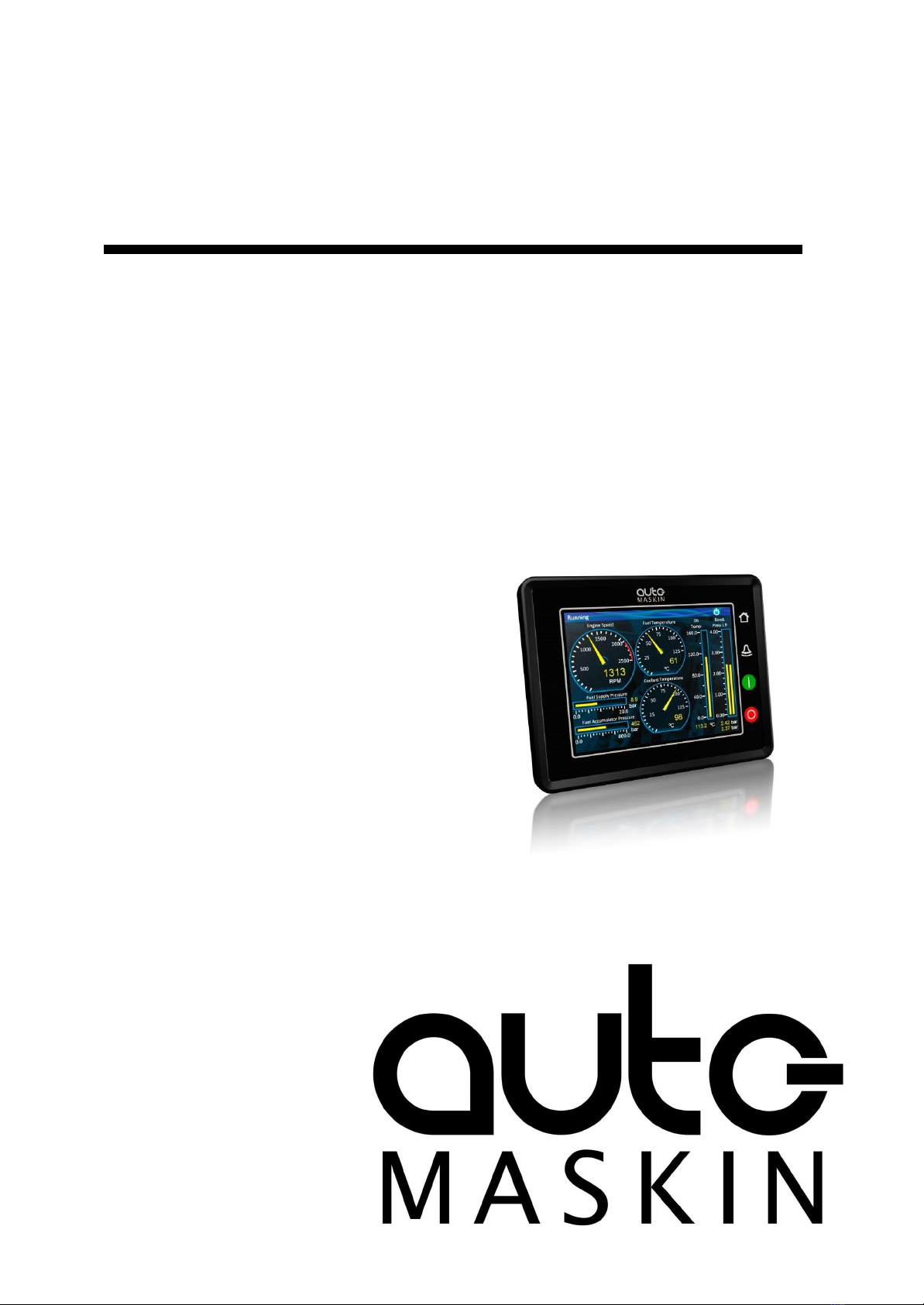

auto maskin Marine Pro 200 Series User manual

Publication P/N 1006494

User Manual

Marine Pro

200 Series

DCU 210E Engine Controller, P/N 1006475

DCU 208E Engine Controller, P/N 1006477

RP 210E Remote Panel, P/N 1006476

RP 220E Remote Panel, P/N 1006472

RP 206E Remote Panel, P/N 1006478

Table of contents

1 Preface 3

1.1 About this Manual 3

1.2 Responsibilities 3

1.3 Revisions 3

2 Ordering Information 4

3 Overview of the 200 series 4

3.1 DCU 210E Engine Controller 4

3.2 DCU 208E Engine Controller 4

3.3 RP 210E/220E Remote Panel 5

3.4 Ethernet Switch 5

3.5 Expansion 5

4 DCU 210E Engine Controller 5

4.1 First Power On 5

4.2 Configuration Dependency 6

4.3 Main Elements of the Touch Screen 6

4.3.1 Screen Navigation and Hot-spots

6

4.4 Panel Buttons 7

4.5 Screen Layout 8

4.5.1 Status Bar Symbols 8

4.6 Start Engine 9

4.6.1 Latched Start 9

4.6.2 Hold-to Start 10

4.6.3 E-Start 10

4.7 Stop Engine 10

4.7.1 Latched Stop 10

4.7.2 Hold-to Stop 11

4.8 Alarm List 11

4.8.1 Indication 11

4.8.2 Enter the Alarm List 11

4.9 Menu 12

4.9.1 Settings 12

4.9.2 Screen Backlight 14

4.9.3 Log & Counters 14

4.9.4 Controls 15

4.9.5 Help 16

5 RP 210E/220E/206E Remote Panel 16

5.1 Introduction 16

5.1.1 Similarities with the DCU 210E

17

5.2 Status Bar Symbols 17

5.3 Other Symbols 17

5.4 Menu 17

5.4.1 Active Station 18

5.4.2 Settings 18

5.4.3 Camera 19

6 The Alarm List 19

6.1 Filter Alarms 20

6.2 Silence the Buzzer 20

6.3 Acknowledge a Single Alarm 20

6.4 Acknowledge All Alarms 20

Page 2 (20)

1 Preface

1.1 About this Manual

This manual has been published primarily for professionals and qualified personnel.

The user of this material is assumed to have basic knowledge in marine systems, and must

be able to carry out related electrical work.

Work on the low-voltage circuit should only be carried out by qualified and

experienced personnel.

Installation or work on the shore power equipment must only be carried out by

electricians authorized to work with such installations.

1.2 Responsibilities

It is the sole responsibility of the installer to ensure that the installation work is

carried out in a satisfactory manner, that it is operationally in good order, that the

approved material and accessories are used and that the installation meets all

applicable rules and regulations.

Auto-Maskin continuously upgrades its products and reserves the right to make

changes and improvements without prior notice.

All information in this manual is based upon information at the time of printing. For updated

information, please contact your local distributor.

The crossed-out wheeled bin symbol indicates that the item should be

disposed of separately. The item should be handed in for recycling in

accordance with local environmental regulations for waste disposal.

By separating a marked item, you will help reduce the volume of waste

sent to incinerators or land-fill and minimize any potential negative impact

on human health and the environment.

1.3 Revisions

This User Manual is valid for the following firmware version of the 200E products.

Firmware Version

Release

3.10 P5

February 2022

Page 3 (20)

User Manual revision: May 2022

2 Ordering Information

The Marine Pro covers a wide range of compatible products within both the 200- and 400

Series. Please visit our website for more information.

3 Overview of the 200 series

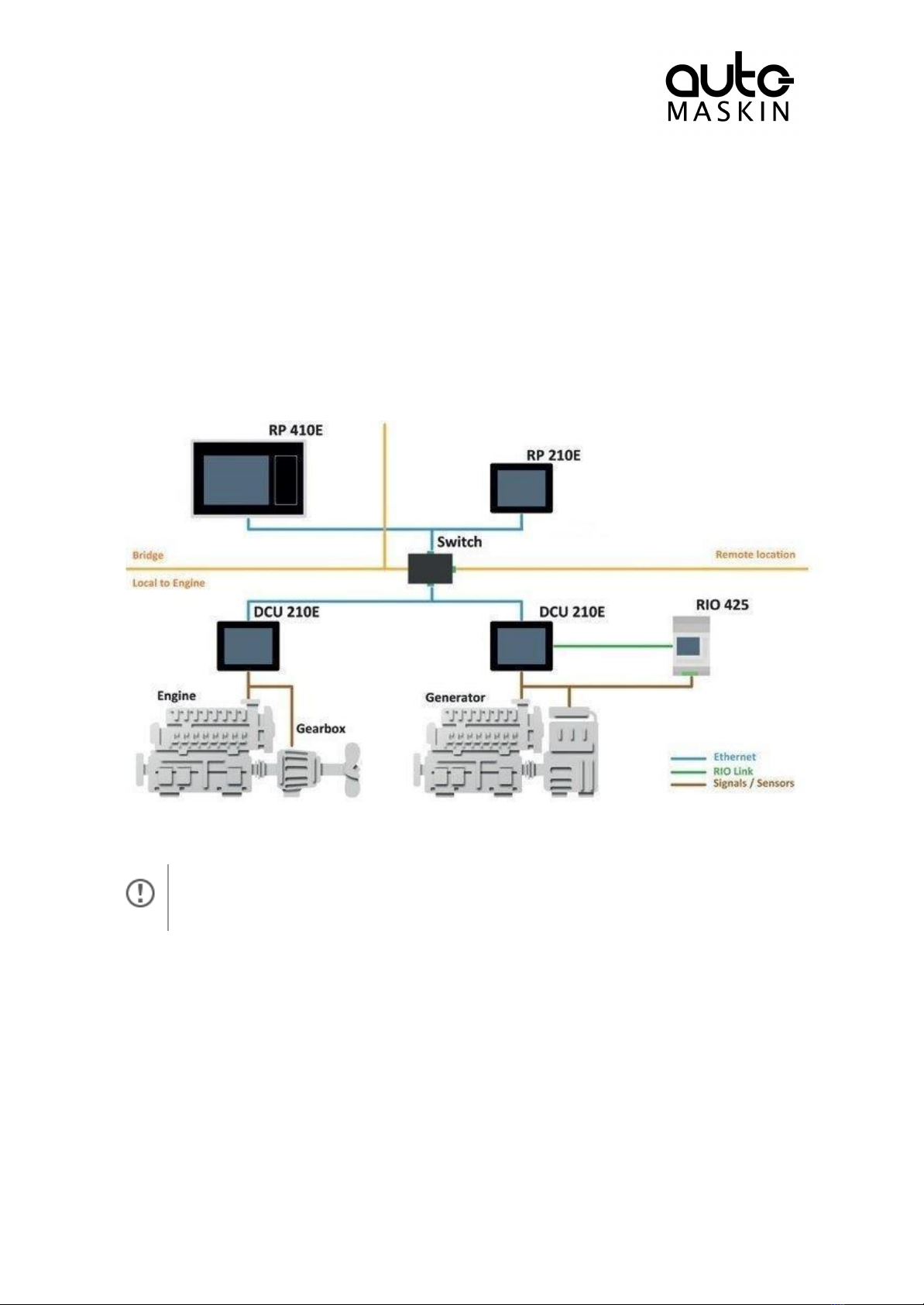

The drawing below shows a typical layout.

All products with a touch screen shall be operated with care. Do not use sharp or

hard objects.

3.1 DCU 210E Engine Controller

The DCU 210E Engine Controller is the main building block in the 200 Series.

Engine sensor values are displayed on the color touch screen, and commands and other

user interaction is also here.

3.2 DCU 208E Engine Controller

The DCU 208E is basically the same as the DCU 210E, but without the color touch screen.

It saves cost being used in smaller engine rooms, where a remote panel is all that is needed.

Page 4 (20)

3.3 RP 210E/220E Remote Panel

The optional RP Remote Panels brings everything on the DCU to a remote location, with the

exact same user interface. It does not need any configuration, as it is reading the

configuration from the DCU.

As such, the RP can easily be retrofitted.

The RP also supports one IP-camera to be installed on the network.

3.4 Ethernet Switch

The Ethernet switch is not necessary if only one DCU 210E and one RP 210E is in use.

These can then be wired with an Ethernet cable directly.

It is recommended to make use of an Ethernet switch though, as it simplifies PC

configuration connection and future expansion to remote panels and/or camera interface.

3.5 Expansion

The basic system can be expanded with more input and output channels using the versatile

RIO units (Remote I/O).

Currently, there are RIO units for

● General I/O expansion, RIO 410 and RIO 210.

● Exhaust temperature monitoring, RIO 412

● Generator monitoring, RIO 425

● Load sharing, LSU 408

4 DCU 210E Engine Controller

4.1 First Power On

Use a Web-browser to set up and configure the DCU.

PC Connection/Setup:

● Connect via Ethernet using a net browser

● From the Address Field in the Browser, type the IP-Address. Factory Default is

192.168.0.101.

● Then log in to the unit. Factory Default Username is ‘DCU’ and Factory Default

password is ‘1234’.

For further details and information, please see the Configuration Manual.

At the first Power-Up the user will be guided through a Setup Wizard

1. Language selection and your choice is valid through the rest of the

procedure.

Page 5 (20)

2. Network settings. Make sure to follow common network configuration

practice and take care when several units need to operate within the same

network.

4.2 Configuration Dependency

The behavior of the panel depends somewhat on its configuration.

For instance, the start/stop buttons can be configured either as latched, meaning the DCU

completes the start/stop cycle once the button is pressed, or hold-to, meaning the operator

must keep the button pressed until the engine has started or stopped.

The configuration of the DCU is not part of this document.

4.3 Main Elements of the Touch Screen

The DCU 210E (not the DCU 208E) uses a touch screen for all user interaction.

The DCU 208E does not have a user interface; please see the RP 210E Remote Panel

section.

4.3.1 Screen Navigation and Hot-spots

The screen has a few hot-spot areas predefined for certain functions.

For instance, pressing the left-hand side of the screen moves to the previous page (if any).

To do this

Press this

Select page

Center of the screen

Previous screen

Left-hand side

(midway) of the

screen

Next screen

Right-hand side

(midway) of the

screen

Screen animations will aid the user in understanding the different hot-spot actions.

Select Page

Press the center of the screen to get a miniature (thumbnail) of all the instrument pages for

easy access.

This is the quickest and easiest way to get an overview and select what page to navigate to.

Page 6 (20)

In the above example, there are two instrument pages available.

Select one of the two thumbnail pages to move directly to that page.

Previous Screen

From the instrument view, press the left-hand side of the screen to move to the previous

screen.

Next screen

From the instrument view, press the right-hand side of the screen to move to the next

screen.

4.4 Panel Buttons

The DCU has four buttons for quick access to main functions.

Home

The Home button located at the upper right corner always

displays the first page of instruments.

Alarm List

The Alarm List button located at the right side of the panel

shows the alarm list. Press the button again to leave the alarm

list.

Start Engine

The Start button located on the right side of the panel can be

configured as latched or hold. See Start Engine Section for

further details.

Stop Engine

The Stop button located at the bottom right side can be

configured as latched or hold. See Stop Engine Section for

further details.

Page 7 (20)

4.5 Screen Layout

At the top area of the screen is the Status Bar. The left-hand side indicates the Engine

Status and the right-hand side is dedicated for Panel Status.

4.5.1 Status Bar Symbols

The following symbols may appear in the status bar and several symbols may be visible

simultaneously.

DCU is in automatic mode.

DCU is in manual mode.

DCU is in local mode.

DCU is in harbor mode.

DCU is in emergency mode.

DCU is in shutdown override mode.

A service interval is past due.

All OK.

(no alarms)

Gear in Neutral position.

Gear in Forward position.

Gear in Reverse position.

Gear Engaged.

(direction unknown)

Gear status Unknown.

Page 8 (20)

Automatic Mode

The DCU is ready to accept automatic start- and stop commands.

Local start and stop is not possible, unless allowed in configuration.

Emergency Mode

To enter this mode the DCU need to be configured as a Combined Harbor/Emergency set.

Channels configured as shutdown will not cause any engine shutdown but indicate with

alarms only.

Overspeed is an exception that can’t be disabled.

Manual Mode

In Manual Mode, the DCU does not accept external automatic start- and stop commands.

Local start and stop is not possible, unless allowed in configuration.

Harbor Mode

This mode is available only if the DCU is configured as a Combined Harbor/Emergency set.

● Shutdown channels are enabled.

● Automatic start/stop is disabled.

Shutdown Override

All channels configured as shutdown will give an alarm only.

Overspeed is an exception that can’t be disabled.

4.6 Start Engine

The start button can be configured as latched or hold-to.

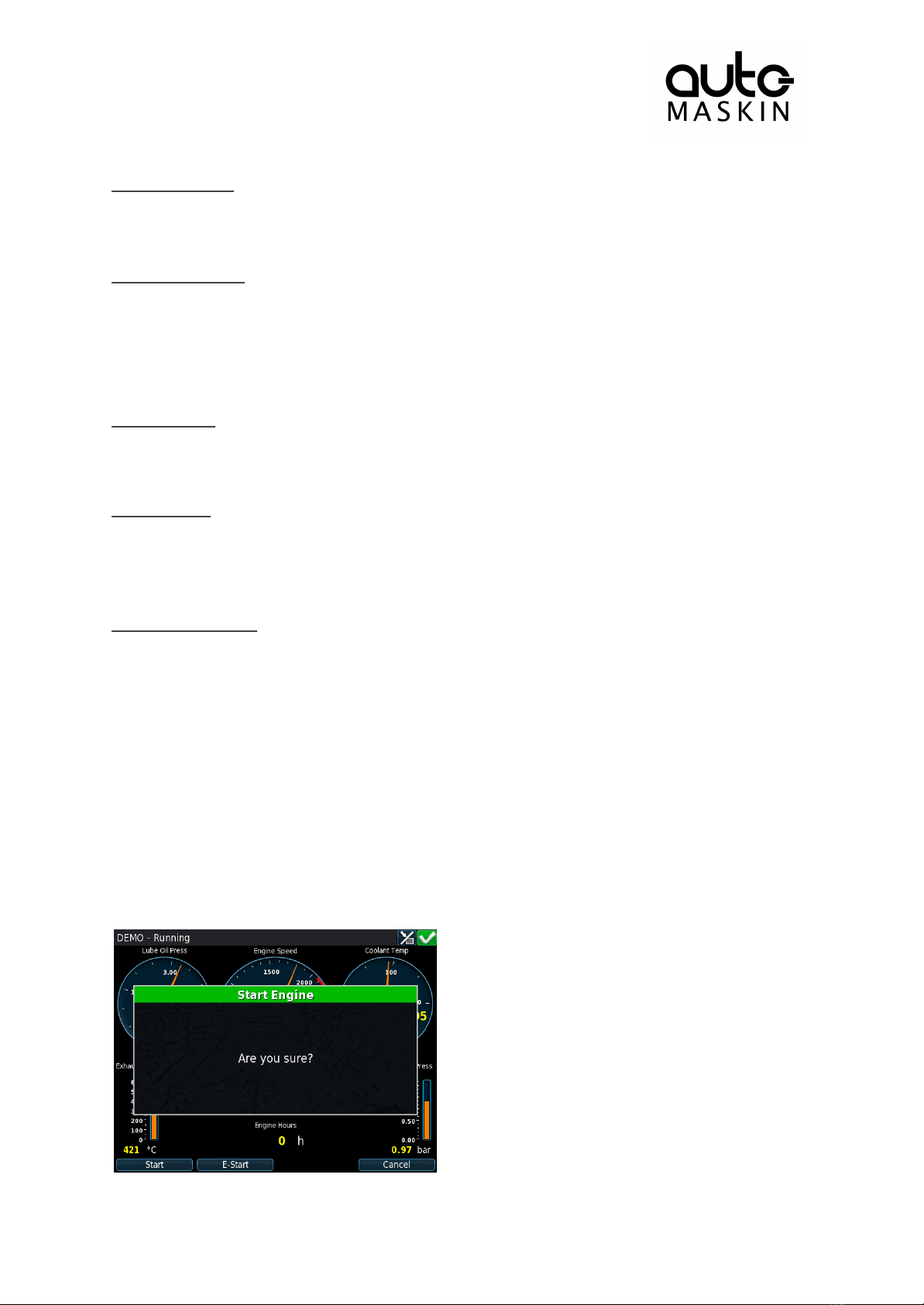

4.6.1 Latched Start

If the button is configured as latched, press the start button, observe the confirmation dialog,

and press the soft-button Start to start.

The DCU will complete the start sequence.

Page 9 (20)

4.6.2 Hold-to Start

If the start button is configured as hold-to, press and hold the start button until the engine

has started.

There will be no confirmation dialog.

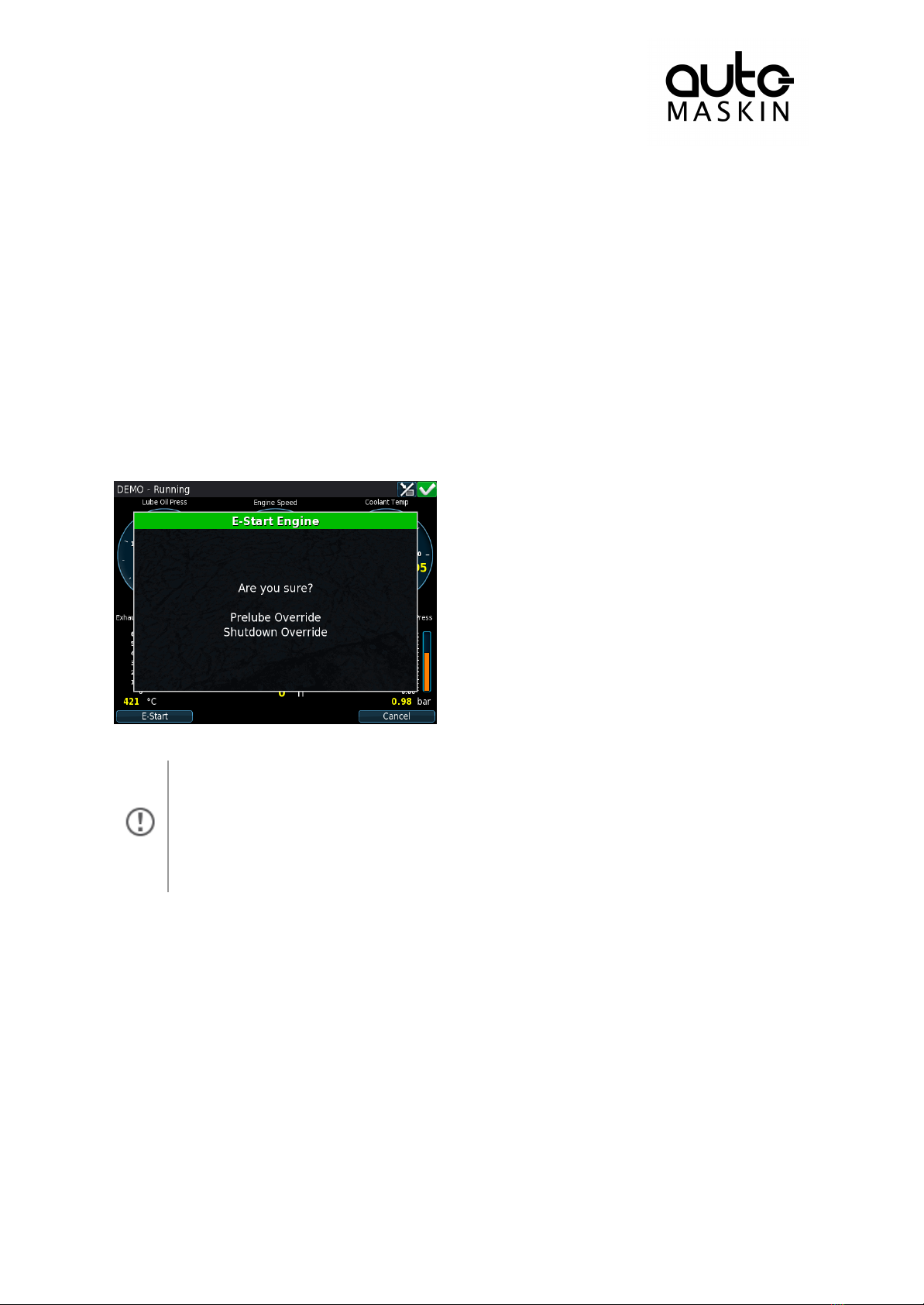

4.6.3 E-Start

If the DCU is configured for it, an Emergency Start option is available in the Start dialog. See

the picture above.

The E-Start is designed to start the engine as quickly as possible in an emergency situation,

and shall not be used for everyday start.

Activating E-Start will override any configured Prelube and also set Shutdown

Override. The engine will start immediately, and run in a Shutdown Override mode

setting.

If desired, the operator can switch off Shutdown Override mode once the engine

has started.

4.7 Stop Engine

The stop button can be configured as latched or hold-to.

4.7.1 Latched Stop

If the button is configured as latched, press the stop button, observe the confirmation dialog,

and press the stop soft-button.

The DCU will complete the stop sequence.

Page 10 (20)

4.7.2 Hold-to Stop

If the stop button is configured as hold-to, press and hold the stop button until the engine

has stopped.

There will be no confirmation dialog.

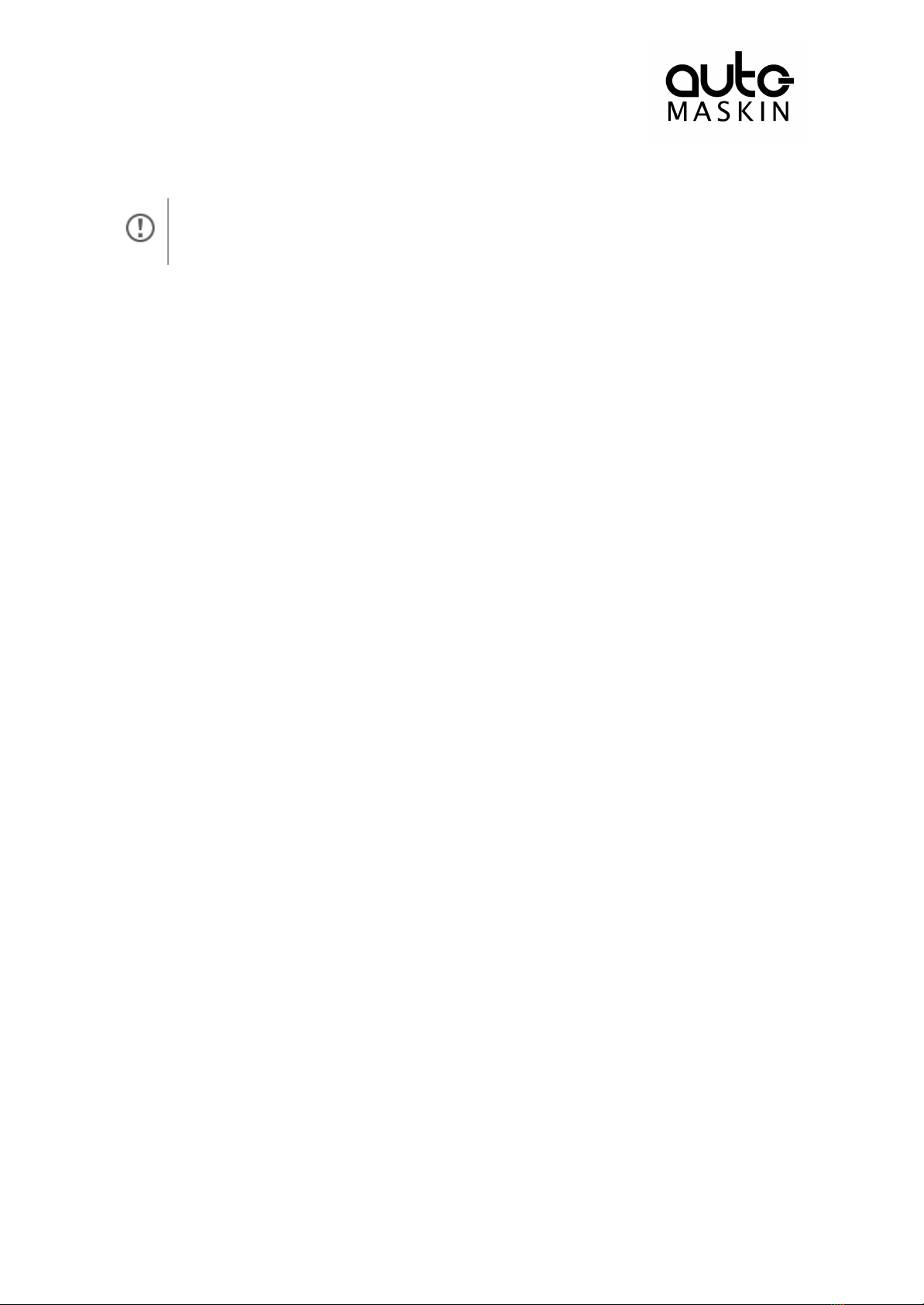

4.8 Alarm List

4.8.1 Indication

Whenever there is a new event in the alarm list, the DCU indicates as follows:

● Buzzer sounds

● The screen status bar flashes yellow or red

The color of the flashing status bar indicates the type of event.

● Yellow: Warning

● Red: Critical Alarm or shutdown

The red bar takes precedence over yellow.

4.8.2 Enter the Alarm List

To see the alarm list, press the alarm list button or the top-right section of the screen, as

discussed earlier.

Page 11 (20)

The above picture indicates a warning in the alarm list.

For further explanation, see the chapter The Alarm List.

4.9 Menu

The menu page has five icons.

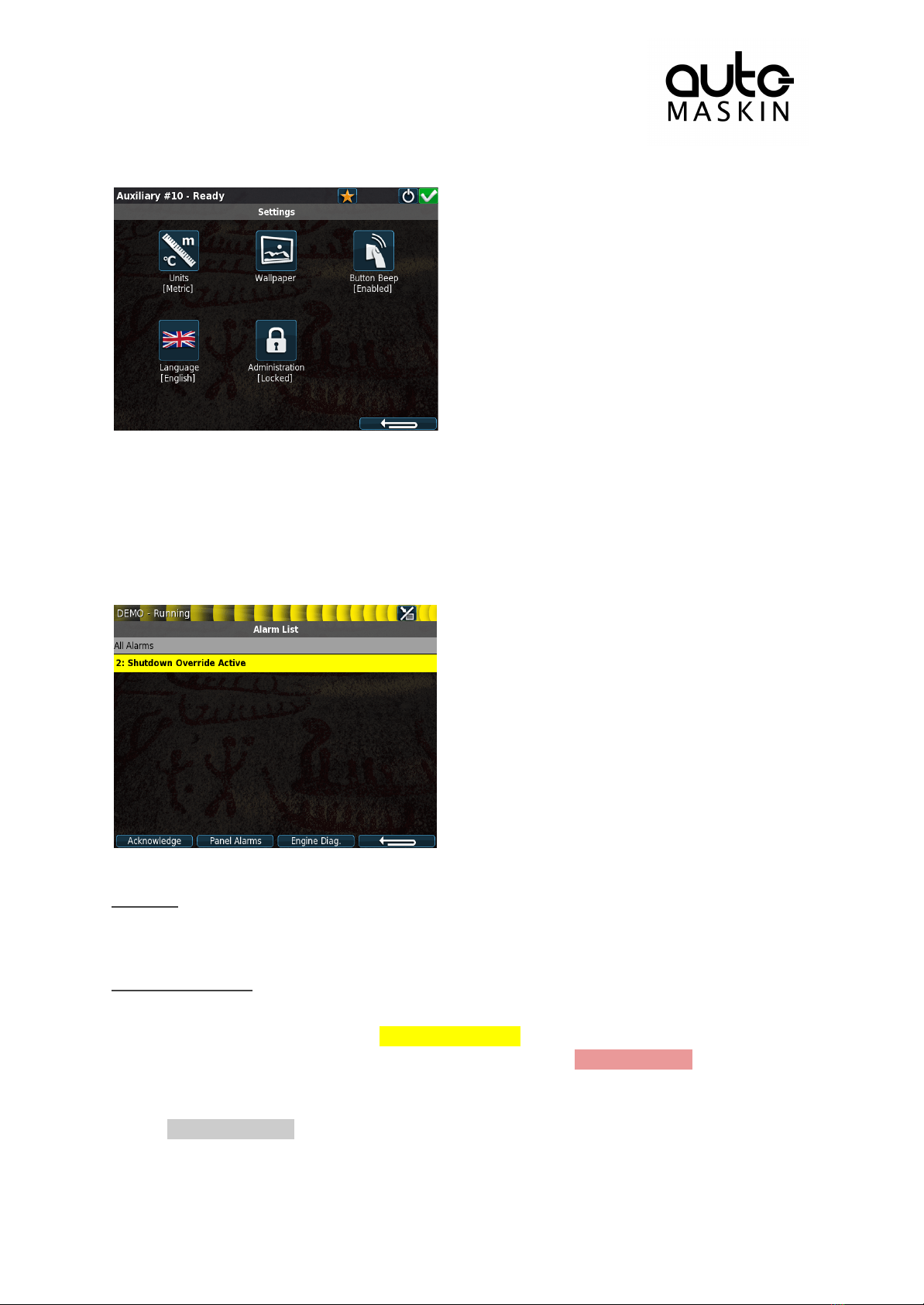

4.9.1 Settings

Access all panel settings.

There are three pages with icon selections in the submenu.

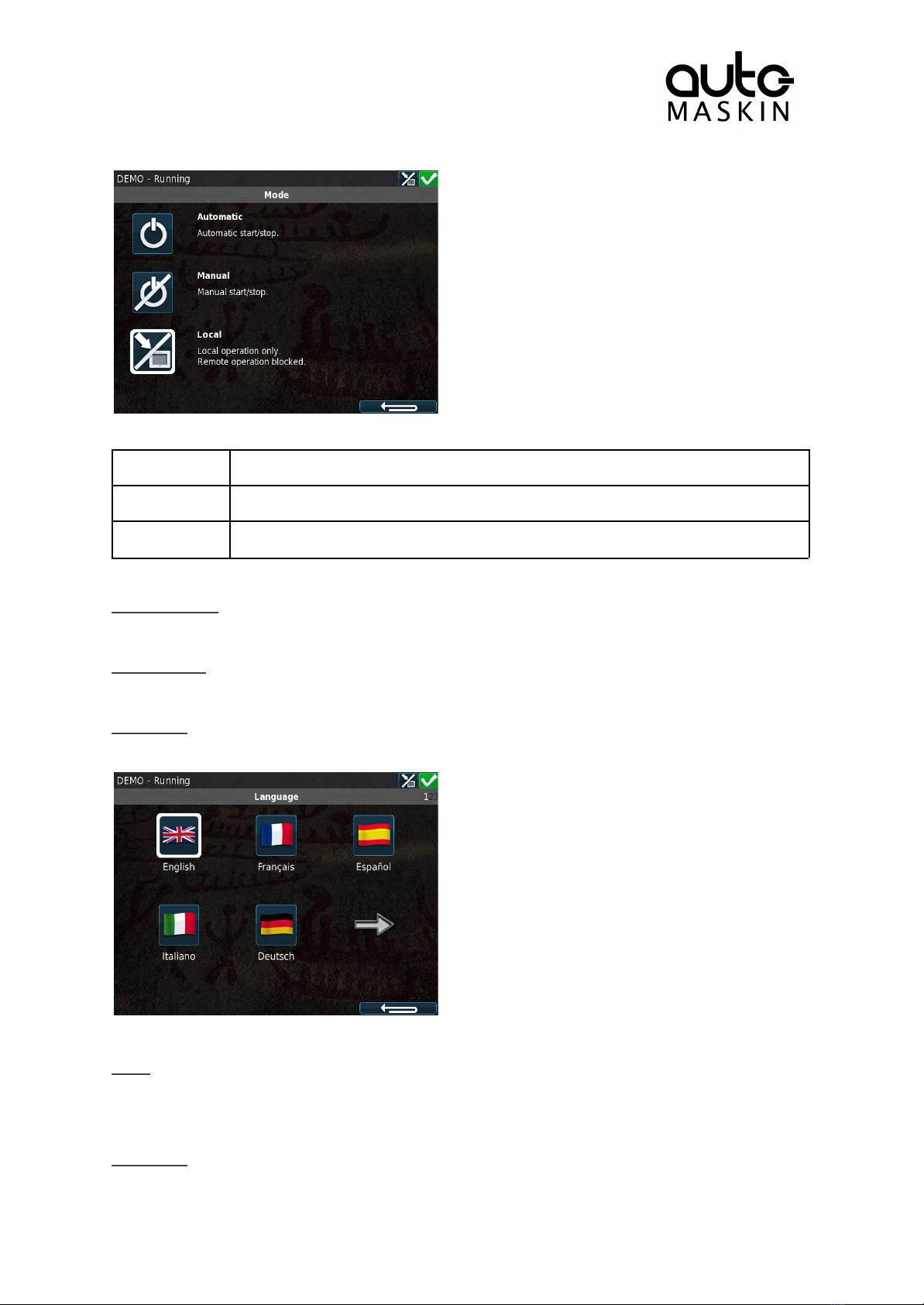

Mode

Select the operating mode.

Page 12 (20)

Automatic

The panel accepts signals for automatic start/stop of the engine.

Manual

The panel does not accept signals for automatic start/stop of the engine.

Local

The panel does not accept any remote commands.

Start Disabled

Set to Active to disable start.

Button Beep

Set to Enable to have each screen press sound the buzzer.

Language

Select any of the panel’s built-in languages.

The panel configuration may not be translated to the selected language.

Units

Select Metric or U.S. units of measure.

Any gauge scaling is handled in the configuration.

Wallpaper

Page 13 (20)

Select any of the built-in wallpapers as a background for instruments, menus and popup

dialogs.

Connect a PC

The panel has an inbuilt DHCP server, and thus can issue an IP address to a PC that is

configured to receive a dynamic IP address in a company network.

Set the Start- and End IP to be outside of the panel’s current IP address, and press OK.

Administration

This section covers deeper configuration options of the panel, and is not covered in this

manual.

4.9.2 Screen Backlight

Adjust screen backlight intensity for varying light conditions.

4.9.3 Log & Counters

There are submenus for engine operating hours, event log and service intervals.

Counters

The submenu has the engine hours, in total, since start and since the last reset.

The Since Start value is automatically reset every time the engine makes a new start.

The Since Reset values can be reset manually using the button provided.

Event Log

All panel events are stored internally, and can be monitored here.

Select an event to see when it first appeared, when it was acknowledged (if applicable for

that event) and when it disappeared (again, if applicable).

Engine Service Interval

If engine service intervals are configured, then this page displays how many hours until the

next service.

Page 14 (20)

4.9.4 Controls

Access certain engine related functions.

Engine Overspeed Test

Set to Active to activate the engine overspeed test.

This temporarily lowers the overspeed setpoint to the nominal speed of the engine. Start the

engine to perform the test.

The test will deactivate automatically after a timeout, or when an actual overspeed (from the

test) is detected.

Gear

Opens the Gear Control form. Note, this function may not be available, as it depends on how

the DCU is configured.

This form is used to inspect transmission related parameters and to request gear changes.

Prelube Override

Activates or deactivates Prelube Override. When active , a start attempt will skip the prelube

sequence and attempt to start the engine immediately. Prelube Override is automatically

deactivated after a start attempt. Note, this function is anly present if the DCU is configured

to perform prelubing prior to start of the engine.

Page 15 (20)

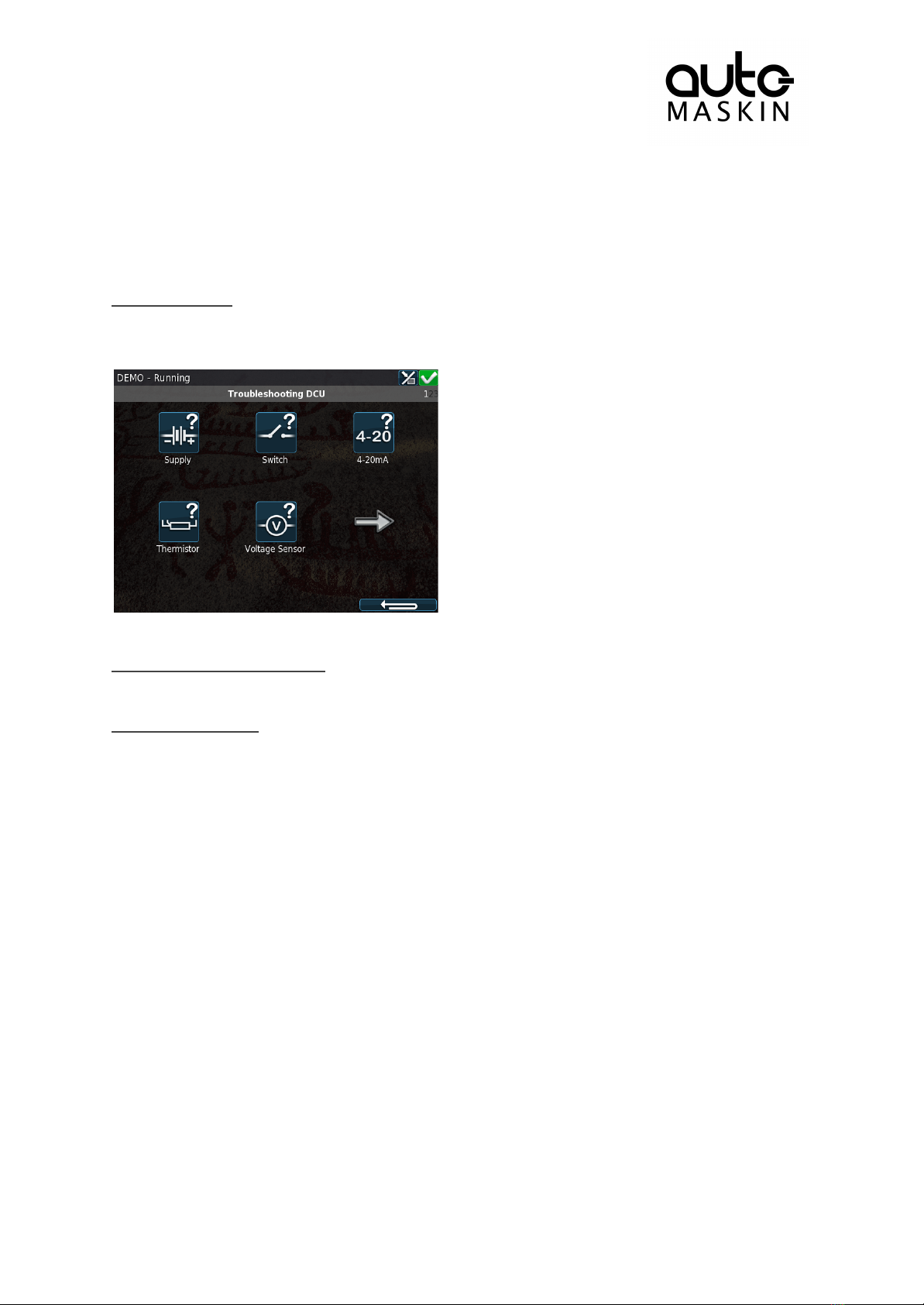

4.9.5 Help

Submenus for troubleshooting and panel version information, such as firmware version and

IP address.

Troubleshooting

This submenu has troubleshooting information for the panel itself in addition to every RIO

expansion unit connected.

Select the icon that represents the area of interest.

Troubleshooting Diagnostics

Additional CPU related Information; Temperature, Frequency and Load.

Version Information

This page displays panel hardware version, software version, kernel version and also the

engine ECM software version (if connected to the J1939 CANbus).

Of special interest here is the panel IP address, which is necessary when connecting to the

panel using a PC.

5 RP 210E/220E/206E Remote Panel

5.1 Introduction

The RP 210E, RP 220E and RP 206E are remote panels for DCUs in the Marine Pro 200

and 400 series.

It reads the configuration from the DCU Engine Controller it is connected to. If the DCU has

a configuration change, then the RP Remote Panel will automatically adapt.

The RP 210E can monitor and control one DCU engine panel only.

The RP 220E can monitor and control two DCU engine panels.

The RP 206E can monitor two DCU engine panels. It can not control start/stop.

Page 16 (20)

5.1.1 Similarities with the DCU 210E

The use of the RP 210E/220E/206E remote panel is very similar to the use of the DCU 210E

panel, so this chapter will only describe the menu sections on the RP 210E/220E/206E that

are not available on the DCU 210E.

5.2 Status Bar Symbols

In addition to the symbols already mentioned for the DCU the RP has one additional symbol

to indicate active station.

This RP is the active station for the connected DCU.

5.3 Other Symbols

The RP supports a function called “Operator Locked”. When operator lock is active, (no user

input accepted from either touch screen or buttons) this symbol is displayed on the bottom

right of the screen.

Operator Lock is active.

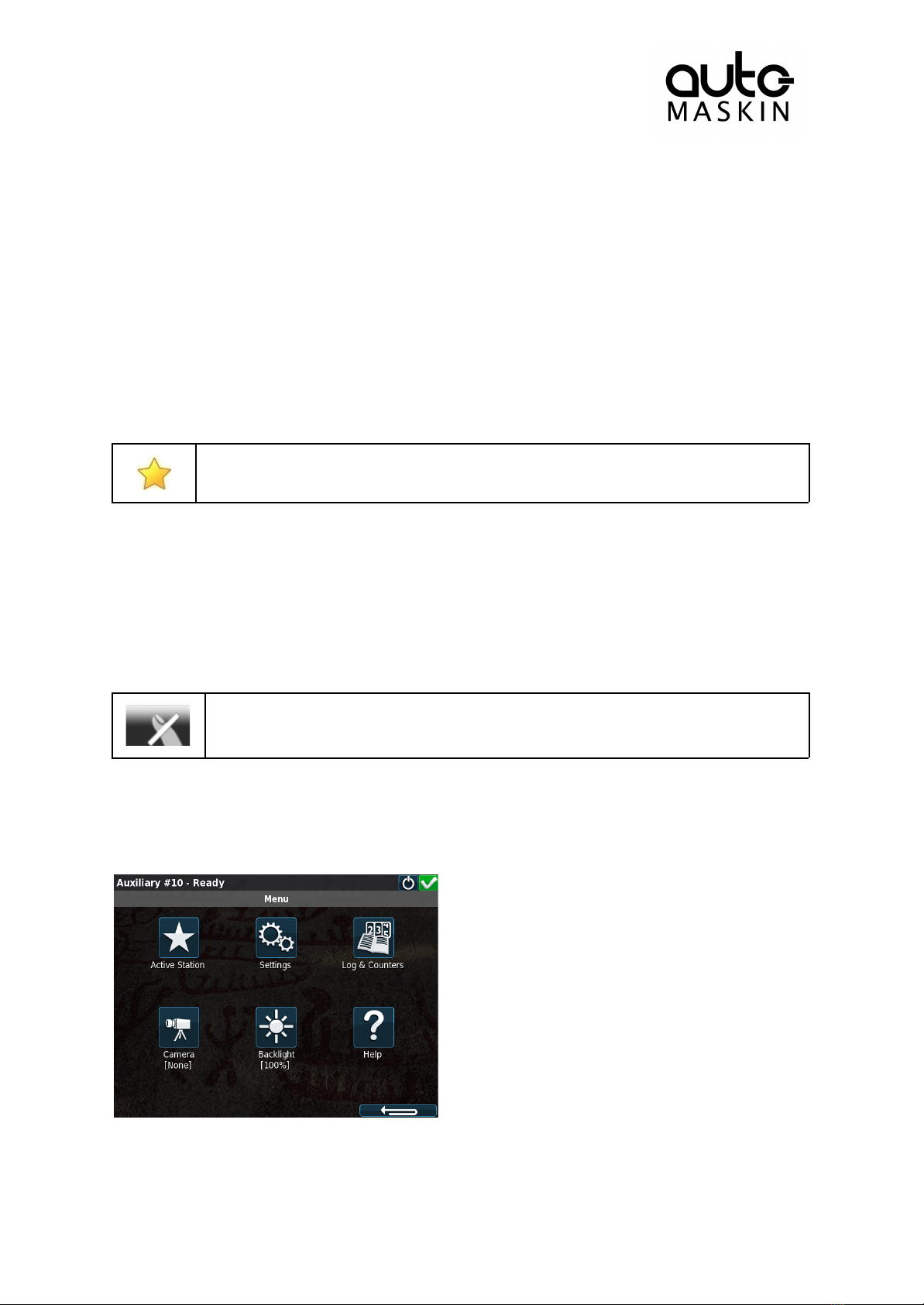

5.4 Menu

The menu is accessed in the same manner as for the DCU 210E.

Upon entering the menu, the previously used menu item is pre-selected.

Page 17 (20)

5.4.1 Active Station

There may be several RP panels in the network, all controlling the same engine.

Only one remote panel can be in control of the engine at any given time.

The Active Station dialog displays the connected engine this RP.

If there is a yellow star in the top-right position of the icon, as in the picture above, then this

RP is currently in control of that engine.

Request the Active Station status

If the RP is not the active station for the engine, send a request to the RP with the current

active station status.

Select the engine and then select Request.

If there is only one RP in the network, it may initially not be the active station.

Select it once to store current selection (this will be valid also after reboot).

Release the Active Station status

The RP can release its Active Station status and make the engine “free” or available on the

network.

Other RP panels with lower priority settings than this RP can now become the active station

for that engine.

Select the engine, and then press the Release button.

5.4.2 Settings

This chapter describes the menu icons that are not found on the DCU 210E only.

Page 18 (20)

5.4.3 Camera

The RP panel can display images from a connected IP-camera.

6 The Alarm List

The following is valid for the alarm list in the DCU and RP panels.

Bold text

● An unacknowledged event is in bold text.

● An acknowledged event is in normal text.

Background colors

● A diagnostic message is displayed on a white background.

● A warning is displayed on a yellow background.

● An alarm and an engine shutdown are displayed on a red background. In addition, an

engine shutdown is indicated with a STOP sign.

● An unacknowledged event that turned inactive before acknowledge, is displayed on a

grey background. For instance, the coolant temperature may have been above the

setpoint, and then dropped below the setpoint again before the operator

acknowledged it.

Page 19 (20)

Active Alarms will stay displayed until they go inactive.

6.1 Filter Alarms

The alarm list can filter alarms in three groups as follows

●All Alarms (alarms and diagnostics)

●Panel Alarms (alarms, no diagnostics)

●Diagnostics (diagnostics only)

Press the corresponding button at the bottom of the screen for the desired filter to take

effect.

The filter currently in use is displayed on the second line of the alarm list, e.g. All Alarms.

6.2 Silence the Buzzer

Entering the alarm list will also automatically silence the buzzer.

If the buzzer sounds while in the alarm list, then press the Ack. Alarms button to silence it.

6.3 Acknowledge a Single Alarm

● In the alarm list, select the alarm to be acknowledged. Observe that the selected

alarm line will expand to reveal additional information, if any.

● Press the Ack. Alarms button to acknowledge the selected alarm.

6.4 Acknowledge All Alarms

● In the alarm list, press and hold (1 sec) the Ack. Alarms button. This acknowledges

all active alarms.

Page 20 (20)

Other manuals for Marine Pro 200 Series

3

This manual suits for next models

10

Table of contents

Popular Controllers manuals by other brands

Renkforce

Renkforce 1688015 operating instructions

LOVATO ELECTRIC

LOVATO ELECTRIC ATL600 instruction manual

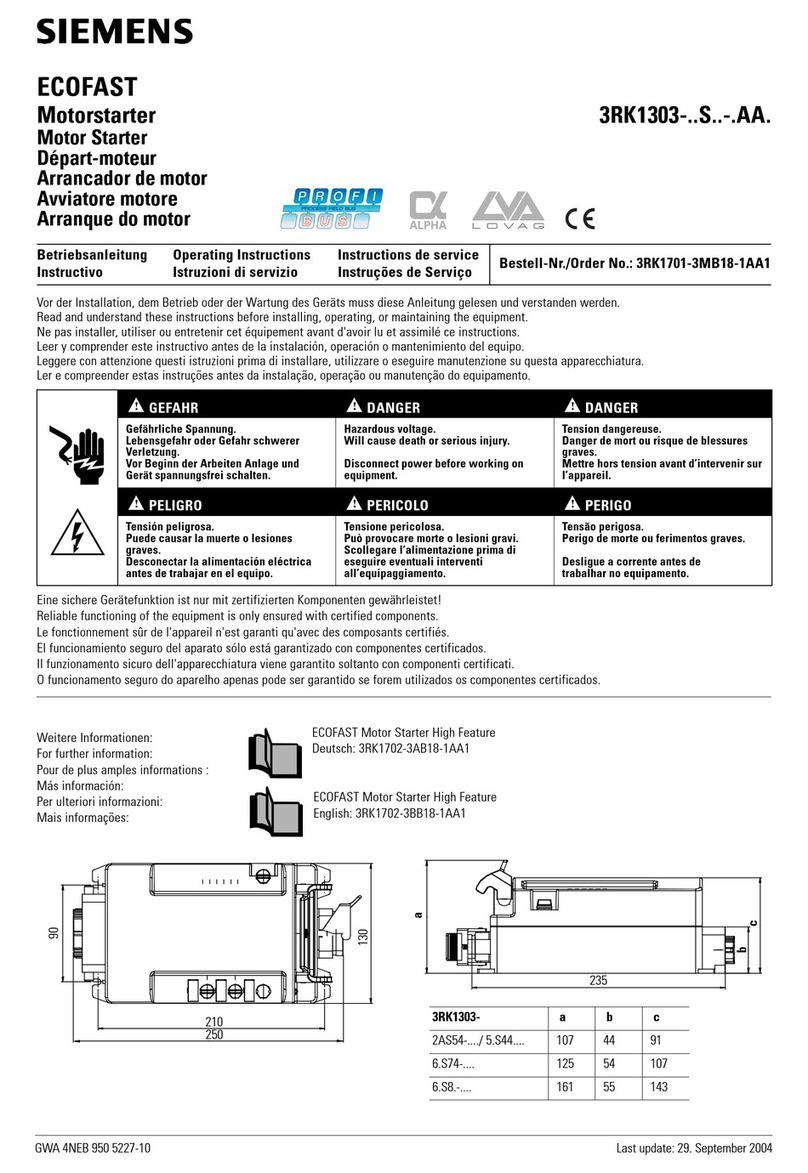

Siemens

Siemens ECOFAST 3RK1303 S AA Series operating instructions

Azbil

Azbil C25 user manual

YASKAWA

YASKAWA YRC1000 instructions

National Instruments

National Instruments SCXI USB-1357 installation guide