gun barrel (in place of the

telescopic end) which screws into the centre casing of the axle

when the small plug has been removed with a *in.box spanner.

The gun handle is screwed down to inject the grease. When

replacing the plug see that the washer is not omitted. Do not

inject too much grease at anyone time as the felt rings will fail

to hold this grease in the axle case, and it will then leak through

on to the brake drums and prevent them from being effective.

Rear Universal Joint

For the rear universal joint a good quality" high speed"

grease should be used. This is of a dark brown colour, an1

will remain in the joint longer than the ordinary yellow grease.

The rear universal joint being of metal must be kept well

lubricated at (A) on account of the movement of the real axle.

It should be one of the points to have striCt attention. The

grease gun is used with the special adapter screwed on the

barrel in place of the standard telescopic end, as described for

the rear axle. The small cover in the top of the centre lIoor

channel. just between the seats, must be removed. Thc car

is moved until the plug in the universal joint is facing upwards

(if it is not already 50), and a * in. box spanner is necessary

to unscrew the plug from the universal joint. The adapter on

the grease gun is screwed in, in place of the plug, and the grease

injected by screwing down the grease gun handle. After

greasing' the plug is refitted, the washer under it not being

omitted. Access for greasing this, together with the grease

connection (B), which should receive yellow grease weekly on

the end of the torque tube, is obtained through the cover (C) in

the lIoor of the body, as shown on the illustration adjoining.

r

Brake Gear

On each of the rear

brakes there is a lubricator

for oiling the cam spindle

bearing. These and all

other joints, etc., should

be oiled once a week.

The front brake cam

spindJe, is lubricated from

the swivel pin as shown

at (B), in the illustration

overleaf.

30

,"

.

~

Front Axle'

The swivel pins are lubricated with the grease gun and

should receive attention once a week.

Radius Rod Anchora~e

Oil should be applied occasionally to the cups and ball

flange, forming the radius rod anchorage on ihe front cross

member, just below the rear of the gearbox.

Shock Absorbers

The shock absorbers should be lubricated only after

dismantling them (see page 47). '

Windscreen Wiper

A drop of thin oil should be occasionally applied to the

windscreeri wiper mechanism-say, once a month. A small

screw (except in the Trico model) is removable from the top of

the casing allowing the oil to be injected.

"

Road Sprin~s

The ends of the road springs where they are attached to the

axles are provided with grease gun connections, and should be

given a charge once a week if the car is continually used. After

a long period of use it is advisable to lubricate the leaves of the

spring with a warm mixture, of white lead and tallow in equal

parts. This can best be applied with a stiff brush, the leaves

being eased apart by a screwdriver; first jack up the car,

not under the axles, nor the radius rods, but under the frame to

take the weight off the springs, The rear 01 the car can be

jacked up one side at a time. The best point of the frame a~

which to apply the jack is each end of the rear cross-member.

At the front, as there is only one transverse spring, the whole

01the car must be lilted, and as a safety measure, the rear wheels

should be " scotched" to prevent the car running off the jack.

A short stiff bar is placed across the frame, just lorward 01 the

engine. oil reservoir, and behind the spring, and the jack lilts

the car Irom the centre 01 this bar. It will be necessary to block

the jack up for this work, with a wood block, to avoid

necessitating an excessive lilt.

1

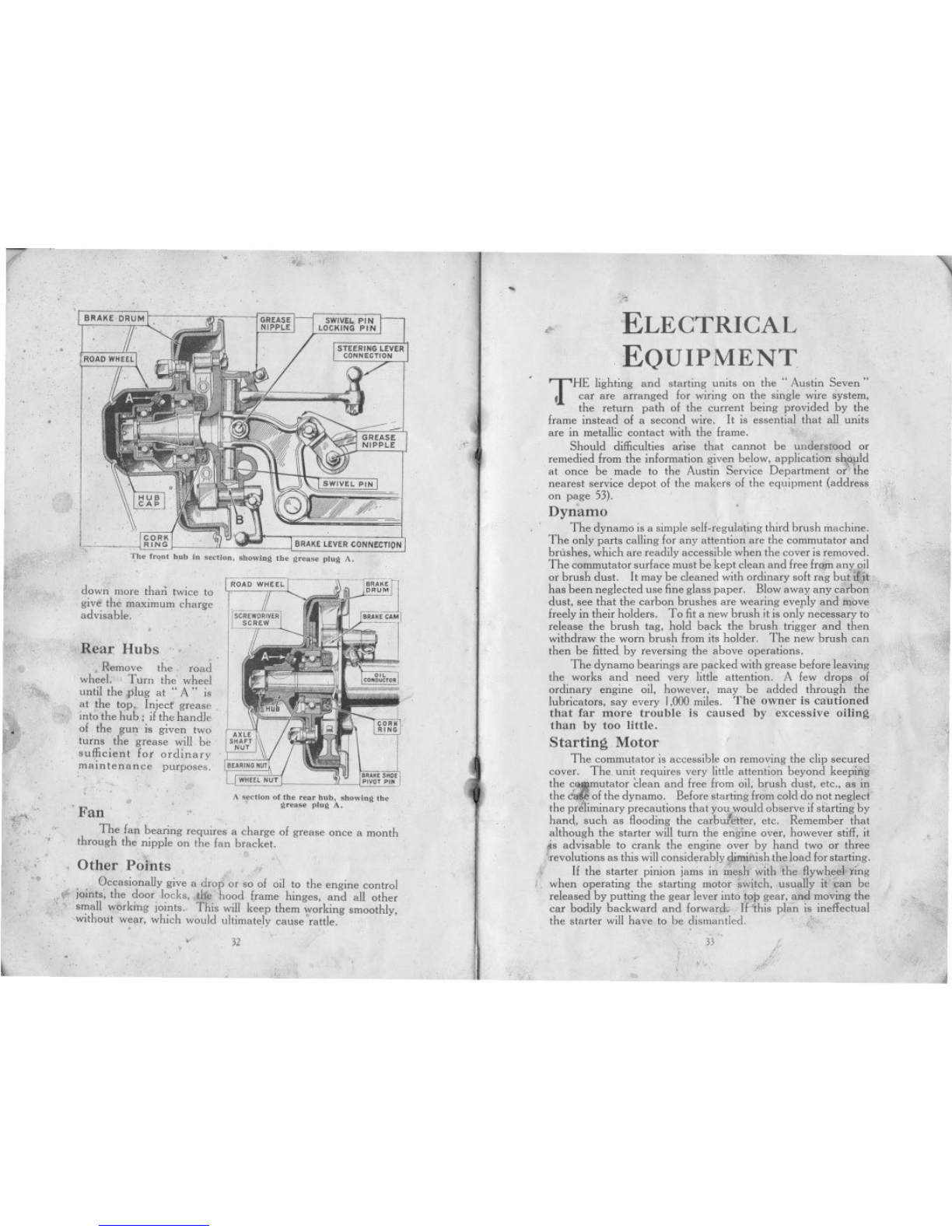

Front Hubs

Remove the road wheel (see page 11). Turn the hub until

the plug" A" is at the top. Screw out the plug and screw

in the adapter ,which is provided in the kit.

Fill the hub with grease. It is important that the hubs are

not given too much Rrease, otherwise the brakes will not be

effective. The handle 01 the grease-gun should not be turned

I

31

j

[-

I

.~

.

......

,.

down more thari twice to

give' the maximum charge

advisable.

Rear Hubs' .'

Remove the road

wheel. Turn the wheel

until the plug at .. A" is

at the top. Injeci grease

into the hub; if the handle

of the gun is givcn two

turns the grease will be

sufficient for ordinary

ma'intenance purposes.

'.

GREASE

NIPPLE SWIVEL, PI N

LOCKING PIN

WHEELNUT """"OE

POVOT.,.

A ",ct/on of the ce.. hub, .howlng the

,g".., plu~A.

Fan "

The fan bearing requires a charge of grease once a month

through the nipple on the fan bracket.

"

Other Points

Occasionally give a drop or so of oil to the engine control

joints, the door locks, (110hood frame hinges, and all other

small working joints. This will keep them working smoothly.

without wear, which would ultimately cause "rattle.

v

-32 --

-

-.'

-- ----"'

,,,>

... ELECTRICAL

EQUIPMENT

THE lighting and starting units on the" Austin Seven ..

I car are arranged for wiring on the single wire system,

the return path of the current being provided by the

frame instead of a second wire. It is essential that all units

are in metallic contact with the frame.

Should difficulties arise that cannot be understood or

remedied from the information given below, application sh,o~ld

at once be made to the Austin Service Department or the

nearest service depot of the makers of the equipment (address

on page 53).

Dynamo '

The dynamo is a simple self.regulating third brush machine.

The only parts calling for any attention are the commutator and

brushes, which are readily accessible when the cover is removed.

The commutator surface must be kept clean and free frOp. any oil

or brush dust. It may be cleaned with ordinary soft rag buti~it

has been neglected use fine glass paper. Blow away any carbon

dust, see that the carbon brushes are wearing evel'ly and move

freely in their holders. To fit a new brush it is only necessary to

release the brush tag, hold back the brush trigger and then

withdraw the worn brush from its holder. The new brush can

then be fitted by reversing the above operations.

The dynamo bearings are packed with grease before leaving

the works and need very little attention. A few drops of

ordinary engine oil, however, may be added through the

lubricators, say every 1.000miles. The owner is cautioned

that far more trouble is caused by excessive oiling

than by too little.

Starting Motor

The commutator is accessible on removing the clip secured

cover. The unit requires very little attention beyond keeping

the s<>W"'utatorclean and free from oil, brush dust, etc., as in

the ~of the dynamo. Before starting from cold do not neglect

the pri!Iiminary precautions that you would observe if starting by

'L.

hanq, such as flooding the carburetter, etc. Remember that

although the starter will turn the engine over, however stiff, it

;.s advisable to crank the engine over by hand two or three

"revolutions as this will considerably diminish the load for starting.

If the starter pinion jams in 4esh with the flywheehing

when operating the starting motor switch, usually it can be

released by putting the gear lever into top gear, and moving the

car bodily backward and forwank IMhis plan is ineffectual

the starter will have to be dismantled. ;.

I

33

,

-

,'\

Never use the starting motor to propel the car, as it throws

too severe a strain on the battery and the starting motor.

If the engine does not start at the first attempt. do not press

the starter switch until the engine has come to rest. If this

precaution is not adopted, the starter ring teeth on the flywheel

cover, or the starter pinion teeth, may be damaged.

If the maximum ammeter reading is much below normal

when the dynamo is charging when the lamps are" off "; or if

the needle fluctuates when the car is running steadily, a low or

intermittent dynamo output can be suspected. The dynamo

may have been neglected, and the trouble may be caused by

say worn brushes, or a dirty commutator (refer to the dynamo

recommendations).

Cut-out and Fuse

The cut-out and fuse are mounted on the same base, the

larger cover" A " protecting the cut-out and the smaller one the

terminals and fuse. The cut-out automatically closes the

charging circuit as soon as the dynamo voltage rises sufficiently

c above that of the battery.

.~. When the dynamo voltage

D~falls below that of the battery,

. . the reverse action takes

010» ,A B .place, the cut-out opens and

A-C"',,~,,~, thereby prevents the battery

B-"""'" f d.h..If

c-w,""o"""",",ru..~,, rom lSC argmg ltse

D'""',""","'~ h h h d

E-"""'" t roug t e ynamo.

"""'"""",,.

. The cut-out is accurately set before leaving the works, and

does not need any adjustment and is therefore sealed.

The cover" D " protecting the fuse holder and terminals is

removed by springing up the retaining wire" C ".

To fit a new fuse it is only necessary to remove the knurled

nut" D " place one of the spare fuse strips" F " over the post,

and then replace and tighten up the nut.

Should it be found that the fuse is continually

blowing, do not use two or more strips to prevent this

occurring, but have the equipment thoroughly examined

to find out the .cause of the trouble.

Battery

It is of the utmost importance that the battery receives

regular attention, as upon its good condition depends the satis-

factory running of

the starting motor

and the illumina-

tion of the lamps.

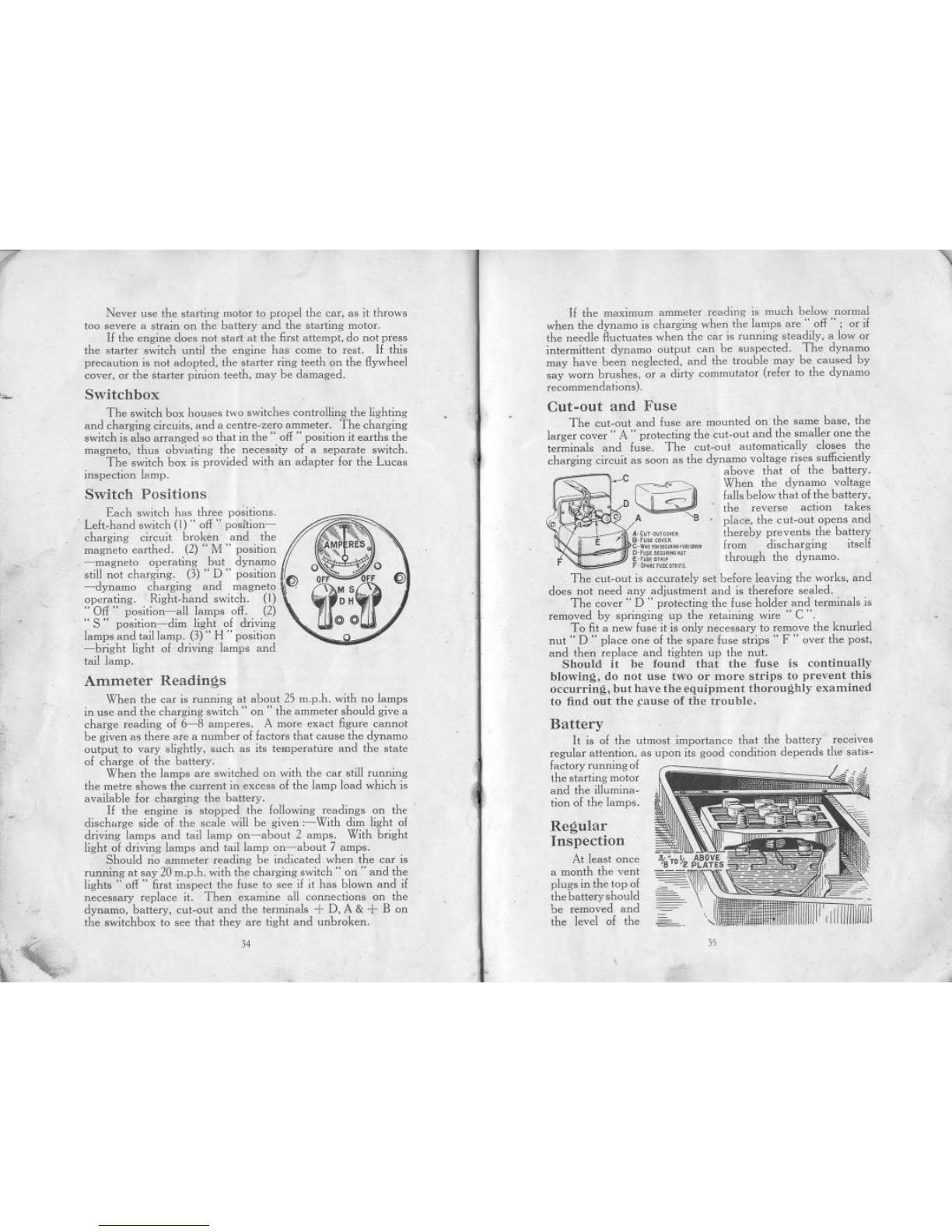

""- Switchbox

The switch box houses two switches controlling the lighting

and charging circuits, and a centre-zero ammeter. The charging

switch is also arranged so that in the" off " position it earths the

magneto, thus obviating the necessity of a separate switch.

The switch box is provided with an adapter for the Lucas

inspection lamp.

Switch Positions

Each switch has three positions.

Left,hand switch (I)" off" position-

charging circuit broken and the

magneto earthed. (2)" M " position

-magneto operating but dynamo

still not charging. (3)" D " position !~~

-dynamo charging and magneto \\ .

operating. Right-hand switch. (I)

" Off " position-all lamps off. (2)

" S" position-dim light of driving

lamps and tail lamp. (3)" H" position

-bright light of driving lamps and

tail lamp.

F

~.

Ammeter Readings

When the car is running at about 25 m.p.h. with no lamps

in use and the charging switch" on " the ammeter should give a

charge reading of 6-8 amperes. A more exact figure cannot

be given as there are a number of factors that cause the dynamo

output to vary slightly, such as its temperattire and the state

of charge of the battery.

When the lamps are switched on with the car still running

the metre shows the current in excess of the lamp load which is

available for charging the battery.

If the engine is stopped the following readings on the

discharge side of the scale will be given :-With dim light of

driving lamps and tail lamp on-about 2 amps. With bright

light of driving lamps and tail lamp on-about 7 amps.

Should rio ammeter reading be indicated when the car is

running at say 20 m.p.h. with the charging switch" on " and the

lights ".off " first inspect the fuse to see if it has blown and if

necessary replace it. Then examine all connections on the

dynamo, battery, cut-out and the terminals -I- D, A & -I- B on

the switchbox to see that they are tight and unbroken.

Regular

Inspection

At least once

a month the vent

plugs in the top of

the battery should

be removed and

the level of the

..

~.,

34

--

35

Other manuals for Austin Seven

1

Table of contents

Other Austin Motor Company Automobile manuals

Austin Motor Company

Austin Motor Company A40 Somerset Sedan User guide

Austin Motor Company

Austin Motor Company LANDCRAB 1993 User manual

Austin Motor Company

Austin Motor Company Austin Seven User manual

Austin Motor Company

Austin Motor Company A40 Somerset Sedan Technical specifications

Austin Motor Company

Austin Motor Company FX4R User manual