WattMaster Auto-Zone Plus User manual

Design, Installation

And Operations Manual

Plus System

Revision 02B

firealarmresources.com

firealarmresources.com

Auto-Zone

Plus

Design, Installation & Operations Manual

Section 1..............................................................................System Overview

Section 2................................................................... Installation and Wiring

Section 3....................................................................................Programming

Section 4........................................................Start-Up and Troubleshooting

This document is subject to change without notice.

WattMaster Controls, Inc. assumes no responsibility

for errors, or omissions herein.

Auto-Zone Plus Installation & Operations Manual - Form WM-AZP-IO-02B

Auto-Zone is a registered trademark of WattMaster Controls, Inc.

Copyright 2003 WattMaster Controls, Inc.

All rights reserved.

firealarmresources.com

firealarmresources.com

Section 1

Design Guide

Table of Contents

Conventions .....................................................................1

General Information.........................................................3

Description of System Components.................................................................................3

Design Considerations.....................................................6

Zone Diversity .................................................................................................................6

Cooling - Partial Load Conditions ...................................................................................6

Heating - Partial Load Conditions ...................................................................................8

Override Conditions.........................................................................................................8

Building Pressurization....................................................................................................8

Design Guide....................................................................9

Step #1 - Zoning ..............................................................................................................9

Step #2 - Sizing the Central Unit ...................................................................................11

Step #3 - Duct Design Considerations...........................................................................11

Step #4 - Room Air Motion/Diffuser Selection.............................................................12

Step #5 - Bypass Damper Sizing ...................................................................................13

Step #6 - Sizing the Zone Damper.................................................................................15

Round Dampers .............................................................................................................17

Rectangular Dampers.....................................................................................................17

Pressure Independent Zone Dampers ............................................................................18

Auxiliary Heat Control Options......................................19

Table of Figures

Figure 1-1: Auto-Zone Plus System ..............................................................................2

Figure 1-2: Control Zones Affected by the Outdoor Load..........................................10

Figure 1-3: Locating the Static Pressure Sensor for Bypass Damper Control ............14

Figure 1-4: Round Damper Dimensions.......................................................................16

Figure 1-5: Rectangular Damper Dimensions ..............................................................16

Table 1-1: Round Air Damper Selection .....................................................................17

Table 1-2: Rectangular Damper Selection...................................................................17

Table 1-3: Pressure Independent Flow Factors............................................................18

firealarmresources.com

firealarmresources.com

Auto-Zone Plus

Section 1

Design Guide 1-1

Conventions

This document uses the following definitions throughout as a guide to the user in

determining the nature of information presented:

Note: Additional information which may be helpful

Tip: Suggestion to make installation, set-up, and troubleshooting easier.

Caution: Items which may cause the equipment not to function correctly but will

not otherwise damage components.

Warning: Errors which can result in damage to equipment and void warranties.

firealarmresources.com

Section 1

Auto-Zone Plus

1-2 Design Guide

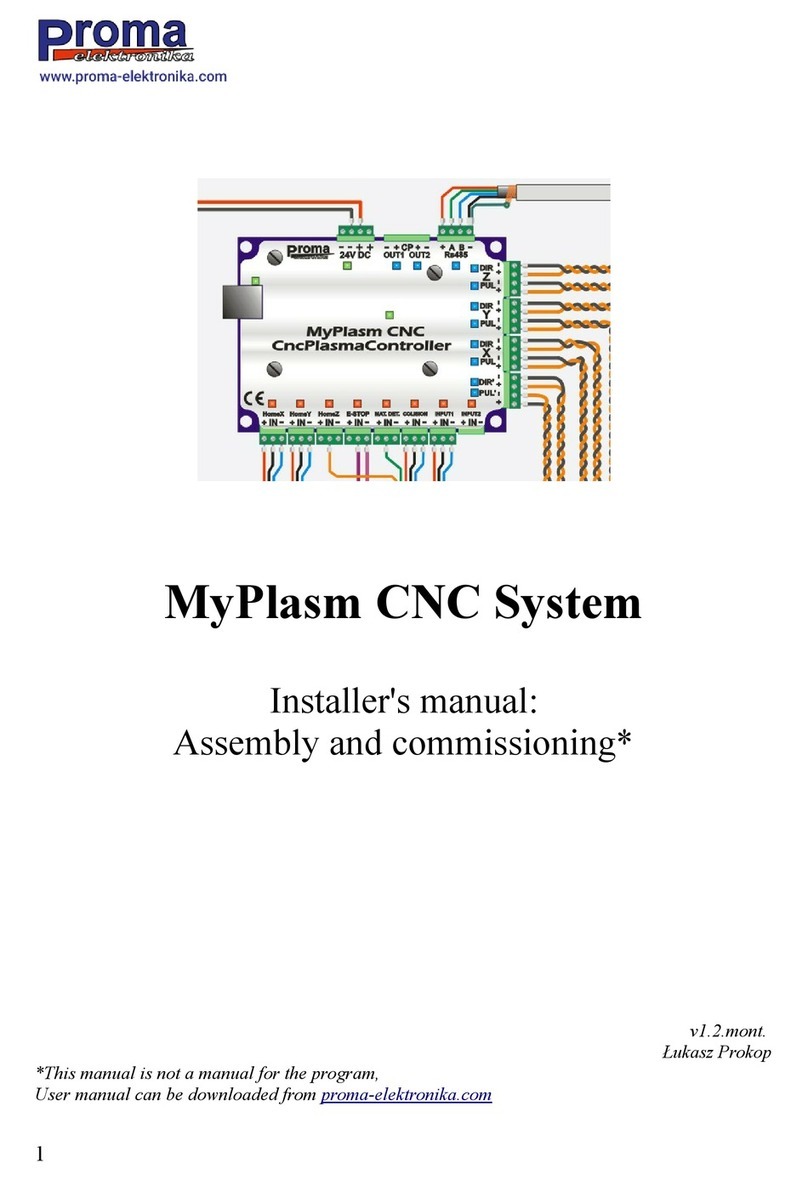

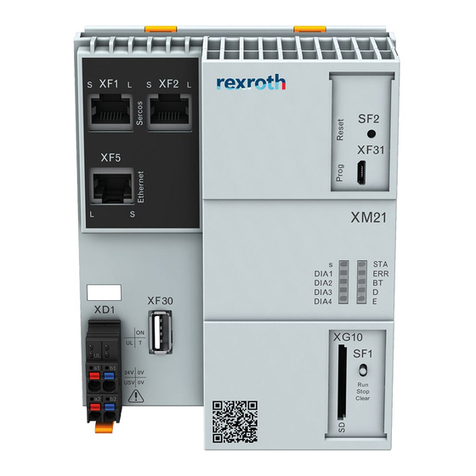

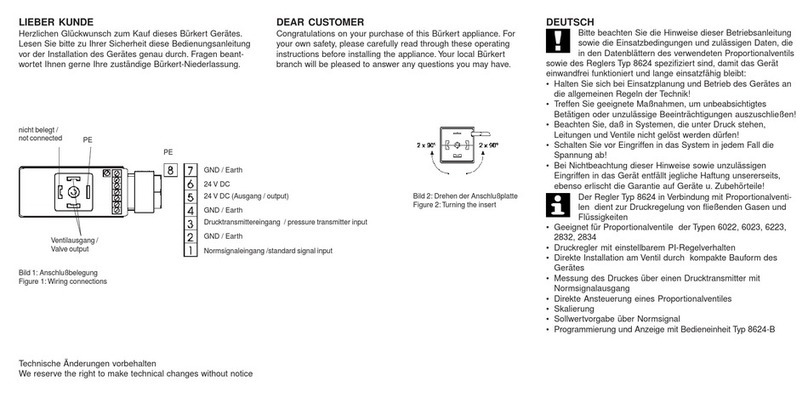

Figure 1-1: Auto-Zone Plus System

CommLink II

Multiple Loop

Computer

(Optional)

To Other Zone

Managers

(Up To 30 Per System)

Zone

Manager

Zone

Manager

RS-485

9600 Baud

Supply

Air Temp

Sensor

Supply

Air Temp

Sensor

To HVAC Unit #1

Control Panel

To HVAC Unit #2

Control Panel

Return

Air Temp

Sensor

Return

Air Temp

Sensor

Bypass Air

Damper

Bypass Air

Damper

Economizer

(Actuator By Others)

Outside

Air Temp

Sensor

Static

Pressure

Sensor

Static

Pressure

Sensor

Typical Zone

24VAC

WCLI

ATTMASTER ONTRO S, NC

COMM LINK IICOMM LINK II

LCM

M

OOO

OMD

PP

E

Constant Volume Units

Up to 13 CV Units May Be added To

Each Zone Manager Loop

System Manager

Local Loop

Local Loop

Network Loop

24VAC

24VAC

Zone Air Dampers

Up to 16 Zone Air Dampers Allowed

Zone Air Dampers

Up to 16 Zone Air Dampers Allowed

#1

#1

#18

#16

#16

#30

24VAC

1

4

2

5

3

6

9

8

0

7

Enter

Esc

*

Minus

Menu

Clear

Dec.

Alarm

Communication

Override

MANAGER

SYSTEM

Auto-Zone Plus

01/01/97 03:38PM WED

OCCUPIED

NO ALARMS

Sychronous Data Link

CONTROLS

SIG

DET

RDY

SND

REC

PWR

Remote Link

(Optional)

Velocity Sensor

(Optional)

Zone Controller

Damper Actuator

RS-485

Comm Loop

24 VAC

Room Sensor

with Optional

Override & Adj.

AIRFLOW

AIRFLOW

firealarmresources.com

Auto-Zone Plus

Section 1

Design Guide 1-3

General Information

The Auto-Zone Plus control system converts single-zone rooftop packaged HVAC units

into variable air volume/variable temperature multiple zone systems. The microprocessor

based Zone Manager calculates the heating and cooling requirements for each zone based

on real time information received from each Zone Controller. The Zone Manager then

directs the HVAC unit to provide the appropriate amount of heating, cooling, and

ventilation to satisfy each zone's requirements. A static air pressure sensor modulates a

bypass damper to maintain constant duct pressure.

The Auto-Zone Plus System Manager allows multiple Zone Managers to be programmed

and monitored from a central operator's panel. Single-zone constant volume rooftop

HVAC units can also be connected to the Auto-Zone Plus communication network,

allowing for both multizone and single-zone equipment to be controlled from the same

system.

Substantial savings can be realized using the Auto-Zone Plus system instead of having to

install multiple rooftop units to accommodate multiple zone requirements. The Auto-

Zone Plus system is versatile and can be used with any packaged roof top unit or split

system. It controls a variety of terminal unit functions including single duct pressure

dependent or pressure independent systems.

An optional color graphics software package is available for on site or remote

monitoring.

Description of System Components

A typical Auto-Zone Plus system is comprised of the following basic components.

System Manager

The microprocessor based System Manager allows multiple Zone Managers and any

single-zone constant volume HVAC units to be programmed and monitored from a

central operator's panel. The System Manager is connected via the Auto-Zone Plus

communication network.

The System Manager is mounted in an attractive, white plastic housing, suitable for wall

mounting. A four line by twenty character backlighted LCD display and membrane

keypad provide a user friendly interface. All system variables, setpoints, and values can

be viewed and modified from the System Manager. Menu driven programming makes the

Auto-Zone Plus easy to set up and operate without the need for specialized training.

firealarmresources.com

Section 1

Auto-Zone Plus

1-4 Design Guide

CommLink II

The CommLink II communications interface allows user access to any controller.

Locally, access is by means of an on-site computer. Remote access is obtained via

modem. The CommLink II may also be configured for Call-Out on Alarm. The

CommLink II comes packaged in an attractive plastic enclosure and is powered by a

small wall mounted transformer. The CommLink II should be located near the computer

which will be used to monitor the system. If no on-site computer is to be used then locate

the CommLink II near the phone line jack if a modem is to be used. The cables from the

CommLink II-to-modem and the CommLink II-to-computer should not exceed twenty-

five feet.

Zone Manager

The Zone Manager is a microprocessor based controller which monitors up to sixteen

zones in the system. The zone manager then controls the HVAC unit to satisfy the

requirements of each individual zone while maintaining efficient operation and comfort.

The Zone Manager operates the fan, heating, cooling, duct static pressure, and

economizer functions. Each Zone Manager also features time scheduling, night set back,

trend logging of sensor values, and automatic changeover.

Bypass Damper

The bypass damper controls proper duct static pressure to insure proper airflow. The

damper is modulated by the Zone Manager, based on a signal received from the static

pressure sensor connected to the main duct.

Zone Controller

The Zone Controller monitors space temperature and allocates proper airflow to the

assigned zone to achieve desired comfort and ventilation levels. If supply air temperature

will benefit the local zone temperature setpoint, the zone damper modulates to reduce or

increase airflow as needed. If supply air will not benefit the local zone, the controller will

direct the damper actuator to a minimum position and wait for a change in supply air

temperature.

Constant Volume Controller

The Constant Volume (CV) Controller is a microprocessor based controller designed to

operate packaged roof top HVAC units. Up to thirteen stand alone CV controllers can be

connected to each Zone Manager's local communications loop to provide a fully

integrated multizone/single-zone control system. The CV controller operates the fan,

heating, cooling, and economizer functions. Each CV controller also features time

scheduling, night set back, trend logging of sensor values, and automatic changeover.

firealarmresources.com

Auto-Zone Plus

Section 1

Design Guide 1-5

Zone Sensor

The patented zone sensor is of a flush, wall mounted design. A special plate on the face

of the sensor accurately senses space conditions. As a result of its unique design, the zone

sensor rejects the influence of internal wall temperature effects. The sensor comes in four

different configurations:

•Sensor only

•Sensor w/push-button override (override is fixed at 2 hours)

•Sensor w/setpoint adjustment

•Sensor w/override & setpoint adjustment

Any combination of these sensor configurations can be used with the system.

firealarmresources.com

Section 1

Auto-Zone Plus

1-6 Design Guide

Design Considerations

Consider the following items when designing an Auto-Zone Plus system.

Zone Diversity

An Auto-Zone Plus system is designed to improve tenant comfort by dynamically re-

balancing the air distribution when used with a typical constant volume rooftop

heating/cooling unit. If zones with extremely different load conditions are serviced by a

single rooftop unit, the result will be poor control and excessive wear due to cycling of

the equipment.

It is especially important to avoid mixing interior zones (which require cooling all year)

with exterior zones (which may require constant heat during winter months). If you must

mix zones under these conditions, consider using either VAV boxes with heat or separate

baseboard heat on exterior zones. Auto-Zone Plus systems offer a variety of methods to

control additional zone heat to help you avoid problems.

Group similar loads on an individual unit and use more than one zoned unit if required.

Any special loads can be handled by using separate constant volume units.

The Auto-Zone Plus system offers the designer considerable flexibility by allowing both

multiple-zoned units and single-zone units to be connected within a single simple system.

Cooling - Partial Load Conditions

The engineer must be aware of several potential problems when applying an Auto-Zone

Plus system during cold weather operation.

Low Ambient Temperature Lockout

During very cold weather it is common for mechanical systems to have “low temp

lockouts” which protect equipment from damage if operated under these conditions.

Auto-Zone Plus also provides user programmed lockouts for protection purposes,

although mechanical safeties should always be used as the final stage of protection.

If the rooftop unit services interior zones with thermal loads which require cooling when

outside temperatures are below the safe operating limits for your equipment, you should

seriously consider installing an economizer on your rooftop unit. The Auto-Zone Plus

control system is designed to take Plus of an economizer if it is installed. The use of an

economizer will save money on utilities and provide comfort under conditions when it is

not possible to operate the mechanical cooling system.

firealarmresources.com

Auto-Zone Plus

Section 1

Design Guide 1-7

Low Supply Air Temperatures

Under lightly loaded conditions much of the supply air may be bypassed back into the

return airside of the system. This bypassing will result in the lowering of the supply air

temperature, which may result in the supply air temperature reaching the low temp safety

limit. If the supply air low temp safety limit is exceeded, the control system will “cut-off”

the mechanical cooling to protect it from damage. Excessive cycling of the mechanical

system will result if this condition persists. Comfort may also suffer if the system cannot

run long enough to satisfy cooling demands.

A number of things can be done to reduce this problem. Some of these things depend

upon the type of installation.

•Avoid oversizing the unit. Do your load calculations carefully. Since Auto-Zone Plus

directs the heating or cooling to the zones which require it, you may find that you can

use a smaller unit in many cases. Oversizing is the number one cause of excessive

low supply air temperature cycling.

•Increase your cooling minimum airflow or damper position settings to allow more air

during cooling operation. Be careful to avoid settings which are so high you cause

over cooling of the spaces. Find a compromise position.

•Bypass the air into the plenum instead of into the return air intake. Be careful if you

use this method since you may get “dumping” of cold air from your return air grilles.

This method works best with plenum returns, do not use this method with ducted

returns unless you have carefully considered the consequences.

•Increase your static pressure setpoint to help reduce the amount of air being bypassed.

Be aware of increased noise levels and the cost of operation if you use excessive

static pressures. This will not work if you are using pressure independent zone

controllers, since they will maintain a constant flow of air to the zones regardless of

duct static pressure. This technique will likely cause over cooling of the spaces due to

increased airflows at minimum positions.

Warning: If the fan system has the capability of producing static pressures

which could damage ductwork you must provide a manual reset,

high pressure limit switch to cut-off the fan system in the event of

high duct static.

Do not use your Auto-Zone Plus system as a safety

device!

•Use an Economizer. Although this is not a cure-all, it greatly improves operation

during cool weather when cooling loads are minimal. Using an Economizer also

improves ventilation and lowers operating costs.

firealarmresources.com

Section 1

Auto-Zone Plus

1-8 Design Guide

Heating - Partial Load Conditions

Heating difficulties are less common than cooling difficulties. They are similar in nature,

however, and the cures are generally the same.

•Increase the Heating minimum setpoints on as many zones as possible.

•Increase the static pressure setting as high as is practical. Increasing static pressure

does not help if you are using pressure independent operation.

•Bypass to plenum instead of the return air intake if acceptable.

•Do not oversize your equipment.

•Use auxiliary heat in either your VAV boxes or baseboard.

Auto-Zone Plus has a number of auxiliary heat control options which provide solutions to

most problems. Refer to the Auxiliary Heat Control Options topic near the end of this

section.

Override Conditions

After-hours overrides can produce aggravated partial load conditions in both the heating

and cooling modes. The problem is most commonly caused by a single zone being

overridden for after-hours use. This causes the rooftop equipment to operate for only one

zone. The Auto-Zone Plus system offers an improved solution to this common problem

by allowing a single override to trigger a group of zones via a “global” override. This

allows the system to operate with sufficient load to reduce cycling caused by light load

conditions.

Building Pressurization

If you are using an economizer, building pressurization must be addressed. Failure to

properly handle building pressurization may result in doors remaining open when the

economizer is operating. Pressurization problems can render economizer operation

useless. The following suggestions will help to avoid potential problems.

•Use powered exhaust when the system uses ducted returns. The return duct pressure

drop will cause most barometric relief dampers to function poorly or not at all. Auto-

Zone Plus has the ability to control a powered exhaust whenever the economizer is

operating.

•Use a separate building pressure control which operates a relief fan or dampers.

firealarmresources.com

Auto-Zone Plus

Section 1

Design Guide 1-9

Design Guide

There are six basic steps to designing an Auto-Zone Plus system:

1. Zoning

2. Sizing the Central Unit

3. Duct Design Considerations

4. Room Air Motion / Diffuser Selection

5. Bypass Damper Sizing

6. Sizing Zone Dampers

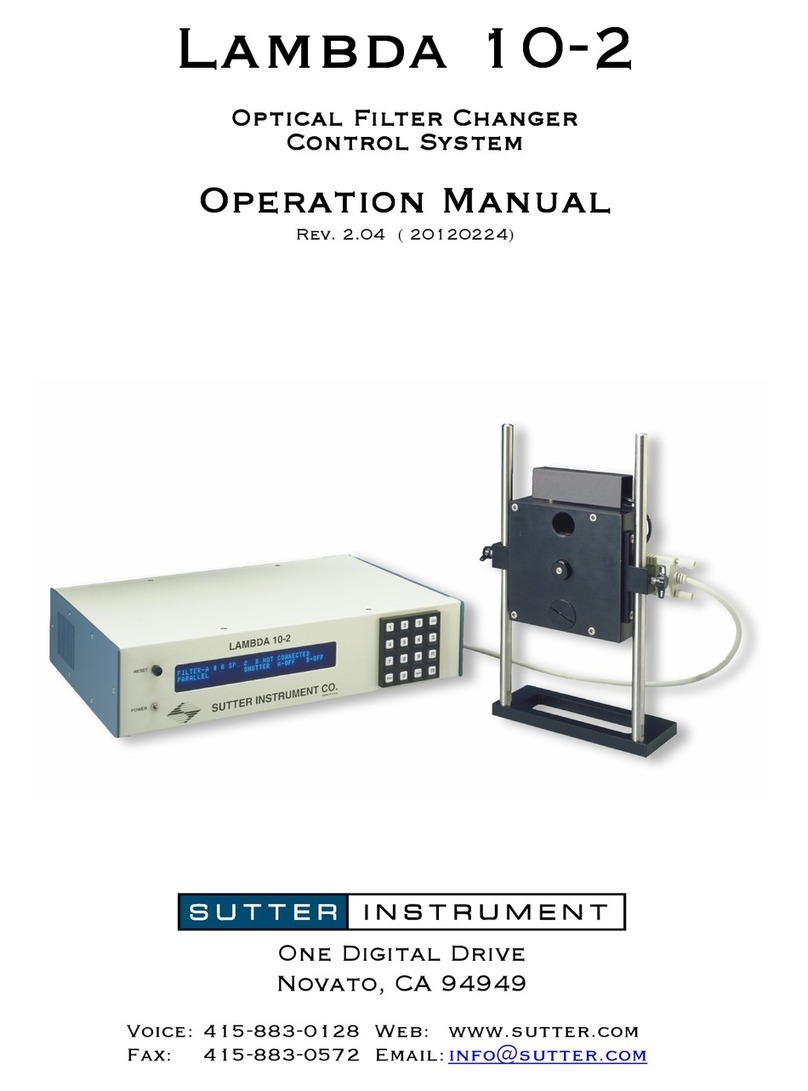

Step #1 - Zoning

Determine the number of zones. A single air handler unit can have no more than sixteen

zones. If the number of zones exceeds sixteen then more than one Zone Manager will be

required.

The primary precaution to be taken in applying the Auto-Zone Plus System is to select

the zoning so that no zone will be at maximum (design) heating (or cooling) load when

any other zone requires the opposite temperature air to satisfy its load. For example,

depending on the wall, ceiling and floor material and location within the building (e.g.

top or middle floor), a typical floor of a building usually has a minimum of nine distinct

temperature or control zones that are affected uniquely by the outdoor load. These zones

are depicted in Figure 1-2.

Depending on the size of the building and partition layout, some of these zones may

overlap or be insignificant from a zoning standpoint. For example, Zone 10 could be

multiple conference or computer rooms where additional zoning would be required, or it

could be as small as a corridor where no zoning is required. Similarly, zones 4 and 5

could have no external windows and no partitions between them and could be considered

a single zone. Zone 3 could be divided into multiple offices with full partitions between

them, thus requiring separate Zone Controllers because of different internal loads, but the

same external load.

Generally, the greater the number of individual Zone Controllers, the greater the comfort.

The designer will have to look at the specific building, balancing the costs of multiple

zones with the added comfort possible with multiple zones, to match the owner's

requirements.

firealarmresources.com

Section 1

Auto-Zone Plus

1-10 Design Guide

It is important to recognize that there are purely internal zones, such as Zone 10, which

may contain separate offices/conference/computer rooms. These internal zones could

easily have high cooling requirements while external zones (1,2,3, etc.) could be at or

near design heating load. This is a misapplication of the Auto-Zone Plus (or any

heating/cooling changeover) system. The interior zones with cooling only loads should

be served with a separate air-conditioning unit (that could be zoned between multiple

rooms with a similar load profile). Supplemental heat could be added to the perimeter

zones and controlled with the auxiliary heat control board from the Zone Controller.

System performance will generally be compromised and frequent changeover from the

heating to the cooling mode will occur during the heating season if purely internal zones

are combined on the same air-conditioning unit serving perimeter zones.

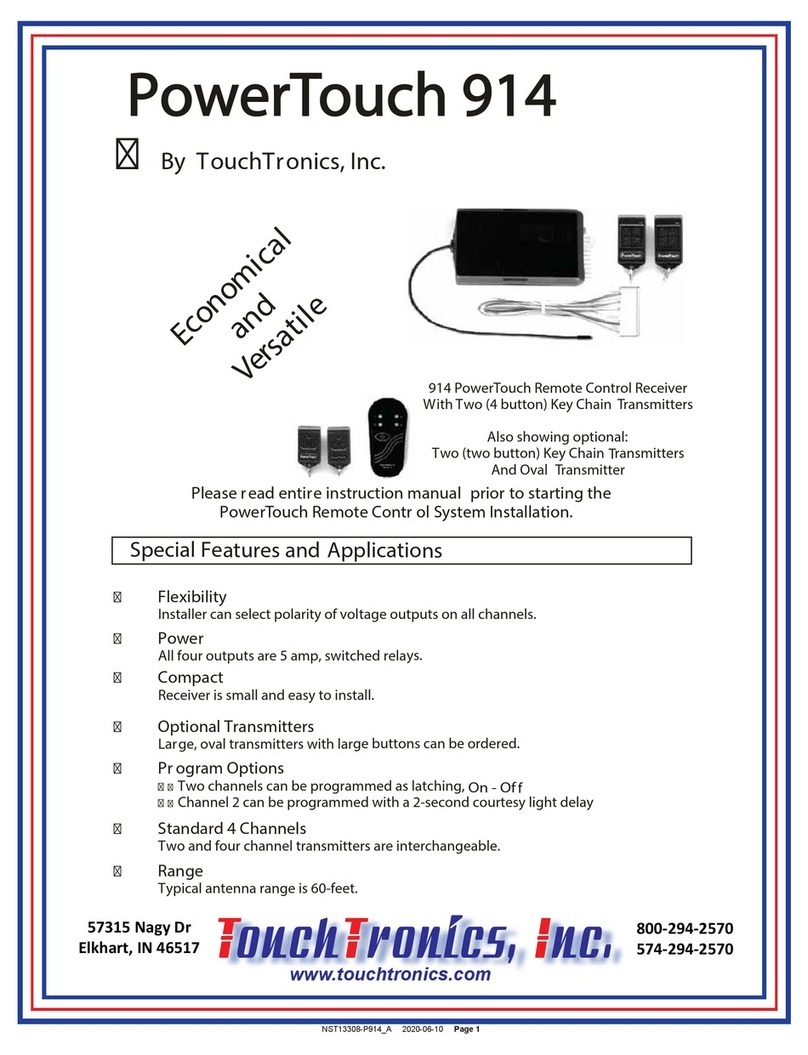

Figure 1-2: Control Zones Affected by the Outdoor Load

N

S

E

W

Room Sensor

(Typical)

Supply Air Duct

Supply Air Duct

Return Air Plenum

Return Air Plenum

Round Zone Damper

(Typical)

Bypass Damper

System Manager

Zoned HVAC Unit

Constant Volume HVAC Unit

1

4

2

5

3

6

9

8

0

7

Enter

Esc

*

Minus

Menu

Clear

Dec.

Alarm

Communication

Override

MANAGER

SYSTEM

Auto-ZonePlus

01/01/9703:38PMWED

OCCUPIED

NOALARMS

WATTMASTERCONTROLSINC.

NORMAL

OVR

W

A

R

M

E

R

C

O

O

L

E

R

NORMAL

OVR

W

A

R

M

E

R

C

O

O

L

E

R

NORMAL

OVR

W

A

R

M

E

R

C

O

O

L

E

R

NORMAL

OVR

W

A

R

M

E

R

C

O

O

L

E

R

NORMAL

OVR

W

A

R

M

E

R

C

O

O

L

E

R

NORMAL

OVR

W

A

R

M

E

R

C

O

O

L

E

R

1

3

2

4

5

6

8

9

10

7

firealarmresources.com

Auto-Zone Plus

Section 1

Design Guide 1-11

Step #2 - Sizing the Central Unit

Because the zones are controlled with variable air volume, it is unlikely that all zones

will be at design load at the same time. The zoning allows for the diversity of loads to be

taken into account and will often provide better comfort with a smaller HVAC unit.

In sizing the system, the individual zone loads should be calculated using any dependable

load estimating program. Because of diversity, the central unit should be selected for the

instantaneous peak load, not the sum of the peak loads, as would be done with a constant

volume single zone system. Consider the following when sizing the central unit.

•Size the peak cooling load based on the month and hour of the greatest total

building/system load.

•Heating should be sized for the lowest design temperature with an additional margin

for morning "pickup". This margin is generally recommended to be 20 to 25 percent

of base design.

Step #3 - Duct Design Considerations

The AZ Plus system uses a typical low pressure duct design. To reduce noise problems

duct pressures should not exceed 1 inch W.C.

Primary trunk ducts should not be "undersized." This is especially true for "pressure

dependent" systems. Pressure dependent refers to the typical Plus Zone Controller without

the airflow sensor. With larger trunk ducts, it is easier to assure relatively constant

pressure to each zone. Runs should be as short as possible, and the trunk duct system kept

as symmetrical as possible to facilitate system balancing. Wherever possible, run the trunk

ducts above corridors and locate the zone dampers above corridors to reduce the noise in

the space and facilitate service of the units. Trunk ducts should be sized for no more than

0.1 inch W.C. drop per 100 feet, and a maximum duct velocity of 2000 FPM.

Note: For pressure independent terminal units with velocity sensors and

conventional "VAV" boxes properly selected for "quiet" operation, this 2000

FPM rule can be exceeded by up to 50 percent. The designer, however, should

be very experienced in VAV system design before considering modification

of this general rule.

Typical VAV systems with pressure independent terminals use the static regain method

for sizing ducts. The typical Auto-Zone Plus system is a low-pressure, pressure

dependent system that utilizes conventional unitary air-conditioning units. These systems

should use the equal-friction method of sizing the ducts, and use the maximum loss of 0.1

inch per 100 feet as described above.

firealarmresources.com

Section 1

Auto-Zone Plus

1-12 Design Guide

Step #4 - Room Air Motion/Diffuser

Selection

Air motion is a consideration for occupant comfort. The selection of diffusers for an

Auto-Zone Plus system requires more care than a constant volume system due to varying

flow of air into the zones. Slot diffusers are recommended due to their superior

performance at low airflows. Because the zone air flow is variable volume, lower cost

round or rectangular diffusers that were satisfactory for constant volume may prove

unsatisfactory with an Auto-Zone Plus system. These diffusers may result in "dumping"

of the cold air at low flows in the cooling mode, and insufficient room air motion at low

air flows in the heating mode. Although high air motion in the heating mode can be

undesirable, a slot diffuser with a high induction ratio generally helps to reduce room air

"stratification" when the heating comes from a ceiling diffuser. Linear slot diffusers

should be properly selected for the airflow and "throw" suited to the specific installation

or zone.

Additional factors to consider in diffuser selection is sound level and throw at design

flow. Generally, multiple diffusers will result in lower sound levels in the space, but this

must be balanced with the additional hardware and installation costs. It is commonly

recommended that slot diffusers be located near the perimeter or outside wall with the

airflow directed into the room. Consult your diffuser supplier or catalog for proper

diffuser sizing and location.

Series fan boxes may be used instead of zone dampers where higher induction rates are

desirable. If the heat loss on perimeter walls is high, such as large areas of glass, the use

of Series Fan Boxes may be indicated to maintain higher induction rates to offset

“downdrafts.” If the heat loss is greater than 275 BTUH/LINEAR FOOT, you should use

high quality slot diffusers next to the outer wall with the airflow directed inward to

counteract downdrafts during heating. Serious downdraft problems occur when heat

losses exceed 400 BTUH/LINEAR FOOT and both high induction diffusers and series

fan boxes are recommended.

firealarmresources.com

Auto-Zone Plus

Section 1

Design Guide 1-13

Step #5 - Bypass Damper Sizing

Using a load calculation program, the bypass damper should be sized to give you the

maximum CFM of air to be bypassed, typically 60 to 70 percent of the HVAC units rated

capacity.

To size the damper, select a damper from the table based on calculated bypass CFM and

a maximum velocity between 1750-2250 FPM. When determining the bypass duct size,

be sure to take into account any transition fittings and associated pressure drops. (See

Table 1-1: Damper Sizing Chart)

Whenever possible, use a single bypass damper and round duct for the bypass. If space

limitations or total airflow requires it, multiple bypass dampers can be controlled in

parallel.

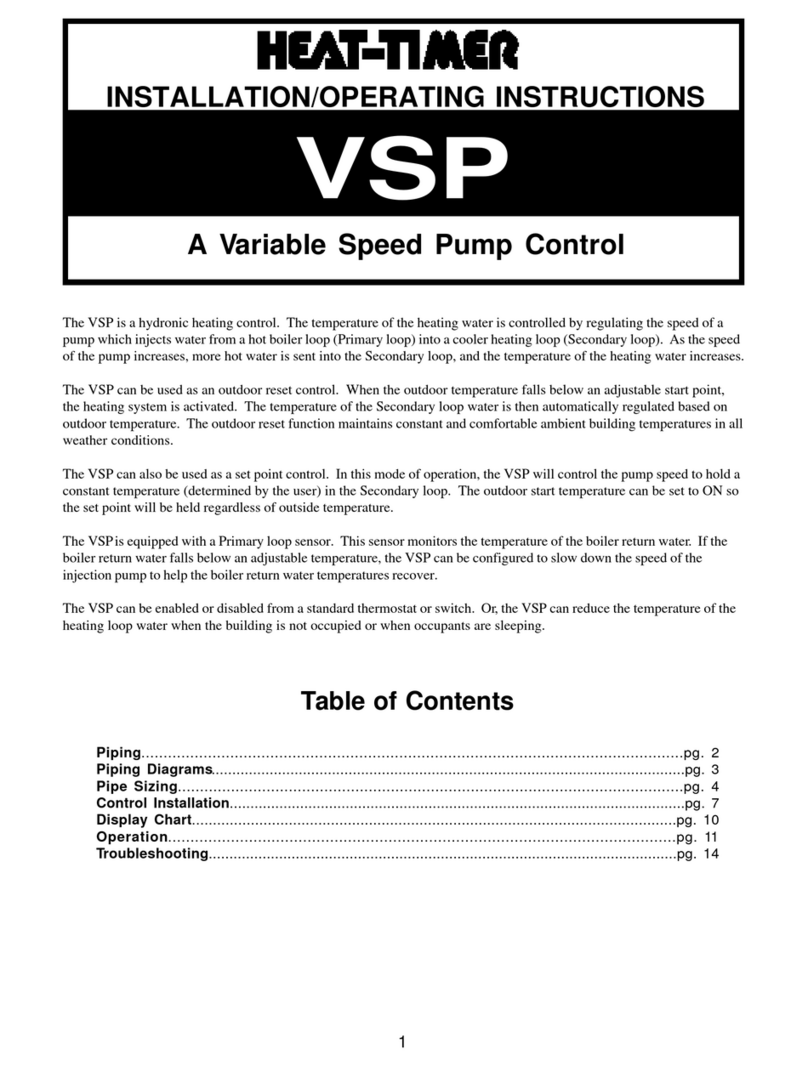

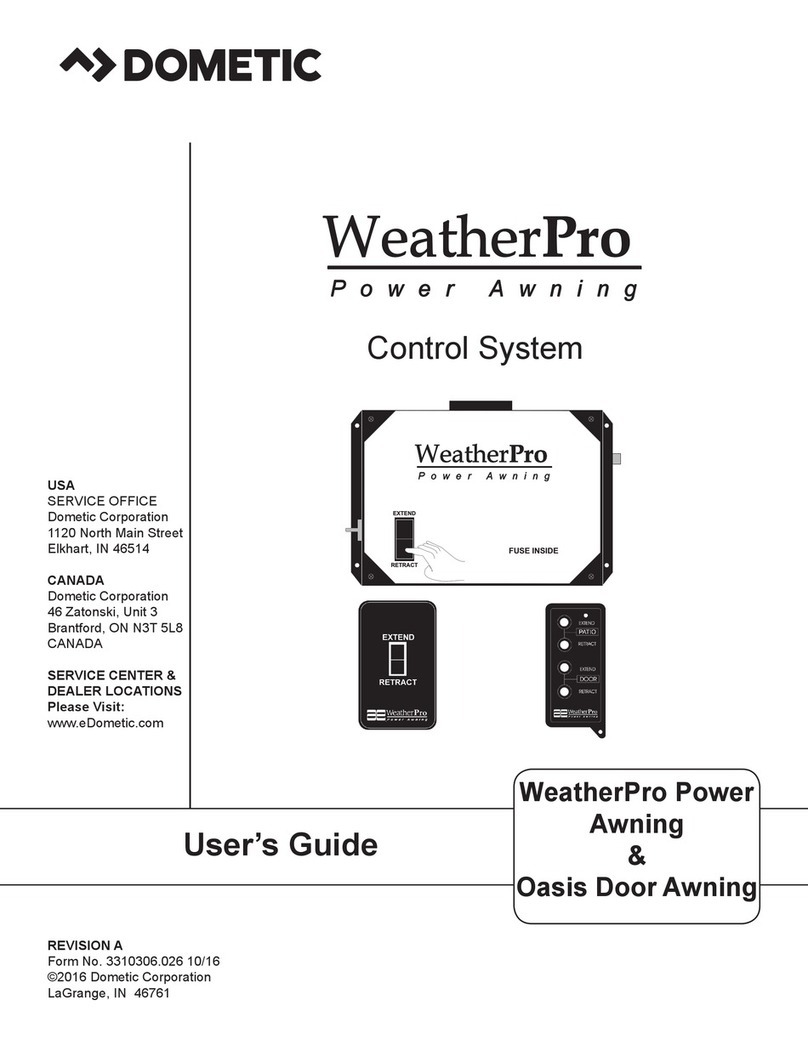

For proper control of the Bypass Damper, the static pressure sensor location is very

important. Refer to Figure 1-3: Locating the Static Pressure Sensor for Bypass

Damper Control for proper mounting locations.

firealarmresources.com

Section 1

Auto-Zone Plus

1-14 Design Guide

Preferred Location

If the trunk ducts are properly

sized for minimum pressure drop,

the location of the static pickup

probe is not particularly critical. It

should ideally be located at right

angles to the airflow in a straight

section of the supply duct

approximately 2/3 the distance of

the total length of the supply duct.

Also the probe should be located

not less than 3 duct diameters

downstream and 2 duct diameters

upstream of any elbow or takeoff.

Fan

RA Sensor

SA Sensor

3D

Min.

2D

Min.

Return Air Duct

Supply Air Duct

SP Pickup

Bypass Damper

SP Sensor

Less Than Ideal, But

Acceptable

Since the "ideal" location is often

difficult to find in an installation, a

location in the main trunk where

the tip is not in a "negative

pressure area" (e.g. just

downstream of the inside curve of

an elbow) or an area where the

tube opening is directly impacted

by the velocity of the supply air.

Fan

RA Sensor

SA Sensor

Return Air Duct

Supply Air Duct

SP Pickup

Bypass Damper

SP Sensor

Least Desirable, But

Acceptable

If the supply duct comes directly

from the unit and immediately

splits in opposite directions, the

pressure pickup should be located

ahead of the split, or as close to it

as possible, even if the bypass

damper(s) are located downstream

of the split.

Fan

RA Sensor

SA Sensor

Return Air Duct

Supply Air Duct

Tubing To Be Equal

Length And Size

Bypass Damper

SP Sensor

SP Pickups

Figure 1-3: Locating the Static Pressure Sensor for Bypass Damper Control

firealarmresources.com

Table of contents

Other WattMaster Control System manuals