-15-

440 V -------------------------------- TR1 tags No. 1 & 4

480 V ------------------------------- TR1 tags No. 1 & 5

2. Connect the motor supply cable (Using 4x0.75-1mm) between control board and Filter junction

box terminals. (Through flexible conduit g land)

Control board Filter Junction box

TB5 - Motor GND. wire. (Yellow/green wire) ---------------ÆTB5

TB6 - Motor U wire. -------------------------------------------------ÆTB6

TB7 - Motor V wire. -------------------------------------------------ÆTB7

TB8 - Motor W wire. ------------------------------------------------ÆTB8

IMPORTANT! Verify good connection to MOTOR GROUND.

3. Connect the flushing solenoid & differential pressure switch cable (Using 3/4x0.75mm)

Between control board and filter junction box terminals. (Through flexible conduit gland)

a. Using 4x0.75 cable.

Control board Filter Junction box

TB9 - Solenoid live. ----------------------------------------------ÆTB9

TB10 - Solenoid natural.-----------------------------------------ÆTB10

TB11 - differential pressure switch live. ---------------------ÆTB11

TB12 - differential pressure switch natural. ----------------ÆTB12

b. Using standard 3x0.75mm cable.

Control board Filter Junction box

TB9 - Solenoid live. -----------------------------------------------ÆTB9

TB10 - Solenoid natural.------------------------------------------ÆTB10 & TB12 jumpered.

TB11 - differential pressure switch live. ----------------------ÆTB11

TB12 – no connection needed.

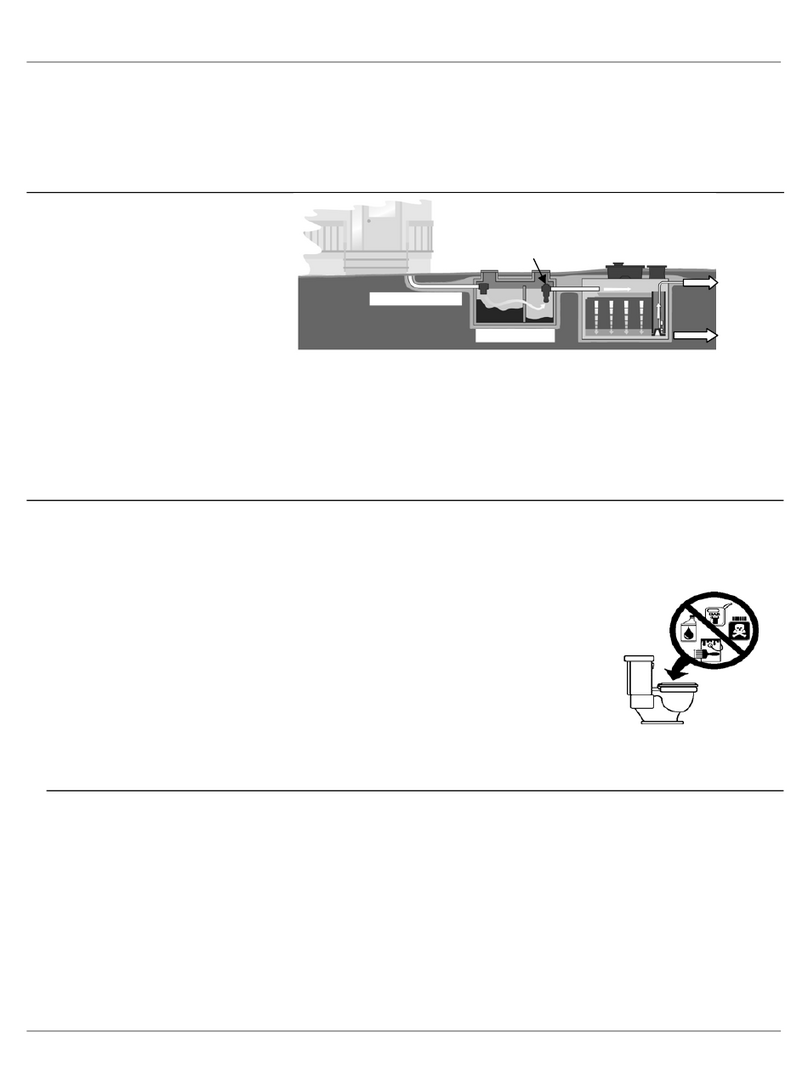

E. OPERATION.

Motor synchronization must be carried out as follows :

a. Switch the [MAIN] switch to ON = 1 position and Verify that L1 [ON] indicator lights.

b. Press pushbutton [MANUAL FLUSH] momentarily and Verify that L2 [FLUSH] indicator lights

and the motor activated simultaneously.

Check the motor axis rotation (Which drives the filter dirt collector), The rotation must be at

the same arrow label direction.

If not , switch the [MAIN] switch to OFF = 0 position , and exchange between two of the

Motor phase and check again.(e.g. Between motor connection to TB 6-7 or TB 7-8 in the control

board or in the filter junction box.)

F. TIMERS FUNCTION.

TP - Differential pressure sense timer. (Factory set to 5 sec.)

Note that in case of differential pressure signal continuation the system will flush every TP

Time set.

TF – Flush timer. (Factory set to 10 sec.)

NOTE that the practical flushing time is the time required for the hydraulic piston to

Complete its movement due to a given line pressure. In order to minimize the flushing

Time/waste of flushed water set TF respectively.

TD – Interval flush timer. (Factory set to 10 hours & enabled - TB 13/14 shorted)

NOTE that the TD timer can be disabled by removing the short wire from TB 13/14-SET

inlets)