AUTEC ASG-3005 User manual

INSTALLATION-MANUAL

Scissor

ASG-3005

ASG-4005

ISSUED 11-02-04

AUTEC Hefbruggen bv

•Wheelfree scissorlifts –electro hydraulic

INDEX OF CONTENTS PG.

1. Introduction 02 2. Packing, transport and storage 02

3. Safety specifications 02 4. Description of the lift 02

5. Installation 03

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

Tel: +31 348 477000 Fax: +31 348 475104 Internet: www.autec.nl - E-mail: info@autec.nl

en/TD-ASG-4005-1

INSTALLATION-MANUAL

Scissor

ASG-3005

ASG-4005

ISSUED 11-02-04

AUTEC Hefbruggen bv

6. Connection to electrical mains

7. Safety checks

8. Goods received report

9Electrical circuit diagram

10 Hydraulic system diagram

04

05

05

06

07

1. INTRODUCTION

CAUTION

This instruction manual is intended

for the assembly personnel who are

going to carry out the installation of

the lift.

2. PACKING, TRANSPORT

AND STORAGE

Every action involving the operation,

transportation or unpacking of the

equipment must only be done by

trained personnel who have a proper

knowledge of the lift, and who are

familiar with the contents of this

operating manual.

LIFTING AND MOVING THE

PACKING CRATES CONTAINING

THE EQUIPMENT

The wooden crates must be lifted and

moved with the help of a fork lift truck or

a lift crane. (Fig. 1)

Fig. 1

The equipment chosen must be

capable of lifting and moving the

equipment safely, keeping in mind

the dimensions of the vehicle, the

weight, the centre of gravity and

projecting and fragile parts.

STORAGE

The packed lift must always the placed

in a covered area at a temperature

between -10 oC and + 40 oC and must

not be exposed to direct sunlight.

OPENING THE CRATES

Check whether the machine have been

damaged during transportation, and

whether all the components as

mentioned in the Packing List are

physically present.

REMOVAL OF CRATES

The wood of the crates may be re-used.

It is strongly recommended

that you should first carefully read

the safety instructions.

3. SAFETY REGULATIONS

The manufacturer hereby refuses to

accept any responsibility for injury to

persons or damage to equipment or

property if it appears that incorrect

handling of the lift has taken place. This

instructions manual only describes the

operating- and safety aspects which

persons who are installing the machine

need to know. In order to understand

the terminology used in this manual, it is

necessary that the person performing

the installation work should have

specific experience in industrial work,

service, maintenance and repair

activities, and must also possess the

ability to explain the drawings and the

descriptions contained in this manual to

other people. At the same time he must

also be aware of the general and

specific safety regulations which apply

in the country where the lift is being

installed.

4. DESCRIPTION OF THE LIFT

(Fig.2)

The lift consists of the following :

Two lifts and two base frames the base

frames are fitted to the ground with the

help of wedge bolts. The vehicle to be

lifted is placed on four rubber support

plates which are supplied along with the

machine. The lifts are capable of being

extended, so that cars with a longer

wheel base can also be mounted. Both

the lifting systems consist of lifting

arms, as well as hydraulic cylinders.

The movement of the cylinder is

transmitted to the arms. The lift is

operated over a control cabinet which is

anchored to the floor next to the

scissors lift.

Fig.2

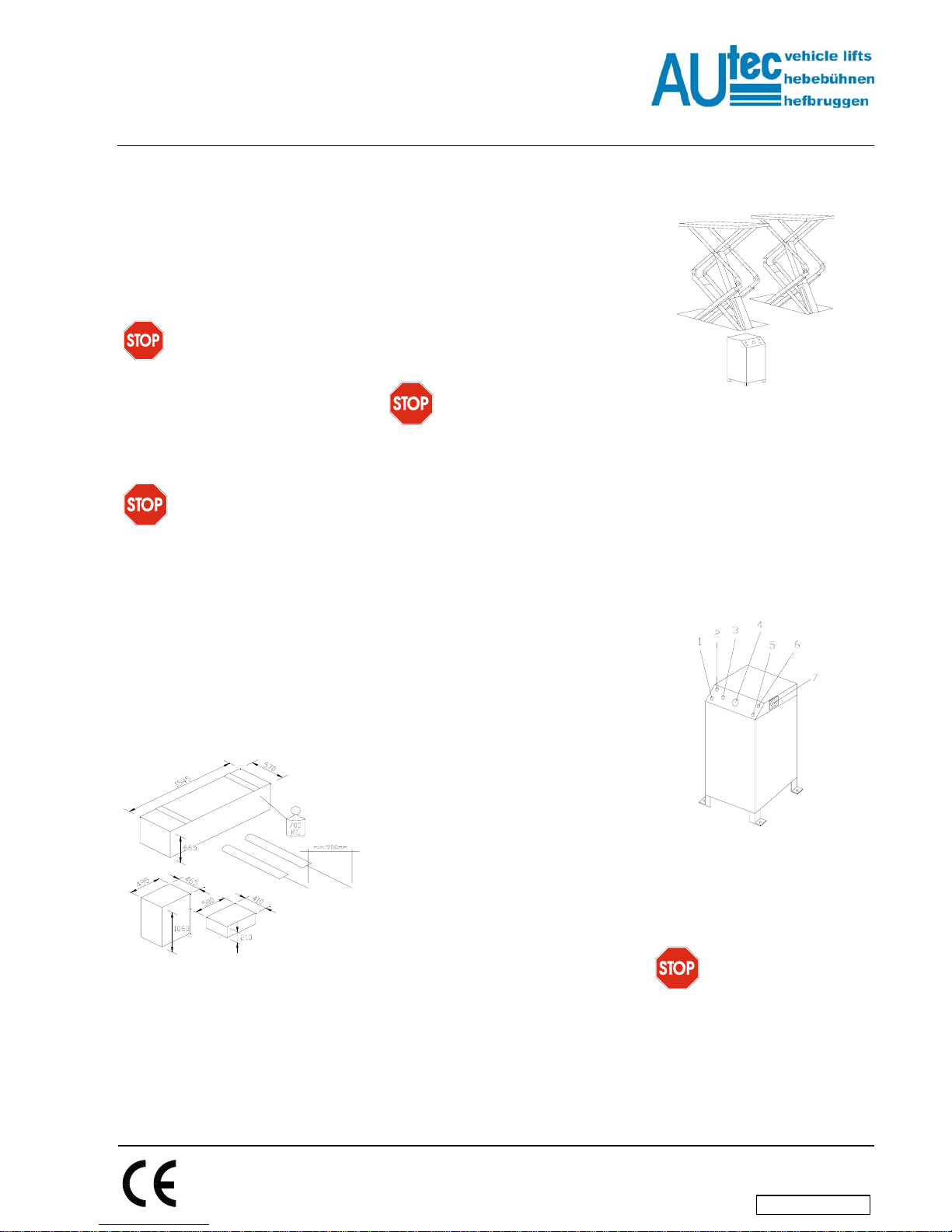

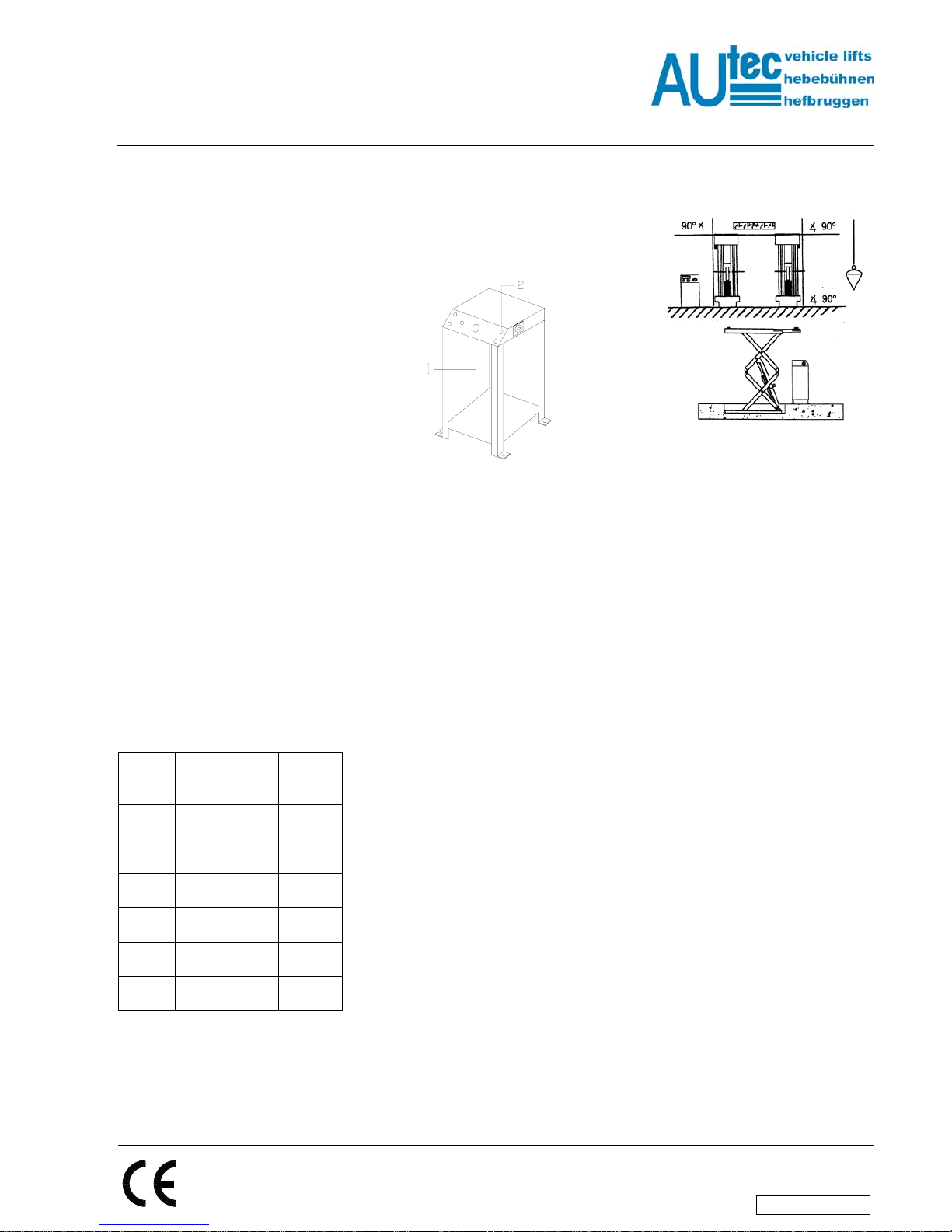

CONTROL BOX (FIG.3)

The controlpanel of the controlbox

consists of the following:

1. Safety switch for completing the

lowering of the platform over the

last 400 mm of the descent

2. Voltage monitoring lamp

3. Horn/signal lamp

4. Emergency stop button

5. Lowering motion button.

6. Lifting motion button.

7. Main switch.

Fig.3

In the control panel, there is a hydraulic

part, which consists of an oil tank, a

hydraulic pump and electrical motor,

solenoid valves and hydraulic hoses

5. INSTALLATION

Installation may only be done

by persons authorised to do so.

BEFORE STARTING INSTALLATION,

PLEASE RECHECK ALL THE

CONTROL POINTS.

The lift must be installed in an enclosed

space where weather influences do not

have any effect. The place of installation

must be at a sufficient distance from the

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

en/TD-ASG-4005-2

INSTALLATION-MANUAL

Scissor

ASG-3005

ASG-4005

ISSUED 11-02-04

AUTEC Hefbruggen bv

storage locations of paint and wax, and

also rooms where there is a danger of

explosion.

ELECTRICAL POWER SUPPLY

POINT.

The client must ensure that there is a

power supply point near the installation

site, which satisfies all the applicable

legal requirements (see page 4). If such

power supply is not available, the

installation technician will arrange for

an emergency cable. The lift shall be

tested after the emergency power

supply has been dismantled. The client

must then arrange for a duly qualified

and recognised installation technician to

lay the final wiring.

IMPORTANT INSTALLATION

MEASURES

The lift must be installed taking into

account the dimensions of other objects

(Fig. 4), and the rules and regulations

applicable in the country where the lift is

installed.

In particular, attention should be paid to

the following :

The minimum height from the floor,

at the installation location, must be

5000 mm

The minimum distance from the

walls must be 1 m.

The minimum working area is 500

mm

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

en/TD-ASG-4005-3

Adequate room for working

Adequate room for maintenance,

access-/ and exit routes.

Position with respect to other

machines

In the neighbourhood of the power

supply point to ensure problem-free

connection.

Fig. 4

LIGHTING

All the parts of the lifting lift must be

uniformly and adequately lighted.

During the installation work,

there must be no unauthorised

persons in the safety zone around

the lift (Fig. 4).

INSTALLATION OF THE LIFT

Take the two parts of the lift out of the

packing case. Seal the hydraulic hoses

openings with tape in order to prevent

the contamination of the hoses. To

move the vehicle loading tracks, one

must use a lifting vehicle having

sufficient lifting capacity. Lower the lift

onto the desired installation location.

Fig. 5

Lift the lifting tracks with the help of a

crane to a height of around 800 mm and

place the lift in its interlock.

Fig. 6

CONNECTING THE HYDRAULIC

SYSTEM (see figure 20)

Put the control cabinet in the selected

spot. Please keep in mind the minimum

distance to be maintained with respect

to other objects. Open the control

cabinet with the help of a socket

wrench. The connections to the

connecting block (Fig. 7) in the control

panel, and the hydraulic system hoses

are marked. Connect the hydraulic

hoses according to the following

drawing. Thereafter firmly tighten the

connections.

Fig. 7

Ref.A

Fig. 8

6. CONNECTING TO THE

MAINS

WARNING

The following actions must only be

carried out by duly authorised

personnel :

First check the following points before

connecting to the mains:

INSTALLATION-MANUAL

Scissor

ASG-3005

ASG-4005

ISSUED 11-02-04

AUTEC Hefbruggen bv

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

en/TD-ASG-4005-4

-

-

-

-

The electrical system at the

workplace must be protected

according to the applicable

standards.

The wires must be of the following

sizes : in the case of 400 V they

must be at least 2.5 mm2fuse max

16A. In the case of 230V 3-phase

supply, the wire size must be at

least 4 mm2.

The supply cable must be provided

with an earthing wire, and must be

suitable for a firm and final

connection.

Connect the power supply cable to

the control cabinet according to

Fig. 15.

Put the main switch in the “1” position.

Check the direction of rotation of the

motor by pressing the lifting-motion

button. The direction of location must be

anti-clockwise.

FILLING THE HYDRAULIC SYSTEM

Fill the hydraulic system with around 15

litres of hydraulic oil which satisfies the

standard ISO 6743/4 :For example Fina

Hydran TS32 or an equivalent oil.

Test Properties Value

ASTM

DF1298 Density at 20°C 0.8Kg/l

ASTM

D 445 Viscosity at 40°C 32cSt

ASTM

D 445 Viscosity at

100°C 5.43 cSt

ASTM

D 2270 Viscosity index 104 N°

ASTM

D 97 Freezing point -30°C

ASTM

D 92 Flame point 215°C

ASTM

D 644 Neutralisation

number 0.5 mg

KOH/g

DE-AERATE THE HYDRAULIC

SYSTEM

•

•

Put the main switch in the “1”

position.

Keep the button 1 in the control

cabinet on the underside of the

control panel (fig. 9) and the lifting

button (2) pressed until both the

lifts are in their highest position.

Hold both the buttons down for at

least 20 seconds. Now fill the oil

tank once more to a height of 5

meters.

Fig. 9

CONNECTING THE PNEUMATIC

SYSTEM (Fig.17 )

The pneumatic system to which the lift

is connected must have a water

separator and lubrication system as well

as a pressure reduction valve.

Raise the lift to its highest position.•

•

•

•

•

•

•

•

•

Connect the pneumatic hoses to

the connecting points in the control

cabinet according to figure 17.

Now connect the compressed air to

the pneumatic valve.

Check the system for proper

functioning. You can do this by

pressing the lowering-motion

button : the pneumatic protection

will thereby be removed.

Lower the lift fully.

Once more carry out the airing

procedure.

Put the panels back into the control

cabinet.

ALIGNING THE LIFT (Fig. 10)

Raise the lift to height of about 1.6

meters (check whether the

pneumatic-mechanical lock is

working).

Check whether the vehicle-

uploading plates are properly

aligned vertically and horizontally

with respect to the floor and each

other (Figure 10). This is

extremely important for the proper

functioning of the lift. If necessary,

insert packing shims under the

base frame to ensure proper

alignment.

Fig. 10

CHECK THE PHOTO CELL

Check whether the photocell

synchronisation guard is correctly

installed, for which you may proceed as

follows :

1. Raise the lift to height of

approximately 1 meter.

2. Cut out a piece of paperboard of

the dimensions 100x100mm, with a

25 mm hole in the middle.

3. Place the carton in the middle of

the reflection mirror.

4. Now press the lifting-motion button.

5. If the lift does not rise, it means

that the lift is not properly aligned.

6. Aligned the lift once again.

FIXING THE LIFT

The lift can be fixed in two ways,

depending on cassette selected:

1. Open cassette: Using a concrete

drill, bore holes of 12 mm and 125

mm depth in the floor. Use the

frame of the lift as a template.

Hammer in wedge bolts of the type

TIKM12x100 into the floor see ref.

2 Fig 11. Tighten the wedge bolts

using a torque wrench with a

torque of 45 Nm.

INSTALLATION-MANUAL

Scissor

ASG-3005

ASG-4005

ISSUED 11-02-04

AUTEC Hefbruggen bv

1

2

Fig. 11

Industrieterrein IJsselveld, Vlasakker 11, 3417 XT MONTFOORT, The Netherlands

en/TD-ASG-4005-5

2. Closed cassette : Screw M12x25

bolts in the tapped holes made for

the same. Tighten the bolts with a

torque of 80 Nm.

HEIGHT OF SETTING BOLTS

(REF. 1 FIG. 11)

Set the bolts in such a manner that the

upper edge of the vehicle-uploading

plates in the lowest position are level

with the floor.

LIMIT SWITCHES

The functions of the various limit

switches are as follows :

1. Limit switch : This is for the

lowering-motion in the last 40 cm.

2. The synchronisation switch

ensures the synchronisation of the

two lifts.

3. The lifting-motion limit switch limits

the lifting-motion.

4. Photocell for synchronisation

protection.

Check the working of the limit

switches.

The limit switches are pre-assembled in

the factory. Check to see whether the lift

gets limited at a height of 1850 mm. If

not, turn the lifting-motion cam ring to

the correct position (Fig. 12).

Check whether the lowering-motion limit

switch is so adjusted that the lift stops at

a safety height of 400 mm. If not, turn

the lowering-motion cam ring to the

correct position.

Caution : While rising to its maximum

position, the lifting-motion proximity

switch is in contact with the cam. At its

maximum working height, the proximity

switch loses contact with the cam, and

the lift will thereby get disconnected.

Caution : While rising to its maximum

position, the lowering-motion proximity

switch is in contact with the cam. At the

safety working height of 400 mm, the

proximity switch detects the cam, and

the lift will thereby get disconnected.

Fig. 12

SYNCHRONISATION SWITCH

(FIG. 13)

The synchronisation switch mounted on

the underside of the lift must be

installed in such a manner that in the

lowest position of the lift, it is 1 to 3 mm

away from the metal plate, see ref. 1

Fig. 13

1

Fig. 13

Monitoring the motion of the lift

without load :

Raise and lower the lift 2 or 3 times

without load, and check whether :

•

•

•

•

•

The lift stops at the maximum

height

Whether the lifting-motion limit

switch is working properly.

Whether the lowering-motion limit

switch is working properly

Whether the synchronisation

switch is working properly (the lifts

must get lifted and lowered

simultaneously).

Whether the lowering-motion signal

is working properly.

Monitoring the motion of the lift with

load :

Check the above points once more, but

this time with a vehicle mounted on the

lift.

7. SAFETY CHECKS

After the complete installation of the lift,

the responsible installation engineer

must check all the safety arrangements

on the lift to check whether they are

working properly.

CLEANING OF THE LIFT (Fig. 17)

The installation engineer responsible

must take care to see that the lift which

is installed is delivered to the client in a

'squeaky clean' condition.

Fig. 17

8. GOODS RECEIPT REPORT

The concerned installation engineer

must prepare a goods receipt report

after completion of the installation. The

goods receipt report must be prepared

as carefully as possible. Any complaints

and/or observations of the client will

also be noted in the report under the

heading ‘Remarks’. The report must be

signed by the responsible installation

engineer, and by the client. The

installation engineer will deliver the

report to the technical department. The

installation engineer must see to it that

the report are filled-in in time in the

service box.

This manual suits for next models

1

Table of contents

Other AUTEC Scissor Lift manuals