CHIZHOU JOUSEHOLD MACHINE TOOL CZ1224 User manual

CZ1224 CZ1237

BENCH LATHE

OPERATING MANUAL

CHIZHOU JOUSEHOLD MACHINE TOOL CO., LTD.

THE PEOPLE’S REPUBLIC OF CHINA

ADDRESS: 8#, BLOCK A, CHIZHOU INDUSTRIAL ZONE, ANHUI

PROVINCE, P. R CHINA.

TEL: 0566-2612032 2612048 FAX: 0566-2612035

1

Thanks for you to have bought CZ300 CZ300/1 bench lathe, under right operating and

maintenance, the lathe will give you a long and précised service. Before operating, please study

the manual carefully. When working, please operate according to requirement and procedure

described in the manual. Besides, please keep the manual in good condition so that you may

look it up all the time.

2

CONTENTS

1 Technical data……………………………………………… 3

2 Standard accessory………………………………………… 4

3 Optional accessory………………………………………… 4

4 Electrical system…………………………………………… 4

5 General dimension…………………………………………… 6

6 Open case…………………………………………………… 7

7 Installation…………………………………………………… 7

8 Leveling……………………………………………………… 9

9 Lubrication chart…………………………………………… 11

10 Operation instruction ……………………………………… 12

11 Protection instrument……………………………………… 20

12 Check problems and repairing …………………………… 20

13 Maintenance…………………………………………… 21

3

1.SPECIFICATION

Specifications

CZ300

CZ300/1

(1) Swing over bed

305mm

305mm

(2) Swing over gap

480mm

(3) Swing over saddle

173mm

173mm

(4) Distance between centers

610mm

940mm

(5) Length of bed

1145mm

1473mm

(6) Width of bed

182mm

182mm

(7) Hole through spindle

36mm

36mm

(8) Tailstock barrel travel

92mm

92mm

(9) Cross slide travel

150mm

150mm

(10) Tool slide travel

89mm

89mm

(11) Saddle travel

520mm

850mm

(12) Taper of spindle hole

M.T.5

M.T.5

(13) Taper of center

M.T.3

M.T.3

(14) Range of spindle speed

12changes 50-1160rpm

12changes 50-1160rpm

(15) Diameter of lead screw

22mm

22mm

(16) Diameter of feed rod

19mm

19mm

(17) Thread of lead screw

8T.P.I(inch) 3mm(metric)

8T.P.I(inch) 3mm(metric)

(18) Thread can be cut

Metric 24 kinds 0.25-7.5mm

Inch 50 kinds 4-112T.P.I

(19) Motor power

1.1Kw

1.1Kw

(20) Net weight with/without stand

368Kg/308Kg

390Kg/330Kg

(21) Packing size without stand

1420×740×750mm

1780×740×750mm

(22) Packing size of stand

720×300×700mm

720×300×700mm

(23) Noise

<83dB

<83dB

4

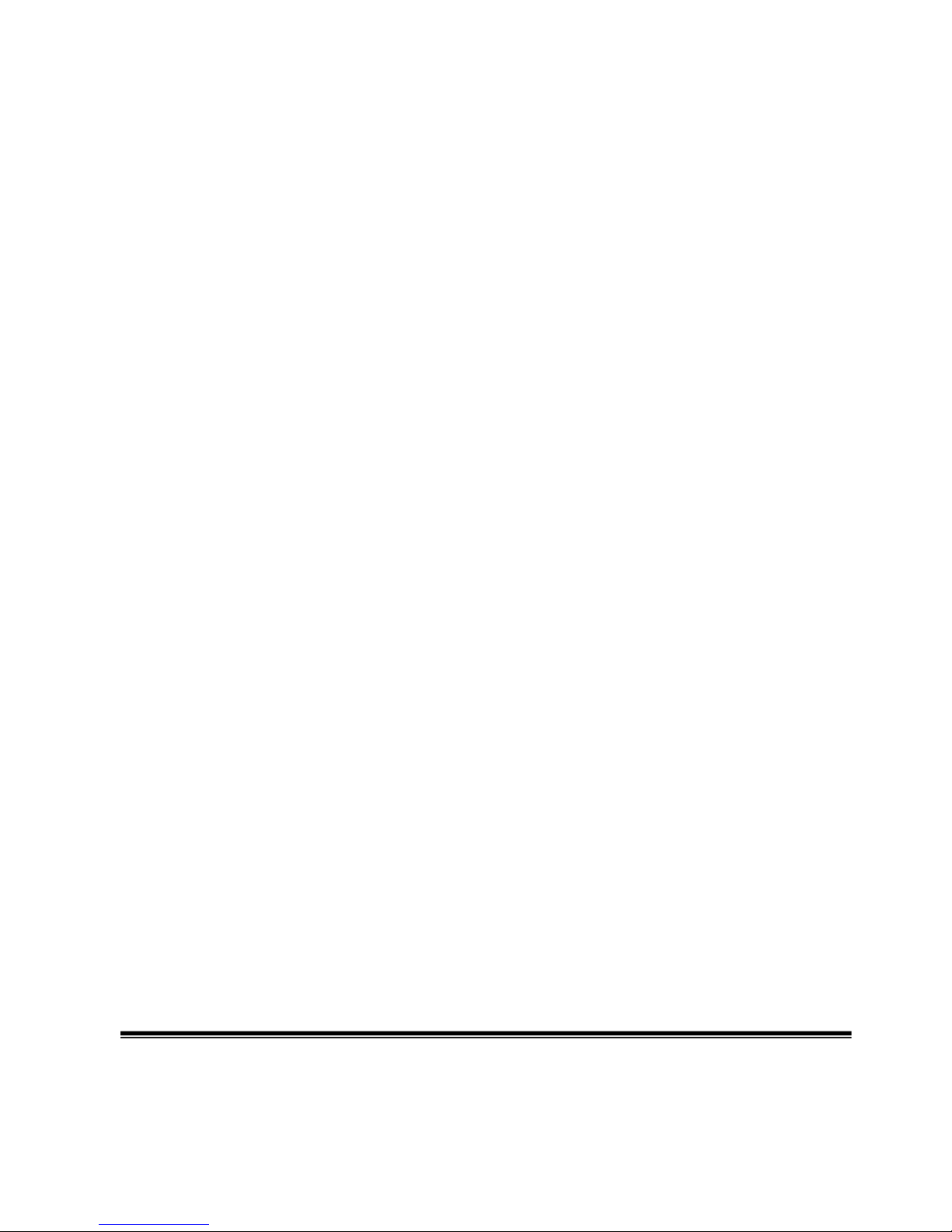

2. STANDARD ACCESSORY

1) Motor pulley 2) Tool post wrench 3) Allen wrench 4)Double end wrench

5) Change gear 6) 3-jaw chuck 7) Center sleeve 8) Screw driver

9) Back plate 10) Center 11) Oil gun 12) Tool box

13) Motor 14) Follow rest 15) Steady rest 16) Face plate

3. OPTIONALACCESSORY

4. ELECTRIC SYSTEM

Standard lathe is wired for 220V, 1 phase 50 cycles, other connection can be made as

customers’ requirements.

The electrical system in the lathe has been installed and adjusted in the factory. Generally,

please don’t open the electrical box. Before operating, wire the proper power source to lathe and

connect the ground wire. Turn on the power and check turning direction of spindle, if wrong,

first, turn off the motor and cut off the poser source, then change the wires as the wiring chart.

CAUTION:

1) IF NEED TO CHANGE THE CONNECTION IN ELECTRICAL BOX, PLEASE

1) Stand

2) 4—jaw chuck

3) Rolling center

4) Drill chuck

5

ASK FOR LOCAL REPAIRMAN OR TECHNOLOGIST TO HELP YOU TO DO AS

THE WIRING CHART, AND THE DIAMETER OF WIRE MUST B E NOT LESS THAN

1.5mm.

2) ELECTRICAL PRINCIPLE CHART ARE DESIGNED ACCORDING TO THE

CONDITOION THAT ALL KINKS OF PROTECTION INSTALLATIONS (SUCH AS

CHUCK MICROSWITCH, MAIN COVER MICROSWITCH, TOOLPOST

PROTECTION MICROSWITCH, NO VOLTAGE PROTECTION) HAVE BEEN

FITTED. PROTECTION INSTALLATIONS ARE OF SPECIAL REQUIREMENTS. IF

YOU DON’T NEED OR REQUIRE. YOUR MACHINE SHOULD BE WITHOUT THEM,

BUT ELECTRICALWIRING CHANGE SEPARATELY.

ELECTRIC PRINCIPLE CHART

THREE PHASES 220V/380V/440V

SINGLE PHASE 110V/220V

6

5. GENERAL DIMENSIONS

7

6. OPENING PACKAGE

The machine is packed in hard wooden case. When opening case, you should be careful not

to damage the surface of lathe. Look up t he operating manual and check if accessories are full, if

not, ask local seller for them.

7. INSTALLATION

CAUTION: THE MACHINE MUST FITTED FIRM AND STABLE. DON’T TURN

DOWN OR MAKE ANY MOVERMENT WITHOUT EXPECTION BECAUSE OF SHAKING,

WIND POWER, LASHING OR OTHER EXPECTED OUTER POWER OR INTERNAL

MOVEMENT FORCE ( SUCH AS INERTIA FORCE, MOTOR POWER FIRCE, ETC. )

7.1 FOUNDATION

The base for machines foundation must be solid and heavy enough to support the weight of

machine and without noticeable deflection. The floor must be fairly level.

Concrete floor is the best foundation. It provides the rigid base and minimizes vibration

form adjacent machines, the floor strength must be tested. The resting method: place a level on

the floor and put the machine on installa tion position, if the bubble show appreciable deflection,

the floor must be reinforced.

When determining the position of installation, leave a certain place in left, right, front and

back of the machine in accordance with its overall dimension and installa tion dimension of the

machine so that the operating and repairing is convenient.

If you use our stand ( optional accessory ), please first, make mark and drill eight holes in

the eight fitting hole position of base according to fitting dimension of the sta nd; secondly, cover

eight foundation bolt in the base ( note position precision when determining the fitting hole

position ). Put the stand on the base, connecting to the eight foundation bolt. Then place two

adjustable iron spacer in each down face of fro nt, back of two stand ( in order to increase the

touched space, please stagger the position of front and back adjustable iron spacer ). Fix the

connecting block of left, right of stand, fit the stand on the base. At last lift the lathe on the stand

and connect and fix the lathe to the stand by using nut and bolt.

If fit the lathe directly on the base, firstly in accordance with fitting dimension, mark and

drill hole in the base of six fitting hole position of lathe, cover six foundation bolt in the base,

place two adjustable iron spacers on the base in front and back of spindle box position and place

one adjustable iron spacer on the base in cross direction of tailstock position, then lift the lathe

on the adjustable iron spacers.

1) Fitting without stand

8

2) Fitting with stand

(1) Foundation bolt (2) Adjustable iron spacer (3) Stand (4) Chip pan (5) Lathe

7.2 LIFTING

Lifting the lathe as following figure

Put the mats in which the lifting tools connect before lifting the lathe, avoid damaging the

9

machine’s surface.

The lathe net weight is 330kg, stand weight is 60kg. When lifting, must keep the machine

in balance and avoid tilting.

The carriage, tailstock and other slide parts of the lathe are locked before leaving factory.

Don’t loosen these when lifting and should inspect to confirm whether they are locked or not in

order to prevent the parts sliding to make danger. Carefully put the machine on the base or stand

which have been fixed and fix the machine to the base or stand by bolt and nut.

7.3 CLEANING

Prior to shipment all machine and finished surfaces are coated to prevent rusting. Before

moving the carriage or tailstock, use clean solvent to remove the rust preventive coating, use

brush and solvent to clean the lead screw, rack, feed -rod, etc. Move the saddle, carriage and

tailstock to cleaned direction about 300mm, clean the ways for any residue of rust preventive

coating. Move the other way the same distance and repeat the process. Such care in the cleaning

will ensure the removal of any foreign particles and prevent the way scoring.

Lubricate the ways when clean finished.

8. LEVELING

The lathe should be kept perfectly level at all times.

LEVELING PROCEDURE:

A. Longitudinal leveling

After the bed-ways are dry after cleaning, back off the base screws, place a 6” precision

machinist spirit level over working table along longitudinal direction ( bed length direction )

move the working table at the headstock end along bed length direction, make leveling by

adjusting the adjustable iron spacer, obtain a reading. Then move the working table to the

tailstock, adjust the screw of the adjustable iron spacer until the spirit level obtain the same

reading as on the headstock end.

put the spirit level on the headstock end put the spirit level on tailstock end

B. CROSS LEVELING

Put the spirit level on the working table alo ng cross direction ( bed width direction ), move

the working table to the headstock end along bed length direction, take a reading, then move the

working table to the tailstock end, the reading at this end must be exactly the same as the other

end. No twist is permissible. If the reading is not same, adjust the screw of the adjustable iron

10

spacer to get the same reading.

Put the spirit level on headstock end put the spirit level on tailstock end

The adjustments at one end will affect the reading of the other, so the leveling procedure

should repeat many times, making necessary adjustments using staff ruler and iron spacer. After

the adjustments finished, turn sown slightly t he screw foundation bolt until they rest under slight

tension. The tension should be such that it does not change the level reading. Recheck level after

fixing the bolt, if necessary, make minor adjustment.

After the machine has been put to use for a perio d of time, check level to observe if the

original condition exists, make adjustments properly as the above mentioned way if necessary.

( make a erasable marker at one end of the spirit level to keep the same direction for every

reading. )

CAUTION: THE LOW PRECISION SPIRIT LEVEL MUST NOT BE USED.

SCHEDULE OR PERIODIC LEVEL CHECK AS A PART OF YOUR MAINTENANCE

SCHEDULE.

9. LUBRICATION CHART

11

A)—Often lubricate with fat B)—Lubricate with oil as oiler ind ication

C)—Lubricate with oil as oiler indication ●—Lubricate as every working time

CAUTION: THE LUBRICATION IS A IMPORTANCE WAY OF MACHINE

MAINTENANCE. THE QUANTITY OF LUBRICATION OIL MUST BE MODER. ATE. IF

THE LUBRICATION IS INSUFFICIENT, IT WILL AF FECT THE PRECISION OF

MACHINES AND SPEED THE MACHENE DAMAGE. IF THE LUBRECATION IS TOO

MUCH. IT WILL BE WASTEN AND MAKE THE WORKING SHOP UNCLEAR. IT IS

SUITABLE FOR THE QUANTITY OF THE LUBRICATION OIL NOT TO OVERFLOW OR

COME OFF.

10. OPERATING INSTRUCT ION

12

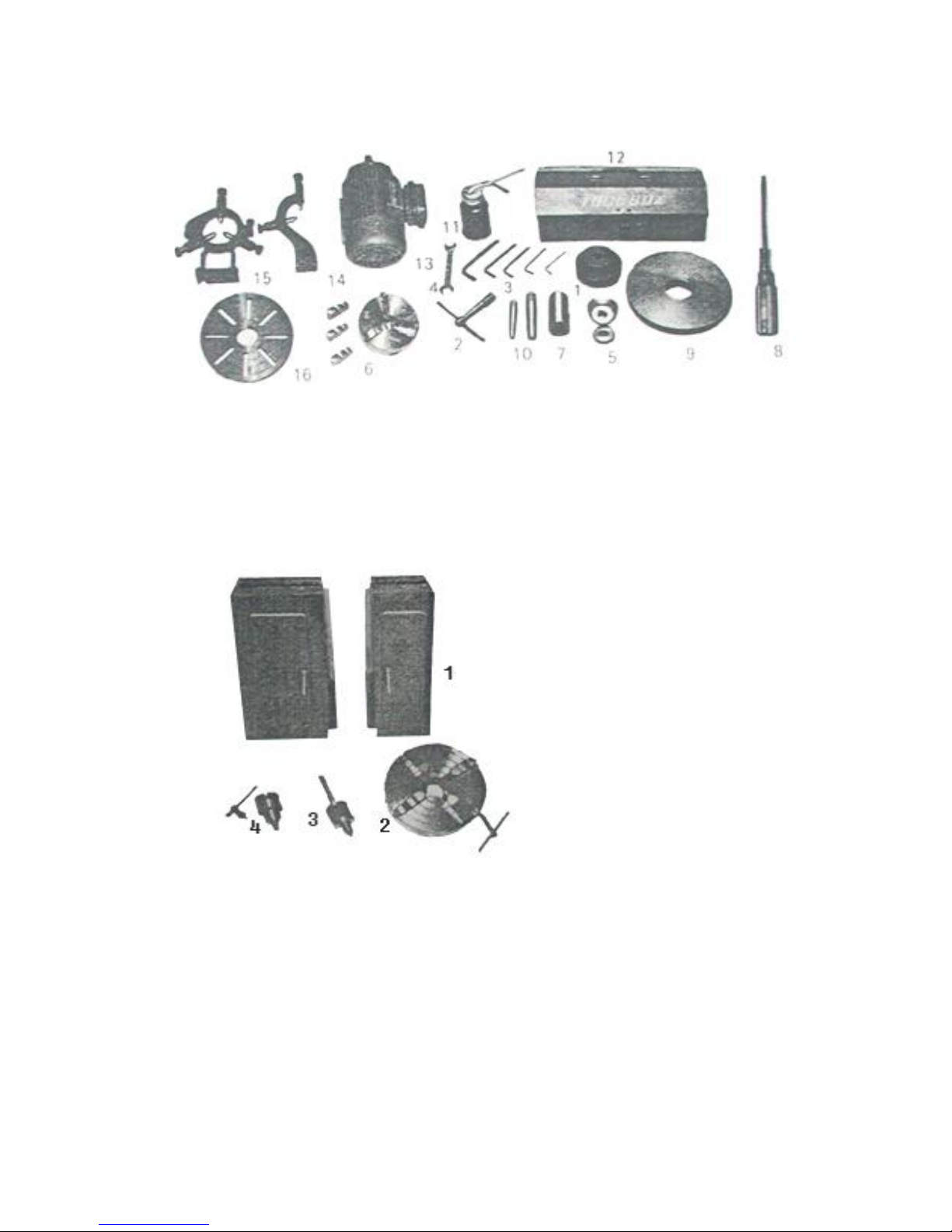

1. Headstock

2. Headstock cover

3. Oil guage

4. Face plate

5. Belt tension lever

6. Chuck

7. Bed

8. Rack

9. Steady rest

10. Follow rest

11. Tool post clamping lever

12. Compound slide

13. Threading dial

14. Compound slide handwheel

15. Sleeve clamping lever

16. Tailstock clamping lever

17. Tailstock handwheel

18. Tailstock

19. Saddle slide

20. Three rod support seat

21. Control lever

22. Chip pan

23. Half –nut lever

24. Cross/longitudinal feed l ever

25. Cross slide handwheel

26. Saddle handwheel

27. Control rod

28. Feed rod

29. Lead screw

30. Micro-switch box

31. Feed rod and lead screw exchange lever

32. Change gear lever

33. Change gear lever

34. Gear box

35. End face cover

36. Thread indication plate

37. Cover locking lever

38. Indication light

39. Change direction lever

40. Emergence push button

41. Start button

42. Name plate

10.1 CAUTION

A: DO NOT OPERATE THE LATHE BEFORE YOU ARE THOROUGHLY

UNDERSTAND ALL THE CONTROLS AND FUNCTION S. BEFORE CUTTING

WORKING PIECE, YOU MAY MAKE A TRIAL RUNNING IN ORDER TO FAMILIARIZE

YOUSELF WITH THE FUNCTION.

13

B: BEFORE OPERATING, CHECK OIL LEVELS AND LUBRECATION OF ALL

SLIDLING AND ROTATING PARTS. IF LUBRICATION IS NOT ENOUGH,SEE

LUBRICATION CHART AN D MAKE LUBRECATION.

C. THE LATHE HAS NO LIGHT EQUIPMENT, THE USER SHOULE PREPARE

ENOUGH FINE LIGHT EQUIPMENT AND REMOVE THE SHADOW INTERRUPTION,

AVOID LEADING DANGERS FOR THE POOR LIGHT DURING THE CUTTING

PROCESS.

D. KEEP CLAMPING THE WORKING PIECE FIRMLY PREVENT IT TO FLY OFF.

THE OUTSTANDING OF THE WORKING PIECE SHOUKD NOT BE TOO LONG IN

ORDER TO KEEP THE CUTTING PRECISION, THE RATE OF THE OUTSTANDING AND

DIAMETER SHOULD BE NOT MORE THAN 4.

E. WHEN TAKING PLACE UNEXPECTED MATTER DURING TURNING, SHOULD

PUSH THE EMERGENCY PUSH BUTTON OR TURN OFF THE POWER AT ONCE TO

STOP RUNNING.

F. WHEN NEED TO ADJUST THE LATHE OR WORKPIECE OR MACHINE TOOL,

PUSH THE PUSH BUTTON, MAKE THE MACHINE COMPLETELY STOP,THEN MAKE

THE ADJUSTMENTS.

g. CUTTING AMOUNT SELECTION: WHEN CH OOSING THE CUT AMOUNT,YOU

MUST CONSIDER THE LATHE, TOOL OR WORKPIECE RIGID, DON’T CUT

OVERLOAD, PREVENT THE DANGER FROM BREAKING. IN GENREAL, CUTTING

METAL MATERIAL AS FOLLOWING FIGURE ( SLIGHTLY ENLARGE THE CUT

AMOUNT WHEN CUTTING THE WOOD, PLASTIC, NONME TAL MATERIAL, AND SO

ON ).

WORKPIECE DIAMETER

CUT SPEED ( RPM)

CUT DEEPTH(mm)

FEED AMOUNT(mm/turn)

≥Φ150

<160

<0.5

<0.1

≥Φ100-150

<200

<0.5

<0.1

≥Φ50-100

<400

<1

<0.15

≥Φ30-50

<100

<1.5

<0.15

<Φ30

<1300

<1

<0.1

NOTE: WHEN THE RATE OF THE OUTSTANDIN G AND DIAMETER OF WORKING

PIECE IS OVER 4, THE CUT DEEPTH AND FEED AMOUNT SHOULD MAKE LESS.

H. WHEN WORKING IS OVER, TURN OFF THE POWER AND CLEAN THE LATHE.

I. WHEN DOING THE NO POWER JOB, SPECIAL AS MAINTENANCE OR REPAIR,

CUT THE MACHINE FROM THE POWER AN D KEEP SAFETY.

10.2 HEADSTOCK

Lift the cover can observe the headstock structure.

The headstock is equipped with 2 belts (1) (2), the tension of the belts has been adjusted. It

is advisable to check the tension before starting the machine. The belts shoul d depress about 1/2

inch by normal finger pressure. Too tight belts will damage the bearings, too loose belts will

lead belts to slide and speed the belt wear and tear. If necessary, adjust the tension of belts. See

the following figure, the link mechanism is provided for adjusting the tension of belts. If the belt

14

is loosen bolt (3) and turn out the screw rod (4) until the desired tension is set, then tighten the

hexagon bolt (3) in position.

The spindle and bearing are lubricated by the oil from two oil r eservoirs (5) which located

at each side of the headstock.

CAUTION: WHENEVER, THE SUFFICIENT OIL IN OIL RESERVOIRS MUST BE

MAINTAINED, IF NOT, PLEASE ADD OILACCORDING TO OIL GAUGE.

10.3 SPINDLE SPEED

There is gear and pulley system in the headstock.

Main spindle can obtain 12 kinds of speeds by

changing the position of belts or gears. In general

condition, light load and small diameter of

work-piece is suitable for high speed. The heavy load

and big diameter of work -piece for low speed.

CAUTION: DON’T CHANGE SPEED WHEN

THE SPINDLE IS RUNNING.

When change the spindle speed.

Please proceed as follows:

1) Move the control lever to middle position,

turn off the motor, make the spindle stop running.

2) Raise the headstock cover and pull the belt

tension lever (1) to the loose position.

3) Move the belt (2) (3) to the desired position as

the speed chart.

4) Push the belt tension lever back to the tightened position.

1——V—belt

2——V—belt

3——Bolt

4——Rod

5——Oil reservoirs

15

When using the back gears for low speed and heavy cutting, pleas e proceed as follows in

order to obtain the low speeds from 50 to 220 rpm.

a) Moving the control lever to middle state, turning off the motor, the spindle stop running.

b) Pull out the lock pin “A” from the gear “B” make a half turn to set it in the “out” position

as show right picture.

c) Pull the lever (4) and turn back to engage the

gears. If difficulty, slightly running the spindle by hand

and make the gears easy to engage.

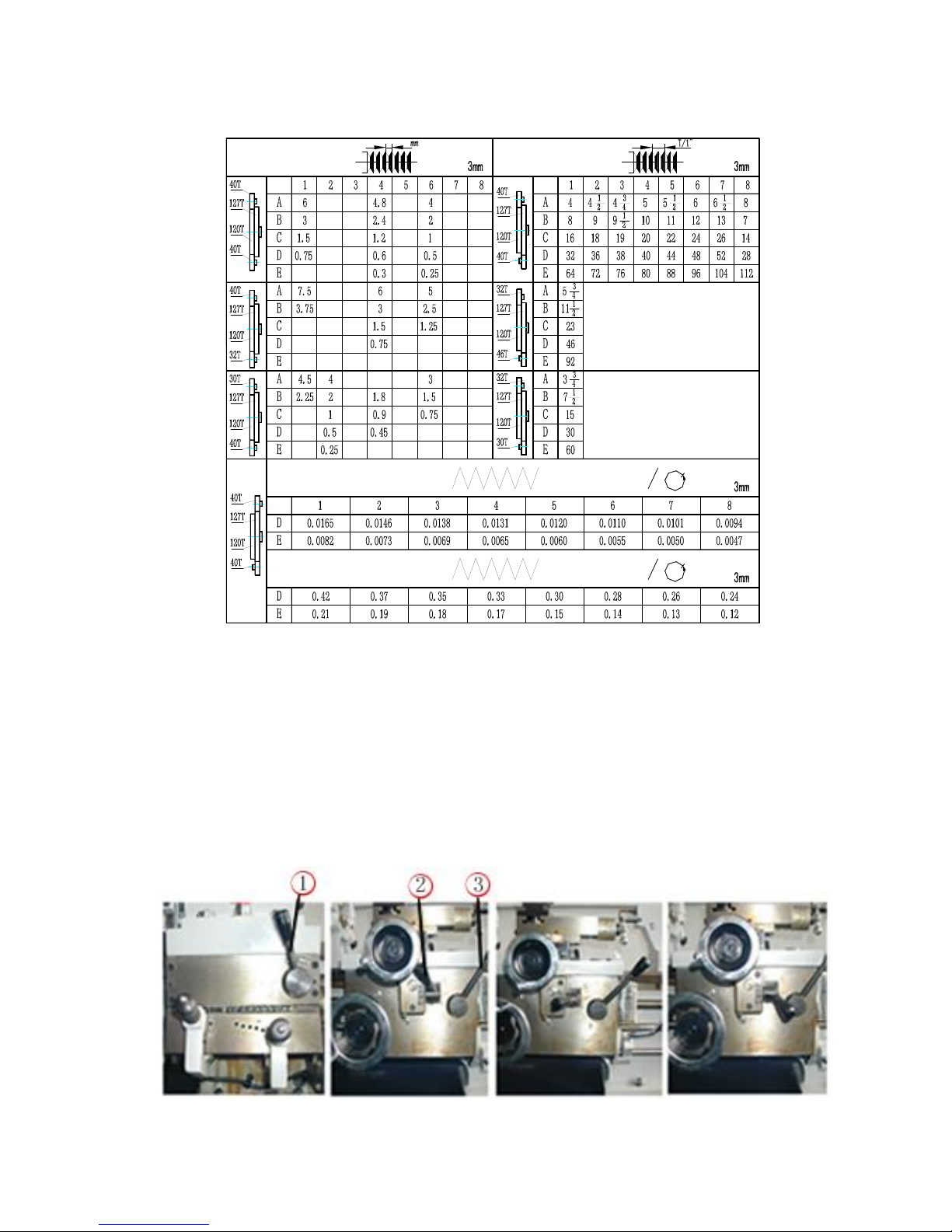

10.4 MAIN SPINDLE ROTATION

Starting, stopping, forward and reverse of spindle can be mad merely by the control lever

(1) , when using the control rod, firstly, pull the lever to headstock direction, then pull it up or

down.

Control rod on the up Control rod on the middle Control rod on the down

See the above picture, moving the control lever down the spindle will be forward rotation,

control lever up the spindle will be reverse rotation. Control lever middle the spindle will stop.

If the motor is one phase and need to change the direction of the spindle. Firstly, please move

the control lever from one side to middle, a little stop till the motor stop then move up or down,

if move control lever from one side directly to another side, the direction of the spindle don’t

change.

10.5 GEAR BOX

Quick—change gear system design the rate of the spindle to lead screw and feed rod when

it is used to cutting thread, external turning and facing. Quick —change gear box is controlled by

two handles. Handle (1) exists A.B.C.D.E. five positions. Handle (2) has 1. 2. 3. 4. 5. 6. 7. 8.

eight positions.

Handle (3) exists left. Middle and right three positions. Handle to right, lead screw running

and the machine is used to external turning, internal turning and facing. Handle to middle, it is

parking.

This machine can be used to cut metric and inch threads when putting the handle (1),

handle (2) to the proper position. Please change the gear A. B. C. D. when it is necessary.

1. Belt tension lever 2. V-belt 3. V-belt

4. Lever 5. Gear B 6. Pin A

16

1) Gear changing handle 2) Gear changing handle A) Gear B) Gear

3) Feed rod and lead screw changing handle C) Gear D) Gear

Half nut must keep to engaged to lead screw all time when the thread is being cut. When

the cutting is finished e very time, firstly, please make the tool back and reverse the motor, then

make the tool to the original start —cutting position and begin the next process, and working

many times at the same until the thread is finished.

CAUTION: CAN NOT CHANGE THE HANDLE (1) (2) (3) WHEN THE MACHINE

IS RUNNING.

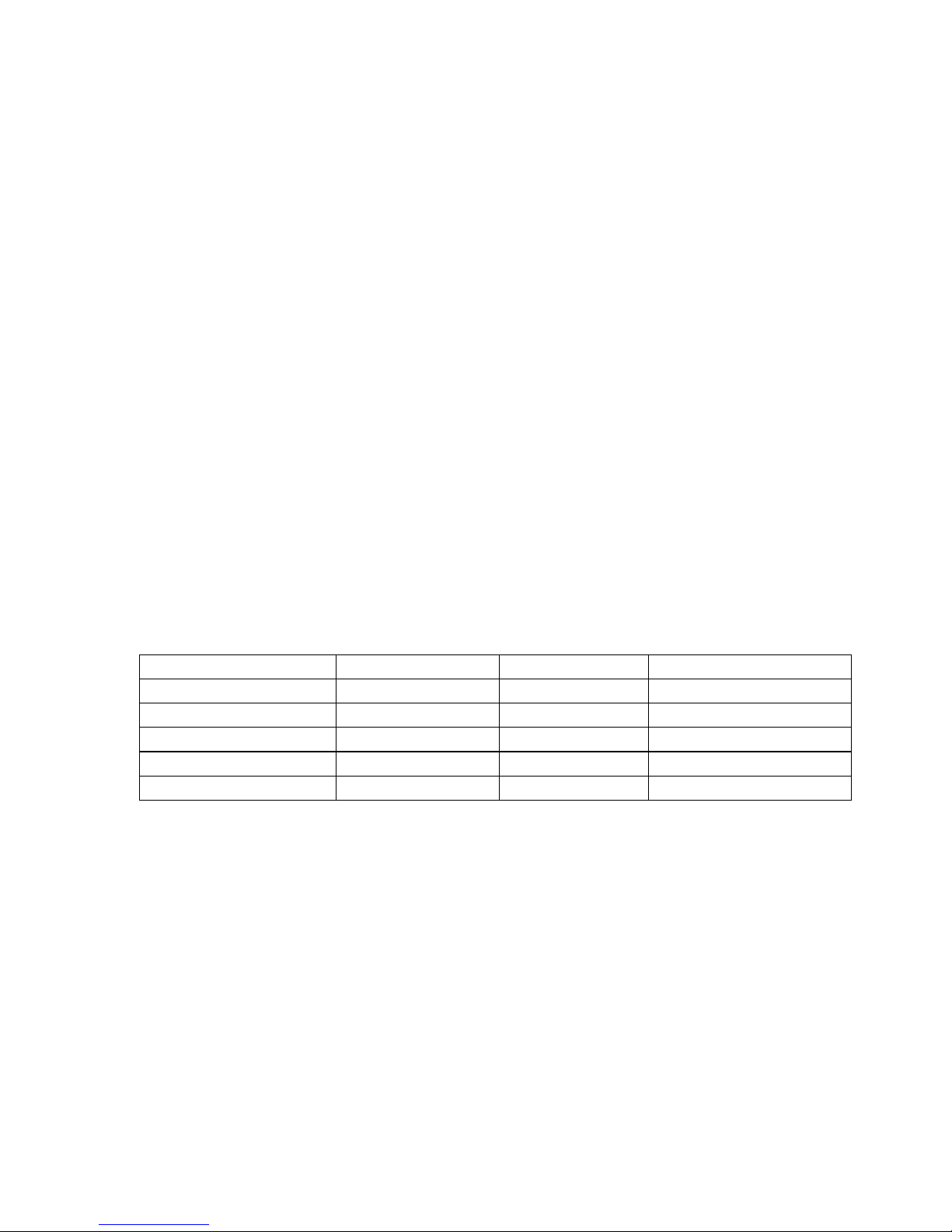

A. THREAD AND FEED TABLE FOR IMPERIAL LEAD SCREW

THREADING THREADING

FEEDING INCHES

mmFEEDING

17

B. THREAD AND FEED TABLE FOR METRIC LEAD SCREW

THREADING

INCHES

THREADING

FEEDING

FEEDING

mm

10.6 CARRIAGE

The function of the carriage is to firml y support the tool post and carry it moving in

longitudinal and cross direction.

10.6.1 POWER FEED

When external turning and facing, please turn the lever (1) on the gear box to left and make

the feed rod rotation.

Need to power feed in longitudinal direct ion, up–engage the cross/longitudinal feed lever (2) .

Need to power feed in cross direction, down –engage the cross/longitudinal feed lever (2).

(1) Feed rod/lead screw changing (2) Cross/longitudinal Feed changing (3) Half nut lever

While the cross /longitudinal feed lever is in the feed position, the half nut lever (3) can not

18

be engaged, the built –in safety interlock mechanism will prevent simultaneous engagement of

(2) and (3).

For threading, put the lever (1) on the gear box to the right and the lead screw rotating,

then make the cross/longitudinal feed lever (2) on the middle and engage the half nut (3), the

result is the lead screw rotating and to make the carriage moving to the right and left.

CAUTION: DO NOT FORCE THE HALF NUT LEVER WHILE ENGAGING WITH

THE LEAD SCREW

When power feed, the direction of spindle rotating, carriage moving and cross –slide

moving nave been designed by mechanism, for example, when the spindle clockwise rotating,

the carriage move to left, conversely to right.

3-star gear system can change the carriage travel direction too, when the spindle clockwise

rotating and the lever (2) on up position, it make the carriage move left, the lever (2) on down

position, carriage move right. The lever (2) on middle, the carriage stop moving.

10.6.2 THREADING DIAL

When the pitch proportion of lead screw and work -piece thread is not integer times and

need to open the half –nut while cutting, it is necessary to use the t hread dial to control tools

and prevent the mixed screw.

The threading dial is located on the right or left side of the apron.

It performs the important function of indicating the proper time to engage the half nut lever

so that the tool will enter the sam e groove of the thread on each successive cut. The dial is

marked with lines numbered 1. 2. 3. 4. and in between are lines with no number. These are half

lines and are called unnumbered lines. The dial when engaged with the lead screw will cause the

rotation of the dial, A single line is marked on the housing of the threading dial ( fixed line ).

The instruction plate riveted on the threading dial shows the selection and sequence of

matching the revolving lines with the fixed line.

For thread cutting, engag e the half –nuts at the appropriate numbers shown on the scale

column of the threading dial plate, 1 - 4 on the scale means the half –nuts can be engaged on any

of the numbered lines 1 - 2 –3–4 . For each successive cuts only numbered lines must be used.

1-3/2 –4 on the scale means the half –nut can be engaged on 1 and 3 or 2 and 4 for successive

cuts, For example, when you engage the half – nut on the numbered line “1” for the first cut,

after that for successive cuts, the half –nut just be engaged on the numbered line “1” or “3” , If

you engage the half – nut on the numbered line “2” for the first cut. After that for successive

(1) 3-star gear

(2) Changing direction lever

19

(1) Compound slide (up)

(2) Cross slide (up

(3) Screw

(4) Tool post clamping lever)

(5) Compound slide (down)

(6) Handle wheel

cuts, the half – nut just be engaged on the numbered line “2”

or “4”. 1- 8 means the half –nuts can be engaged on any line,

numbered or unnumbered.

If half –nut engage with the lead screw all time while

cutting the thread, no need to use threading dial, In this case,

after finished each successive cut, firstly, back the tool and

reverse the motor, then move the tool to the la st start –

cutting position and make the next successive cut.

10.7 FOUR POSITIONS TOOL POST

Main function of tool post is to fix tool, If necessary, tool

post may fix more than one tool ( at most 4 ), Tool thickness

must be less than tool groove, When i nstalling tool again , should confirm tool head direction to

work-piece revolving center line, permitting to use iron spacer to adjust, after adjusting correctly,

please fix the tool. If need to turn the tool post, turn the tool post locking handle counter

clockwise to loosen the locking handle and turn the tool post to the position you needed and

then turn the tool post lock handle clockwise to make tool post lock.

10.8 COMPOUND SLIDE

Using the compound slide can cut taper , When cutting taper, please loosen the screw on the

saddle, round the compound slide, let the graduated line towards the graduation number on the

saddle. Then fix the screw, round the driving hand wheel, the tool post move the tool, now there

is a angle between the traveling line and turning line of spindle, thus you can turn taper.

10.9 TAILSTOCK

The tailstock slides along the bed -ways freely and can be locked in any position by the

clamp lever. There is an end pin to stop the tailstock sliding down. Rot ating the tailstock hand

wheel can slide the quill. The quill can be locked by the quill lock lever. Before leaving the

factory, it will be sure that it is the same line between the tailstock center and spindle center. For

(1) Threading dial

This manual suits for next models

1

Table of contents