austriamicrosystems AS5030 User manual

Revision 1.0, 29-May-08 www.austriamicrosystems.com Page 1 of 8

1General Description

The AS5030 is a contactless magnetic rotary encoder for accurate angular measurement over a full turn of 360°.

It is a system-on-chip, combining integrated Hall elements, analog front end and digital signal processing in a

single device.

To measure the angle, only a simple two-pole magnet, rotating over the center of the chip is required.

The absolute angle measurement provides instant indication of the magnet’s angular position with a resolution of

8 bit = 256 positions per revolution. This digital data is available as a serial bit stream and as a PWM signal.

In addition to the angle information, the strength of the magnetic field is also available as a 6-bit code.

Data transmission can be configured for 1-wire (PWM), 2-wires (CLK, DIO) or 3-wires (CLK, DIO, CS).

A software programmable (OTP) zero position simplifies assembly as the zero position of the magnet does not

need to be mechanically aligned.

A Power Down Mode together with fast startup- and measurement cycles allows for very low average power

consumption and makes the AS5030 also suitable for battery operated equipment.

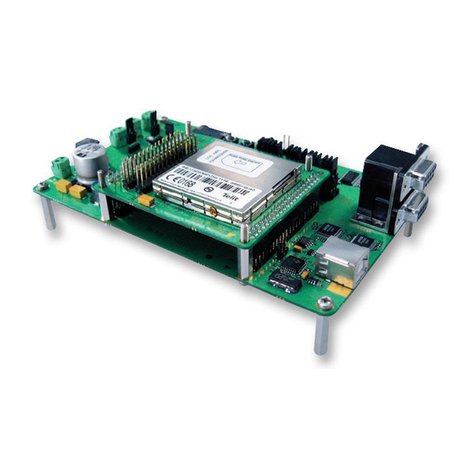

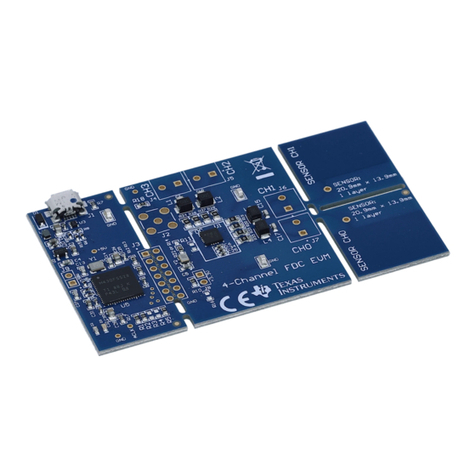

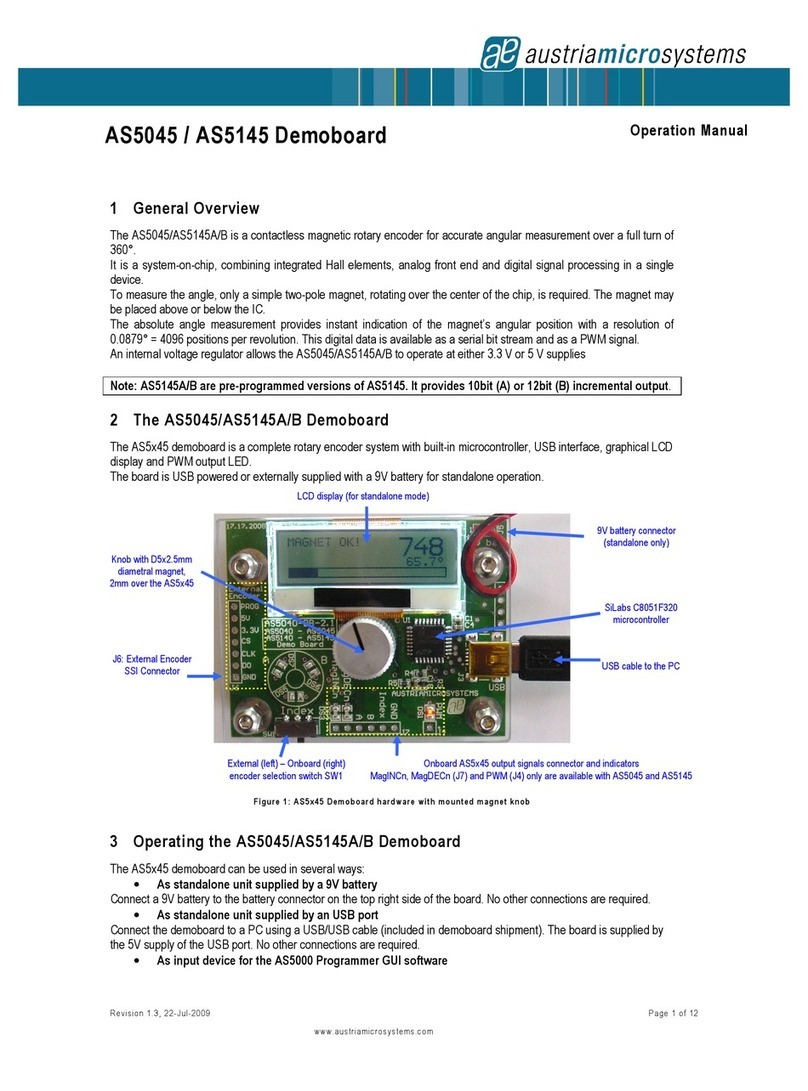

The AS5030 Demoboard

The AS5030 demoboard measures the angle of a diametral magnet turning over the AS5030 sensor. It is

controlled by a built-in microcontroller and shows the result on the LCD display or on the PC GUI via the USB

interface.

The board is powered from the USB plug if it is connected to a PC, or from an external power supply on the DC

Jack (>7.5V) if the board works in stand alone mode without any PC. The angle and AGC values are displayed on

the LCD screen in both modes.

Dimensions of the demo board: 77mm x 84mm (3.03 x 3.30 inch).

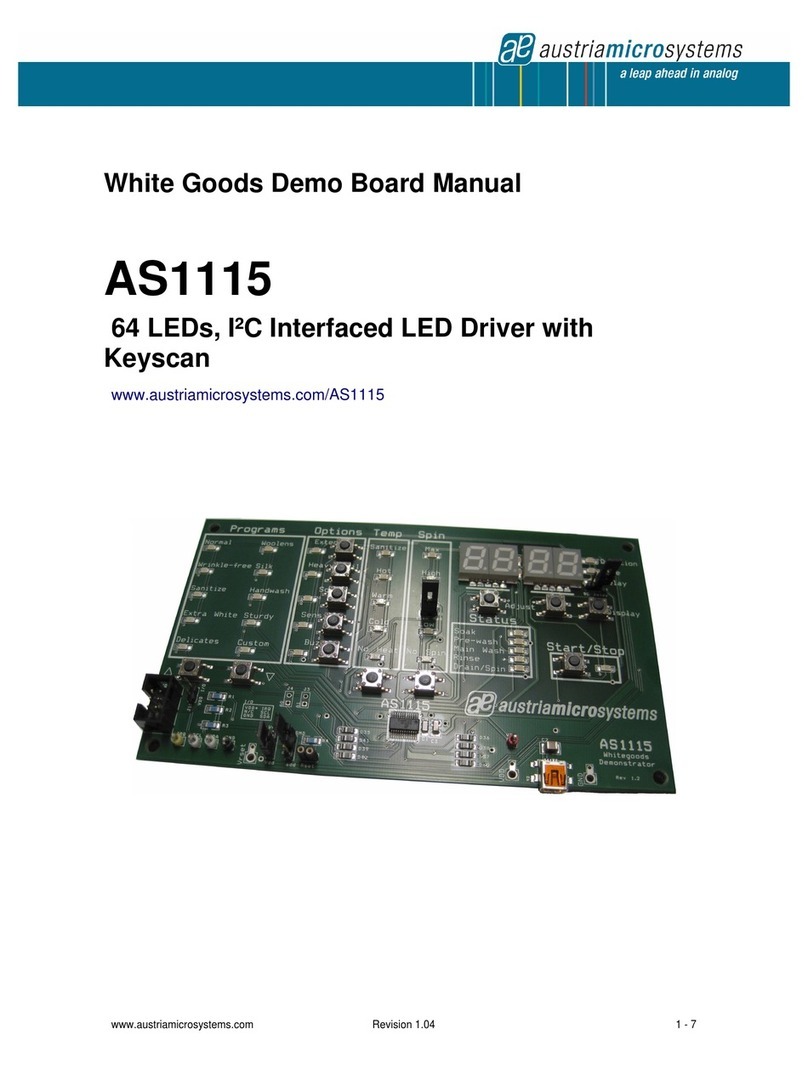

Figure 1: AS5030 demoboard, TOP side Figure 2: AS5030 demoboard, BOTTOM side

AS5011

Low power Integrated Hall IC for

human interface applications

DEMOBOARD AND SOFTWARE

OPERATION MANUAL

AS5030

8 BIT PROGRAMMABLE HIGH SPEED

MAGNETIC ROTARY ENCODER

DEMOBOARD OPERATION MANUAL

AS5030 8 bit high speed magnetic rotary encoder

Demoboard Operation Manual

Revision 1.0, 29-May-08 www.austriamicrosystems.com Page 2 of 8

2AS5030 Software

2.1 Getting Started

This software allows you to become familiar with the principle of the AS5030 sensor. In order to get started, you

need:

•The AS5030 Demo Software installer, downloadable on the Austriamicrosystems website

•Win-XP® or Windows Vista® operating system

•one free USB slot on your PC to connect the demoboard

2.2 Installing the Software

The installation process consists of three steps:

•Unzip the Demoboard software installation AS5030_DemoBoard_Software_Setup.zip in any local

directory

•Execute the .exe setup file

•Follow the instructions on the screen

The demoboard and the software don’t need any other files or drivers to be installed on the computer.

2.3 Software Usage

Before starting the software the board needs to be connected to the PC.

After starting the software, two modes can be selected: SSI-Readout and OTP.

For both modes, the following functions are present:

Figure 3: USB Connect

USB: Connected/No connection. If the demoboard is correctly connected to the PC, the software should find

immediately the demo board.

Onboard / External:

Switch the actual AS5030 sensor from the on-board one (by default), to an external AS5030 connected

on the “external AS5030 header” (see Figure1).

AS5030 8 bit high speed magnetic rotary encoder

Demoboard Operation Manual

Revision 1.0, 29-May-08 www.austriamicrosystems.com Page 3 of 8

2.4 SSI-Readout

After starting the demo software and selecting the “SSI-Readout” tab, the magnet angle, AGC value, PWM out

value are displayed (see Figure 4).

For a correct reading of the magnet angle, the airgap between the AS5030 top side and the magnet should be

chosen that the 0<AGC<63. If the AGC value reaches 63, the ALARM LED will blink to indicate that the magnet is

too far away from the sensor, and the measurement is not accurate or not valid.

Figure 4: SSI-Readout tab

Periodic Readout:

By unchecking this option, the angle and AGC values are not read anymore, and the displayed value

keep their last state during the normal readout.

The read period can be adjusted between 50ms and 1s (default 200ms), to have more or less reactivity.

State: Displays the state of the C2 pin on the selected AS5030. By default C2 = 0 (three wires mode).

The Lock indicator is the state of the lock bit in the serial stream. This bit should be always enabled.

Low Power / Ultra Low Power / Wakeup:

Function not yet implemented

AS5030 8 bit high speed magnetic rotary encoder

Demoboard Operation Manual

Revision 1.0, 29-May-08 www.austriamicrosystems.com Page 4 of 8

2.5 OTP

The “OTP” tab, displays the OTP configuration bit of the selected AS5030 sensor.

•In Onboard mode, the configuration bits can be temporary changed (access to the Read and Write

functions only). After a new power up, the configuration bits are set back to their default state.

•In External mode, the AS5030 can be temporary configured, and can be permanently programmed too.

The Read, Write and Prog functions are available.

Figure 5: OTP tab

Zero Position Programming:

The Zero Position Programming tool is used to assign a zero value to a defined mechanical position.

Move the magnet to a desired reference position, which is the mechanical 0°.

Click on “Get absolute position”. The actual angle seen on the sensor side is displayed in decimal and

binary (Z7..0 bits).

Click on “Write zero position”. The bits Z7..0 are written to the Zero Position register of the AS5030.

Now the actual mechanical angle is the 0° angle on the AS5030 side.

This value can be permanently fused on an external AS5030 sensor by clicking on Prog.

OTP registers:

In On-board mode, the OTP registers can’t be permanently fused.

•Read: Reads back the OTP configuration registers of the selected sensor.

•Write: Writes the configuration bits as represented in the checkboxes to the selected AS5030. Those bits

won’t be permanently written, and will be lost if the sensor is powered down.

•Prog (external mode only): After having written the configuration bits to the AS5030, those bits can be

permanently fused by clicking on Prog. After a new power up of the device, this new configuration is enabled.

AS5030 8 bit high speed magnetic rotary encoder

Demoboard Operation Manual

Revision 1.0, 29-May-08 www.austriamicrosystems.com Page 5 of 8

3AS5030 Demoboard hardware

Figure 6: AS5030_DB_1.3 Demoboard schematics

3.1.1 Power supply

The demoboard is powered directly from the USB plug of a PC or from an external DC power supply (>7.5V, 100mA) connected

on the DC jack J6 and regulated through a 5V voltage regulator (I1, ZR78L05).

The programming high voltage (8.5V) for the external AS5030 is generated directly from the 5V source through a DC/DC step-up

converter U3. This source is used for the LCD power supply as well, for the contrast control through the P1 potentiometer.

The U2 voltage regulator is necessary for the 3.3V LCD power supply.

3.1.2 AS5030 Encoder

The AS5030 (U4) is running with the 5V source. The resistor R27 (0R) can be removed if the user wants to use his own power

supply for his own tests.

The SSI serial interface (DIO, CS, DCLK) is controlled by the microcontroller U5.

The LED D7 is directly connected to the AS5030 on the MagRngn pin on one side, and on U5 for the other side to make it

blinking if MagRngn = 5V (magnet too far away).

The PWM LED is directly connected on the PWM signal of U4.

The Test3..0 signals are connected to U5 but are not used.

3.1.3 Microcontroller

The microcontroller PIC 18F4550 (U5) from Microchip includes an on-chip USB interface.

The U1 switch enables the bootloader mode of the microcontroller, if pressed during power up.

In normal mode, pressing the switch makes the microcontroller writing the zero position value into the active AS5030.

The connector U7 is used for ISP programming of the microcontroller only.

AS5030 8 bit high speed magnetic rotary encoder

Demoboard Operation Manual

Revision 1.0, 29-May-08 www.austriamicrosystems.com Page 6 of 8

3.1.4 J4 connector for external AS5030

An external AS5030 device can be wired to this connector. It allows the user to test his own board, and/or fuse the configuration

bits for the mass production.

•Pin 1: ePROG.

Is the 8.5V source for fusing. The high voltage is switched only during the programming phase.

•Pin 2: eCS

Is an independent CS signal provided by the microcontroller, only for the external sensor

•Pin 3: eDIO

Is the same signal as DIO used for the on board sensor. Both are connected through the R14 resistor (0R). Only one

sensor, on-board or external, can be selected at the same time with the CS and eCS signal.

•Pin 4: eDCLK

Is the same signal as DCLK used for the on board sensor. Both are connected through the R46 resistor (0R). Only one

sensor, on-board or external, can be selected at the same time with the CS and eCS signal.

•Pin 5: 5V

Is the power supply of the external sensor

•Pin 6: 3.3V

Not used

•Pin 7: VSS

•Pin 8: eVOUT

Analog input. Not used

4Troubleshooting

When operating the demo board and software it is advisable to proceed as:

•Running the demo software

Before starting the demo software the demo board needs to be connected to the USB port of the PC.

1. Connect to the USB port.

2. Start the software.

•Closing the demo software

After finishing the work with the demo board the software needs to be closed before disconnecting the demo board.

1. Close the software.

2. Disconnect from the USB port.

AS5030 8 bit high speed magnetic rotary encoder

Demoboard Operation Manual

Revision 1.0, 29-May-08 www.austriamicrosystems.com Page 7 of 8

Table of contents

1General Description...........................................................................................................................................................1

The AS5030 Demoboard........................................................................................................................................................1

2AS5030 Software...............................................................................................................................................................2

2.1 Getting Started..........................................................................................................................................................2

2.2 Installing the Software ..............................................................................................................................................2

2.3 Software Usage........................................................................................................................................................2

2.4 SSI-Readout.............................................................................................................................................................3

2.5 OTP..........................................................................................................................................................................4

3AS5030 Demoboard hardware..........................................................................................................................................5

4Troubleshooting.................................................................................................................................................................6

Table of contents........................................................................................................................................................................7

Copyrights..................................................................................................................................................................................8

Disclaimer...................................................................................................................................................................................8

Contact Information....................................................................................................................................................................8

AS5030 8 bit high speed magnetic rotary encoder

Demoboard Operation Manual

Revision 1.0, 29-May-08 www.austriamicrosystems.com Page 8 of 8

Copyrights

Copyright © 1997-2008, austriamicrosystems AG, Schloss Premstaetten, 8141 Unterpremstaetten, Austria-Europe.

Trademarks Registered ®. All rights reserved. The material herein may not be reproduced, adapted, merged, translated,

stored, or used without the prior written consent of the copyright owner.

All products and companies mentioned are trademarks or registered trademarks of their respective companies.

This product is protected by U.S. Patent No. 7,095,228.

Disclaimer

Devices sold by austriamicrosystems AG are covered by the warranty and patent indemnification provisions appearing in its

Term of Sale. austriamicrosystems AG makes no warranty, express, statutory, implied, or by description regarding the

information set forth herein or regarding the freedom of the described devices from patent infringement. austriamicrosystems

AG reserves the right to change specifications and prices at any time and without notice. Therefore, prior to designing this

product into a system, it is necessary to check with austriamicrosystems AG for current information. This product is intended

for use in normal commercial applications. Applications requiring extended temperature range, unusual environmental

requirements, or high reliability applications, such as military, medical life-support or lifesustaining equipment are specifically

not recommended without additional processing by austriamicrosystems AG for each application.

The information furnished here by austriamicrosystems AG is believed to be correct and accurate. However,

austriamicrosystems AG shall not be liable to recipient or any third party for any damages, including but not limited to

personal injury, property damage, loss of profits, loss of use, interruption of business or indirect, special, incidental or

consequential damages, of any kind, in connection with or arising out of the furnishing, performance or use of the technical

data herein. No obligation or liability to recipient or any third party shall arise or flow out of austriamicrosystems AG rendering

of technical or other services.

Contact Information

Headquarters

austriamicrosystems AG

A-8141 Schloss Premstaetten, Austria

Tel: +43 (0) 3136 500 0

Fax: +43 (0) 3136 525 01

For Sales Offices, Distributors and Representatives, please visit:

http://www.austriamicrosystems.com

This manual suits for next models

1

Table of contents

Other austriamicrosystems Motherboard manuals

austriamicrosystems

austriamicrosystems AS5045 User manual

austriamicrosystems

austriamicrosystems AS1323 Installation and operating instructions

austriamicrosystems

austriamicrosystems AS3935 Instruction manual

austriamicrosystems

austriamicrosystems AS3607 EVAL BOARD User manual

austriamicrosystems

austriamicrosystems AS1351 Installation and operating instructions

austriamicrosystems

austriamicrosystems AS3610-AN01-Demoboard Guide

austriamicrosystems

austriamicrosystems AS1109 User manual