Page 2

PRINTED IN CANADA

WIRING

• Deactivate any power supplies until all connections are made to the device to prevent electrical shock or equipment damage.

• Follow proper electrostatic discharge handling procedures when installing the device.

• Use 22 AWG shielded wiring for all connections and do not locate the device wires in the same conduit with wiring used to supply inductive

loads such as motors.

• Make all connections in accordance with national and local codes.

• The analog input signal is connected to the IN+ and IN- terminals and the analog output signal is connected to the OUT+ and OUT- terminals.

The input and output signals are completely isolated from each other.

SPECIFICATIONS

GENERAL

Power Supply....................................... Powered by loop-current (15-30 Vdc)

Isolation ................................................. 1000 Vrms input to output

Accuracy ................................................ ±0.1% typical

Operating Conditions ....................... 0 to 50°C (32 to 122°F), 5 to 95 %RH non-condensing

Storage Conditions............................ -30 to 70°C (-22 to 158°F), 5 to 95 %RH non-condensing

Wiring Conditions .............................. Screw terminal block (12 to 24 AWG)

Weight.................................................... 56gm (1.98 oz)

Enclosure............................................... Snap track mounting, 61mm L x 83mm W (2.4" x 3.25")

Country of Origin................................ Canada

INPUT SIGNAL

Input Voltage Ranges........................ 0-5, 0-10, 1-5, and 2-10 Vdc

Input Voltage Impedance................ >10 KΩ

Current Signal Type............................ Sink (external transducer generates 4-20 mA)

Input Current Ranges........................ 0-20 and 40-20 mA

Input Current Impedance................ 250 Ω

OUTPUT SIGNAL

Output Current Range...................... 4-20 mA

Output Current Impedance............ 750 Ω max with 24 Vdc supply

Current Signal Type............................ Sink (requires a loop power supply)

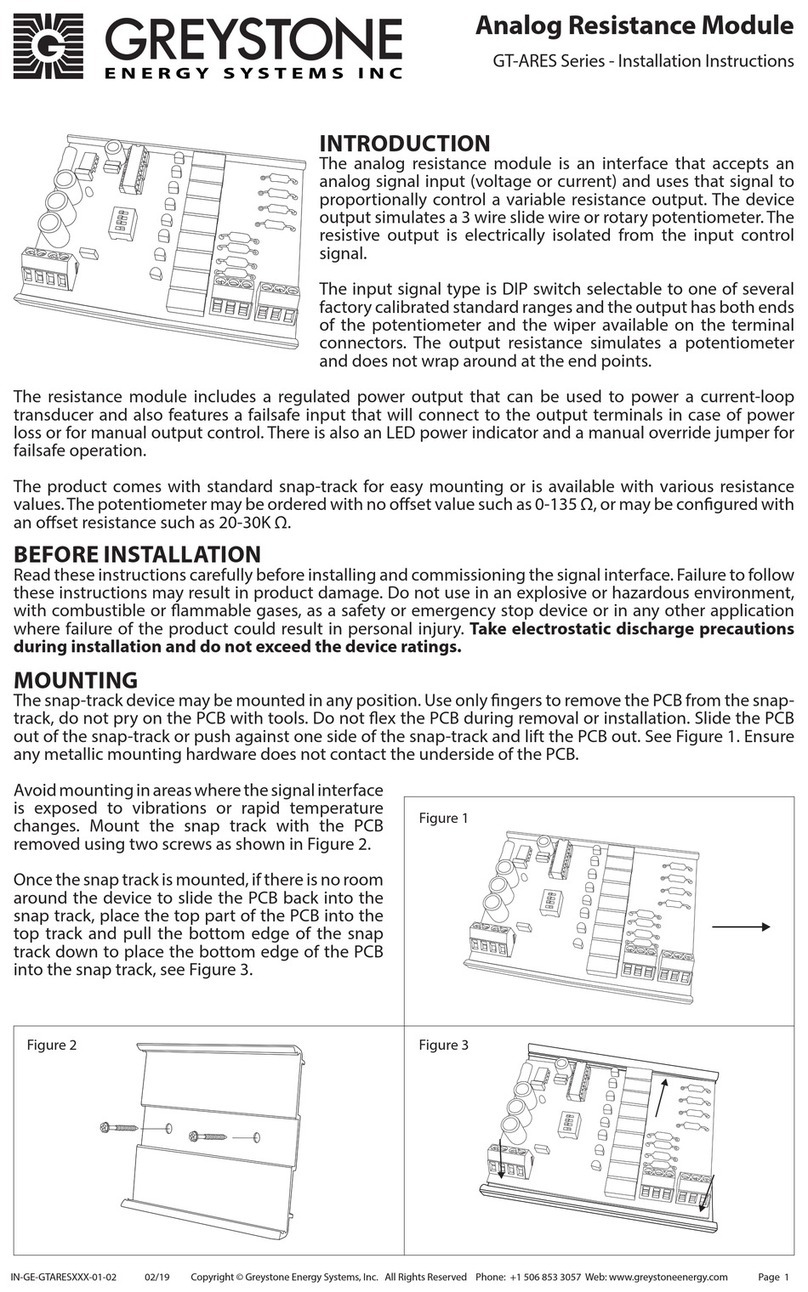

Study the wiring diagrams for proper connections with various input/output signal types and

with both sinking or sourcing applications.

FACTORY CONFIGURATIONS

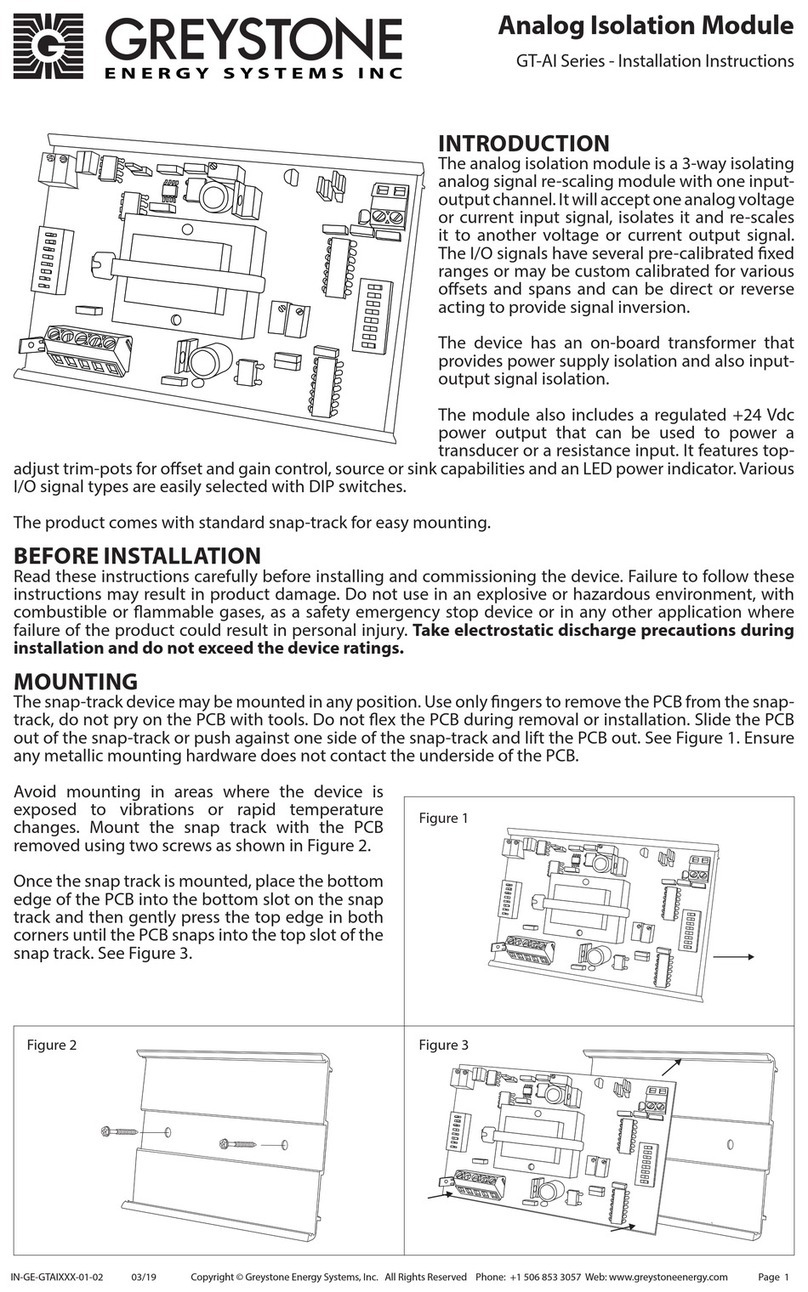

The Isolation Module is preset for 4-20 mA input / 4-20 mA output. The input signal may be

changed by using the DIP switches as shown in Figure 5.

CALIBRATION

The isolator is factory calibrated to ±0.1% accuracy on the 0-5 vdc input type. Using any other

range will result in a transfer accuracy or <±1%. If a higher accuracy signal is required simply

apply the full-scale input signal and adjust the output signal to 20.00 mA using the calibration

pot.

Calibration pot

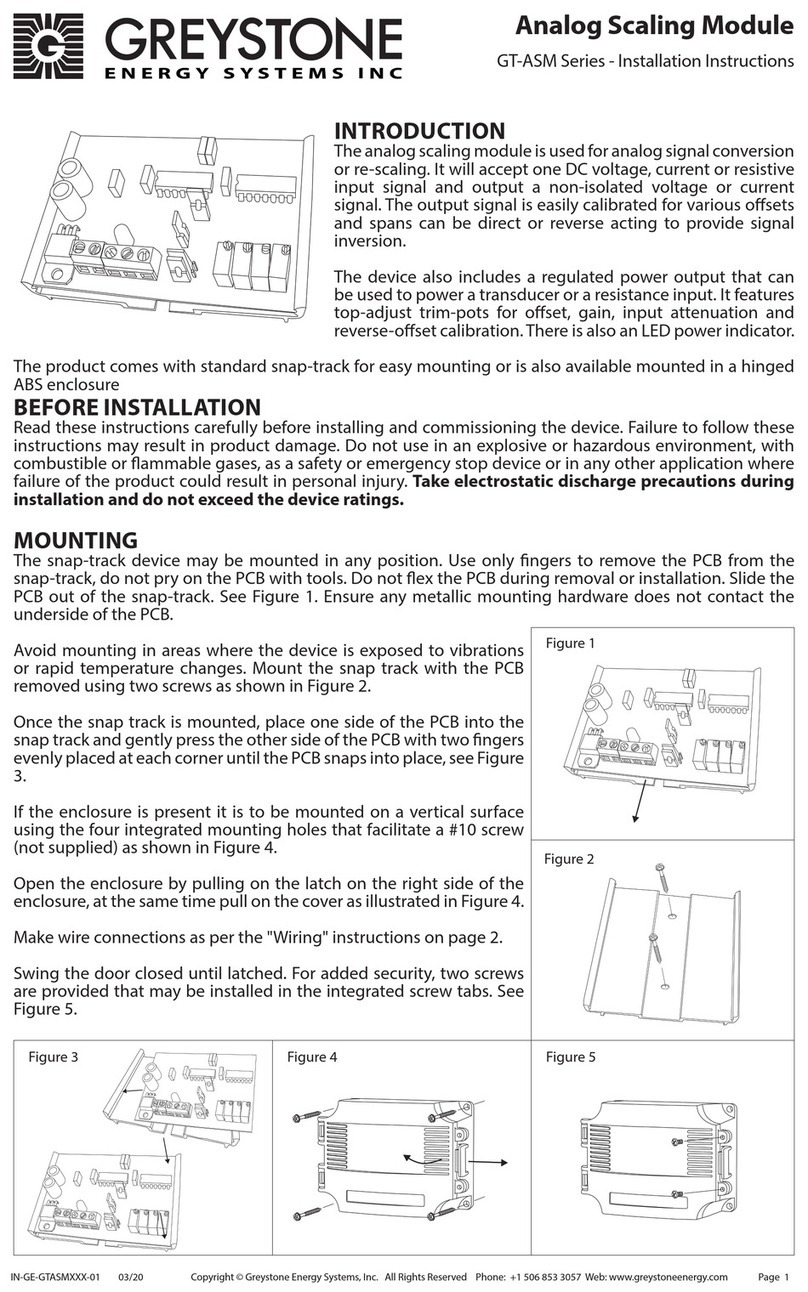

DIMENSIONS

61mm

2.4"

83mm

3.25"

Figure 4

+24 Vdc

Input

OUT+

OUT -

4-20 mA Receiver

Out

Power

IN+

IN -

4-20 mA Transmitter

Power Supply

+24 Vdc

Common

Out

Common

IN +

IN -

0-10 Vdc Transmitter

Input Signal Type S1 S2 S3

0-5Vdc OFF OFF OFF

0-10 Vdc OFF ON OFF

1-5 Vdc OFF OFF ON

2-10 Vdc OFF ON ON

0-20 mA ON OFF OFF

4-20 mA ON OFF ON

S1

S2

S3

INPUT TYPE

0-5 Vdc Shown

Figure 5

IN-GE-GTAI420XXX-01-02 02/19 Copyright © Greystone Energy Systems, Inc. All Rights Reserved Phone: +1 506 853 3057 Web: www.greystoneenergy.com