ny other form of use or one going

beyond this shall be considered as

inappropriate. We shall have no liability

whatsoever for any damage incurred as a

result .

Appropiate use

Notes for starting up

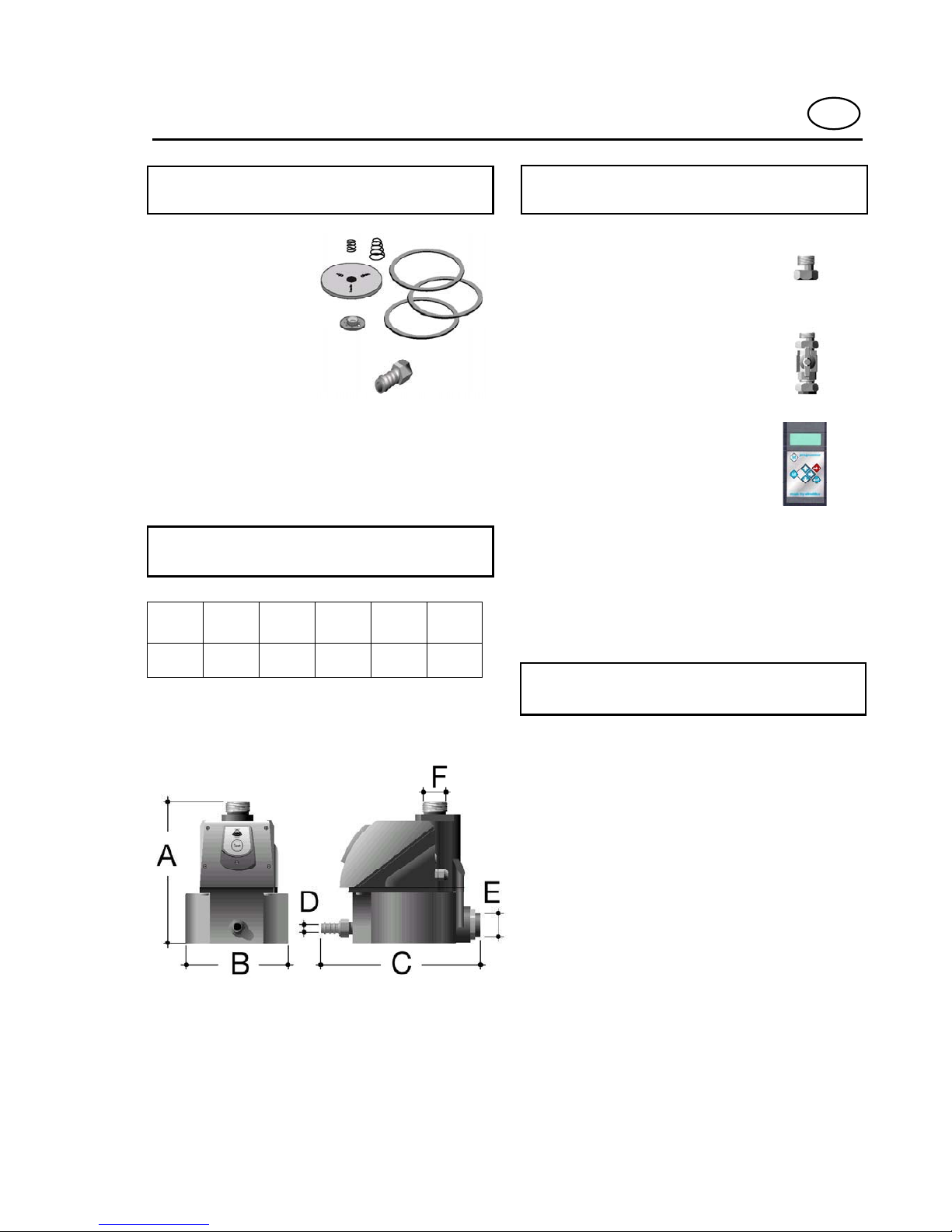

The inlet piping must have a internal

diameter of at least 0.74" to ensure

optimum bleeding of the condensate

drain if condensate gets in (1).

The inclination of the unit may not

exceed an angle of +/- 5° in both axles

(1/2).

It is recommended that a ball valve is

installed between the inlet piping and

the condensate drain and also

between the air shuttle line and the

pressure vessel (1/8).

Connecting two pressure vessels to

one condensate drain is wrong and

leads to functional problems with the

unit (3). Ensure that each pressure

vessel has its own drain.

Make sure that the chosen power

supply matches with the power supply

of the rating on the name plate.

After installation the isolation must be

mounted (4).

Ensure that no water pockets are

formed in the piping (5). Trapped air

prevents the condensate from flowing

out of the drain.

Example of piping to remove water

from piping (6).

The information channel (programmer

interface) provides the option to call

up or amend the units settings (7).

When using the rear condensate inlet

it is absolutely essential to use an air

shuttle line (8).

Pay attention that the top area of the

condensate drain is cleaned. Existing

labels on this area must be removed.

The condensate drain is ready for

operation if the power supply is

connected and the LED lights (9) and

pressure and condensate are applied.

Connect a hose (internal diameter

1/2") to the condensate drain and

the outlet adapter (10).

When the test button is pressed the

unit must audibly blow out condensate

or air (11).