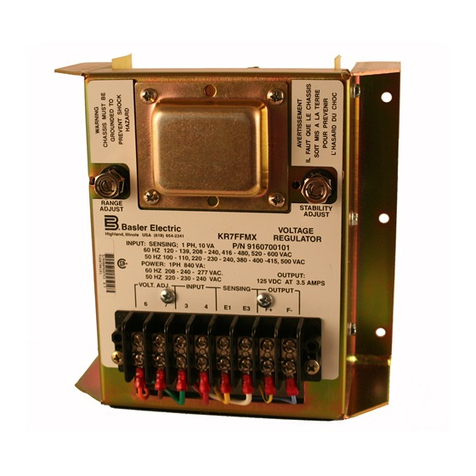

VOLTAGE ADJUST RHEOSTAT (V)

An internal screwdriver preset (V) provides

coarse adjustment of generator output voltage.

A clockwise adjustment of V increases voltage.

Thevoltageregulatorisshippedfromthefactory

with a link across terminals P and Q. If a re-

mote voltage adjust rheostat is used, the link

should be removed and the rheostat connected

to P and Q. A 1 kilo-ohm, 0.5 W potentiometer

will provide a 'fine' voltage range adjustment of

approximately ±10% over most of the coarse

range of adjustment. See Figure 5,

Intercon-

nection Diagram

.

V/HZ "CORNER FREQUENCY" SELECTION

For50 Hzsystems,theregulatoris presetat the

factory for a47 Hz "corner frequency" witha link

fitted across terminals “50". If operation at 60

Hz is required, this link should be removed; the

"corner frequency" is now set to 57 Hz. Do not

operate the system at 60 Hz with the 50 Hz link

still in place.

OVEREXCITATION SHUTDOWN

Overexcitation shutdown is provided to remove

output excitation should the regulator output

voltage exceeds 52 ± 2 Vdc for a sufficient time.

Theinverse-time-delay curve isshownin Figure

2. For voltages above 95 ±5 Vdc, there is a

second and much shorter inverse time curve.

Afteroutputpowerisremoved,theregulatorcan

be reset by decreasing the input voltage to less

than 6 Vac for a minimum of 2 seconds. This

may be accomplished by stopping the prime

mover or interrupting the regulator input by

means of a reset switch.

In cases where the generator is operating in a

parallel mode, it is sometimes considered

undesirable to allow the regulator to shut down,

whichmay cause the generator to be ”motored.”

Terminals N and D may be linked together to

prevent overexcitation shutdown. Note, how-

ever, that continuous running at output levels

greater than the continuous rating may result in

eventual regulator failure, and that other means

should be employed to protect the system.

OPERATION

GENERAL

The following system operation procedures

provide instructions for adjusting the AEC 42-7

voltage regulator. Symptoms resulting from a

faulty regulator and certain generator system

problems are included, together with suggested

remedies.

Complete the followingsteps before proceeding

with system startup.

PRELIMINARY SETUP

a. Verify that the voltage regulator

specifications conform with the generator

system requirements.

b. Ensure that the regulator links are fitted

correctly where required, as follows.

(1) If the remote voltage adjust rheostat is

not required, ensure terminals P and

Q are linked together.

(2) If a 57 Hz corner frequency for 60 Hz

systems is desired, ensure the”'50 -

50" link is removed. If a 47 Hz corner

frequency for 50 Hz systems is

desired, ensure the “50 - 50" link is

connected.

(3) If the system is to be run in parallel,

consider whether shutdown of the

generator's excitation is acceptable. If

not, ensure that the link between

terminals N and D is in place.

c. Ensure that the voltage regulator is cor-

rectly connected to the generator system:

F+ to field positive, F- to field negative, and

terminals 3 and 4 to the auxiliary winding

supply. It is vital that the sensing con-

nections are correctly made to all 4 wires

U, V, X, and Y. Ensure that the metal ring

tag at one mounting hole is bonded to

ground via either a metal screw or short

length of cable.

d. Install the fuses as directed in the previous

section.

e. Set the regulator and external voltage

adjust, if used, as follows:

Regulator Volts Adjust 'V' Fully CCW

Remote Volts Adjust Centered

Stability Adjust 'S' Centered

SYSTEM STARTUP

a. Perform the preliminary setup procedure

checking wiring carefully.

b. Start prime mover and bring up to rated

speed.

RESULT: The voltage should build up to less

than nominal value.

c. Slowly adjust the regulator voltage adjust V

until the generator output voltage reaches

the nominal value. Should a low frequency

oscillation or hunting be present on the

generator output voltage, adjust stability

control S to cause this to be damped out.

In general, clockwise increases the

stability. But in some cases, too far CW

may start to reduce stability again, and will

invariably slow the response of the

generator to load changes. An optimum

setting method is to adjust S slowly CCW

until the generator voltage just starts to

become unstable. Then turn it up to ¼ turn

CW from that position.

d. If used, adjust the external voltage adjust

rheostat to fine trim the voltage to the exact

value desired.

RESULT: Voltage should now have built up

and be stable at the desired value. If voltage

does not build up to rated value, check that

there is no short circuit or excessive load

present on the generator lines. If a minimum

residual of 6 Vac is not present, perform “Field

Flashing” as ex-plained later.

e. Check regulator under normal operating

and loading conditions.

RESULT: Voltage regulation should be better

than ±1.0% no-load to full-load. If regulation is

not within this range, check the following:

(1) Voltage reduction under loads of cosq >

0.0 may be due to speed reduction due

to loading of the prime mover. This may

be causing the frequency compensation

(V/Hz) circuit to reduce voltage at a

speed which is less than the "corner

frequency".

(2) Replace voltage regulator.

FIELD FLASHING

When the regulator is operated with the

generator for the first time, the polarity of

residual magnetism may be reversed or too

small to achieve the necessary buildup voltage

for the regulator. If reversing the field con-

nections does not induce buildup, and the

residual voltage is less than the specified value

of 6 Vac, shut down the prime mover and pro-

ceed with the following steps:

a. With the prime-mover at rest and the

regulator field output wires disconnected,

apply a DC source (NOT ground-ed) of not

more than 24 Vdc with Positive to F+ and

Negative to F-, in series with a

current-limiting resistor of 3-5 ohms. (The

set battery is a suitable source.)

b. Allow approximately 3 seconds before

removing the DC source.

c. With the voltage regulator disconnected

(wires 3 and 4), start the prime mover and

measure the “residual” voltage available at

the auxiliary winding. If this voltage is

greater than 6 Vac, reconnect voltage

regulator, and voltage buildup should be

successful.If less than6 Vacis measured,

repeat field flashing procedure.

d. If repeating steps a and b does not result

in generator voltage buildup, and residual

is greater than 6 Vac, replace voltage

regulator.

MAINTENANCE

PREVENTIVE MAINTENANCE

A periodic inspection of the unit should be made

to ensure it is kept clean and free from

accumulations of dust and moisture. It is vital to

ensurethat allthewireandterminalconnections

are kept sound, secure and free of corrosion.

OPERATIONAL TEST

a. Connect the test setup as shown in Figure

6. Do NOT apply power. Ensure the light

bulbs are rated120 volts andless than 100

watts. Alternatively a single 240 V bulb

may be used.

b. Adjust theinternal (V) andexternal voltage

adjust potentiometers fully CCW.

c. Apply 240 Vac, 50/60 Hz power to the

regulator.

d. Slowly turn the internal voltage adjust V in

the CW direction.

WARNING!

If a glass fuse is used, it

should be enclosed for safety.

CAUTION

Meggers and high-potential test

equipment must not be used.

Incorrect use of such equipment could

NOTE

All AC voltage readings are to be taken

with an 'average' reading voltmeter rated

speed.