Automatic Filters Tekleen MSAF User manual

Table of Contents

SECTION I INTRODUCTION

1.1 Safety Instructions 1

1.2 General Description & Filter Assembly 2

1.3 Theory of Operation 3

1.4 Technical Data 4

SECTION II INSTALLATION AND HOOK-UP

2.1 Mechanical Hook-Up and Orientation 5

2.2 Plumbing Hook-Up 5

2.3 Piston and Electric Ball Valve (EBV) Installation 5

2.4 GB6, DP Gauge, and Electric Ball Valve Connection 5

SECTION III MAINTENANCE

3.1 System Shut Off Procedure 7

3.2 Periodic Checks 7

3.3 Fine Screen Assembly Removal & Installation 8

3.4 Handle Assembly Removal & Installation 10

3.5 Dirt Collector Assembly Removal & Installation 10

3.6 Individual Parts Breakdown 13

WARRANTY 15

1

SECTION I INTRODUCTION

1.1 Safety Instructions

Prior to installation or handling of the filter, carefully read the installation and

operation instructions.

Confirm that filter is properly drained prior to servicing.

Take precautions when lifting, transporting, or installing the filter.

Avoid splashing water directly on to the filter parts during installation.

Confirm that the wet filter weight does not exceed any structural limitations.

Confirm that the line pressure does not exceed the filter's maximum

operational pressure.

Use standard flanged/NPT connections only.

Check all cover bolts and connections are properly secured.

There should be no back-pressure on the flush line. Do not use rubber hosing

or flexible tubing for the waste line.

The filter should be oriented so that the unfiltered media source is directed to

the inlet, the NPT port on the bottom of the filter. The outlet, the NPT port

perpendicular to the body, is the source of filtered media.

Use original parts only to service the filter. Any changes or modification to the

equipment will nullify all warranties.

2

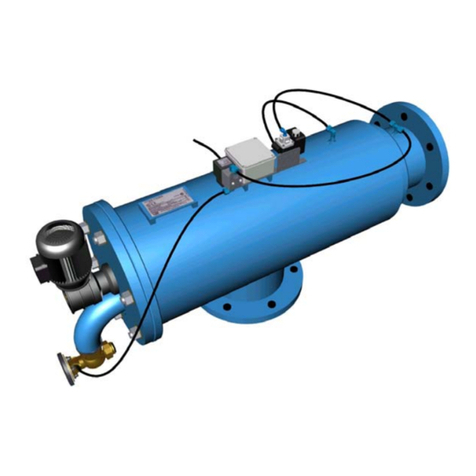

1.2 General Description & Filter Assembly

The MSAF semi automatic self-cleaning filter enables high quality filtration at a

grade of 80-3000 microns. The filter may be used to filter different types of media

sources such as sewage, reservoir water, river water, lake water, and well water.

The MSAF Filter contains the following parts:

1. Inlet

2. Screen

3. Dirt Collector

4. Handle

5. Flushing Valve

6. Flushing Chamber

7. Nozzle

8. Outlet

9. Pressure Indicator

Figure 1: Filter Assembly

3

1.3 Theory of Operation

Pressurized water enters the filter inlet and travels through the neck of the filter to

the body. The water then passes through a fine mesh screen where small

contaminants are filtered out. The clean water then exits through the outlet of the

filter.

As more water flows through the filter the screen becomes contaminated. The

accumulation of impurities causes a pressure imbalance on either sides of the

screen. When the difference in pressure (ΔP) reaches 0.5 bar the pin on the

pressure indicator will pop up. This is the optimal pressure differential to initiate a

flush cycle to prevent reduced filter performance. At this time the operator should

initiate a flush but may initiate one at a later time in accordance to an

independent timetable determined by the operator.

To perform the flush, the operator may follow the steps below:

1) Confirm that the dirt collector is in its' fully lowered position by turning the

handle clockwise until it stops.

2) Open the flush valve completely.

3) Turn the handle of the dirt collector counterclockwise until the dirt collector

comes to a stop in the fully raised position.

4) Close the flush valve completely.

When the flush valve opens, water begins to flow out reducing the pressure in

the flush chamber and dirt collector. The drop in pressure allows the nozzle to

generate a suction. The turning of the dirt collector and the spiral axis motion

allows the entire inside of the screen to be suctioned. It should be noted that

even during the flush cycle, the filtration process continues uninterrupted.

4

1.4 Technical Data

Standard Features

Minimum operating pressure:

Maximum operating pressure:

Clean filter pressure loss:

Maximum working temperature:

Flushing water consumption

(at minimum working pressure):

Filter housing material:

1 bar (14.5 psi)

10 bar (145 psi)

0.1 bar (1.45 psi)

65°C (149°F)

10 liter (2.64 US gallon)

Epoxy Coated Carbon Steel

*For high quality water at a filtration grade of 100 microns.

**For minimal operating pressure of 1 bar (14.5psi).

Figure 2: Filter Dimensions

Connection

Size Ø D1

Connection

Size Ø D2

*Maximum

flow rate

(m3/h)

** Flushing

flow rate

(m3/h)

ØD

(inch)

X

(mm)

Y

(mm)

H

(mm)

Weight

(Kg)

2" NPT

2" NPT

25

6

6

125

175

570

10

5

SECTION II INSTALLATION AND OPERATION

2.1 Mechanical Hook-Up and Orientation

The positioning of the filter should be determined by the disposal of waste water

and to allow easy access and removal of the filter element. The filter can rest on

the inlet or outlet and can be mounted on a stand if desired. The filter can be

mounted in any position (vertical, upside down, etc.) to allow easy operation.

2.2 Plumbing Hook-Up

The waste discharge pipe should be larger in diameter than the size of the flush

valve. The waste pipe should be kept as short as possible with no more than one

elbow. This will minimize back pressure on the flush line.

Flush lines should not be elevated. This will affect the pressure difference

required for the cleaning cycle. If it is necessary to run flush lines uphill, please

consult with the manufacturer.

Flush line pipe must be ridged. It should not be made out of flexible tube or

rubber hosing. Any restrictions in the flush line will reduce the cleaning ability of

the filter.

2.3 Filter Installation

1. Remove filter from packaging and inspect the contents of the packaging.

2. Connect the inlet and outlet line to the filter.

3. Connect a flush line to the flush valve outlet. The water must flow freely out

without any back pressure.

4. Check that all connections are properly secured

5. Check that all bolts on the filter cover are properly tightened and secured

2.4 Initial Operation

During start-up, the isolation valve at the filter inlet should be only partially open

to prevent a surge of pressure across the filter when the pump is started. Once

the pump is on-line, slowly open the isolation valve. This will prevent any

possible damage to the filter due to a pressure surge.

☐Do not proceed until the tasks above have been completed

6

During the initial filling of the main pipeline, there may not be enough back-

pressure downstream from the filter to allow the cleaning cycle to function

properly. Therefore, it is necessary to install a valve at the outlet to be partially

closed (i.e., gate valve, ball valve or butterfly valve). Once the total system is fully

charged, the downstream valve can be adjusted as desired.

☐Do not proceed until the tasks above have been completed

Initiate the first cleaning cycle as described in "Section 1.3". During the first

cleaning cycle, air in the system will be expelled, so it may require more than one

cycle to achieve proper cleaning.

☐Do not proceed until the tasks above have been completed

Confirm that the differential pressure indicator is not showing a pressure

difference at this point. When the filter is clean, the pressure difference should

not exceed 0.1 bar.

☐Do not proceed until the tasks above have been completed

7

SECTION III MAINTENANCE

3.1 System Shut Off Procedure

If your system is not equipped with a bypass valve or any similar other

mechanism the entire system must be shut off. Precede the steps below with

shutting off your pump and draining the system.

1. Open the bypass valve.

2. Close the outlet valve completely.

3. Close the inlet valve completely. The filter is now isolated and the system flow

is bypassed.

4. Relieve any residual pressure in the filter housing by opening the flush valve.

5. Drain the remaining water from the filter body by loosening the cover nuts and

slightly opening the cover.

3.2 Periodic Checks

It is strongly recommended that annual checks be performed at the same time

every year.

1. Check filter and all connections for leaks.

2. Check the filter housing for paint damage

and corrosion. If required, clean the area

by sanding and reapply a thin layer of

paint and epoxy.

3. The system must be properly shut off as

described in "Section 3.1" before

performing the following checks. Do not

proceed until this has been complete.

4. Check the condition of all seals. Replace

any damaged or deteriorating seals.

5. Check the condition of the fine screen

assembly. If necessary, replace

according to "Fine Screen Assembly

Removal & Installation".

6. Check the dirt collector suction nozzles

height (See Figure 3). If necessary,

replace according to "Dirt Collector

Removal & Installation"

Figure 3: Nozzle Height (44mm)

8

3.3 Fine Screen Assembly Removal & Installation

Perform the proper shut off procedure as described in "Section 3.1" before

working on the fine screen assembly. Refer to Figure 4 below for help.

1. Remove the nuts and washers to the cover of the filter housing.

2. Remove the cover with the handle and the dirt collector from the filter

housing.

3. Remove the body seal from the filter housing groove.

4. Remove the screen from the filter housing by pulling it away from the base.

5. Remove both the upper and lower O-Rings from the used fine screen

assembly.

6. Position both the upper and lower O-Rings in the new fine screen assembly.

7. Lubricate the upper and lower seals with silicon grease.

8. Slide the new fine screen assembly into the filter housing.

9. Position the body seal in the groove located on the filter housing.

10.Return the cover to its place on the filter housing. Confirm that the dirt

collector pin is properly seated inside the dirt collector.

11.Tighten the nuts and washers connecting the cover to the filter housing.

12.Open the outlet valve completely.

13.Gradually open the inlet valve while closing the bypass valve.

14.Check the filter assembly and its connections for leaks.

15.Spin the handle first counter-clockwise until it stops, and then clockwise to

check the motion.

16.Perform a flushing cycle as described in "Section 1.3".

17.Confirm that the differential pressure indicator is not showing a pressure

difference at this point. When the filter is clean, the pressure difference should

not exceed 0.1 bar.

9

Figure 4: Exploded Fine Screen Assembly

10

3.4 Handle Assembly Removal & Installation

Perform the proper shut off procedure as described in "Section 3.1" before

working on the handle assembly. Refer to Figure 5 below for help.

1. Release the bolt connecting the handle plug to the dirt collector stem. The

metal handle and handle plug is a single piece and must be removed

together.

2. Position replacement handle onto the dirt collector stem. Reinsert bolt into the

hole and tighten.

3. Open the outlet valve completely.

4. Gradually open the inlet valve while closing the bypass valve.

5. Check the filter assembly and its connections for leaks.

6. Spin the handle first counter-clockwise until it stops, and then clockwise to

check the motion.

7. Perform a flushing cycle as described in "Section 1.3".

8. Confirm that the differential pressure indicator is not showing a pressure

difference at this point. When the filter is clean, the pressure difference should

not exceed 0.1 bar.

3.5 Dirt Collector Assembly Removal & Installation

Perform the proper shut off procedure as described in "Section 3.1" before

working on the handle assembly. Refer to Figure 5 below for help.

1. Release the bolt connecting the handle plug to the dirt collector stem. The

metal handle and handle plug is a single piece and must be removed

together.

2. Remove the nuts and washers to the cover of the filter housing.

3. Remove the cover with the handle and the dirt collector from the filter

housing.

4. Remove the body seal from the filter housing groove.

5. Unscrew the used dirt collector from the flushing chamber and pull it out.

6. Insert the new dirt collector into the flushing chamber and screw it back into

place.

7. Return the cover to its place on the filter housing. Confirm that the dirt

collector pin is properly seated inside the dirt collector.

8. Position handle onto the dirt collector stem. Reinsert bolt into the hole and

tighten.

9. Tighten the nuts and washers connecting the cover to the filter housing.

11

10.Open the outlet valve completely.

11.Gradually open the inlet valve while closing the bypass valve.

12.Check the filter assembly and its connections for leaks.

13.Spin the handle first counter-clockwise until it stops, and then clockwise to

check the motion.

14.Perform a flushing cycle as described in "Section 1.3".

15.Confirm that the differential pressure indicator is not showing a pressure

difference at this point. When the filter is clean, the pressure difference should

not exceed 0.1 bar.

12

Figure 5: Exploded Handle & Dirt Collector Assembly

13

3.6 Individual Parts Breakdown

Please note that some of the following parts may not be sold individually and can

only be purchased as a set or assembly.

Figure 6: Individual Parts Breakdown

14

No.

Description

1

Nut

2

Handle

3

Screw

4

O ring number 211

5

"T" connection (flushing chamber)

6

O ring number 226

7

Body Cover

8

Body Screw

9

O Ring number 230

10

Dirt collector Bushing

11

Dirt Collector

12

Suction Nozzle

13

Dirt Collector Plug

14

Body Hydraulic Sealing

15

Body Housing

16

Body Outlet

17

Pressure Indicator

18

Body Inlet

19

1/4" Socket

20

Body Nut

21

Washer

22

O Ring number 250

23

Screen Handle

24

Dirt Collector Axis

25

Fine Screen

26

Bushing for Flushing Valve

27

Manual Flushing Ball Valve

28

Upper Bushing

29

O Ring number 138

15

Table of contents

Other Automatic Filters Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Ecosoft

Ecosoft AquaPoint user manual

Pontec

Pontec PonDuett 5000 operating instructions

Bühler technologies

Bühler technologies BKF Installation and operation instructions

Hellenbrand

Hellenbrand H-150 Series owner's manual

Aqua Flo

Aqua Flo GEN4-8R1 owner's manual

GE

GE Smart Water PNRV18ZWH01 installation instructions

Pentair

Pentair FLECK 2815 Service manual

Pentair

Pentair CLEARPRO TECHNOLOGY TR100 Installation and user guide

Prozone

Prozone PZ2 Series Installation guide & operation manual

Viqua

Viqua VH200 owner's manual

Premier

Premier 500320 UV-3 Installation, operation and maintenance manual

Dustcontrol

Dustcontrol S 11000 Original instructions