AutomationDirect AcuAMP ACS035 Series User manual

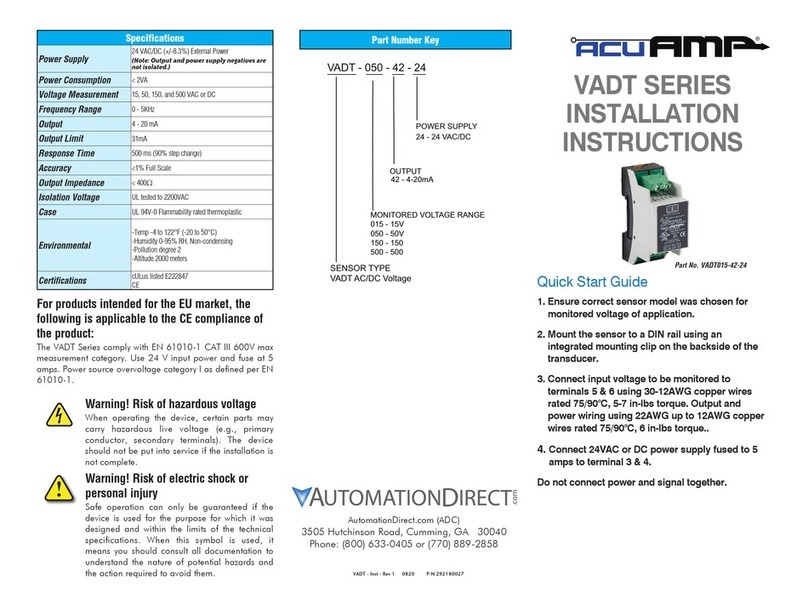

Part Number Key

AutomationDirect.com (ADC)

3505 Hutchinson Road, Cumming, GA 30040

Phone: (800) 633-0405 or (770) 889-2858

ACS035/ACS400

SERIES

INSTALLATION

INSTRUCTIONS

Quick Start Guide

1. Route monitored wire through aperture.

2. Mount the sensor to a DIN rail or panel.

3. Connect power supply and output wiring.

a. Use 30-12 AWG copper wire and tighten termi-

nals to 7 in-lbs torque.

b. Ensure supply power and load matches that

shown on sensor label.

4. Adjust setpoints.

a. Use trip adjust potentiometers to select

setpoints.

b. LED shows Green with power supply

connected, Amber when the current has

exceeded the setpoint.

®

ACTS - Inst - Rev 1 0820 P-N 394000024

Specifications

Power Supply 24VAC/DC ( +/- 8.3%)

Power Consumption < 2VA

Output (2) Independent Single Pole, Double Throw mechanical

Relays

Contact Rating 1A @ 120VAC, 2A @ 30VDC

Response Time 40 - 120ms

Hysteresis 4% of setpoint

Setpoint Ranges 2-35 Amps (ACS035)

25-400 Amps (ACS400)

Setpoint Adjust Two 3/4-turn potentiometers

Sensed Current

Limit

1.1x range continuous

3x range for 6 seconds

5x range for 1 second

Isolation Voltage UL508, UL tested to 1240VAC

Frequency Range 40-65 Hz

Sensing Aperture 1.31 in (33.3 mm) dia.

Environmental

-Temp -4 to 122°F (-20 to 50°C)

-Humidity 0-95% RH, Non-condensing

-Pollution degree 2

-Altitude 2000 meters

Case UL 94V-0 Flammability rated thermoplastic

Certifications cULus listed E222847

CE

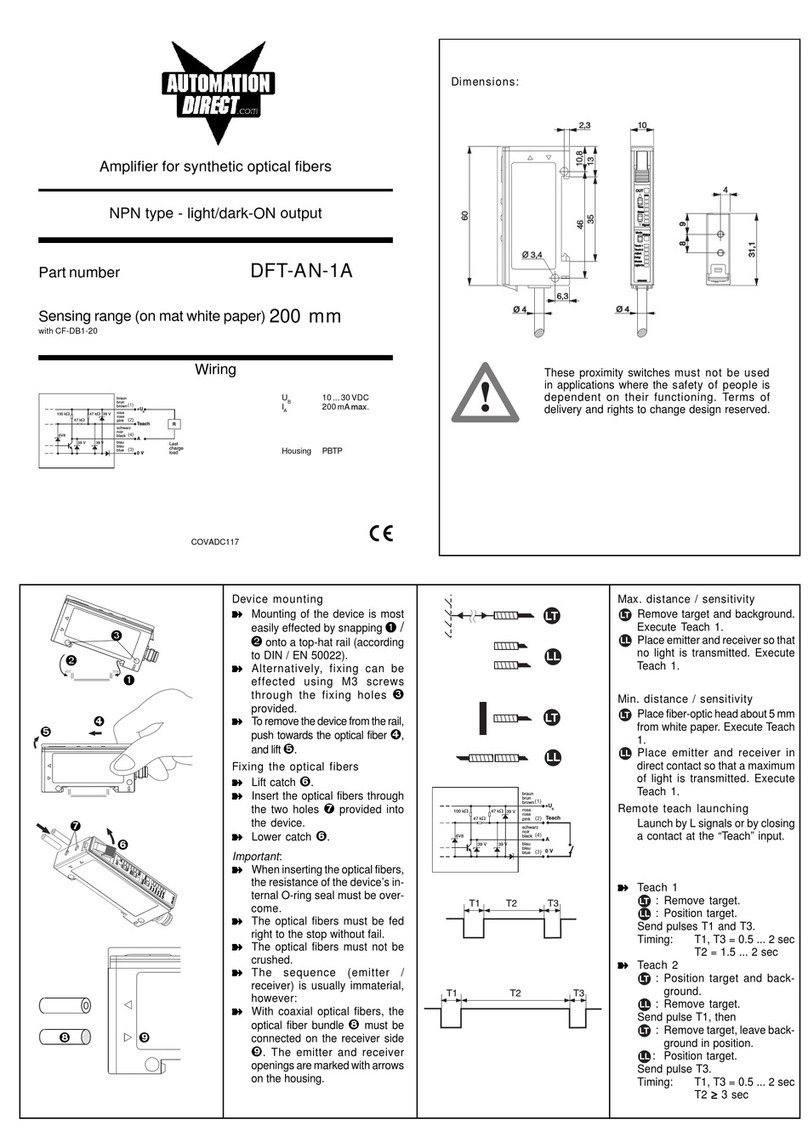

A C S 035 - 2C - 24 - F

SENSOR TYPE

A

CS AC current operated switch

OUTPUT

CASE STYLE

2C - (2) SPDT relay outputs,

independant setpoints

RANGE

035 - 2-35 Amps AC

400 - 25-400 Amps AC

POWER SUPPLY

24 - 24 VAC/DC

F - Fixed Core

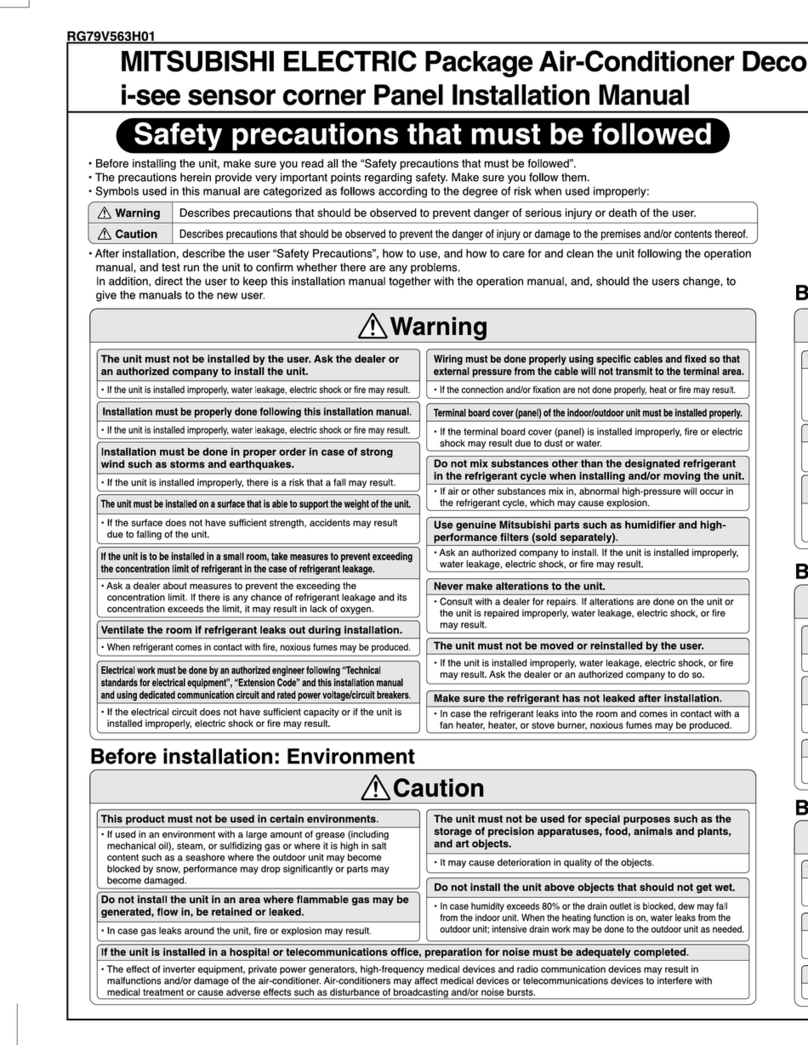

Warning! Risk of electric shock or

personal injury

Safe operation can only be guaranteed if the

device is used for the purpose for which it was

designed and within the limits of the technical

specifications. When this symbol is used, it

means you should consult all documentation to

understand the nature of potential hazards and

the action required to avoid them.

Warning! Risk of hazardous voltage

When operating the device, certain parts may

carry hazardous live voltage (e.g., primary

conductor, secondary terminals). The device

should not be put into service if the installation is

not complete.

For products intended for the EU market, the

following is applicable to the CE compliance of

the product:

The ACS035/ACS400 Series may comply with EN 61010-1

CAT III 300V max line-to-neutral measurement category. If

insulated cable is used for the primary circuit, the voltage rating

of the measurement category can be improved according to

the characteristics given by the cable manufacturer.

Use 24V input power and fuse at 5 amps. Power source

overvoltage category I as defined per EN 61010-1.

Part No. ACS035-2C-24-F

Description

The ACS035 and ACS400 Series products are powered,

current-operated switches which trigger when sensed

current levels exceed the adjusted setpoint. There are two

independent setpoints, one for higher than normal current and

another for lower than normal, or one for alarm at too high

and the second for shut down at an excessive current level.

The two independent outputs are single pole, double throw

relay contacts.

Installation

The ACS035 and ACS400 switches can be located in the

same environment as motors, contactors, heaters, pull-boxes,

and other electrical enclosures.

Mounting can be made in any position to a panel or a 35mm

DIN rail, or hung directly on wires with a wire tie. Keep at

least one inch clearance between sensor and other magnetic

devices.

Wiring

Run wire to be monitored through aperture (opening) in the

sensor.

For power supply and output wiring, use 30-12AWG copper

wire and tighten terminals to 7 in-lbs torque. Be sure the

output load requirement does not exceed the contact rating.

Connect power supply to terminals 4 and 5 on the sensor.

Check to ensure supply power matches voltage and type

required by sensor. Once powered, the LEDs on the unit

should indicate unit is on by glowing green.

Connect output wiring to be controlled by Setpoint #1 to

terminals 1-2 for the normally closed (opens on current rise)

or 2-3 for the normally open (closes on current rise) contact.

Connect output wiring to be controlled by Setpoint #2 to

terminals 6-7 for the normally closed (opens on current rise)

or 7-8 for the normally open (closes on current rise) contact.

Note that if unit is powered and monitored conductor has

current flow, the output contacts may change state depending

on setpoint adjustment settings.

Power Supply and Output Wiring

24VAC or DC

Power Supply

Common Common NO (Closes to Common on Current Rise)

NO (Closes to Common on Current Rise)

NC (Opens to Common on Current Rise)

NC (Opens to Common on Current Rise)

Set Point #1

Adjustment

LED Shows Contact Status

Set Point #2

Adjustment

LED Shows Contact Status

1 2 3 4 567 8

Setpoint Adjustment

The ACS035 and ACS400 Series setpoints are adjusted

using two 3/4-turn pots which have arrow indication of the

selected value. The arrow points to the current magnitude

which will cause the output relay(s) to energize or change

state. Possible to control one DC circuit and one AC circuit.

Typical Adjustment

1. Turn the setpoint adjustment pot #1 to the point where

you want the first relay to change state.

2. Turn the setpoint adjustment pot #2 to the point where

you want the second relay to change state.

3. Thread the load conductor(s) through the sensing

aperture. If multiple conductors are used to power the

monitored load, each conductor must be connected to

the same phase.

4. Energize the sensor with 24VAC/DC (+/-8.3%)

5. Both indicating LEDs will be illuminated Green.

6. After energizing the monitored load, if the current used

is over the adjustment level of Setpoint #1 the LED will

change to Amber to indicate that the output relay has

changed state.

7. When the monitored current exceeds the level of Setpoint

#2, that LED will also change from Green to Amber.

8. The most common use would be to adjust Setpoint #1 to

be in the tripped condition during normal load operation,

reverting to “normal” if current falls below that point; and

to have Setpoint #2 adjusted so it is “untripped during

normal operation, and change state in an over current

condition.

9. The output contacts are floating, and can be wired in

parallel (OR wiring) or in series (AND wiring) for a two

wire over/under switch action. See Application Examples.

Troubleshooting

1. Sensor is always tripped.

A. The setpoints may be too low.

Turn pot Clockwise to increase setpoint.

B. Switch has been overloaded and contacts are burned out.

Check the output load, remembering to include inrush on

inductive loads (coils, motors, ballasts)

2. Sensor will not trip.

A. The setpoints may be too high.

Turn pot Counter Clockwise to decrease setpoint.

NC NC NO

NO POWER

Closed at Normal Closed at Normal

Open at Low Current Open at High Current

Control circuit is open at either

over or under normal current conditions.

Series Over/Under Current Window

(AND wiring) Example

NC NC NO

NO POWER

Open at Normal Open at Normal

Closed at Low Current Closed at High Current

Control circuit is closed at either

over or under current conditions.

Parallel Connection Current Alarm

(OR wiring) Example

AC Current

Setpoint #2

Setpoint #1

Setpoint #2 Contact Action

Setpoint #1 Contact Action

Red Line Indicates Current Rising and Falling

1-2 Closed Open Closed Open

2-3

Open Open

Closed Closed

5-6 Closed Closed

Open

6-7 Open Open

Closed

Troubleshooting continuted:

B. Monitored current is below minimum required.

Loop the monitored wire several times through the aperture

until the “sensed” current rises above minimum. Sensed

Amps = (Actual Amps) x (Number of Loops). Count loops on

the inside of the aperture.

C. Switch has been overloaded and contacts are burned out.

Check the output load, remembering to include inrush on

inductive loads (coils, motors, ballasts).

3. LEDs do not illuminate.

A. Power supply is not energized.

B. Power supplied is not sufficient, 24VAC/DC (+/-8.3%).

Application Examples

This manual suits for next models

2

Other AutomationDirect Accessories manuals