Troubleshooting

1. Transducer has no output.

A. Power supply is not properly sized.

Check the power supply voltage and output rating. Each

transducer requires less than 2VA to operate.

B. Output polarity is not properly matched.

Check and correct wiring polarity.

2. Output signal too low or too high.

Transducer model improperly sized for application.

Determine the normal operating voltage of your monitored

circuit and ensure transducer selected is equal to or slighly

higher than the normal operating voltage.

3. Transducer output is always at 4mA.

A. Primary circuit is not on.

Check that the monitored circuit is actually energized.

4. Transducer output is always at 20mA.

Voltage is higher than transducer range.

Select a higher range product.

Description

VADT Series Voltage Transducers are designed to monitor AC

or DC voltage and detect conditions where supply voltage

is above or below normal. Detecting such conditions helps

users to avoid problems commonly associated with voltage

irregularities such as motor overheating, brownouts and

conductor failure or poor connections.

Installation

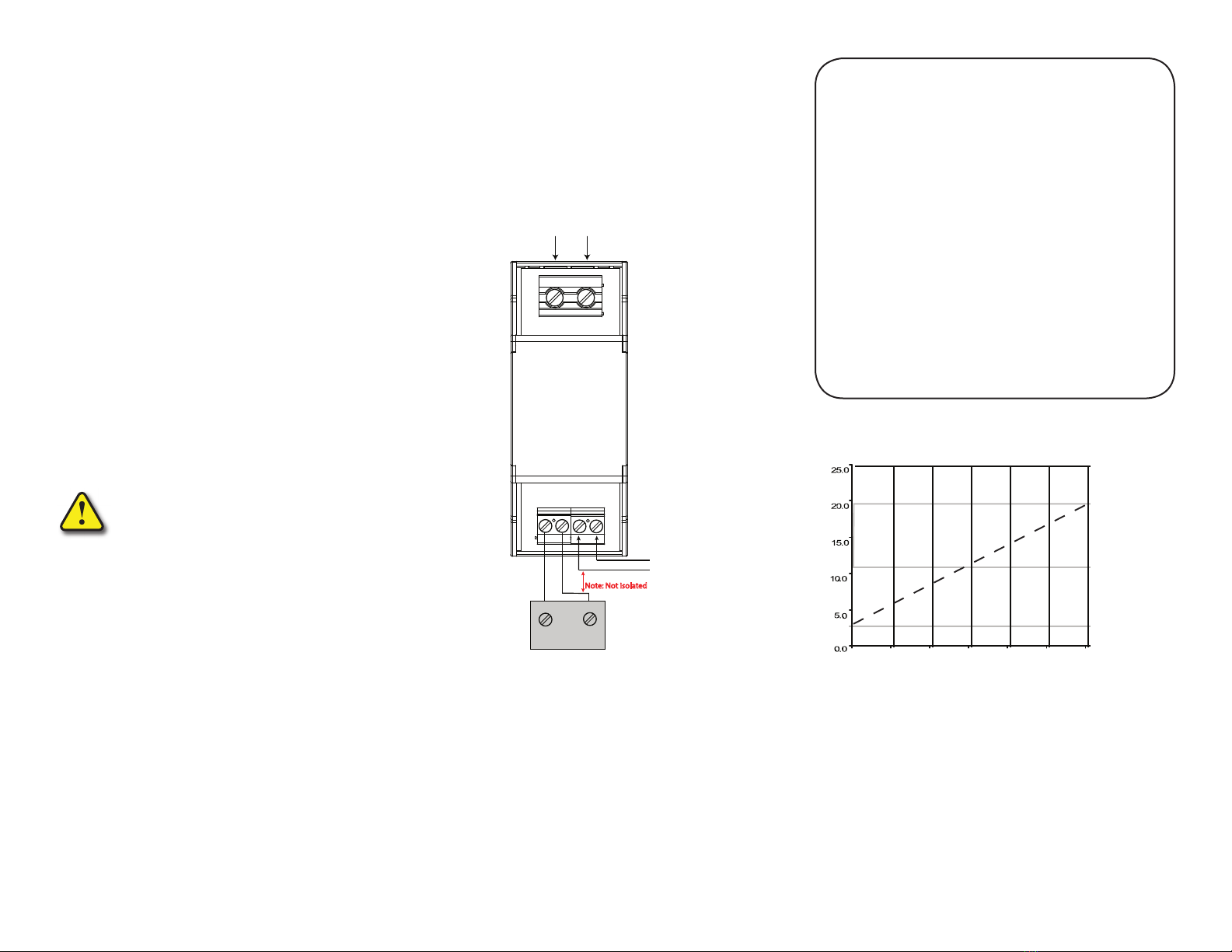

VADT transducers feature a 35mm wide DIN rail-compatible

enclosure and are typically located in the same environment

as motors, contactors, heaters, pull-boxes, and other electrical

enclosures.

To mount on DIN rail: Orient transducer so that line voltage

terminals L1 and L2 are upright/on top of unit and snap

securely onto DIN rail. To remove, insert a small screwdriver

into the lower mounting hole of the spring-loaded clip, and

push the handle end of the screwdriver toward the sensor base

to release the tension on the rail.

Output Wiring

Connect control or monitoring wires to the sensor terminals

1 and 2. Use 22-12 AWG copper wire insulated to 75/90°C

and tighten terminals to , 6 in-lbs torque.

Observe polarity, terminal 1 is the postiive output, 2 is

negative.

To mount using screws: Insert screws and mount to

backplane or other suitably flat surface.

Monitored Voltage Wiring Connection

CAUTION: To avoid any potential for shock

or safety hazard, ensure line voltage is

disconnected at source before wiring to unit.

Connect input voltage to be monitored to terminals (5) and

(6) on transducer using 30-12 AWG copper wires and tighten

terminals 5-7 inch pounds torque.

Do not connect the power supply and signal together.

There is no isolation between power and signal.

(mA)

(% FS)

Transducer Output vs. Input Voltage

0.0 100.0

50.0

Input Voltage

Current Output

VADT Series

+

AC/DC Voltage (primary)

(5) (6)

+-

Load

(PLC, meter,etc.)

24 VAC/DC

Power Supply

(1) (2) (3) (4)