Automation Controls Group UniDrive SCC-3 Guide

Installation and

Troubleshooting Guide

UniDrive

®

Smart Conveyor Control

Generation III (SCC-3)

Product 110515

Copyright ©2013-2018 Automation Controls Group, Inc. A division of MEC Companies, Inc. All Rights Reserved.

This document is the property of Automation Controls Group, Inc., and may not be reproduced in hole or in part ithout prior ritten approval.

Other trademarks and service marks used or referenced in this document are the property of their respective o ners.

C O N T E N T S

1

Product Diagram

4

2

General Notes

5

2.1

Motor Cable & Connection Header ......................................................................................................................... 5

2.2

+24V DC Power Input Connection Header ........................................................................................................... 5

2.3

PNP ensor Connection Header .............................................................................................................................. 5

2.4

mart/User Input-Output Connection Header ..................................................................................................... 5

2.5

Feedback LED Indicators............................................................................................................................................ 6

2.6

Configuration witches ............................................................................................................................................... 6

2.7

Upstream Cable Connection ..................................................................................................................................... 6

2.8

Downstream Cable Connection ............................................................................................................................... 6

2.9

Mounting Plate/Heat ink ......................................................................................................................................... 6

2.10

Cover ................................................................................................................................................................................. 6

3

Installation Guide

6

3.1

Mount the Control ......................................................................................................................................................... 7

3.2

elect a Motor ................................................................................................................................................................ 7

3.3

elect a peed ............................................................................................................................................................... 7

3.4

Configure the Location ................................................................................................................................................ 7

3.5

Configure the Operating Mode ................................................................................................................................. 7

3.6

Configure the Rotation ................................................................................................................................................ 7

3.7

Configure Communications ....................................................................................................................................... 7

3.8

Connect User Input/Output ....................................................................................................................................... 8

3.8.1

Entry Zone ................................................................................................................................................................... 8

3.8.2

Intermediate Zone .................................................................................................................................................... 8

3.8.3

Exit Zone ...................................................................................................................................................................... 8

3.8.4 Braking & Zero Motion Hold (ZMH)……………………………………………………………………………………….. 9

3.8.5 lug & Reverse lug Input Operation………………………………………………………..….……………………….. 9

3.8.6 Other Modes of Operation……………………………………………………………………………………………………...9

4

Special Functions

9

4.1

Zone Hold Input…………………………………………………………………………………………………….…………………9

4.2

Configuring an CC-3 as a BMC……………………………………………………………………………………….……….9

4.3

earch and Rescue ...................................................................................................................................................... 9

4.3.1

During Power Up ....................................................................................................................................................... 9

4.3.2

After Discharge of a Parcel from the Downstream Edge of a Zone……………………………………...…..9

4.3.3

After Removal of a lug ignal…………………………………………………………………………………………….10

4.3.4

After Removal of a Rev lug ignal………………………………………………………………………………………10

5

Diagnostics Troubleshooting

10

5.1

Feedback LEDs ........................................................................................................................................................... 10

5.1.1

Fuse LED (Red)……………………………………………………………………………………………………………………10

5.1.2

Fault LED (Red)…………………………………………………………………………………………………………………..10

5.1.3

Motor LED (Amber) ................................................................................................................................................ 10

5.1.4

Power LED (Green) ................................................................................................................................................ 10

5.2

Firmware Version Display ....................................................................................................................................... 10

5.3

6-Wire Modular Cable Orientation ……………………………………………………………………………………….…11

5.4

Additional Assistance……………,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,11

SCC-3 Product 110515 Revision 1.3 April 19, 2018 | Pa e 3

L I S T O F F I G U R E S

Figure 1: SCC-3 Controller Components ................................................................................................ 4

Figure 2: Motor Connector Orientation ................................................................................................... 5

Figure 3: Firmware Version Displa Example ....................................................................................... 10

L I S T O F T A B L E S

Table 1: DC Power Inputs Pinout............................................................................................................ 5

Table 2: Sensor Connections Pinout ...................................................................................................... 5

Table 3: Smart PNP Inputs and Outputs Pinout ..................................................................................... 5

Table 4: Configuration Switch Settings ................................................................................................... 6

Table 5: Motor Selection Switch Settings ............................................................................................... 7

Table 6: Operating Speeds ..................................................................................................................... 7

Table 7: Switch 3 Settings for Control Location ...................................................................................... 7

Table 8: Switch 2 Settings for Operating Mode ...................................................................................... 7

SCC-3 Product 110515 Revision 1.3 April 19, 2018 | Pa e 4

1

Product Diagram

1) Motor Connection Header

2) +24V DC Power Input Header (plug included)

3) PNP Sen or Connection Header (plug included)

4) Smart/U er Input-Output Connection Header (plug included)

5) Feedback LED Indicator

6) Configuration Switche

7) Up tream Peer-to-Peer NPN RJ-25 Connection

8) Down tream Peer-to-Peer NPN RJ-25 Connection

9) Mounting Plate/Heat Sink

10) Cover

NOTE: This guide refers to the components by their item number as listed above.

Figure 1: SCC-3 Controller Components

SCC-3 Product 110515 Revision 1.3 April 19, 2018 | Pa e 5

2

General Notes

2.1

Motor Cable & Connection Header

C UTION: Use of extension cables may cause permanent

damage and will void the product warranty.

UniDrive® motors and controls are designed to operate together as

a complete and compatible drive system. Proper care must be

taken to prevent damage to the Automation Controls Group (ACG)

control motor and connection cable.

UniDrive® motors come with a permanent built-in power & control

cable having either a 20 inch or a 72 inch cable length for connection

solely to compatible ACG controls. See the specific UniDrive® motor

or PowerCube™ specification sheet for details. Do not attempt to

connect the motor cable to any control other than one

manufactured by Automation Controls Group (ACG).

Do not put tension on the motor cable connection. Tension cable

strain or stress on the motor cable could deform the pressure

contacts inside the motor connector. This could result in

intermittent motor connections and in extreme cases may bend the

pins on the control board.

The motor connector is designed to be installed on the control and

then remain connected to the control for the life of the motor. Do

not remove the motor connector except in the rare in tance of

motor or control replacement. The motor connector mu t not be

u ed a a power on/off witch.

If the motor connector must be removed from the control remove

the connector slowly by carefully lifting while also gently rocking the

connector from side-to-side (“inch-worming”) in order to lift the

connector off the control pins a little at a time. Lift the motor

connector straight up by grasping the sides of the motor connector

and avoid using the cable strain relief as a handle to lift the

connector.

Power to the control and motor must be removed by turning off or

removing input power at the source (Lock-out & Tag-out preferred).

Alternately by disconnecting the +24V DC Power Input Connection

Header (see section 2.2 below) on the control. The motor

connector mu t not be u ed a a power on/off witch.

Do not disassemble the motor cable. If the motor cable becomes

damaged obtain a replacement motor.

NOTE: The motor connection cable must be oriented on the

control header pins as shown in the figure below.

2.2

+24V DC Power Input Connection Header

C UTION: Power must be applied with proper polarity to

avoid potentially damaging the controller. Follow the

pinout shown in Table 1 below.

A 2-pin Phoenix PT1.2/2-PVH-3.5 plug is supplied. The SCC-3 operates

off a +22 to +28 Volt DC power supply. The control reads the

configuration switches only when the unit is powering up. Make the

power connection only after all other connections have been made.

Pin: Signal:

1 +22 to +28 Volts DC

2 DC Ground

Table 1: DC Power Inputs Pinout

NOTE: When adjacent zones are operating from separate

power supplies you should connect their 0VDC grounds.

However, do not connect their positive voltage pins together.

2.3

PNP Sen or Connection Header

C UTION: If the sensor is mounted on non-conductive

equipment, such as a plastic slide, ground the body of

the sensor to provide a non-destructive discharge path in

the event of a static electric shock.

A 3-pin Phoenix PT1.5/3-PVH-3.5 plug is supplied.

Pin: Signal:

1 DC Ground

2 Input From Sensor

3 +VDC*

Table 2: Sensor Connections Pinout

*NOTE: The +VDC signal for pin number 3 is fused with a 0.1

mp self-resetting fuse. Use of this output for any purpose

that requires more than 0.1 mps will cause the fuse to

open and temporarily disable this output.

2.4

Smart U er Input-Output Connection Header

A 7-pin Phoenix PT1.5/7-PVH-3.5 plug is supplied. Function depends

upon the controller’s current configuration based on the

configuration switch settings. If the smart I/O is not being used

leave the connector in place to avoid accidentally shorting the pins.

Pin: Description:

1 Smart Input 1*

2 Slug Input*

3 Rev Slug Input*

4 Smart Output 2

Analog Input +

6 Analog Input –

7 Zone Hold Input*

Table 3: Smart PNP Inputs and utputs Pinout

*NOTE: Smart I/O is active above +18 Volts DC (PNP)

Figure 2: Motor Connector rientation

SCC-3 Product 110515 Revision 1.3 April 19, 2018 | Pa e 6

2.5

Feedback LED Indicator

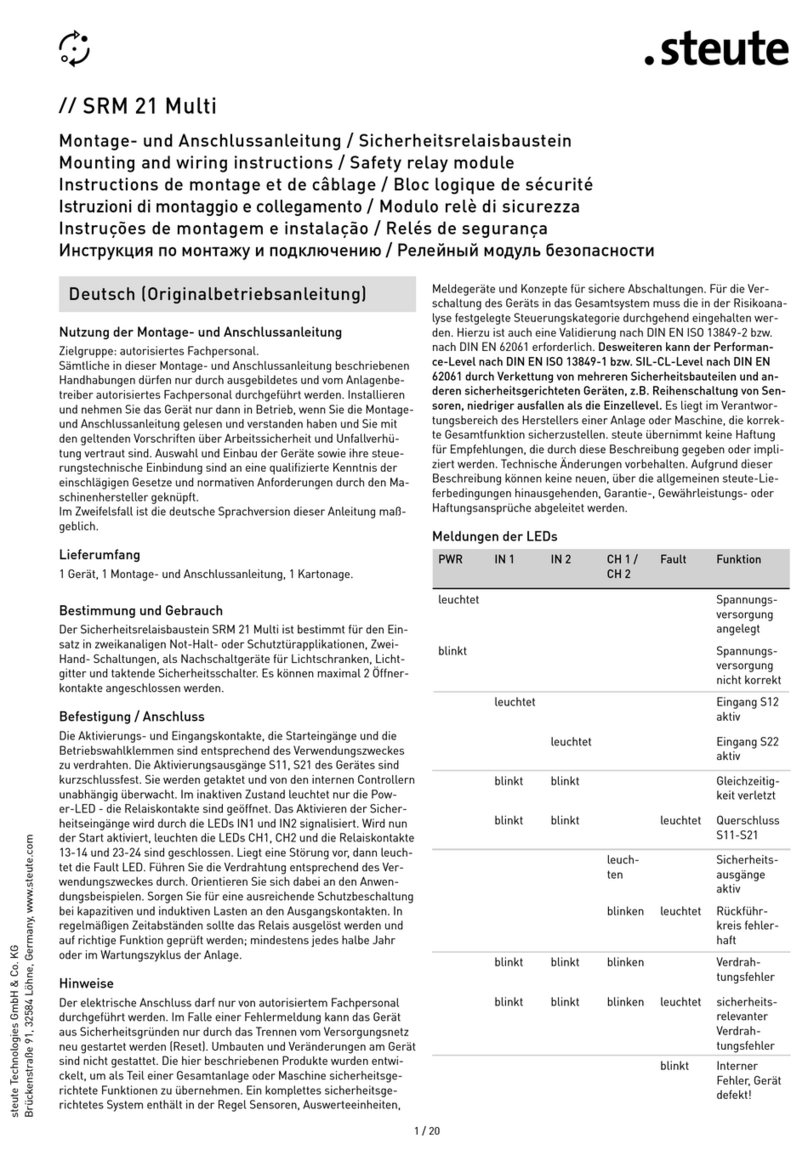

The control board contains four (4) LED feedback indicators:

One (1) Red Fuse LED

One (1) Red Fault LED

One (1) Amber Motor LED

One (1) Green Power LED

To learn more see 5.1 Feedback LEDs and 5.2 Firmware

Version Display.

2.6

Configuration Switche

The control reads the configuration switches only when the

unit is powering up. To change a setting disconnect power

set the switch and then reconnect power. The OFF position

is to the Left and the ON position is to the Right as seen in

Figure 1: SCC-3 Controller Components. Switch descriptions

are given in the following table:

Switch:

Description: OFF Setting ON Setting

1 Rotation Direction Counter-Clockwise* Clockwise*

2 Mode ZPA/ZIP ZPA ZIP

3 Zone Type Exit/Xport Entry/Xport

4 Target Speed

(with SW , SW6)

See Table 6: Operating Speeds. Target Speed

(with SW4, SW6)

6 Target Speed

(with SW4, SW )

7 Motor Selection 100W24 12 W24

8 Braking & ZMH Enabled Disabled

Table 4: Configuration Switch Settings

*NOTE: The direction of rotation is defined when viewed

from the back side of the motor with the shaft extending

away from the viewer.

NOTE: The switches are read during power-up only.

Set the switches, and then connect power to the board.

2.7

Up tream Cable Connection

This connector is intended for use with a 6-wire modular phone

cable to connect to an adjacent upstream SCC board. See Section

5.3 for information on the cable. The cable is not provided.

2.8

Down tream Cable Connection

This connector is intended for use with a 6-wire modular phone

cable to connect to an adjacent downstream SCC board. See

Section 5.3 for information on the cable. The cable is not provided.

2.9

Mounting Plate/Heat Sink

This component is for mounting the control assembly to the

conveyor frame using two ¼ inch or 0.25 in (6.35 mm) bolts to keep

the controller cooler.

C UTION: If mounting the control on a curved section of

conveyor, use washers between the mounting plate and

the conveyor frame. This is to assure that the mounting

plate is not distorted, causing damage to the enclosed

printed circuit board assembly.

2.10

Cover

C UTION: Removal of the cover will void the warranty.

The cover does not make the controller waterproof or

dustproof.

The cover can help reduce the severity of damage to the

controller from foreign objects.

3

Installation Guide

This section describes how to install and use the SCC-3 and

UniDrive® Motor in the most common configurations. For

additional information refer to the application notes.

1. Mount the Control

2. Select a Motor

3. Select a Speed

4. Configure the Location

5. Configure the Operating Mode

6. Configure the Rotation

7. Configure Communication

8. Connect U er Input/Output

SCC-3 Product 110515 Revision 1.3 April 19, 2018 | Pa e 7

3.1

Mount the Control

Mount the control in a location where the motor cable

reaches the connection header without putting strain on the

cable connector or the header.

3.2

Select a Motor

Select the motor you will be using. Properly match the

control settings to the motor in use to deliver the best and

most predictable performance.

SW8: SW7: Motor: omments:

OFF OFF 100W24 Previously STD

OFF ON 12 W24 Previously HO.

Table 5: Motor Selection Switch Settings

3.3

Select a Speed

Three switches determine the operating speed making it

simple to match speeds in multiple zones. The actual speed

selected also depends on the motor that you selected in the

previous step so set those switches first.

There is also an option to use a 0-10 V differential input for

remote dynamic speed adjustment while the system is

running.

Switches

:

Speed

Selection (RPM)

:

SW6 SW5 SW4 100W24 125W24

OFF OFF OFF 280 3 0

OFF OFF ON 248 310

OFF ON OFF 216 270

OFF ON ON 184 230

ON OFF OFF 1 2 190

ON OFF ON 120 1 0

ON ON OFF 88 110

ON ON ON 6 70

Table 6: perating Speeds

3.4

Configure the Location

Identify the location of the control and then set Switch 3.

If this control is placed at the entry end of the conveyor

section where objects are loaded set Switch 3 to the ON

position.

If this control is placed between two other SCC-3

controls set Switch 3 to either ON or OFF.

If this control is placed at the exit end of the conveyor

section where objects are discharged set Switch 3 to the

OFF position.

Entry: In Between: Exit:

ON ON or OFF OFF

Table 7: Switch 3 Settings for Control Location

3.5

Configure the Operating Mode

Identify the operating mode that this section of conveyor will

use for transporting objects and then set Switch 2.

If the conveyor will be operating in the most

conservative conventional Zero-Pressure Accumulation

(ZPA) mode set Switch 2 to the OFF position.

If the conveyor will be operating in the higher

throughput enhanced accumulation ZIP mode set

Switch 2 to the ON position.

If the conveyor will be operating in the Slug or Slug

Reverse mode or as a stand-alone unit Switch 2 may be

set to the ON or OFF position because the Slug and Slug

Reverse inputs override all of the accumulation logic.

ZPA: Slug, Slug Reverse,

or Stand-alone: ZIP:

OFF OFF or ON ON

Table 8: Switch 2 Settings for perating Mode

3.6

Configure the Rotation

Identify the proper direction of rotation for the motor shaft

in order to move objects from the upstream (entry) end of

the conveyor towards the downstream (exit) end of the

conveyor. The direction of rotation is defined when viewed

from the back side of the motor with the shaft extending

away from the viewer.

For clockwise rotation set Switch 1 to the ON position.

For counter-clockwise rotation set Switch 1 to OFF.

3.7

Configure Communication

Make the peer-to-peer communication connections. These

controls pass request and permission signals between adjacent

zones over 6-wire modular phone cables. See Section 5.3 for

information on the cable orientation.

At the exit end of the conveyor do not connect the

phone cable to the Downstream Peer-to-Peer NPN RJ-25

Connection (item 8).

Connect one end of a 6-wire phone cable to the

Upstream Peer-to-Peer NPN RJ-25 Connection (item 7)

and then connect the other end of the phone cable to

the downstream phone jack on the adjacent upstream

control.

At each adjacent intermediate control connect another

6-wire phone cable to the Upstream Peer-to-Peer NPN

RJ-25 Connection (item 7) and then connect the other

end of that cable to the downstream phone jack on the

adjacent upstream control.

At the entry end of the conveyor do not connect a

phone cable to the Upstream Peer-to-Peer NPN RJ-25

Connection (item 7).

SCC-3 Product 110515 Revision 1.3 April 19, 2018 | Pa e 8

3.8

Connect U er Input/Output

3.8.1

Entry Zone

1.

Use Smart 1 (a PNP input called a request) to notify the

control that there is a parcel ready for input to the zone. If

the zone is not already occupied when this signal is active it

will cause the zone to run. The signal may be provided by

any number of alternative sources such as a PLC a simple

switch a photo sensor etc. as long as the input voltage is

positive and between 18 volts and 29 volts DC.

2.

Use Smart 2 (a PNP output called permission) to notify an

external device that the zone is empty and ready to receive a

parcel.

3.

Use Slug (a PNP input) to override all logic internal to the

control and force this zone to run regardless of whether it is

occupied or empty.

NOTE: When this signal is active, parcels are pushed into

the next downstream zone even if it is already occupied.

4.

Use Rev Slug (a PNP input) in one of two ways:

Alone: Assert it by itself to cause the zone to coast. The

motor will not be energized and will not provide any

active braking power.

In Combination: Assert it in combination with the Slug

input to override all logic internal to the control and force

this zone to run in the reverse direction regardless of

whether it is occupied or empty.

NOTE: When this signal is active, parcels are pushed out

of the upstream end of the zone regardless of the

availability of any upstream device to accept the parcel.

In this scenario, if there is nothing there, any parcels

could potentially fall to the floor.

5.

Use Analog In+ and Analog In- in combination to provide a

0-10 V differential signal that overrides the settings on the

speed control switch. If the voltage differential is less than

0.5 VDC the control ignores the input and the speed control

switch settings will prevail. If the signal is 9.5 VDC or higher

the control operates the motor at its maximum speed

setting of 280 or 350 RPM depending on the motor selected.

3.8.2

Intermediate Zone

An intermediate zone is between two adjacent SCC-3

controlled zones.

NOTE: Do not connect anything to Smart Input 1 or

Smart Output 2.

1.

Use Slug (a PNP input) to override all logic internal to the

control and force this zone and all adjacent upstream zones

to run regardless of whether they are occupied or empty.

Note that when this signal is active parcels will be pushed

into the next downstream zone even if it is already occupied.

2.

Use Rev Slug (a PNP input) in one of two ways:

Alone: Assert it by itself to cause this zone and all adjacent

upstream zones to coast. The motor will not be energized

and will not provide any active braking power.

In Combination: Assert it in combination with the Slug

input to override all logic internal to the control and force

this zone and all adjacent upstream zones to run in the

reverse direction regardless of whether they are occupied

or empty.

NOTE: When this signal is active, parcels are pushed out

of the upstream end of the conveyor regardless of the

availability of any upstream device to accept the parcels.

In this scenario, if there is nothing there, any parcels

could potentially fall to the floor.

3.

Use Analog In+ and Analog In- in combination to provide a

0-10 V differential signal that overrides the settings on the

speed control switch. If the voltage differential is less than

0.5 VDC the control ignores the input and the speed control

switch settings will prevail. If the signal is 9.5 VDC or higher

the control operates the motor at its maximum speed

setting of 280 or 350 RPM depending on the motor selected.

3.8.3

Exit Zone

1. Use Smart 1 (a PNP input called permission) to notify the

control that it has permission to discharge a parcel. The

signal may be provided by any number of alternative sources

such as a PLC a simple switch a photo sensor etc. as long as

the input voltage is positive and between 18 volts and 29

volts DC. Note that when permission is removed the zone

will attempt to stop any discharge that may be in process.

2. Use Smart 2 (a PNP output called request) to notify an

external device that the zone is occupied and ready to

discharge a parcel.

3. Use Slug (a PNP input) to override all logic internal to the

control and force this zone and all upstream zones to run

regardless of whether they are occupied or empty.

NOTE: When this signal is active, parcels will be pushed

off the end of the conveyor if there is nothing in place to

receive them.

4.

Use Rev Slug (a PNP input) in one of two ways:

Alone: Assert it by itself to cause the zone and all

upstream zones to coast. The motors will not be

energized and will not provide any active braking power.

In Combination: Assert it in combination with the slug

input to override all logic internal to the control and force

this zone and all upstream zones to run in the reverse

direction regardless of whether they are occupied or

empty.

NOTE: When this signal is active, parcels are pushed out

of the upstream end of the zone regardless of the

availability of any upstream device to accept the parcels.

In this scenario, if there is nothing there, any parcels

could potentially fall to the floor.

5.

Use Analog In+ and Analog In- in combination to provide a

0-10 V differential signal that overrides the settings on the

speed control switch. If the voltage differential is less than

0.5 VDC the control will ignore the input and the speed

control switch settings will prevail. If the signal is 9.5 VDC or

higher the control will operate the motor at its maximum

speed setting of 280 or 350 RPM depending on the motor

selected.

SCC-3 Product 110515 Revision 1.3 April 19, 2018 | Pa e 9

3.8.4

Braking & Zero Motion Hold (ZMH)

When DIP Switch 8 is placed in the OFF position motor

dynamic braking will be used to bring the motor to a stop as

quickly as possible. When DIP switch 8 is in the OFF position

Zero Motion Hold (ZMH) will also be active so that if the

motor shaft continues rotating due to inertia increasing

current will be applied to the three motor phase windings in

an attempt to hold the motor shaft at the requested stop

position.

When DIP Switch 8 is placed in the ON position the motor

will be allowed to coast and no motor braking will be

applied.

3.8.5

Slug & Rever e Slug Input Operation

1. Use Slug (a PNP input) to override all logic internal to the

control and force this zone and all upstream zones to run

regardless of whether they are occupied or empty. Slug is

sometimes also referred to as Jog

NOTE: When this signal is active, parcels will be

pushed off the end of the conveyor if there is

nothing in place to receive them.

2. Use Rev Slug (a PNP input) in one of two ways:

Alone: Assert it by itself to cause the zone and all

upstream zones to coast. The motors will not be

energized and will not provide any active braking power.

In Combination: Assert it in combination with the slug

input to override all logic internal to the control and force

this zone and all upstream zones to run in the reverse

direction regardless of whether they are occupied or

empty.

NOTE: When this signal is active, parcels are pushed

out of the upstream end of the zone regardless of

the availability of any upstream device to accept the

parcel. In this scenario, if there is nothing there, any

parcels could potentially fall to the floor.

______________________________________________________

3.8.6

Other Mode of Operation

If you need to do something other than those things listed

above please contact either our Sales or Application

Engineering Departments for assistance at (619) 677-6530.

4

Special Functions

4.1

Zone Hold Input

When the zone hold input (I/O pin 7) goes active prior to an

object reaching the primary (downstream-edge) sensor then

that object will be held in that zone and will not exit while the

zone hold signal remains active.

All objects in the upstream zones will also be held while the

zone hold input is active.

When an object is actively exiting the zone hold input will have

no effect on that object exiting.

4.2

Configuring an SCC-3 a a BMC

In certain applications it may be necessary to eliminate the 2.5

second motor run-on feature which is a part of the Search &

Rescue function (see section 4.3). To accomplish this the SCC-3

control can be configured as a Basic Motor Control (BMC) or

standalone motor control. To accomplish this implement the

following steps;

1) Place Control DIP switch 3 in the ON position (slide the

switch to the right)

2) On the GREEN 3-pin sensor connector wire the sensor

input (center pin) to the sensor +voltage (pin on the right).

3) Apply a 24Vdc signal to the Slug input (I/O pin 2) to start

and stop the motor

4) When the Slug input goes high then I/O pin 4 will go high

to indicate that the motor is running

4.3

Search and Re cue

This function has been added to the control in order to avoid

situations where parcels could become stranded between

photo sensors creating a nuisance at the very least. The

function works under the following circumstances:

During Power Up

After Discharge of a Parcel from the Downstream Edge of a Zone

After Removal of a Slug Signal (if Rev Slug is Not Active)

After Removal of a Rev Slug Signal (if Slug is Not Active)

4.3.1

During Power Up

When the power is off parcels are not tracked. When power is

first applied each control goes through a self-check and report its

firmware revision as described in 5.2 Firmware Version Display.

Beginning at the Exit end and then flowing zone by zone after very

brief intervals to avoid creating high inrush current at the power

supply each zone then runs for up to 2.5 seconds or until a parcel

arrives at the respective zone sensor whichever comes first.

In this fashion any parcels that may have been stranded between

sensors when power was removed are discovered and will then

be processed by the conveyor in either ZPA or ZIP control mode as

determined by the switch settings.

NOTE: 2.5 seconds is a nominal time period. The actual

time is adjusted up if zones are set to a lower than

maximum speed. For example, if a zone is set to half its

maximum speed, the run time is doubled to 5.0 seconds.

4.3.2

After Di charge of a Parcel from the

Down tream Edge of a Zone

It is not unusual for operators who are manually loading parcels

onto a conveyor to place two small parcels in a single zone. If the

zone stopped immediately after a parcel passed its downstream

sensor the second parcel could become stranded. Therefore each

zone will operate for up to 2.5 seconds after these events. When

the zone is already running very little additional power is

consumed. This is a local function that directly affects only the

zone that just discharged its parcel.

SCC-3 Product 110515 Revision 1.3 April 19, 2018 | Pa e 10

4.3.3

After Removal of a Slug Signal

(If Rev Slug is Not Active)

During Slug mode of operation parcels are not tracked by the

system logic. Some parcels will likely be between sensors at the

time the Slug signal is removed.

Beginning with the zone where the Slug signal was asserted and

cascading upstream each zone will run for up to 2.5 seconds

until either the time expires or a parcel is discovered.

4.3.4

After Removal of a Rever e Slug Signal

(If Slug is Not Active)

Since Reverse (Rev) Slug causes the zones to coast parcels that

were in motion will come to rest in more or less random

locations. Beginning with the zone where the Rev Slug signal

was asserted and cascading upstream each zone will run for up

to 2.5 seconds until either the timer expires or a parcel is

discovered.

5

Diagnostics Troubleshooting

5.1

Feedback LED

The SCC-3 provides four (4) LED indicators shown as item 5 in Figure

1: SCC-3 Controller Components. These LEDs are often useful in

diagnosing various wiring and connection problems. If power is

connected there will always be at least one LED illuminated or

flashing. When no LED is illuminated there is no power.

5.1.1

Fu e LED (Red)

C UTION: This robust next-generation fuse will not blow

under normal circumstances. Inspect all wiring

connections to assure that there are no short circuits.

This LED is off under normal circumstances. It illuminates

constantly if the 10 amp replaceable fuse is blown and power is

applied with the proper polarity. The 10 amp fuse on the board is

not user-accessible. If the blown fuse LED is illuminated return

the board to your distributor or supplier for analysis or repair.

NOTE: The control’s on-board fuse is NOT replaceable.

5.1.2

Fault LED (Red)

This LED is off under normal circumstances. If a problem is

detected it provides one of the following five signals:

One (1) fla h in 4 econd : The board has a hardware

problem. Return it to your supplier.

Two (2) fla he in 4 econd : The input voltage is too high.

Reduce the voltage.

Three (3) fla he in 4 econd : The input voltage is too low.

Increase the voltage.

Four (4) fla he in 4 econd : There is a problem with the

motor cable or connection. Check to see that the cable is not

damaged and that all of the wires are secure.

Five (5) fla he in 4 econd : Control over temperature.

Six (6) fla he in 4 econd : Extreme over current.

Con tantly ON: The motor is stalled or the sensor is

continuously blocked. Check for mechanical obstructions.

5.1.3

Motor LED (Amber)

Four fla he in 4 econd : Components on the board

have overheated and the circuit is limiting the power to

the motor to about half (50%) of normal. This problem

will correct itself when the board has cooled adequately.

Check for mechanical obstructions.

Con tantly ON: Motor current is at the maximum

allowed and is being electronically limited. Check for

mechanical obstructions.

Flickering: If the motor starts under significant load the

current may be limited briefly causing the LED to flicker.

If the LED flickers constantly this is an indication that the

motor is operating at its upper limit and may never reach

the full speed. This is not a cause for concern and no

corrective action is required.

5.1.4

Power LED (Green)

Con tantly ON: Power is properly applied as long as the fuse

is not blown.

5.2

Firmware Ver ion Di play

Three (3) of the feedback LEDs are used to communicate

the firmware revision of the control assembly during the

start-up sequence. Each time that power is applied to the

board the green (power) and red (fault) LEDs will turn on

immediately. After 1.0 second the amber LED will flash on

for 0.75 seconds followed by an off period. An off period of

1.5 seconds represents a decimal point separating major

revisions from minor revisions. An example is shown below.

The example sequence above represents firmware revision

1.2. When the red (fault) LED turns off the start-up sequence

has ended and normal operation begins.

Figure 3: Firmware Version Display Example

SCC-3 Product 110515 Revision 1.3 April 19, 2018 | Pa e 11

5.3

RJ25,6-Wire,Modular Cable Orientation, L<10ft

5.4

Additional A i tance

To request the latest revision to our user manual visit our

website at www.automationcontrolsgroup.com.

For additional assistance please contact our National

Sales Manager at (414)-426-6539 or our Application

Engineering Department for assistance at (619) 677-6530.

6

Document Revision History

Rev: Date: Summary:

1.0 Feb 2014 Original Release.

1.1

May 2016 Eliminate reference to 4 0 and 60 RPM

1.2 Apr 2018 Add Zone Hold, BMC Conversion & Cable info

1.3 Apr 2018 Add Braking & ZMH and Appendix Information

Appendix A

ZPA Mode (Standard Sigulation) compared to ZIP Mode

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

steute

steute SRM 21 Multi Mounting and wiring instructions

emmeti

emmeti T3 Installation and commissioning instructions

HP

HP Synergy 480 Gen9 Maintenance and service guide

GEM

GEM B56 operating instructions

Canford

Canford 58-321 Technical data sheet

Telit Wireless Solutions

Telit Wireless Solutions GE864 DUAL V2 Hardware user's guide