Autogard AG/500 User manual

Automatic road gates

AG/500, AG/900, AG/M1

Operating instructions

Manufactured by:

AUTOGARD spol. s r.o.

Dornych 47, 617 00 Brno, CZ

tel.: +420 - 5 - 45 53 54 62 - 3, fax.: +420-5-45 53 54 65

http://www.autogard.cz

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

2

Introduction

Thank you for choosing our automatic road gate. All items in the Autogard production range are All

items of company AUTOGARD are state in market after long term tests and hard-set at laboratory

fitting in heavy industry operation.

Used materials and components applicated in fabrication are high quality and are during all

manufacturing case conquest many checks and proofs.

Our road gates was designed for high power, long lifetime and no need of periodical adjustments.

Are manufacture according generally avowed engineering standards and in alive area agree to

specified technical norms.

General futures

Automatic road gates AG/500, AG/900, AG/M1 are driven by electric motor along with high torsion

moment and belt driven equally dimensioned gearbox. They are designed for intensive continual

operation.

There is installed the control unit with microprocessor (AGN 2.0 / AGN 2.1).

The case is made from sheet iron flesh 2,5 mm (type AG/500) or alternatively 3 mm (type AG/900),

with zinc and coated by pulverized polyester dye colour.

Technical parameters

AG/500 AG/900 AG/M1

Motor 230 VAC

370 W

230 VAC

250 W

230 VAC

550 W

Boom length 3 - 5 m 6 - 9 m 1 - 3 m

Rise time 3 s 5 s 1 s

Dimensions 350 x 300 x

1070

450 x 350 x

1070

350 x 300 x

1070

Weight 95 kg 130 kg 95 kg

Control units AGN 2.0

AGN 2.1

AGN 2.0

AGN 2.1

AGN 2.0

AGN 2.1

Closure Automatic Automatic Automatic

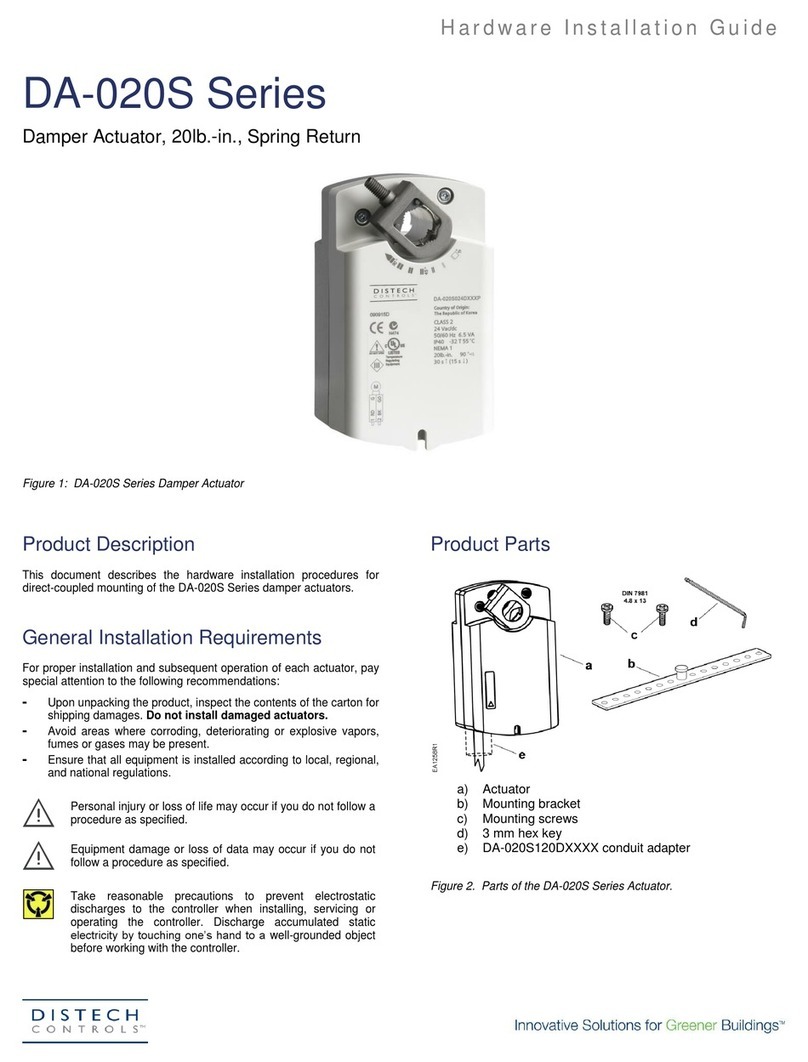

AG/500: AG/900:

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

3

Outlet journal of AG/500

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

4

Outlet journal of AG/900

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

5

Foundation kit positioning

The road gate is installed on fast mounted (on the concrete base, welded to iron ground etc.)

foundation kit, which include foundation plate and 4 long screws M12 along with females intended for

the concreting. The gate base make no a less then 600 mm, power supply and signal cables brings

cable guard, including the cable from car detector loop (like on the picture).

! WARNING ! Power supply alimentation have to include device enabling disconnecting of the cable

in which the distance of disconnected contacts is on less than 3 mm.

Foundation plate:

[mm] AG/500

AG/M1

AG/900

X260 310

Y150 170

A350 450

B310 350

Design of the concrete gate base with foundation kit:

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

6

Setting of gate and fixing of rod

Unpack gate lodge to right clear guy kit with from off-screw nuts and without gate doors, so that we

need fully check the setting of the gate on the screws M12 and booting of all cables through the

aperture at bottom gate. Then you use pads 12,5 mm and nuts M12, that fast screw all. The column of

the gate must be fixed fast, because during working time there are the forces like 5kN. The rod we

affix by means of competent holder (for profile or tube) with 4 screws M8 (imbus type) into fulcrum of

the rod.

The length of the pull enclose a rod opening in the bulk 90o and is adjusted during producing.

In case of emergency it is possible to change this dimension.

Earthing of road gate

After the fixing of the gate column we finish the earthing of metallic gate column. From the power

supply cable 230V AC, like CYKY 3x1,5 we affix the line wire PE to earth screw located on the right

side below.

Please verify the connecting of the motor PE clamp with herewith earth screw.

Length of rods, pulleys, springs

For different length and models of rods we need to apply specified springs (for right balancing of the

rod) and pulleys which correspond with rod rise time (see the following table):

The rods from z Al profiles:

gate rod Spring type Pulley

type length [m] Rod without

accessories

Rod with

accessories

d [mm]

AG/M1 3 O Z 75

AG/500 3 O Z 75

4 Z M 100

5 M W 112,5

AG/900 6 Z + O Z + Z 100

The rods from z Al tubes:

gate rod Spring type Pulley

type length [m] Rod without

accessories

Rod with

accessories

d [mm]

AG/M1 3 O Z 75

AG/500 3 O Z 75

4 Z M 100

5 M W 112,5

AG/900 6 M W 100

7 Z + Z Z + M 112,5

8 Z + M M + M 150

9 M + M M + W 150

Description:

Z – green spring

O – orange spring

M – blue spring

W – white spring

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

7

The rod balancing with spring

After assembling of the gate is necessary check the balancing of the rod with the spring / springs

choose by previous table. Every piece of make road gate is assembled for specified rod length, rice

time, spring balancing.

As far as is used other length of the rod, than is specified on manufacture label, you need to read

following instructions:

The spring balancing you can do with installed final length rod including all accessories, with spring /

springs (according the table) disconnected pull between gearbox and lever. Let's verify the balancing

of the rod with tensing or alternatively unfastening of the spring through spring bottom bolt. Balanced

rod - spring system has in all moving area the easy running and there's no need to help with hand

more then slightly.

After the spring balancing use the pull for connecting the gearbox to lever, check the place of 90o

sector and feeze the safety nuts. These operations has grand amount at views of rod running fluency

and mechanical stress limitation of all gate case deals.

Note: The verifying of spring balancing is necessary after every change of rod length, type of rod,

adding of any accessories etc.

Setting of limit switches

The limit switches are check the run of the rod and guarantee switch-off the motor in last places of rod

running. The limit switches are located on the console near the gearbox. Switching flags are attached

with screws M5 (imbus type) on the bracket which is situated in outgoing gearbox axis.

Generally the limit switches guarantee 90oangle of rod running and coming of gearbox lever near the

dead position, like with 180oangle of running. It means, that the rod has zero angle speed in last

places of rod running. The system is designed in so far that the mechanical limits are not required.

Emergency opening

During using of road gate can arrive the situation, when is necessary open the gate alternatively (f.e.

the power supply is aborted).

! WARNING ! Emergency opening or closing do only

with shut-down power supply switch ! Harm hazard !

In this case you need apply the key on opposed motor site then pulley.

There are the flats put on the key. With swinging of the key you can move with gate rod.

Periodical adjustment

Automatic road gate is designed and made as without service device. For permanent error free

function we advice advise to execute these advances every three working months:

1) verify the earthing point - the screw, and in

case of findings feeze the nut

2) verify visualy of all threaded joints and in

case of findings feeze all needed

3) apply the WD 40 alternatively alike on the

functional area articulated bearing of the lever

4) verify the belt tension, whom the deflection

must be amount 10 mm (like on the picture),

in case of findings adjust the tension

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

8

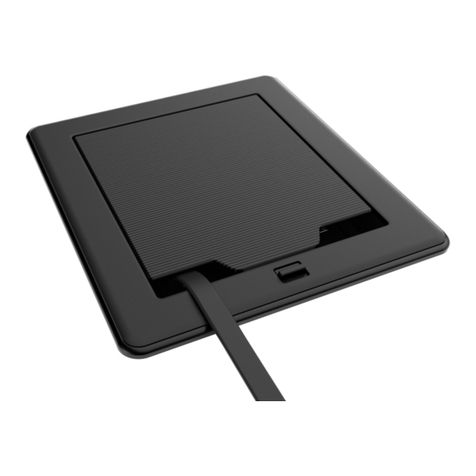

Control unit AGN2.0 / AGN2.1

Barriers of mod. AG500 a AG900 AGM1 are delivered with control unit AGN2.0 / AGN2.1 on

microprocessor basis which enable to adapt plug-in modules of radio receiver and loop detector.

Control unit AGN2.0 / AGN2.1– connection schema:

Fuses:

fuse Type Value

F1 T0,5 A

F2 T5 A

F3 F1 A

F4 T2 A

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

9

Description of AGN2.0 / AGN2.1 connectors :

Pin Part Signal

L POWER Power supply 230V AC – L wire

N Power supply 230V AC – A wire

PE Power supply 230V AC – PE wire

CASE CASE case

RED SEMAPHORE Traffic light pin – phase on signal STOP

GRN Traffic light pin – phase on signal FREE

N Traffic light pin - common

PE MOTOR Motor – PE wire

N Motor - N wire

L1 Motor – phase in direction open

L2 Motor – phase in direction close

+ BRAKE Motor brake 24V +

- Motor brake 24V -

+ LAMP Output for flashing lamp or lighting 24V AC

- Output for flashing lamp or lighting24V AC

+ 24V Output 24V DC for power supply of accesories,

GND max 300 mA

COM START Common pin for control inputs

OPEN Input of push-button „open“ (NO)

CLOSE Input of push-button „close“ (NO)

S/S Input of push-button „ step-step “ (NO)

COM LIMIT Common pin for control inputs

OPEN Input of NC contact of limit switch upper position

CLOSE Input of NC contact of limit switch low position

COM SAFE Common pin for control inputs

FOTO Input of safety contact FOTO ( blocks closing )

( NC )

STOP Input of safety contact STOP of push-button

( blocks all move ) ( NC )

LOCK input contact LOCK ( NO) , the arm is blocked in

open position

COM Common pin for control inputs

ANT + ANT Input of antenna‘s central wire for plug-in receiver

of radio control

ANT GND Input of antenna‘s shell for plug-in receiver of

radio control

LOOP DET Pins for connecting of inductive loop

Plug-in modules:

Connector Module

MODUL RADIO plug-in module of radio receiver – control the barrier following programmable

parameters. Suitable for type MRS2E receiver. Suitable for loop detectors of

PLD1 type (the loop conneted instead of antenna) for opening function.

MODUL DETECTOR plug-in module of presence detector – closing of barrier + safety function

Suitable for loop detectors of PLD1 type, see progr. parameter no. 01.

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

10

Top side of control unit – left part – Input signal

Pin Part Signal

MAIN SWITCH POWER Head power switch 230V AC

FAN X6 fan 24V DC ( for AG/M1)

TAMPER - COM Tamper switch terminal (for checking of door opening)

LOCK OPEN input for LOCK ( NO), the arm is blocked in open position

LOCK CLOSE input for LOCK ( NO), the arm is blocked in close position

COMM Common pin for safety inputs

BOOM input for damage boom sensor

SEM + input for external traffic light driving +24V

SEM- input for external traffic light driving -24V

Top side of control unit – right part – Output signal ( only AGN2.1 version )

(max. loading for each one is 24V / 0,3A ! )

Pin Part Signal

LM_UP X7 output of NO contact of limit switch upper position

LM_CLOSE output of NO contact of limit switch low position

CAR ON LOOP output for car detection (deactivated with some LOCK signal)

PULS output signal impulse (0,5sec.) when the barrier is open and car is

detected on the loop, (deactivated with some LOCK signal)

NOT CLOSED output status signal when the boom is not in low position

BOOM output signal when the barrier broken ( NC contact )

TIMEOUT output for "barrier obstructed

ERROR output for Barrier Out Of Order ( NC )

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

11

a) Start of control unit:

After connecting of power supply red LED in upper right corner is switched-on and in the line

of LED behind the plug-in module relative LED according the activated inputs.

Than the systém is in a standard status, lines on display are blinking.It means the barrier will

work normally.

Standard function:

In case the boom is in closed position the control unit waits for command OPEN - UP. This

can be made by following kinds : Push-button UP, Push-button Step-Step or by radio transmitter. If

during the opening an opposite command is given the boom stops for ca.1s and then starts to move

the opposite way. During the closing cycle inputs FOTO and DET are tested. If they are active, the

boom again stops and starts to move contrary. Input STOP blocks all moves.

b) new setting of control unit:

By simultanous pressing of both programming buttons

you can entry to the programming modus. Number of

programmable function is displayed on. This number can be

changed with the help of programming keys UP and DW. Choose

number of function, you want to change. By simultanous pressing

of both programming keys you can entry to the parameters

settings of this function. Values can be changed again with

programming keys UP and DW following the table of

programmable functions. After setting of required values they are

saved by simultanous pressing of both keys and control unit returns to standard status (lines are

blinking ). When changing other parameters repeate the same way.

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

12

Table of programmable functions:

Function –

number of

item

Description of function

Values Pre-

setted

01 DETECTOR – Choice of PLD1 plug-in loop detector function

Not used (00), Safety ( 01 ), safety+closing ( 02 )

00 - 02 01

02 RADIO1 – Relay A has following functins (for MRS2E):

Open ( 00 ), step-step ( 01 ), or with the help of plug-in loop

detector LPD1 ((the loop conneted instead of antenna) to open

the barrier (02)

00 - 02 00

03 RADIO2 – Choice of relay B function of plug-in receiver

MRS2E

Switched-off( 00 ), or „closing“ ( 01 )

00 - 01 00

04 LAMP – Choice of function of blinking lamp or warning lamp

Blinking only during the movement ( 00 ), or blinking full time( 01 )

00 - 01 00

05 FOTO – memory of closing pulse during break of input

FOTO.

Control unit disregards closing command during break of input

(00), closing command is memorised and after performed ( 01 ).

00 - 01 01

06 TIMER – setting of automatice reclosure time after opening

Reclosure is switched-off ( 00) , reclosure is activated, setted

value coresponds to the time of reclosure ( 01 – 99 )

00 - 99 00

07 DELAY – delay of start of closing after receiving command

close (pre-blinking of flashing light)

time of delay is setted in sec. ( 00 – 99 ).

00 - 99 00

08 Choice of time of switching traffic light on STOP

Traffic light is switched by activation of any safety inputs (when

the car is nearby the barrier)(00), traffic light is switched by

command (01), external driving of traffic light through the input

SEM (02)

00 - 02 00

09 Choice of arm movement concerning the FOTO or loop

detector safety device activation

Stop the boom and rise (00), Stop the boom and finish the

movement when the safety signal falls (01), Stop the boom and

finish the movement with delay 2 sec. when the safety signal falls

(02)

00 - 02 00

10 Stop on obstacle – if the boom bump on an obstacle motor will

stop.

Function is disactivated (00), function is activ, the time of

reaction is setted (O1 – 20).

00 - 20 00

11 Blocking of closing with input OPEN – If the contact on input

OPEN is switched-on, boom cannot be closed. Function is

disactivated (00) , or activated (01)

00 - 01 00

12 Multiply of automatic reclosure time – In case the time of

automatic reclosure set in Item 8 is not sufficient, there is a

possibility to multiply it 10 times. Resulting time is when the value

set in Item no. 8 multiplied by the value of this function (01 – 10

01 - 10

13 Reset of automatic reclosure time – New start of reclosure

time whem opening signal is given during the reclosure time is

activ ( 01 ). Continue of reclosure time regardless to new opening

signal during the reclosure is activ ( 00 ).

00 - 01

14 Setting of barrier model (only for full version of control unit)

AGM1 (00), AG500 (01), AG900 (02)

00 - 02 00

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

13

Loop detector PLD1 – 1-channel plug-in model

For safety functions and automatic closing the barrier after leaving the loop

insert plug-in loop detector module to socket "detector".

The safety loop connect to LOOP pins.

The head function of plug-in loop detector you can set with function no. 01(as

you require) and 09 (to value

02) in setup menu of AGN1.1

control unit.

Change DIP switch (on

AGN1.1 control unit)

according the picture (the arrow on the picture helps you).

If you want to use plug-in loop detector for opening the barrier, insert plug-in loop detector to socket "radio".

The loop connect to ANT pins. This type of function requires setting of function no. 02 to value 02.

You can also apply two plug-in loop detectors in control unit (first for opening, second for safety function and

closing), but the distance between opening and safety/closing loop must be more then 2 meters.

Setup ! After each device setting, a readjustment has to be made by pressing the reset key.

Dip switch 1,2

Frequency setting - with the frequency switches, several operationg frequencies per channel can be set in order

to avoid couplings by nearby loops.

Two ore more detectors may not operate at the same frequency.

Frequency high S1 - left S2 - left (delivery status:high)

right left

left right

Frequency low right right

Dip switch 3

Holding time (only relay A) - static (presence) - (S3 - on) or pulse 100 ms (S3 - off).

Dip switch 4,5,6

Sensitivity of the loop

DIP4 DIP5 DIP6 Function

on on on Sensitivity high

on on off

on off on

on off off Sensitivity med

off on on

off on off

off off on Sensitivity low

off off off DIP3 off - relay released - test operation

off off off DIP3 on - relay picked-up - test operation

Status LEDs

Detect - green LED – the switching status "Loop Covered" is signalled by shining of the green LED.

Error - red LED – A loop failure through loop short-circuit, disconnection or loop inductivity beyond a

permissible range is displayed by shining of the red LED.

Power – yellow LED – during the adjustment, the yellow LED is blinking for a few second. The yellow LED

will shine permanently after the adjustment.

! No vehicle may be on the loop during the adjustment phase, since it will then not be detected any more.

!After each device setting, a readjustment has to be made by pressiong the reset key.

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

14

Wiring diagram

The road gate we can control with all means. For example we can used double button OPEN/CLOSE

which required cabling, like on the next wiring diagram.

Another eventual means for driving are here:

¾radio control

¾inductive car detector

¾access system with magnetic cards, contact keys and proximity tags and cards

¾access system for public cash parking

Accessories to request

9inductive car detector

9safety photocell

9pneumatic skirting

9flash light

9rod flash light

9radio control

9sign STOP

9full or half size banisters on the rod

9articulated rod

9compact or free bracket of the rod

9access systems

Required recyclation of gate components in reason the statute 238 / 91 Sb.

The road gate which is intended for liquidation is necessity to demount and separate components sort

in accordance with material origin (several type of metal, plastic).

All sorted materials you can store on the places intended for safe the planet.

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

15

The EC – Declaration of the Conformity

1) We

AUTOGARD spol. s r.o.

Dornych 47

617 00 Brno - CZ

Ident. No.: 49446053

declare herewith

that the below mentioned product on the basis of its conception and construction as well as

the versions launched by us fulfils the relevant basic safety requirements of the European

directives. In the case of a modification of the product not agreed upon by us this

declaration loses its validity.

Identification: The Automatic Bar

Model series: AG500; AG900; AGM1

Technical parameters: 230 V / 50 Hz

370 W/ 250 W/ 550 W

Manufacturer, Point of

producing:

AUTOGARD spol. s r.o.,

Dornych 47, 617 00 Brno - CZ

The description and using: The automatic bar is determined for the regulation of the entry

and departure of the cars to/from a dedicated area.

The relevant decrees of the government / the European directives:

The Decree of the Government No. 168/1997 Coll. as amended (the Directive of the

European Council 93/68/EEC),

The Decree of the Government No. 169/1997 Coll. as amended (the Directive of the

European Council 93/68/EEC),

The Decree of the Government No. 170/1997 Coll. as amended (the Directive of the

European Council 98/37/EEC).

The applied harmonised standards, national standards and technical specifications:

ČSN EN 60204-1:2000 (EN 60204-1:1997), ČSN EN 61000-6-3:2002 (EN 61000-6-3:2001),

ČSN EN 61000-6-1:2002 (EN 61000-6-1:2001), ČSN EN 292-1:2000 (EN 292-1:1991),

ČSN EN 292-2+A1:2000 (EN 292-2+A1:1995)

Under conditions of common and determined using the product is safe.

The manufacturer has taken precautions for ensuring of the conformity of all launched

products with the technical documentation and wit the requirements of the technical

standards mentioned above.

2) The appreciation of the conformity was carried out in the co-operation with the ITI TÜV

s.r.o., Modřanská 98, 147 00 Praha 4 – Czech Republic, Ident.No: 63987121 – The Product

Certification Body.

The certificate No. 99/03/07/02/0 was issued, from 10.6.2003, valid till: 30.6.2006.

Brno, 12.6.2003 Ing. Martin SKOUMAL ...............................................

Place of issue, date Name and function of the

responsible person

Signature

1) The accredited person cooperative on appreciation of the conformity.

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

16

Certificate

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

17

Operation instructions for road gates AG/500, AG/900, AG/M1

© Autogard spol. s r.o. 2004

18

Contents

Introduction ........................................................................................................................................ 2

General futures .................................................................................................................................. 2

Technical parameters ........................................................................................................................ 2

Foundation kit positioning................................................................................................................ 5

Setting of gate and fixing of rod....................................................................................................... 6

Earthing of road gate......................................................................................................................... 6

Length of rods, pulleys, springs ...................................................................................................... 6

The rod balancing with spring.......................................................................................................... 7

Setting of limit switches.................................................................................................................... 7

Emergency opening........................................................................................................................... 7

Periodical adjustment........................................................................................................................ 7

Control unit AGN2.0 / AGN2.1 .......................................................................................................... 8

Loop detector PLD1 – 1-channel plug-in model ............................................................................. 13

Wiring diagram................................................................................................................................. 14

Accessories to request ................................................................................................................... 14

Required recyclation of gate components in reason the statute 238 / 91 Sb............................ 14

The EC – Declaration of the Conformity........................................................................................ 15

Certificate ......................................................................................................................................... 16

Contents ........................................................................................................................................... 18

This manual suits for next models

2

Table of contents

Popular Control System manuals by other brands

Rockford Fosgate

Rockford Fosgate SSC-1500 GEN II installation manual

Kolver

Kolver ACE Screw Counter Operator's handbook

WattMaster

WattMaster Auto-Zone Plus Design, installation and operation

LELY

LELY CRS M3 Operator's manual

Samsung

Samsung Wi-Fi Kit 2.0 User & installation manual

Systemline

Systemline 4.4 Installer manual