Distech Controls DA-020S Series Manual

Hardware Installation Guide

DA-020S Series

Damper Actuator, 20lb.-in., Spring Return

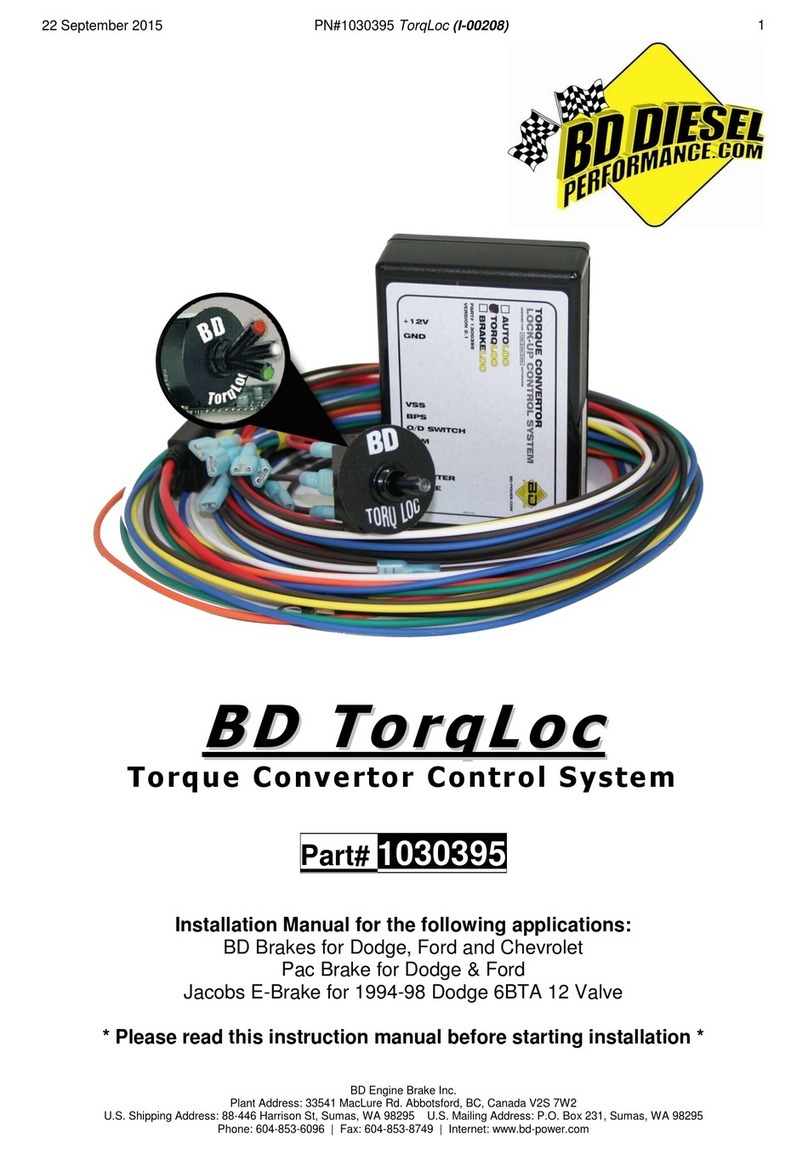

Figure 1: DA-020S Series Damper Actuator

Product Description

This document describes the hardware installation procedures for

direct-coupled mounting of the DA-020S Series damper actuators.

General Installation Requirements

For proper installation and subsequent operation of each actuator, pay

special attention to the following recommendations:

- Upon unpacking the product, inspect the contents of the carton for

shipping damages. Do not install damaged actuators.

- Avoid areas where corroding, deteriorating or explosive vapors,

fumes or gases may be present.

- Ensure that all equipment is installed according to local, regional,

and national regulations.

Personal injury or loss of life may occur if you do not follow a

procedure as specified.

Equipment damage or loss of data may occur if you do not

follow a procedure as specified.

Take reasonable precautions to prevent electrostatic

discharges to the controller when installing, servicing or

operating the controller. Discharge accumulated static

electricity by touching one’s hand to a well-grounded object

before working with the controller.

Product Parts

a) Actuator

b) Mounting bracket

c) Mounting screws

d) 3 mm hex key

e) DA-020S120DXXXX conduit adapter

Figure 2. Parts of the DA-020S Series Actuator.

2/8

Product Components

Figure 3. Components of the DA-020S Spring Return Actuator.

Figure 4. DA-020S120DXXXX Only, Conduit Adapter.

Figure 5. Conduit Adapter Box Shipped Only with DA-

020S024DX2XP, DA-020S024FX2XP, DA-

020S024QX2XP, and DA-020S120DX2XX actuators

Mounting Instructions

Do not open the actuator. If the actuator is inoperative,

replace the unit.

- The shaft adapter can be mounted on either side of the actuator.

The actuator mounting orientation and shaft length determine how

they will be mounted on the actuator.

- The minimum damper drive shaft length is 3/4-inch (20 mm).

- See Specifications for the minimum and maximum damper shaft

dimensions.

- A mounting bracket is included with the actuator.

Adapter Mounting

Figure 6.

Figure 7. NEMA 1 IP40 in All Positions

3/8

Shaft Mounting

Figure 8.

Wiring

Do not expose the actuator's

connecting cables to water or lay the cables in water.

Device of protection class II (protective

insulation)

Device of protection class III (protective

insulation)

DA-020S024DXxxx

2-Position: 24 Vac/dc

Class III

DA-020S024FXxxx

Floating: 24 Vac/dc

Class III

DA-020S024QXxxx

Modulating: 24 Vac/dc

Class III

DA-020S120DXxxx

2-Position: 120 Vac

4/8

Special Applications

DA-020S024QXxxx, 4 to 20 mA

Auxiliary Switches

Figure 9.

Actuator

Position

Switch A Common

Connected to

Switch B

Common

Connected to

0 to 5°

N.O.

N.O.

5 to 85°

N.C.

N.O.

85 to 95°

N.C.

N.C.

Mixed switch operation to the switching outputs of both

dual end switches (5° and 85°) is not permitted.

Either AC line voltage from the same phase must be

applied to all six outputs of the fixed dual end switches,

or UL-Class 2 voltage must be applied to all six

outputs.

DIP Switch Functionality for

DA-020S024QXXXP

The black position indicates the active switch setting.

Description

Label

Description

Function

Inverse Acting

Direct-Acting

Input Signal

Inversion

Inverse-Acting

Feedback

Direct-Acting

feedback

Feedback

Signal

inversion

Not In Use

Input Signal Inversion

Allows inverting the control input signal

The arrow direction indicates opening or closing (closing or opening)

when operating an actuator with a given control signal.

= Direct acting (Factory setting)

Input signal 2 Vdc ► fail-safe position

= Inverse acting

Input signal 10 Vdc ► fail-safe position

Feedback Signal Inversion

Allows inverting the position feedback output signal

= Direct acting feedback (Factory setting)

Fail-safe position ► Output signal 2 Vdc

= Inverse acting feedback,

Fail-safe position ► Output signal 10 Vdc

Wiring

All wiring must conform to NEC and local codes and regulations.

Use earth ground isolating step-down Class 2 transformers. Do not use

autotransformers.

The maximum rating for a Class 2 step-down transformer is 100 VA.

Determine the supply transformer rating by summing the VA ratings of

all actuators and all other components used. It is recommended that

one transformer power no more than 10 actuators (or 80% of its VA).

Installations requiring Conformance:

All wiring for 24 Vac/dc actuators must only be safety extra-

low voltage (SELV) or protective extra-low voltage (PELV)

per HD384.

Use safety transformers per EN61558 with double isolation,

designed for 100% duty-cycle for supplying SELV or PELV

circuits.

Over-current protection for supply lines is maximum 10A.

5/8

Start-Up/Commissioning

DA-020S024QXxxx

Spring Return, Modulating Control, 24 Vac/dc

1. Check Operation:

a) Connect wires 1 (red) and 2 (black) to the 24 Vac/dc

power supply.

NOTE: With no input signal present, the DA-

020S024QXXXP actuator with input signal inversion

switch set to Inverse Acting, will start driving towards

90°.

b) Use a Digital Multimeter (DDM) and set the dial to Vdc

for the actuator input signal.

c) Connect wires 2 (black) and 8 (gray) to the DMM.

d) Apply to input signal wire 8 (gray):

Y = 10 Vdc (DA-020S024QXXXP with input signal

inversion switch set to Direct Acting).

Y = 2 Vdc (DA-020S024QXXXP with input signal

inversion switch set to Inverse Acting).

Allow the actuator shaft coupling to rotate from 0° to 90°.

e) Apply to input signal wire 8 (gray):

Y = 2 Vdc (DA-020S024QXXXP with input signal

inversion switch set to Direct Acting).

Y = 10 Vdc (DA-020S024QXXXP with input signal

inversion switch set to Inverse Acting).

The shaft coupling returns to the "0" position.

DA-020S024DXxxx

Spring Return, 2-Position, 24 Vac/dc

2. Check Operation:

a) Connect wires 1 (red) and 2 (black) to 24 Vac/dc power

supply. Allow the actuator shaft coupling to rotate from

0° to 90°.

b) Disconnect wire 1 (red) and the actuator shaft coupling

returns to the "0" position.

3. Check Spring Return:

a) Connect wire 1 (red). Allow the actuator shaft coupling

to rotate halfway.

b) Disconnect wire 1 (red). The spring returns the actuator

shaft coupling to the fail-safe "0" position.

DA-020S024FXxxx

Spring Return, Floating, 24 Vac/dc

1. Check Operation:

a) Connect wires 1 (red) and 2 (black) to a 24 Vac/dc

power supply.

b) Apply a control signal (24 Vac/dc) to wire 6 (violet).

Allow the actuator shaft coupling to rotate from 0 to 90°.

c) Stop the control signal to wire 6 (violet).

d) Apply a control signal (24 Vac/dc) to wire 7 (orange).

Allow the actuator shaft coupling to rotate from 90° to 0°.

2. Check Spring Return:

a) Apply a control signal (24 Vac/dc) to wire 6 (violet).

Allow the actuator shaft coupling to rotate half way.

b) Disconnect wire 1 (red). The spring returns the actuator

shaft coupling to the fail-safe "0" position.

c) Connect wire 1 (red). The actuator shaft coupling begins

to move.

DA-020S120DXxxx

Two-Position, 120 Vac

1. Check Operation:

a) Switch on 120 Vac power.

b) Allow the actuator shaft coupling to rotate from 0 to 90°.

2. Switch off power. The actuator shaft coupling will return to the "0"

position.

3. Check Spring Return:

a) Switch on 120 Vac power.

b) Allow the actuator shaft coupling to rotate halfway.

c) Switch off 120 Vac power. The spring returns the

actuator shaft coupling to the fail "0" position.

Troubleshooting

To avoid injury or loss of life, pay attention to any

hazardous voltage (for example, 120 Vac) when

performing checks.

- Check that the wires are connected correctly.

- Check that DIP switch is set correctly, if used.

- Use a Digital Multimeter (DMM) to verify that the operating

voltage is within range.

- If the actuator is not working, check the damper for blockage.

- If blocked, remove the obstacle and cycle the actuator power off

and on. The actuator should resume normal operating mode.

6/8

Wiring Terminations

Each wire has the standard symbol printed on it.

Table 1. Wiring Terminations

Connecting

Standard

Symbol

Function

Color

Color

Symbol

24 Vac/dc

Actuator

1

Supply (SP)

Red

RD

2

System Neutral

Black

BK

6

Control signal clockwise

Violet

VT

7

Control signal counterclockwise

Orange

OG

8

Input Signal: 2 to 10 Vdc or 10 to 2 Vdc

(DA-020S024QXxxx)

Gray

GY

9

Position Output: 2 to 10 Vdc or 10 to 2 Vdc

(DA-020S024QXxxx)

Pink

PK

120 Vac

3

Supply

Black

BK

4

Neutral

White

WH

Auxiliary Switches

1

Switch A Common

S1

Gray/red

2

Switch A N.C.

S2

Gray/blue

3

Switch A N.O.

S3

Gray/pink

4

Switch B Common

S4

Black/red

5

Switch B N.C.

S5

Black/blue

6

Switch B N.O.

S6

Black/pink

Retrofit Wiring

Modulating Control

(2 to 10 Vdc)

Function

Distech Controls

DA-020S Series

Siemens

GQD Series

Belimo

TF Series

Honeywell

MS7503 Series

Johnson

M9203 Series

Color

Number

Color

Number

Color

Number

Terminal

Only

Number

Color

Number

Supply (24V)

Red

1

Red

1

Red

2

1

Red

2

Common

Black

2

Black

2

Black

1

2

Black

1

0(2) to 10 Vdc Input

Gray

8

Gray

8

White

3

3

Gray

3

0(2) to 10 Vdc Feedback

Pink

9

Pink

9

Orange

5

5

Orange

4

2-Position Control

(24 Vac/Vdc)

Function

Distech Controls

DA-020S Series

Siemens

GQD Series

Belimo

TF Series

Honeywell

MS8103 Series

Johnson

M9203 Series

Color

Number

Color

Number

Color

Number

Terminal

Only

Number

Color

Number

Supply (24V)

Red

1

Red

1

Red

2

1

Red

2

Common

Black

2

Black

2

Black

1

2

Black

1

2-Position Control

(120 Vac)

Function

Distech Controls

DA-020S Series

Siemens

GQD Series

Belimo

TF Series

Honeywell

MS4103 Series

Johnson

M9203 Series

Color

Number

Color

Number

Color

Number

Terminal

Only

Number

Color

Number

Line (120V)

Black

3

Black

3

Black

2

1

Black

2

Neutral

White

4

White

4

White

1

2

White

1

7/8

Dimensions

Figure 10. Actuator and Mounting Bracket for models: DA-020S024DXXXP / FXXXP / QXXXP

Figure 11. DA-020S120DXXXX Actuator Only.

Figure 12. Actuators with Conduit Adapter for

DA-020S024DX2XP / FX2XP / QX2XP

©, Distech Controls Inc., 2014. All rights reserved.

While all efforts have been made to verify the accuracy of information in this manual, Distech Controls is not responsible for damages or claims arising from the use of this

manual. Persons using this manual are assumed to be trained HVAC specialist / installers and are responsible for using the correct wiring procedures and maintaining safe

working conditions with fail-safe environments. Distech Controls reserves the right to change, delete or add to the information in this manual at any time without notice.

Distech Controls, the Distech Controls logo, and Innovative Solutions for Greener Buildings are trademarks of Distech Controls Inc. All other trademarks are property of their

respective owners.

8/8

DA-020S Series_IG_10_EN

Dimensions (cont’d)

Figure 13. Dimensions of the DA-ASK75.7U Weather Shield in Inches (Millimeters).

This manual suits for next models

1

Table of contents

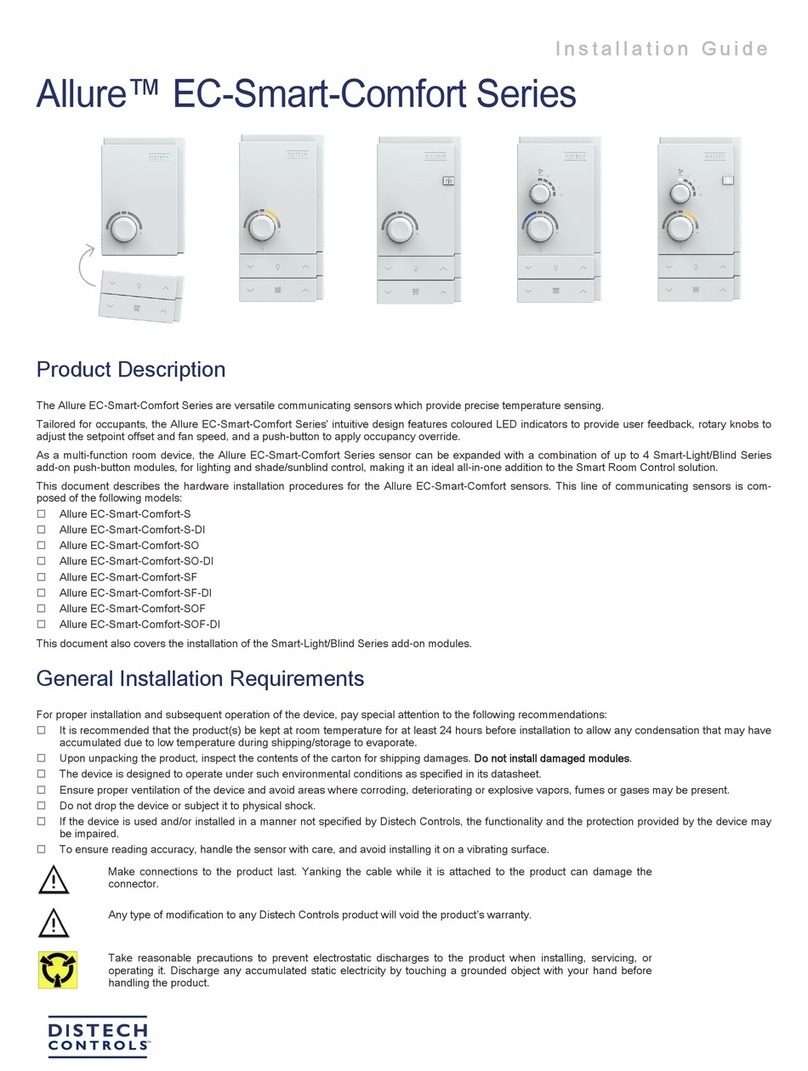

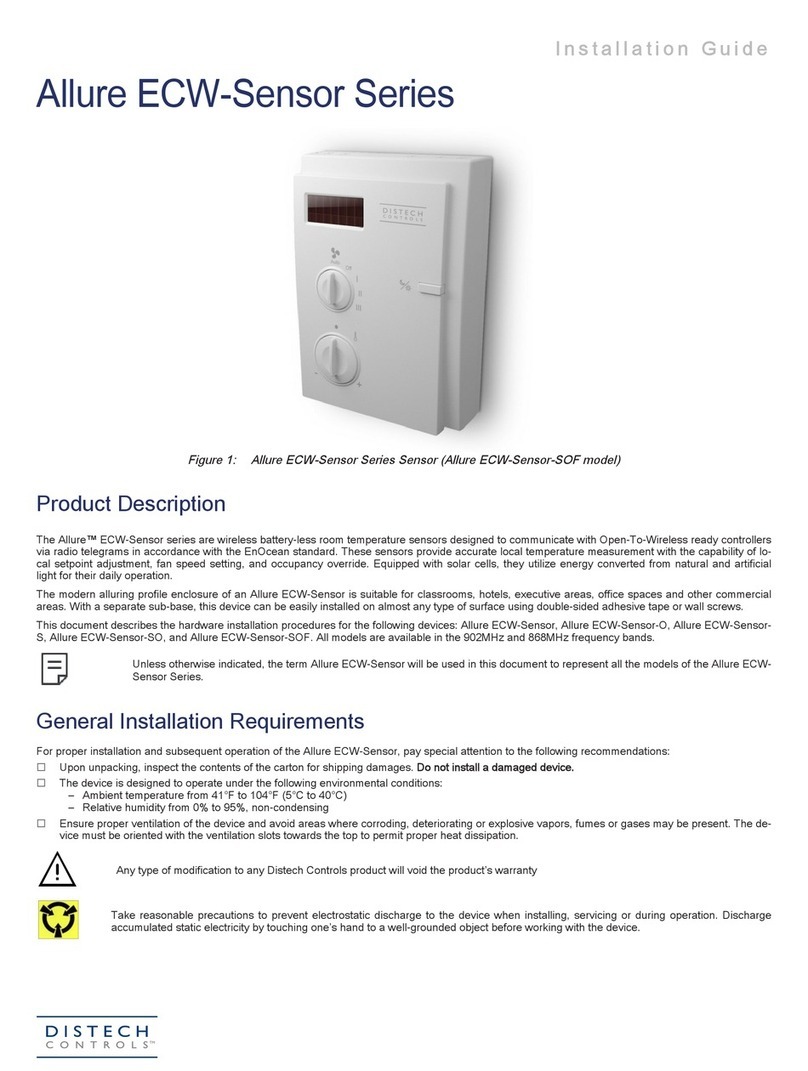

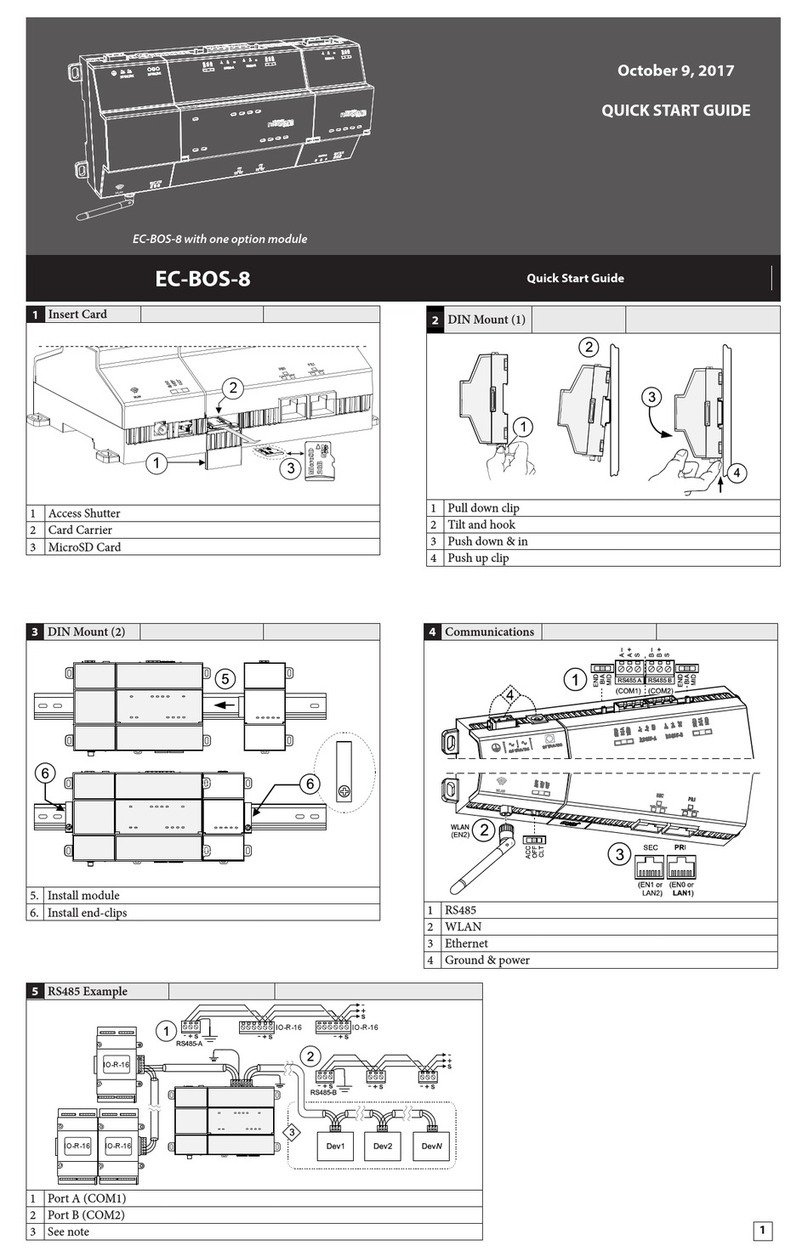

Other Distech Controls Control System manuals

Distech Controls

Distech Controls ECLYPSE APEX User manual

Distech Controls

Distech Controls Allure EC-Smart-Comfort Series User manual

Distech Controls

Distech Controls EC-BOS-6AX Programming manual

Distech Controls

Distech Controls Allure ECW-Sensor Series User manual

Distech Controls

Distech Controls EC-BOS-8 User manual

Popular Control System manuals by other brands

ABB

ABB Advant AC500 manual

Telensa

Telensa Telecell installation manual

REGLOPLAS

REGLOPLAS RT 45 operating instructions

Carlin

Carlin EZ-Temp 90320 quick start guide

Jay electronique

Jay electronique ORION Series Installation and user technical manual

Crestron

Crestron FlipTop FT2-1200-ELEC-PTL Getting started