The product must be installed according to the instructions included in the product packaging and the

door should be apertured according to the door “cut-out” dimensions and tolerances shown.

Prior to tting ensure that:

• Doors stored on site are stored in a clean dry area free from cement, lime, paint, acid etc.

During tting of the lock ensure that :

• No metal swarf or other contaminants enter the lock body.

• The xing screws do not damage the product nish.

After installation of the door ensure that:

• The door is correctly adjusted with the correct clearances.

• The lock engages the catch plate correctly.

• The door is protected from building fall-out such as wet plaster, mortar, and paint.

If the door becomes contaminated:

• Do not paint the lock body or faceplate.

• Remove wet plaster, cement, mortar and other droppings immediately, using clean water

and a sponge or rag, to avoid permanent staining or scratching of the product nish. If

removal is delayed and scraping becomes necessary the surface nish may suffer.

Annually inspect the door to conrm that the door operates with the correct clearances, closes and

opens without obstruction. Conrm that the lock beaks engage easily with the catch plate when the

door is closed and the lever or key is turned - adjust the door if necessary.

Annually check that when the door is closed, the lock can be locked by key and by the lever.

NB : The lock assembly has been lubricated for life, and should not be disassembled by the user.

Every six months, powder coated surfaces should be cleaned to protect the nish. However, in areas

where pollutants are more prevalent, especially in coastal or industrial regions, cleaning should be

carried out every two to three months.

To clean the powder coated surface:

1. Carefully remove any loose deposits with a wet sponge.

2. Use a soft brush (non abrasive) or cloth and a mild household detergent solution to

remove dust, salt and other deposits. Do not use steel wool, scrapers, scouring liquids or

powders to remove deposits as these permanently scratch the coating surface.

Plated nishes are susceptible to tarnishing if they come into contact with moisture, wet paint,

or water vapour. All plated nishes should be coated with a non-abrasive furniture or car wax

immediately after installation. Plated nishes should be regularly wiped with a non-abrasive

furniture or car wax, taking care not to scratch any protective nishes that are employed to protect

the surface and prevent tarnishing.

Installation

Maintenance

Cleaning Powder Coatings

Cleaning Chrome, Satin Chrome, Gold and Brass Finishes

MAINTENANCE LOG

5.

8.

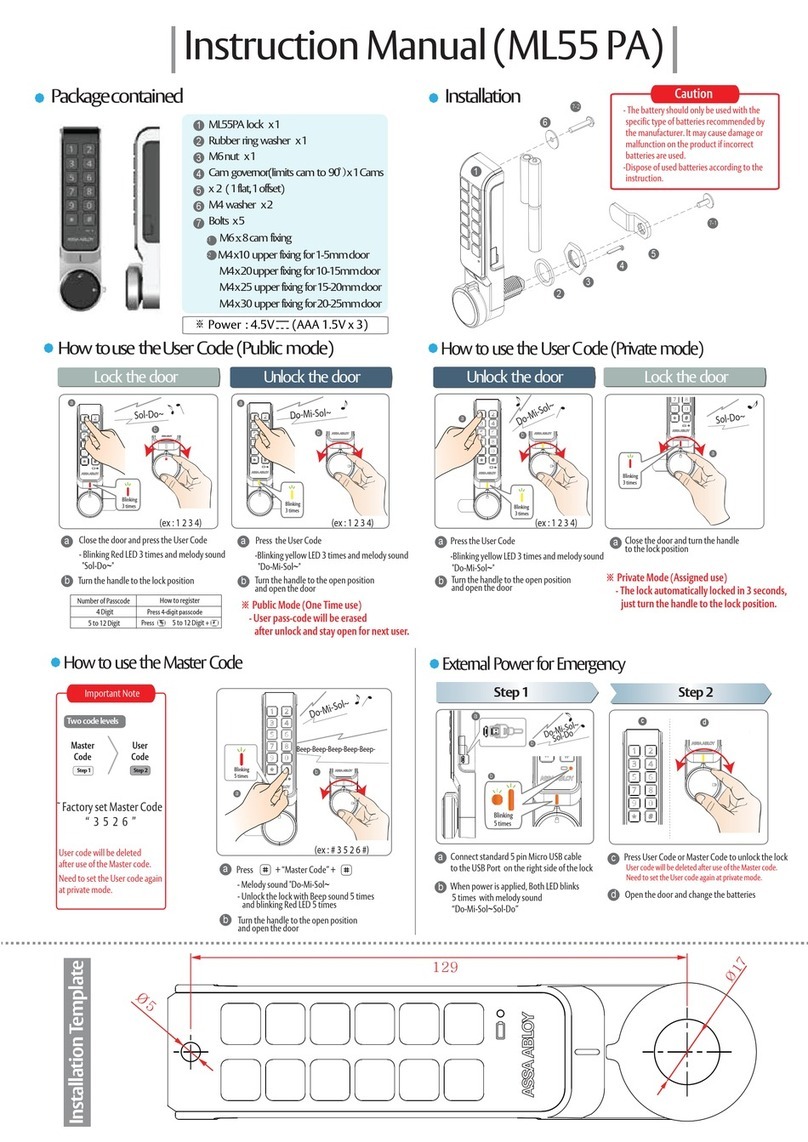

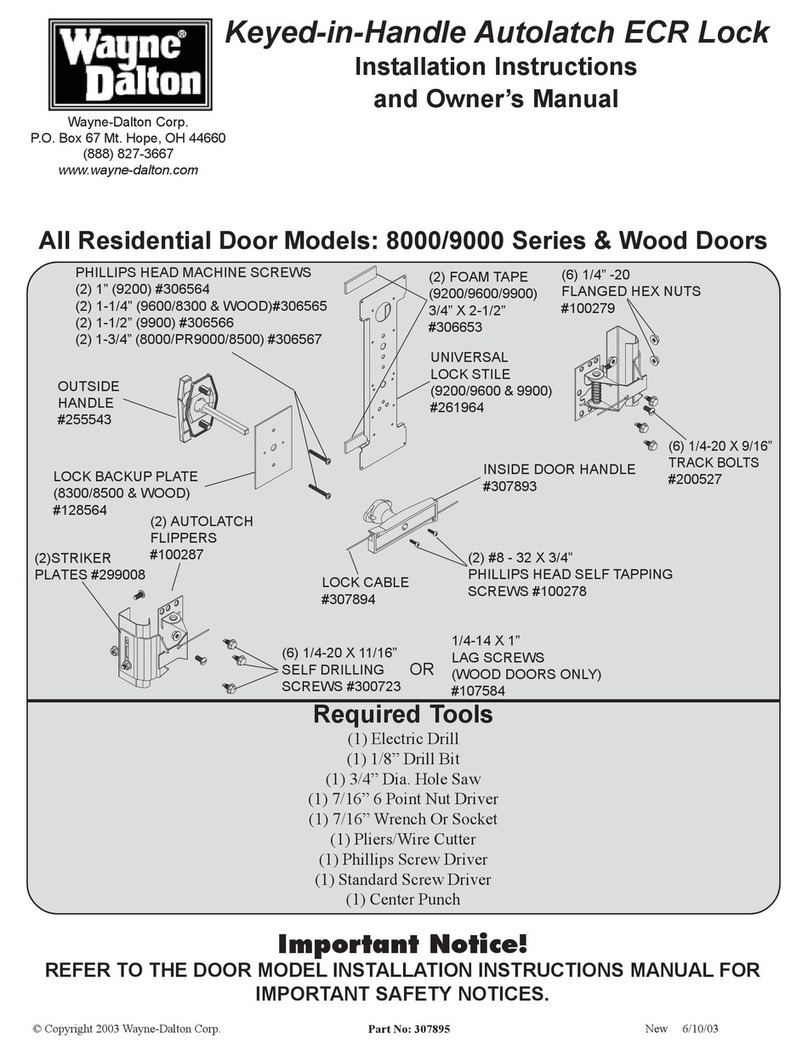

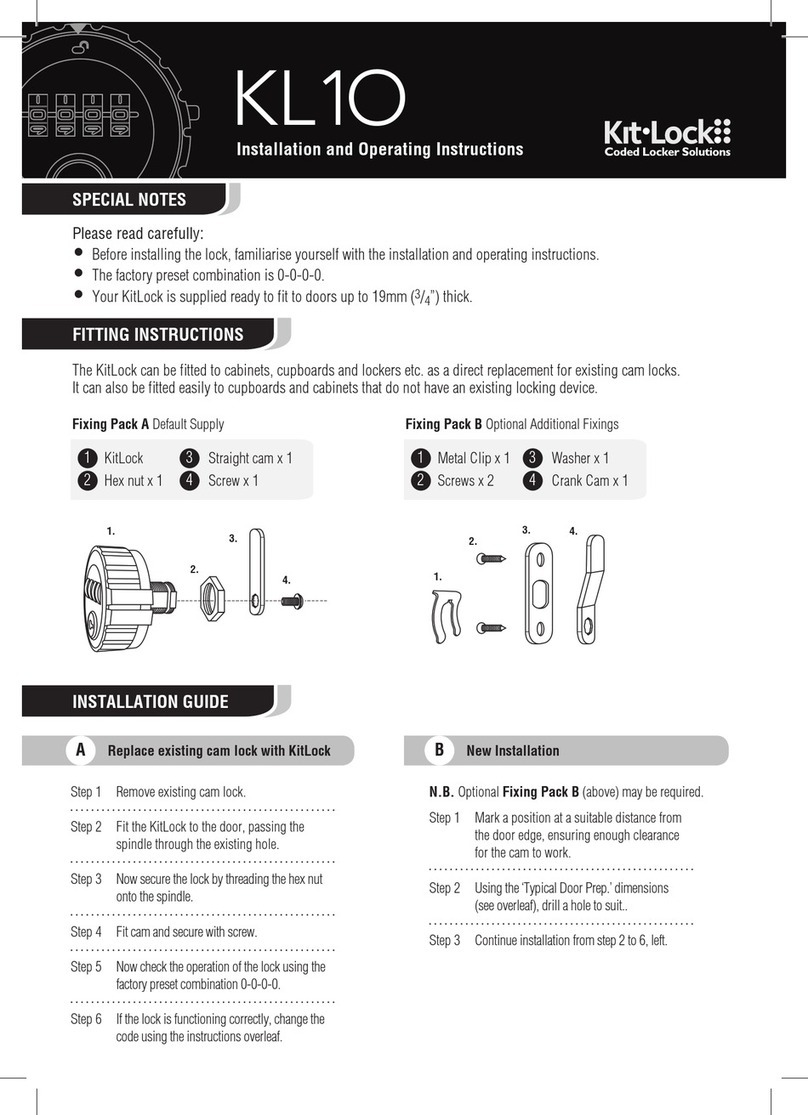

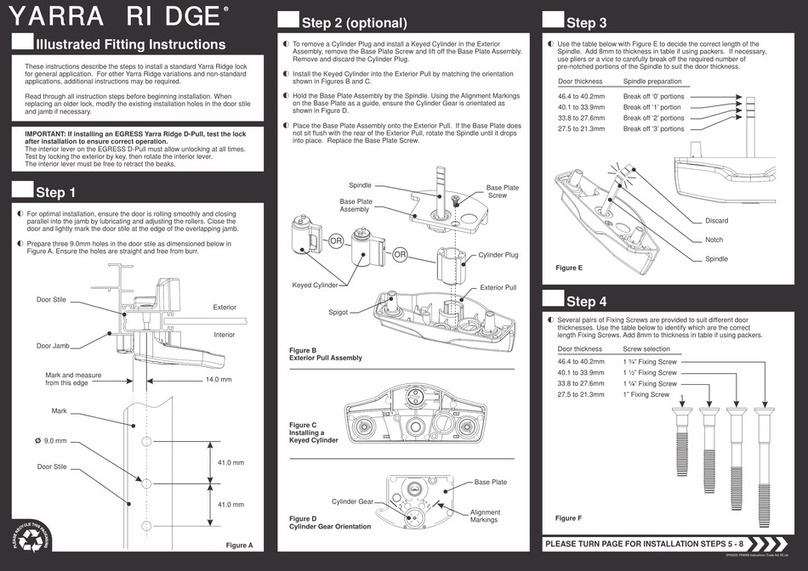

Fasten lock to door

Catch plate installation

7. Fit interior pull

• If the Beaks of the Interior Assembly are extended, use

the Lever to retract them.

• Remove the Handle Screws and lift the Interior Handle

off the Interior Base, place them aside.

• Place the Exterior Assembly onto the exterior face of the

door stile. Rotate the protruding Spindle into a vertical

position.

• While placing the Interior Base onto the interior face of

the door stile, note the following:

- Allow the protruding Spindle to enter the receiving slot

on the underside of the Interior Base.

- Locate the bosses on the underside of the Interior Base

into the holes in the door stile.

• Pass the correct length Fixing Screws through the

Interior Base and screw rmly into the Exterior Assembly.

Reverse the Adjustment Screws 3 anti-clockwise turns from fully

‘screwed-in’ position.

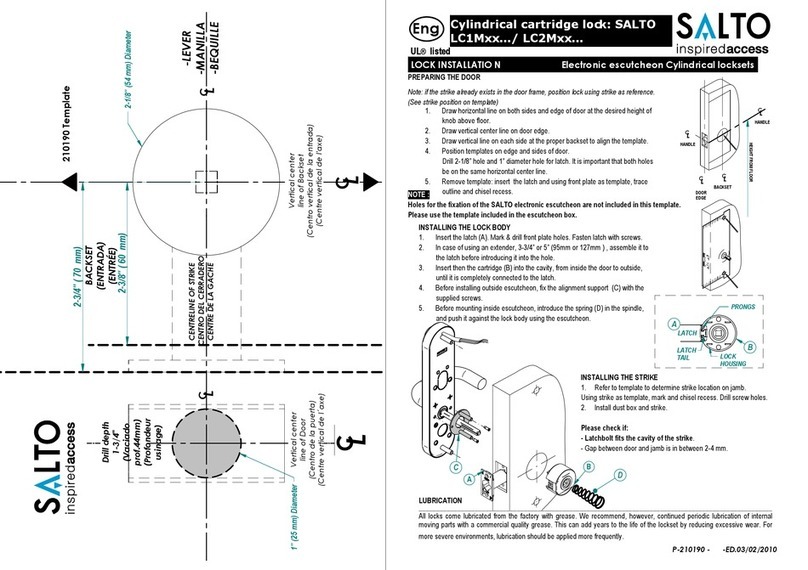

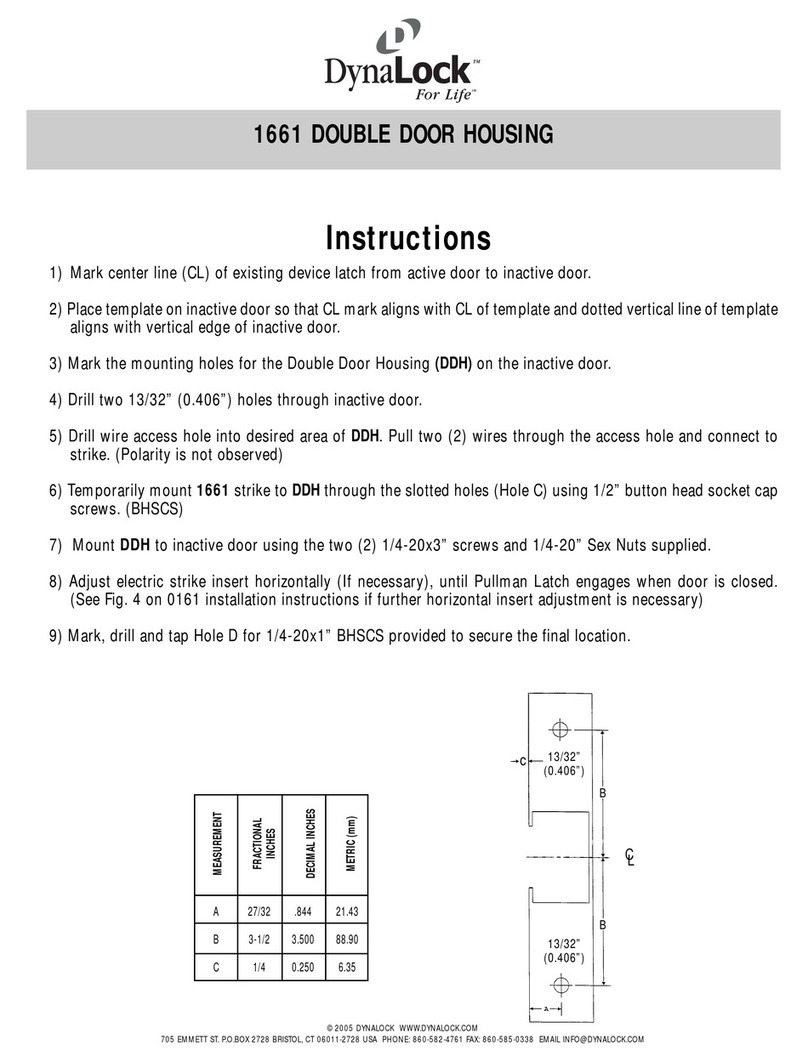

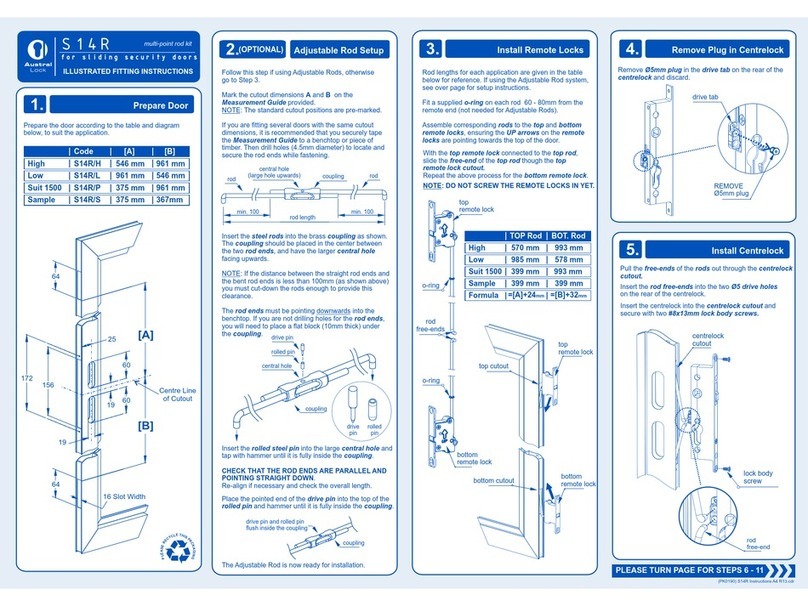

Front Fix Catchplate Installation:

Remove the cover x screws and the cover.

Close the door and position the Catch Assembly on the jamb

opposite the lock with a 1 to 2mm gap between the lock and Catch

Assembly. Mark the centre of the ‘front x’ slots and drill 3.5mm

pilot holes.

Use two ‘Front Fix’ 9.5mm long screws to t the Catch Assembly

lightly to the jamb. Gently close the door and operate the Lever to

test the Beak engagement. Move the CatchPlate Assembly up and

down and adjust the Catch Plate in and out to achieve the best t.

Tighten the ‘Front Fix’ Catch Screws, ret the Cover and re-install

the cover x screws.

Face Fix Catchplate Installation:

Leave the Cover in place. Mark the centre of the ‘face x’ slots.

Screw to the jamb using two ‘Face Fix’ 25mm long screws. Adjust

catchplate position as described above.

OEM1DOC01

ZINC 3749 0917

• To install a Keyed Cylinder into the Interior

Assembly, remove and discard the Cylinder Plug

from the underside of the Interior Handle.

• Install the Keyed Cylinder into the Interior Handle

matching the orientation shown in Figure E.

• Place the Interior Handle over the Interior Base.

It may be necessary to rotate the Lever to nd its

correct orientation. Ret the two Handle Screws.

• Depress the Plunger and test the lock operation by

operating the Lever and Cylinder Key(s) if applicable.

NOTE: Ensure the Beaks are in the retracted

position before closing the door.

SPACERS

Timber doors with a weather

seal and some aluminium

doors may require spacers

between the door and lock.

Interior base

Fixing Screw

Plunger

Handle Screw

Beak

Cylinder Plug

Keyed Cylinder

Interior Handle

OR

Figure E

6. Install cylinder(optional)

Face Fix Installation

Door Jamb

Face Fix

Screws

Interior Door

enters here

“Face Fix” Screw

9.5mm long

Cover

Figure F Front Fix Installation

Door Jamb

Front Fix

Screws

Cover Fix

Screws

Adjustment

Screws

Interior Door

enters here

“Front Fix” Screw

9.5mm long