Auto Mate Raptor TC-1417 User manual

RAPTOR TC-1417

COMPACT TURRET LATHE

Safety Guidelines | Deli ery & Set-Up Guide | Maintenance Schedule | Quick-Start Guide

800-476-4849 | 170 Aprill Drive | Ann Arbor, Michigan 48103 | USA

Thank You For Your Order!

Congra ula ions on your purchase of an Au oMa e CNC La he. Wi h proper se up and care, your

machine will provide many years of quali y work and produc ivi y.

This guide covers general ins ruc ions for se up and main enance for he Au oma e CNC La he. In

addi ion o his guide you will also receive a machining opera ions and programming handbook

for he Siemens 808D con rol sys em. We s rongly recommend keeping his se up guide wi h he

manual when your machine arrives.

Enjoy your new CNC Lathe!

This manual is specifically written for the

RAPTOR TC-1417 CNC LATHE

by

De roi Machine Tools

170 Aprill Drive

Ann Arbor, MI

48103

For additional assistance or information,

you may contact us by

Phone: 800-476-4849

Fax: 800-431-8892

Email: [email protected]

Web: www.detroitmachine.tools

Index

Safety Guidelines ……………………………………………………………………………. 3

Specifications …..…………………………………………………………………………… 14

Deli ery & Setup ……………….………………………………………………….…… 16

Maintenance ………………………………………………………………..………………. 26

General operation …………………………………………………………………………. 30

Warranty ………………………………………………………………………………………. 31

Safety Guidelines

General Safety Guidelines - Safety

First!

O er iew

General opera ional echniques and safe y

procedures will be ou lined in hese

guidelines. Please no e, for example, ha

all ro a ing par s, wherever feasible, are

pro ec ed by specially designed covers and

shields. If he machine is opera ed in

accordance wi h he manufac urer’s

ins ruc ions, i will provide you wi h reliable

service. Wi h machines of his na ure,

serious acciden s may occur due o

improper or careless opera ion. I is

s rongly recommended ha you read his

manual and accompanying manuals o

unders and horoughly he con en s. No

every example of improper opera ion or

unau horized usage which may lead o

malfunc ion can be an icipa ed. If a

par icular opera ion is no documen ed in

his manual as an au horized usage of he

equipmen , i should be assumed ha i is

an unau horized or improper usage wi h

po en ial danger and should be avoided or

he manufac urer should be consul ed

before use.

Safety

This machine is provided wi h various safe y

devices o pro ec he opera or and

machine, however hese canno cover all

aspec s of safe y. The opera or mus

horoughly read and unders and he

con en of his manual before he machine

is urned on and opera ed. The opera or

should also ake in o considera ion safe y

aspec s rela ed o heir par icular

environmen al condi ions, ma erials and

ools.

Always observe the safety instructions

inscribed on the name plates fixed to the

machine.

DO NOT remove or damage these name

plates

DO NOT attempt to operate or turn on the

machine until you have read and

understood the manuals supplied with the

machine.

Safety Symbols Used In This Manual

Three ca egories of safe y guidelines have

been used hroughou his manual. Please

ake no e of hese symbols and unders and

heir meanings.

Danger

If his ac ion is no avoided, i could resul in

serious injury or even dea h. I may also

cause permanen damage o your machine.

Warning

If his ac ion is no avoided, i may cause

po en ial harm o your heal h resul ing in

serious injury. This oo has he po en ial o

cause serious damage o your machine.

Caution

If his ac ion is no avoided, i may cause

po en ial harm o your heal h such as minor

o modera e injury. No avoiding his ac ion

could resul damage o your machine.

DANGER SYMBOLS

WARNING SYMBOLS

Basic Points of Safety

There are high vol age erminals on he

elec rical con rol panel, mo ors, junc ion

boxes and o her equipmen . DO NOT ouch

any of hese componen s under any

circums ances, when he power supply is

ON.

Make sure ha all safe y covers are fi ed

and elec rical boxes are closed and secured

before he power is swi ched o ON.

If any componen s or safe y covers are o

be removed, firs swi ch off or disconnec

he main plug.

Memorize he posi ion of he EMERGENCY

STOP BUTTON on he machine so ha you

can press i immedia ely from any posi ion

is case of emergencies.

DO NOT ouch he ool holder while he

machine is running.

Under no circums ances, should you ouch

a ro a ing ool holder or work piece while

he machine is in opera ion mode.

To preven incorrec opera ion of he

machine, carefully check he posi ion of he

swi ches before opera ion.

If in doub , consul his manual or an

Au oMa e echnician for advice and

sugges ions.

Always unplug he main plug when he

machine is no in use.

If more han one person is opera ing he

machine, DO NOT proceed o he nex s ep

wi hou informing he o her opera or(s)

ha you are abou o do so.

DO NOT modify he machine in any way

ha will affec safe y.

Clothing & Safety

DO NOT subjec he machine, con rol box,

opera or panel, or elec rical con rol panel

o a high vol age surge.

DO NOT change he parame ers or

elec rical se ing values wi hou good

reason. If i becomes necessary o change

he parame ers or se ings, firs check wi h

an Au oMa e echnician o assure ha i is

safe o do so. Be sure o no e he original

values so ha he con rol can be rese o

ha value if necessary.

DO NOT pain , soil, damage, modify or

remove any of he safe y name pla es.

If he de ails become illegible or if he name

pla e is los , ob ain a replacemen from

De roi Machine Tools and moun i a he

original loca ion.

DO NOT remove any safe y covers while he

machine is in au oma ic opera ion mode.

STOP all machine opera ions before

cleaning he machine or any of he

peripheral equipmen . Af er a job has been

comple ed, se up each par of he machine

so i is ready o be used for he nex series

of opera ions.

Tie back long hair o preven en angling

wi h ro ary ools.

Always wear safe y equipmen .

Always wear a pro ec ive mask when

machining Magnesium alloys.

Ne er wear loose or baggy clo hing.

DO NOT opera e he machine while under

he influence of drugs or alcohol.

DO NOT opera e he machine if you suffer

from dizziness.

ALWAYS USE GLOVES when loading and

unloading workpieces or ools and

removing chips from he work area o

pro ec your hands from sharp chips and

burns caused by hea genera ed during

machining.

Close all covers and junc ion boxes before

running he machine.

Check all elec rical cables for damage o

preven elec rical shock.

DO NOT handle coolan wi h bare hands o

avoid irri a ion.

Always use wire rope or slings as per

s andards sui able for he load o be

suppor ed.

DO NOT remove or adjus swi ches o

increase axis ravel beyond he machine

specifica ions.

DO NOT wipe he workpiece or clear away

chips wi h your hand or a rag while he

spindle is in opera ion.

DO NOT allow chips o accumula e in he

work envelope.

Warm up he spindle and axis mo ion

before running he machine in au oma ic

mode.

DO NOT opera e he keyboard or opera ion

panel swi ches when wearing gloves.

DO NOT disconnec he main power cable

wi hou swi ching off he CNC and PC

connec ions.

Safety Aspects Related To Tools & Work

Holding

Always use proper cu ing ools and work

holding clamps sui able for he work and

wi hin he specifica ions of he machine.

DO NOT s all he machine during cu ing

due o improper feed and dep h of cu

sui able for he work piece ma erial.

DO NOT opera e he spindle above he

ra ed speed of he arbors/ ool holders and

cu ing ools you expec o moun and use

in any machining opera ion.

Replace worn ools as soon as hey are

iden ified.

Take care no o place any par of your body

in possible pinch poin s on he machine.

Make sure he ool leng h o diame er ra io

is proper in order o minimize vibra ion due

o excessive overhang condi ions.

Make sure he drawbar and he ool holders

are igh ened o he proper cu ing

condi ions before ac ual cu ing opera ions

begin.

Safety Aspects Related To

Maintenance

Always disconnec he power o he

machine before carrying ou any

main enance work.

Af er he power has been swi ched off for a

minimum of 60 minu es, check vol age wi h

a mul i-me er or equivalen me er o make

sure here is no residual vol age.

Main enance of elec rical and mechanical

componen s should only be carried ou by

individuals wi h working knowledge of he

machine ool.

DO NOT remove or modify swi ches.

Clean he machine areas af er main enance

is comple ed.

DO NOT use compressed air o clean he

machines.

Safety Aspects Related To The

Workplace

Always provide sufficien work space

around he machine and peripheral

equipmen .

Pro ec all cables from being damaged by

cu ing chips.

More Guidelines for Safe Machine Tool Operations

This machine is provided wi h various mechanical and elec rical safe y devices o pro ec he

opera or and he machine. The safe y devices include he in erlock devices and emergency

s op swi ches. However, i is absolu ely necessary ha he opera or familiarizes himself wi h

he ins ruc ion manual of he machine before opera ing he machine. The manufac urer

emphasizes ha i is he sole responsibili y of he opera or o ensure ha all opera ions using

he Au oMa e CNC La he are carried ou in a comple ely safe manner.

Nei her he manufac urer, i s represen a ives nor dealers can assume responsibili y for any

mishaps, damage or personal injury which may occur as a resul of improper opera ion or from

failure o observe he safe y precau ions men ioned in his manual.

Never opera e a CNC machine wi hou proper raining or consul ing he specific

opera or’s manual for ha par icular machine and con rol ype.

Never a emp o program a CNC machine wi hou proper raining or consul ing he

specific programmer’s manual for ha par icular machine and con rol ype.

CNC Machine Safety System

The buil -in safe y sys em on a CNC machine includes guards and pro ec ive devices which

should be securely fi ed and always kep in posi ion while he machine is being used. I may

include:

Emergency Stop Button

Used o shu down he machine immedia ely. I is loca ed on he con rol panel and a o her

poin s on he machine, for example he handheld uni .

Soundproof Cas ng

Reduces noise emission genera ed by he opera ing sec ion and pro ec s he opera or from he

risk of flying objec s or ool fragmen s.

Curta n Guards

Made of PVC and designed o pro ec he opera or from he risk of airborne chips or ool

fragmen s.

Guard Fence

The fence marks he working area in which he machine moves. I pro ec s he opera or from

he risk of in erference wi h moving par s. The guard may be of an open ype or made of mesh.

General Personal Safety Rules

Below are some general personal safety

rules that you should use as a guide only.

You might like to add any other rules that

apply to you and your environment.

Always:

Wear safe y glasses and hearing pro ec ion

when opera ing CNC machines.

Wear safe y glasses when closely observing

cu ing ools.

Wear safe y boo s or o her sui able

foo wear.

Keep long hair covered when opera ing CNC

machines.

Keep hands clear of moving par s during

machining opera ions.

S and clear of he machine while i ’s

running and warn o hers of he dangers of

being oo close.

Avoid con ac wi h cu ing edges when

handling ools or changing ools by hand.

Turn he CNC machine off comple ely and

clean i up when you have finished using i .

Check ha he machine is no opera ing

when loading a ool magazine.

Check ha he ools are in good condi ion,

for example sharp and free of cracks.

Check ha ools are se correc ly.

Double check ha he correc ool da a is

en ered in o he CNC program.

Tes ools before use.

Check ha he sea ing surfaces are clean

before ins alling ools.

Check ha he spindle direc ion is correc

for righ -hand or lef -hand opera ion.

Only use ools wi hin he limi s specified by

he manufac urer.

Only igh en ools o recommended orque

values.

Keep he area around machine clear of

obs acles.

S ack ma erial where you can reach i bu

where i is clear of he moving par s of he

machine.

Make sure ha all guards are in posi ion

while he machine is in opera ion.

Make sure ha all work and fix ures are

clamped securely before s ar ing machine.

Conduc a dry run o ensure he program is

correc .

Follow company policy on correc

procedures when handling or lif ing par s or

ooling.

NEVER:

Wear loose clo hing or jewellery.

Reach in o a CNC machine while i is

running.

Place hands near a revolving spindle.

Leave he machine so ha someone else is

able o s ar i by pressing he cycle s ar

bu on.

Use blun ools.

Use cracked or chipped ools.

Use ools wi h damaged ungs en ips.

Use he machine able as a workbench.

Use compressed air o blow chips from he

par s of he machine, machine surfaces,

cabine s, con rols or floor around he

machine.

Safety Methods For Carrying

1. Never wis your body - Change

direc ion by moving your fee .

2. Always have clear vision - Should

never have o move around objec s

ha could cause you o rip over or

bump in o any hing.

3. Slide he load - Uses less effor and

s ress han lif ing.

4. Place he load on he bench - Pu

load on edge and slide i forward.

Personal Protect ve Equ pment (PPE)

Before en ering a machine shop you mus

wear personal pro ec ive equipmen a all

imes.

Eye Protect on

I is necessary o wear safe y glasses,

goggles or face shields a all imes in areas

where small flying fragmen s or dus can be

encoun ered when working in he machine

shop.

Hear ng Protect on

Hearing pro ec ion mus be worn a all

imes. Generally opera ors choice for

comfor depending on volume of sound.

Earplugs for less sound, earmuffs for louder

sound.

Footwear

Sui able foo wear mus be worn. A closed

shoe wi h lea her uppers or safe y boo s

would be he mos appropria e.

Cloth ng

I is impor an o remember ha while you

are working in he machine shop you should

no be wearing loose clo hing or jewelry

which may ge caugh in revolving cu ers.

The moving par s of a machine revolve a

high speeds and if any loose clo hing or

jewelry is caugh in he revolving cu ers,

you will be dragged in o he machine

causing serious injury or dea h.

Risk Control

Long Hair:

Keep long hair covered.

Tie hair back.

Wear a hairne .

Noise:

Wear earmuffs.

Wear earplugs.

Eyes:

Wear safe y glasses.

Wear safe y shield.

Footwear:

Wear closed shoe wi h non-skid sole.

Dust:

Wear dus mask.

Never dus yourself or a workma e down

wi h an air hose. (compressed air)

Chemicals:

Wear gloves or pro ec ive clo hing.

Wear face mask.

Guards:

Guards on machines mus be used a all

imes.

Hazards

The three steps in ol ed in dealing with hazards:

1. Spot the hazard - A hazard is any hing ha could hur you or someone else, is unsafe, or

could cause an acciden . Use all your senses o spo hazards. Look around, lis en,

no ice any s range smells (like smoke or chemicals) and use your knowledge abou

hings ha migh be dangerous.

2. Assess the r sk - Figure ou how likely i is for he hazard o hur someone and how

badly. Always ell someone abou hazards you canno fix yourself and remember i is

more urgen o make he changes if he hazard is likely o cause serious injury.

3. M n m ze the r sk - Fix he hazard yourself if you can, or ell someone who is able o fix

i . The bes way o fix he hazard is o ge rid of i , bu as his is no always possible,

here are some ways you can make he hazard less dangerous.

1. Subs i u e i for a less hazardous ma erial or i em.

2. Isola e i o an area where i ’s fur her ou of harm’s way such as a locked room.

3. Add safeguards, for example, pu clear guards around cu ing or slicing

equipmen or warning signs for people o see.

4. Use personal pro ec ive equipmen and clo hing any ime you are working wi h

hazardous ma erials and/or equipmen .

Hazard Control

Electr cal Hazards: Elimina e/ins all elec ric droppers ins ead of using ex ension cords.

Tox c Chem cals: Subs i u e/in roduce less oxic ma erials (polishes, adhesives e c).

No ses: Enclose/ins all canopies o he noisies machines.

Fly ng part cles: Isola ion, se aside specific areas for grinding.

Mach n ng dust: Engineer con rols, ins all and use dus ex rac ion equipmen .

Sl p/Tr p hazards: Adop be er housekeeping procedures.

Fat gue: Ro a e job asks among workers.

New equ pment: Train all s aff on every piece of equipmen o assis hazardous breakdowns.

Dust/no se etc: Use personal pro ec ive equipmen .

Final Safety Notice

Au oMa e CNC machines have been proven o be safe and reliable. However, if abused or

opera ed improperly, any machine can cause injury o you or o hers. Please read his guide and

accompanying manuals carefully before you s ar machining. Proper use will crea e a safe

working environmen and prolong he life of your machine.

Specifications

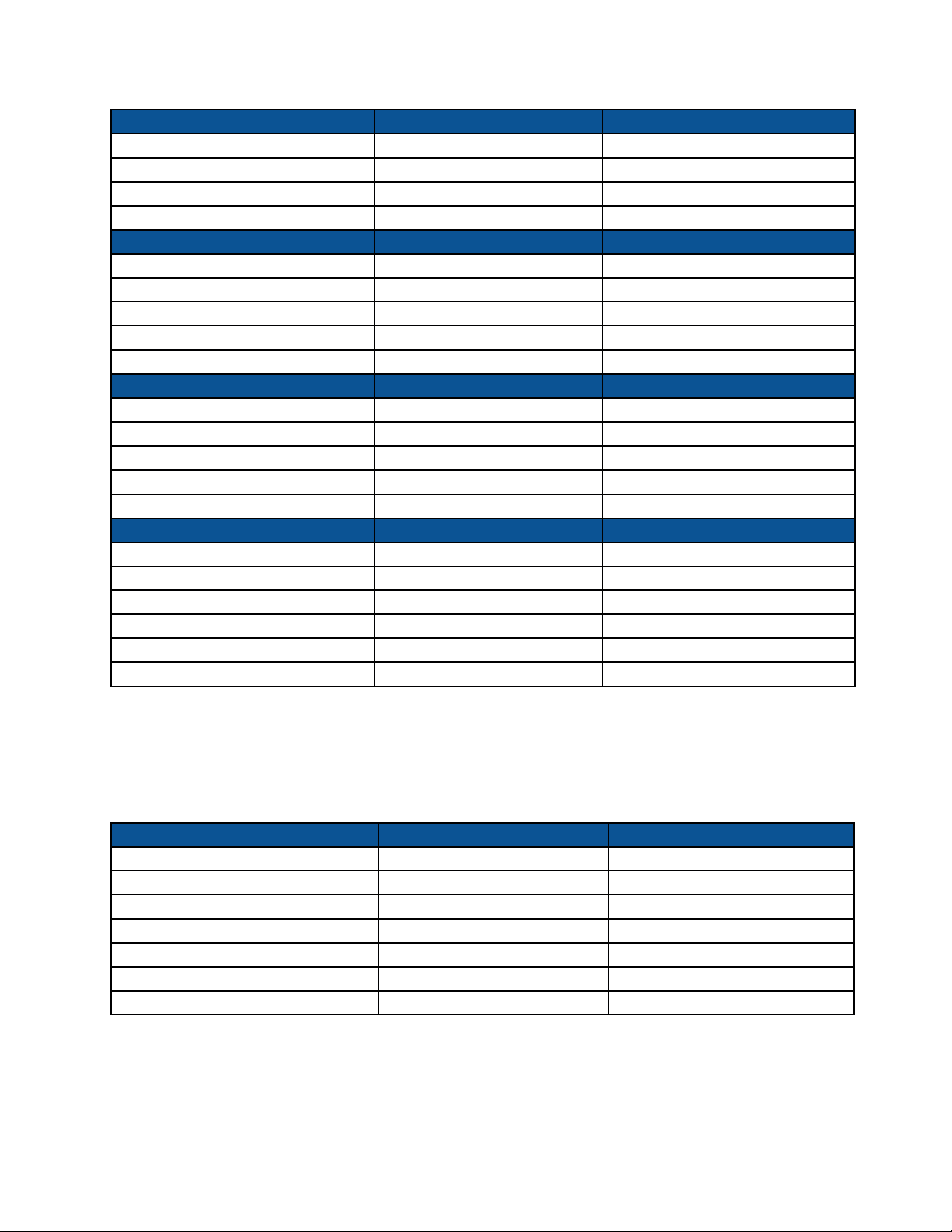

Tra els Inch Metric

X Axis 9.5” 241mm

Z Axis 12.5”317mm

Max Swing O er Bed 13.25” 340mm

Swing O er Carriage 5” 127mm

Spindle Inch Metric

Power 4 HP 3.0kw

RPM 100-2800 100-2800

Spindle Taper MT5 MT5

Spindle Bore 1.65” 41mm

Dri e System Bel Bel

Axis Motors Inch Metric

X Power 6NM 6NM

Z Power 6NM 6NM

Rapids on X 120 IPM 3m/min

Rapids on Z 230 IPM 5.75m/min

Max Cutting Speed 100 IPM 2420mm/m

Accuracy Inch Metric

Repeatability .0004” 0.01mm

Tool Changer Tool Pos Tool Pos

Type N/A N/A

Capacity 6 6

Max Tool Height 0.78” 20mm

Speed (chip to chip) or Tool

General Inch Metric

Machine Weight 2425lbs 1100kg

Machine Dimensions (LxWxH) 61”x 53.5”x 66.9” 1550mm X 1359mm X 1699mm

Shipping Weight 2646 lbs 1200kg

Crate Dimensions (LxWxH) NYA NYA

Air for Pneumatic Chuck 90 PSI 620 kPa

Coolant Capacity 10 Gal 37 L

Power Requirements 220v 60 Hz 3 Phase 220v 60 Hz 3 Phase

DELIVERY & SET-UP

Tracking Your Shipment

The bes way o be prepared is o know exac ly when your machine will arrive. Once your

machine leaves our warehouse, you’ll be sen an email wi h he Tracking or PRO number o

rack your shipmen . You have mul iple op ions o rack your shipmen as your Au oMa e CNC

Sys em makes i s way o you.

By Phone

ESTES - 800.755.2728 - Press 3 and you will be direc ed o a live cus omer service

represen a ive who can help you.

UPS - 800.PICKUPS - Selec 1 and say your racking number.

U.S. Ma l - 800.275.8777 - Selec desired language hen selec 5.

On The Web

ESTES - Go o www.es es-express.com On he righ hand side of he screen here will be a box

ha says “En er PRO Number”. En er your racking number in ha box.

UPS - Go o www.ups.com On he mains screen here will be a box o en er your racking

number in. En er number, rack package.

U.S. Ma l - Go o www.usps.com Click on he “Track and Confirm” op ion, en er your pro

number, click GO.

We make every effor o ship your comple e order a one ime. If you ordered a 4 h axis ro ary

able a he ime of he machine order, he ro ary able will be shipped wi h he machine. If

ordered a a separa e ime, i will be shipped via Es es as well. If you ordered he 4 h axis wi h

an Au oMa e 808D Advanced Con rol Sys em wi h 4 h axis op ion on your CNC La he, he board

is pre-ins alled in o he con rol box.

Smaller i ems such as end mill adap ers, end mills and general machine accessories are sen via

UPS Ground or US Mail. I is possible ha you may see your machine arrive before your UPS

shipmen . Please give any i ems shipped UPS or USPS 7-10 days for delivery. If your email

address was provided a he ime of order, a de ailed lis of he i ems you ordered, along wi h

informa ion on how hey were shipped will be emailed o you. The associa ed racking

numbers for your shipmen will be emailed o you along wi h his se up guide.

We handle complex Au oMa e CNC orders every day. Orders usually consis of a leas one

cra e and several boxes of varying sizes and weigh s. We work closely wi h Es es, UPS and USPS

o make sure you are ge ing fas , convenien delivery a a reasonable cos .

Your order may arrive in several installments over a period of 7-10 days after you receive this

letter.

PREPARING FOR DELIVERY

There are a number of hings you can do o prepare your shop or work space for your new

Au oMa e CNC La he. You will need a designa ed area wi h a level floor ha is capable of

suppor ing your Au oMa e CNC La he, plus he maximum allowable workpiece weigh for your

specific model of CNC La he. (Please refer o he specifica ion char for he la he you ordered

o ob ain hese numbers). As a rule, he suppor ing s ruc ure should be able o hold 5-6 imes

he weigh of he machine wi hou any appreciable, permanen deforma ion.

Set-Up Clearances, Conditions & Location

Se up he La he in a loca ion where you have plen y of working space. The chosen loca ion for

your CNC La he should be a permanen loca ion for he machine. Transpor ing machines are

hard on he machine and he people involved. Make sure he ground is as level as possible. I

will make leveling he machine much easier. The maximum empera ure of your shop or

working environmen should no exceed 125°. Humidi y levels should no exceed 80%.

Power Requirements

When searching for a loca ion for your machine, i is also impor an o remember you will need

o be running power cables o i . You’ll wan good access where your power source is

convenien o he power supply on he machine o minimize exposed wires and elec rical

hazards.

Model Voltage Amps Phase

TC-1417 TURRET LATHE 220 30 3 Phase

220 Plug Configuration

Three phase machines are supplied wi hou a plug as here are numerous connec ions for hree

phase circui s.

Taking Deli ery

Here are some recommenda ions for aking delivery of your Au oMa e machine. In some cases,

you will pick up he cra ed machine a a rucking erminal. Before picking up your machine,

con ac he designa ed erminal and ask abou he loading arrangemen s for easy and imely

pickup. You may also arrange o have he machine delivered o your shop loca ion if you have

no already done so.

Inspecting Your Shipment

When your machine arrives, horoughly inspec each cra e and car on for signs of loss or

damage. While a shipping company employee is presen , open any cra e or car on ha shows

signs of loss or damage and examine he con en s of he package wi h he employee. If any

damage is presen , record an exac , de ailed descrip ion of he resul s of he examina ion on

bo h he shipper’s and your delivery receip . BE SPECIFIC. If damage is presen , i is bes o

documen he damage even if you deem he damage as minor. Undocumen ed and unno ed

damage will resul in a denied claim.

**NOTE: The cra e is in ended o pro ec he machine; damage o he cra e does no

necessarily mean ha your Au oMa e CNC machine has been damaged. However, no ing any

damage o he cra e on he delivery receip will make i much easier o subs an ia e a claim if

here ac ually is damage.

Loading The Machine

Af er you have inspec ed he cra e and signed for he machine, a shipping company employee

will load your machine in o your vehicle. The loading procedure depends upon your vehicle

and he facili ies a he erminal. If he shipping company’s forklif is no res ric ed o he

loading dock, you can have he cra e loaded direc ly in o he ruck or railer bed wi h he

forklif . Regardless of how you load he machine, always be sure o ie he load down securely

so ha i does no shif during ranspor .

Opening The Crate

Before opening he cra e, remove he packing lis from he plas ic bag a ached o he cra e and

pu he documen in a safe place. **Wear lea her work gloves and safe y glasses for his

opera ion, especially when cu ing he me al bands. These bands encircle he cra e and are

under ension.

Step 1: Cu he me al bands encircling he cra e wi h in snips. (Depending on he machine,

here may no be me al bands.)

Step 2: Using a hammer and claw, remove he nails from he bo om cra e cover which secure

he cra e cover o he palle .

Step 3: Once all he nails from he cra e cover have been removed, remove he nails from one

side of he cra e in order o pull he side off of he cover.

Step 4: Af er he side has been removed, and wi h he help of an associa e, il he cra e op

back off of he palle .

**No e: The cra e op is very heavy, i can weigh up o 100lbs, Make sure you’ve go assis ance

when sliding he cra e cover off of he palle .**

Step 5: Se he cra e aside. I is advised you keep he cra e in he even you were ever o

re urn he machine for repair. **No e: Check he machine carefully for signs of damage,

especially if you no ed damage o he cra e earlier. If concealed damage is found, please call

De roi Machine Tools a 800.476.4849 immedia ely.**

Remo ing Machine From Pallet

You will need a forklif wi h a minimum of 6’ forks o remove he Au oMa e CNC Mill from he

palle . If you do no own one, you can ren one from a local equipmen ren al shop. We highly

recommend a forklif over any o her me hod of ranspor ing his machine, acciden s will be less

likely o occur due o he machine and cra e no being 100% s abilized. A ipped or dropped

machine will resul in significan damage o he machine and any individual loca ed in i s

vicini y. There are four bol s securing he machine o he palle , use an adjus able wrench o

remove nu s loca ed on he machine. Once have been removed, he a ached bol s will likely

fall hrough. If he bol s do no fall hrough, jus ap he screws hrough he cas ing and palle .

Remove he shee me al cover from he lower fron of he machine. I is a ached wi h several

Allen head cap screws. This will allow access o he bol s holding he machine o he “C”

channel. he nu s

The machine can be picked up from ei her he fron or back. Shop floor layou will de ermine

which me hod is bes for your si ua ion. Molded in o he base cas ings are slo s for forklif

forks. Inser forks in o base as far as hey will go wi hou hi ing he elec rical box or chip guard

enclosure. Lif he machine only high enough o slide palle ou from undernea h. As always,

be cau ious and ry o keep sudden movemen s o a minimum. Once he palle is removed,

gen ly lower he machine un il i is a few inches off he ground. Loca e he leveling screws and

pads ha were shipped wi h he machine.

Le eling Machine

Adjus ing machine ools so hey are level is very impor an and has benefi s ha aren’ of en

considered. Ver ical machining cen ers produce more accura e par s ha will las longer when

properly leveled. A machine ool ha isn’ properly leveled will no lubrica e evenly hroughou

he machine and cause par s o wear unevenly.

1. Screw he hreaded rod all he way down in o he leveling foo .

2. Place he beveled washer over he hreaded rod wi h he bevel down.

3. Unscrew he large adjus ing ring of he leveling foo .5” above he base of he foo . This

will ensure ha you will have bo h up and down movemen available when leveling he

machine.

4. Ins all he leveling fee in each of he four loca ions on he machine and a ach he foo

wi h he hex nu . DO NOT igh en he hex nu a his ime, i mus remain loose un il

he leveling process is comple ed.

Once he leveling fee are ins alled, place he machine in i ’s final loca ion. Lower i slowly o

he floor. Sudden dropping of he machine can cause severe loss of precision. Then remove

he forklif and adjus he leveling screws as needed o make sure all four fee are securely on

he floor. This is a preliminary adjus men only.

Connecting The Electrical

All elec rical work mus be done according o he Na ional Elec rical Code and any o her local

elec rical codes and safe y requiremen s. I is recommended ha a licensed elec rician perform

hese asks. 3 phase power mus be connec ed o he L1, L2, and L3 erminals inside he

machine.

Power mus be rou ed hrough an approved 40 amp breaker. Important!!! Wire size and length must

conform to local electrical codes. The neu ral line is no used as a ground. A separa e ground

conduc or mus be run o ear h ground.

Connecting The Hydraulics (optional hydraulic chuck)

All hydraulic hoses for he machine are already ins alled on he machine i self. They require a achmen

o he hydraulic power module.

Connec he wo pressure lines and re urn line o he hydraulic power module. Hoses are

marked on he hose as o proper loca ion on he module.

This manual suits for next models

1

Table of contents