AUSTIN SCIENTIFIC M600 User manual

TABLE OF CONTENTS:

1. FEATURES

2. DESCRIPTION

3. TECHNICAL SPECIFICATION

3.1 SUMMARY SHEET

3.2 OPERATING AND COOLANT CONDITIONS

3.2.1 OPERATING CONDITIONS

3.2.2 COOLANT CONNECTIONS

3.2.3 COOLANT QUALITY

3.3 ELECTRICAL CONNECTION

3.3.1 POWER INPUT

3.3.2 MAIN CABLE AND LEADS

3.3.3 COLD HEAD CONTROLS

3.3.4 AUTO RESTART FUNCTION

4. INSTALATION

4.1 UNPACKING AND INSPECTION

4.2 MOUNTING

4.2.1 OPERATING ANGLE

4.2.2 FLEXLINES AND CONNECTIONS

4.2.3 COLD HEAD CONNECTION

5. OPERATION

5.1 SWITCHING ON

5.2 NORMAL OPERATION

5.3 SAFETY DEVICES

6. MAINTANANCE AND SERVICE

6.1 ABSORBER REMOVAL

6.2 HELIUM PRESSURE ADJUSTMENT

7. TROUBLE SHOOTING

1. MAIN FEATURES

• Absorber can be replaced from the front of the unit,

permitting convenient rack or cabinet installation.

• Both high and low side pressure gages.

• Electrical box is a field replaceable unit.

• High and low voltage units available for use at both 50 Hz

and 60 Hz.

• Water flow meter provides user feedback to ensure adequate

water supply.

• Compressor can be controlled remotely.

2. DESCRIPTION

Compressed helium is used as a refrigerant when trying to achieve

cryogenic temperatures (as low as 4 Kelvin). The high-pressure helium is

delivered from the compressor to a cold head through the supply line (300-350

psi). The helium is expanded in the cold head to produce a temperature drop.

The cold head uses a motor and a piston like “displacer” to move the expanded

helium though regeneration materials to increase the thermodynamic efficiency of

the cycle. After expansion, the helium returns to the compressor through the

return line (50-100 psi). Theses magnets operate at cryogenic temperatures and

the chilled radiation shield helps maintain these temperatures.

The compressor itself consists of five main components: The compressor

capsule, the heat exchanger, the mist separator, absorber, and volume tank.

Compressing helium generates a large amount of heat. To remove this

heat from the compressor, oil is mixed into the helium as it is being compressed.

The compressor removes most of the oil from the helium stream before it leaves

the capsule. The oil is then pumped (by the differential pressure generated by the

compressor) out of the compressor, through the water-cooled heat exchanger, and

then back to the compressor.

The heat exchanger is a brazed, flat plate heat exchanger. It has two

circuits for hot fluids. One is for the oil (as mentioned above). The other circuit

is for the helium. Removing the heat of compression from the helium makes it

better able to chill the cold head. The two hot fluids are cooled by water. The

water enters and exits the compressor from the front panel.

The helium leaving the compressor still has a small amount of oil mixed

with it. If this oil makes it to the cold head, it will freeze and foul the cold head.

The function of the mist separator and absorber is to remove this oil from the

helium stream. The mist separator is filled with fiberglass. Oil agglomerates on

the glass fibers, drops to the bottom of the separator and is plumbed back to the

compressor, again by differential pressure. The absorber is filled with activated

charcoal. This charcoal adsorbs the remaining oil from the helium stream. The

absorber eventually fills with oil and must be changed. A typical time between

replacements is 20,000 hours.

The volume tank is an empty tank that provides extra volume on the low

side of the system to keep the low side pressure from going negative when the

system is running.

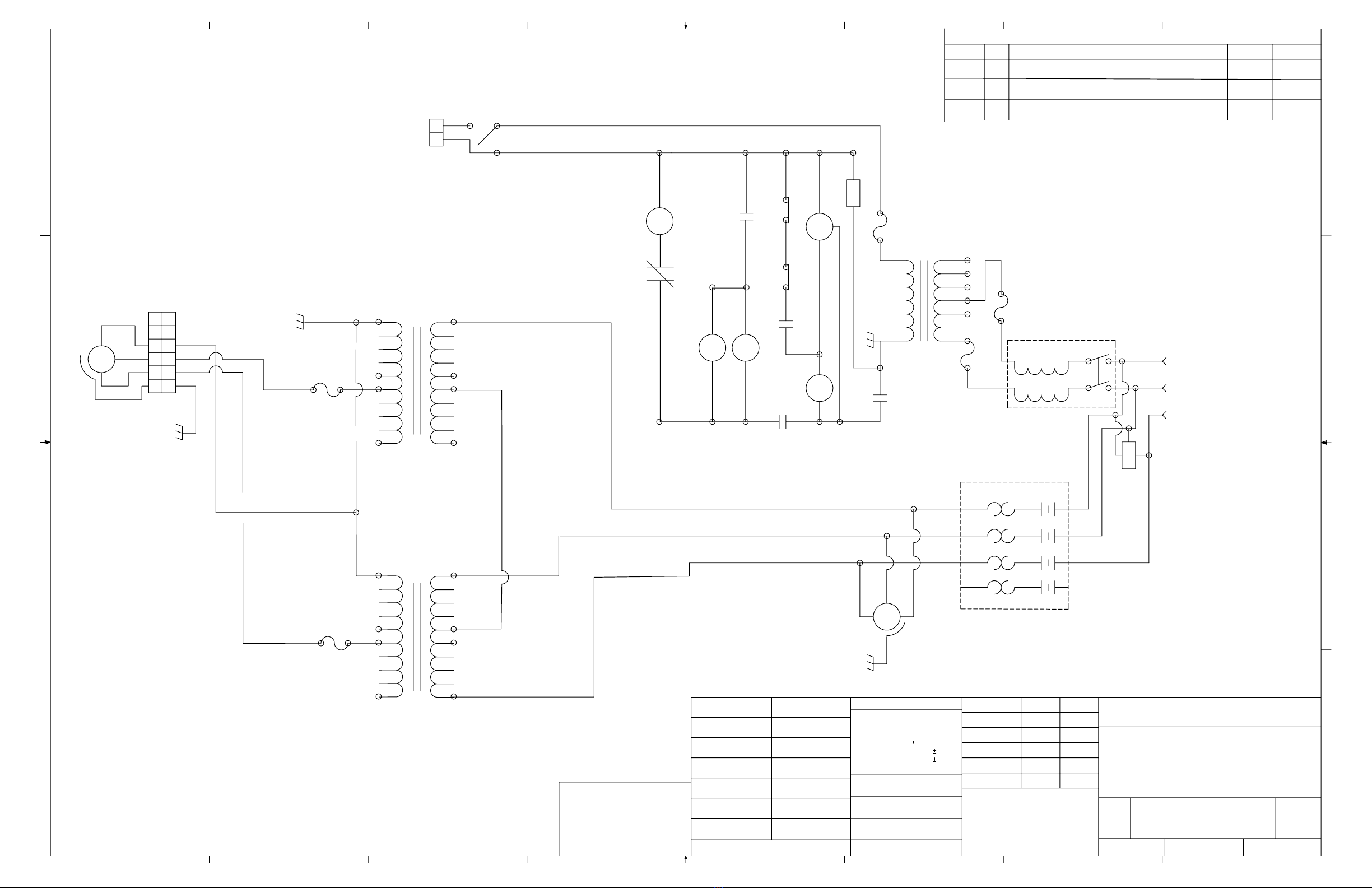

There are a number of subsystems that support these five main

components. There is an electrical box that contains the power and diagnostic

electronics and provides a user interface. The compressor electrical box also

supplies power to run the cold head motor though a connector on the front panel.

There are two thermostats attached to the plumbing lines that open should

temperatures get out of range. There is a solenoid valve that opens when the

compressor shuts down, providing a passage between the high and low side,

equalizing the two.

Flow diagram of the compressor system

3. TECHNICAL SPECIFICATION

3.1 SUMMARY SHEET

COMPRESSOR SPECIFICATION UNITS M600-HV M600-LV

VOLTAGE REQUIREMENTS (±10%)

50HZ-3 PHASE V 400 200

60HZ-3 PHASE V 460 230

POWER REQUIREMENTS

50HZ-3 PHASE KW 8.2 7.5

60HZ-3 PHASE KW 8.8 7.8

OPERATING CURRENT WITH WARM COLD HEAD

50HZ A 10 21

60HZ A 10 21

REMOTE CONTOL VOLTAGE VAC 24 24

HELIUM CONNECTORS IN ½”

Aeroquip

Same

STATIC HELIUM PRESSURE

50HZ PSI (bar) 240(16.5) 240(16.5)

60HZ PSI (bar) 240(16.5) 240(16.5)

458

18.0

532

21.0

441

17.4

RETURN HELIUM PRESSURE

50HZ PSI (bar) 50 50

60HZ PSI (bar) 50 50

SUPPLY HELIUM PRESSURE

50HZ PSI (bar) 280 280

60HZ PSI (bar) 300 300

COOLANT DATA

FLOW RATE (MIN) GPM 1.5 1.5

MIN. INLET TEMPERATURE °F(C) 40(5) 40(5)

MAX. INLET TEMPERATURE °F(C) 85(30) 85(30)

WEIGHT Lb(kg) 230(105) 230(105)

3.2 OPERATING AND COOLANT CONDITIONS

3.2.1 OPERATING CONDITIONS:

When the compressor is operating, the ambient temperature must

remain between 40°F and 104°F (5°C and 40°C).

3.2.2 COOLANT CONNECTIONS:

The standard connections on this compressor, for the coolant system,

are 3/8” Swagelok connectors. Connections can be modified to meet

customer requirements.

3.2.3 COOLANT QUALITY

Heat exchanger manufacturer recommends 1200-840 micron strainer

on water supply and the following water requirements:

Electrical conductivity: >50 µS/cm

Iron: <1.5 mg/l

Manganese: <0.5 mg/l

Ammonia: <2 mg/l

pH value: 6 – 9

Chloride: <100 mg/l

Free carbon acid: <20 mg/l

Nitrate: <100 mg/l

Sulphate: <50 mg/l

Sulphide: 0 mg/l

3.3 ELECTRICAL CONNECTIONS

3.3.1 POWER INPUT

The power input can be adjusted to accommodate the different volt

outputs from the customer.

3.3.2 MAIN CABLE AND LEADS

Production units can be fit with a variety of cord lengths and

connectors. Which polarized connector, if any, are to be fitted to

production units is yet to be determined.

3.3.3 COLD HEAD OUTPUT

The stock compressor will have the ability to control Austin

Scientifics’ cold heads. Compressors can be easily fitted with a wide

variety of cold head drives, connectors and cables to meet customer

requirements.

3.3.4 AUTO RESTART FUNCTION

Our unit will have an automatic restart with brownout or blackout in

power, when power is reapplied to the system. A manual reset will be

necessary for a unit that stops operating with a fault condition.

3.4 MULTI-CRYO SYSTEMS

3.4.1 COMPRESSOR CAPACITIES

The stock compressor has the ability to supply multiple cold heads.

Compressors can be operated with various Cryopump configurations.

Using Helium hose manifolds and drive cable Splitter Boxes to meet

customer requirements.

3.4.2 CRYOPUMP CONFIGURATIONS

The M600 is capable of operating cryopumps in the following

configurations.

1. Up to Three (3) CP-8’s.

2. Two (2) CP-10’s, or one CP-10 & one CP-8

3. One (1) CP-16

4. INSTALLATION

4.1 UNPACKING AND INSPECTING

Once the units have been received, examine the packaging for signs of

damage. This type of packing is reusable for these compressors.

Unpack the equipment and verify that no damage has occurred in

transit. Check the tip and tell devices and the pressure gauges for

signs of mishap during transit. The tip and tell device should insure

that the unit has not been transported at an angle greater than 45° and

the pressure gauges should read 240psi±10%.

The unit comes with a removable castor frame. We have the option to

install feet, castors or rails, depending on the customer requirement.

If damage is detected contact the carrier and Austin Scientific as soon

as possible.

4.2 MOUNTING

4.2.1 MAX OPERATING ANGLE

The compressor unit can be installed and operate with a

maximum tilt of 10° in any direction.

4.2.2 FLEXLINES and CONNECTORS

The lines and connectors have been equipped with self-sealing

coupling, this maintains the positive seal so no helium can

escape during any maintenance.

These couplings should never see oil or grease and before any

installation check all connections for foreign material and clean

if necessary. Verify that all flat seals on the male connectors

are in good condition and replace if necessary.

Work with the flex lines only if the compressor switch is in the

off position and the internal pressure is below 400psi.

Never twist the flex lines.

Tighten down coupling as far as possible and then back it off by

¼ of a turn.

4.2.3 CONNECTING THE COLD HEAD

Connect the flexline from the compressor supply; this is marked

with a green washer, to the inlet of the cold head. Then connect

the flexline from the compressor return; this is marked with a

red washer, to the outlet of the compressor. This can be

changed with customer requirement.

Crossing the connection on the cold head will cause damage to

the internals of the cold head.

With the appropriate cable supplied from Austin Scientific,

complete the connections form the compressor electronic box to

the electrical connection on the cold head. This will supply

power and logic to the cold head.

5. OPERATION

5.1 SWITCHING ON

Turning the compressor on will automatically start the compressor

and cold head. It is not recommended to run a compressor without all

the proper connections verified.

5.2 NORMAL OPERATION

The helium used for this compressor must be ultra high pure quality

(99.9999% pure) any impurities can cause problems inside the cold

head that the compressor is controlling.

5.3 SAFETY DEVICES

The unit is fitted multiple safety devices:

An external pressure relief valve

A thermal switch on the oil temperature

A thermal switch on the helium temperature

Fuses for the main power

Fuses for the cold head

An internal pressure relief valve

Electronic Phase monitoring device

Motor overload and thermal switch for the compressor

6 MAINTANENCE AND SERVICE

Before any service verify that the power has been removed from the

system

6.1 ABSORBER REMOVAL

The service interval of the absorber of the M600 is 20,000 hours (27.4

months).

The M600 absorber has been placed at the front of the unit, behind a

removable cover, to facilitate replacement. Absorber replacement

should take about 15 minutes. This is ideal for rack and rail mounted

compressor units.

6.2 HELIUM PRESSURE ADJUSTMENTS

The helium charge can be increased or decreased by using the ¼” self-

sealing connector on the front of the unit, this connection is marked

by a white washer.

Never charge the compressor above a static pressure of 250psi

(17.2bar)

7. TROUBLE SHOOTING

For any trouble or questions installing and operating the M600 unit

please contact the service department of Austin Scientific at:

Austin Scientific

Phone (512) 441-6893 x 112

Fax (512) 443-6665

RETURNING EQUIPMENT

Before returning any equipment, please contact Austin Scientific to receive special

instructions and to obtain a Return Good Authorization (RGA) number.

Austin Scientific

4114 Todd Lane

P.O. BOX 18863

Austin, TX 78760

(512) 441-6893

FAX (512) 443-6665

Austin Scientific

West Coast Service Center:

500 Laurelwood Road #9

Santa Clara, CA 95054

(408) 496-0782

FAX (408) 469-0785

PM1

REMOTE

SWITCH

AB

2

A

A

BC

C

B

3

1

DE

E

D

F

F

RED

13

TS1

R2

2

ETM

24V

TS2

M2

14

M2 R1

O. L.

TD1

3

1

F6

T3

S1

12 8

S2

K1

13 K1

F4

480V

415V

230V

380V

F5

208V

SW1

L1 L2

WHT

BLK

5

9

K1

14

BLK

RED

WHT

M2

PM1

4

L3

3

5

M1

F2

F1

NCBA NCBA

123 4 12

34

T2 T1

YEL

14

13

18

96

95

Notes:

1. Each E-Box must be fuctionally

tested prior to receipt

D

C

B

A

A

B

C

D

1

2

3

4

5

678

87654321

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

AUSTIN SCIENTIFIC. ANY REPRODUCTION

IN PART OR AS A WHOLE WITHOUT

THE WRITTEN PERMISSION OF

AUSTIN SCIENTIFIC IS PROHIBITED.

PROPRIETARY AND CONFIDENTIAL

NEXT ASSY USED ON

APPLICATION

DIMENSIONS ARE IN INCHES

TOLERANCES:

SURFACE FINISH 32RMS OR BETTER

ANGULAR: MACH 1° BEND 2°

TWO PLACE DECIMAL .01

THREE PLACE DECIMAL .005

INTERPRET GEOMETRIC

TOLERANCING PER:

MATERIAL

FINISH

--

--

DRAWN

CHECKED

ENG APPR.

MFG APPR.

Q.A.

COMMENTS:

DATE NAME AUSTIN SCIENTIFIC

TITLE:

SIZE

B

DWG. NO. REV

SHEET 1 OF 2

WEIGHT:

SCALE: 1:1.5

REVISIONS

REV. DESCRIPTION DATE APPROVED

UNLESS OTHERWISE SPECIFIED:

ECO

0000 CRK

11/22/02

RELEASE SCHEMATIC

A

93-00001-011 B

ELECTRIC BOX, LV, M600,

ASC DRIVE

B

360 ADDED PG2, W/ TRANS MOUNT NOTE 8/31/04 JAM

B.V.

8/31/04

7/24/02 CRK

This manual suits for next models

1

Table of contents

Popular Air Compressor manuals by other brands

RFC

RFC SL Series Technical manual

CVS

CVS RKL 160 Mounting instructions

GEA

GEA HG22P Series Assembly instructions

Campbell Hausfeld

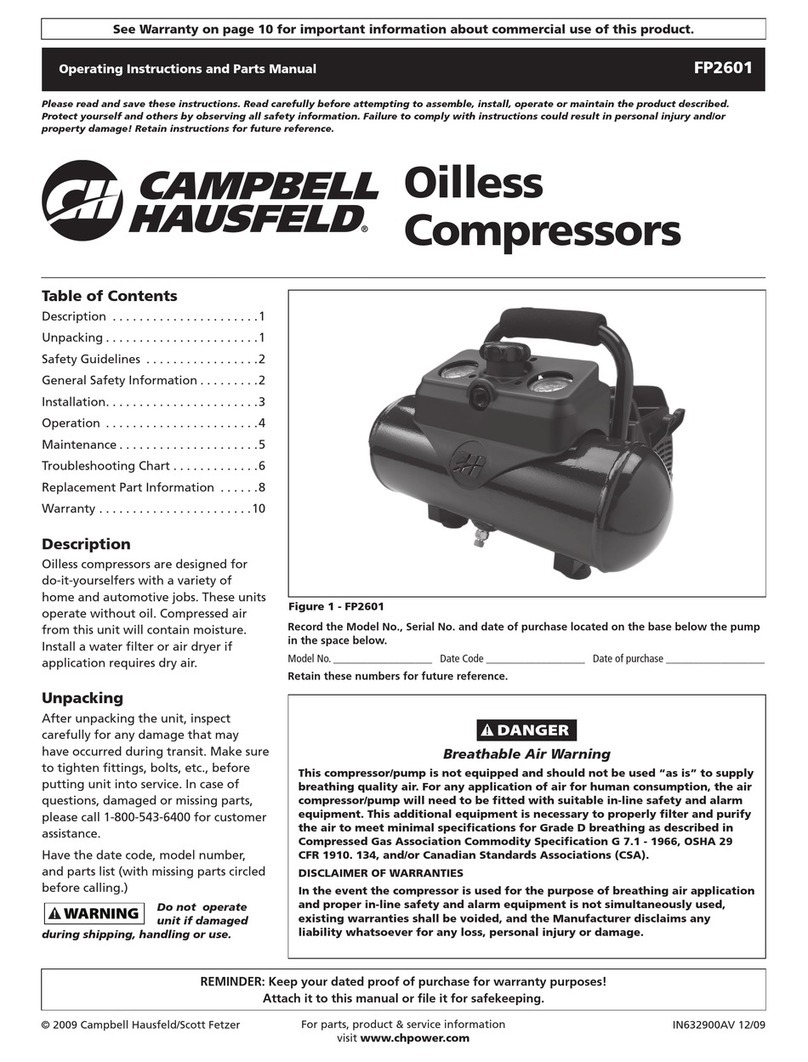

Campbell Hausfeld FP2601 Operating instructions and parts manual

Craftsman

Craftsman evolv 921.167500 Operator's manual

Zgonc

Zgonc YELLOW PROFILINE YPL 183-2 KIT Translation from the original instruction manual

Chicago Pneumatic

Chicago Pneumatic CPVS 40 instruction manual

Huvema

Huvema BL 50 AIR manual

Sullivan-Palatek

Sullivan-Palatek 75UDG Operating and parts manual

Ozito

Ozito ACP-5020K instruction manual

Parkside

Parkside PKO 270 A4 Operating and safety instructions

Clarke

Clarke BOXER 55 Operation & maintenance instructions