Introduction

The O2X DUO sensor is designed to continuously measure dissolved oxygen levels in

liquids. The O2X DUO is effective in saving energy costs associated with aeration

systems in an activated sludge process. In addition, accurate measuring of dissolved

oxygen allows for better control of nitrification/denitrification.

The O2X DUO features two different principles of measuring; Clark Cell electrode or

optical cell. See section 3 below.

1.

A few words about this manual

This manual details installation procedures and operational features of the Cerlic O2X

DUO sensor. Menu navigation and technical data for the BB1/BB2 control box can be

found in the BB1/BB2 service manual.

2.

Design

The O2X DUO sensor is manufactured with SS2343 (316SS) stainless steel. Built-in

flushing nozzles allow for the most accurate readings with little maintenance. The

electronics is protected in the rugged casing, ensuring its reliability in very demanding

environments.

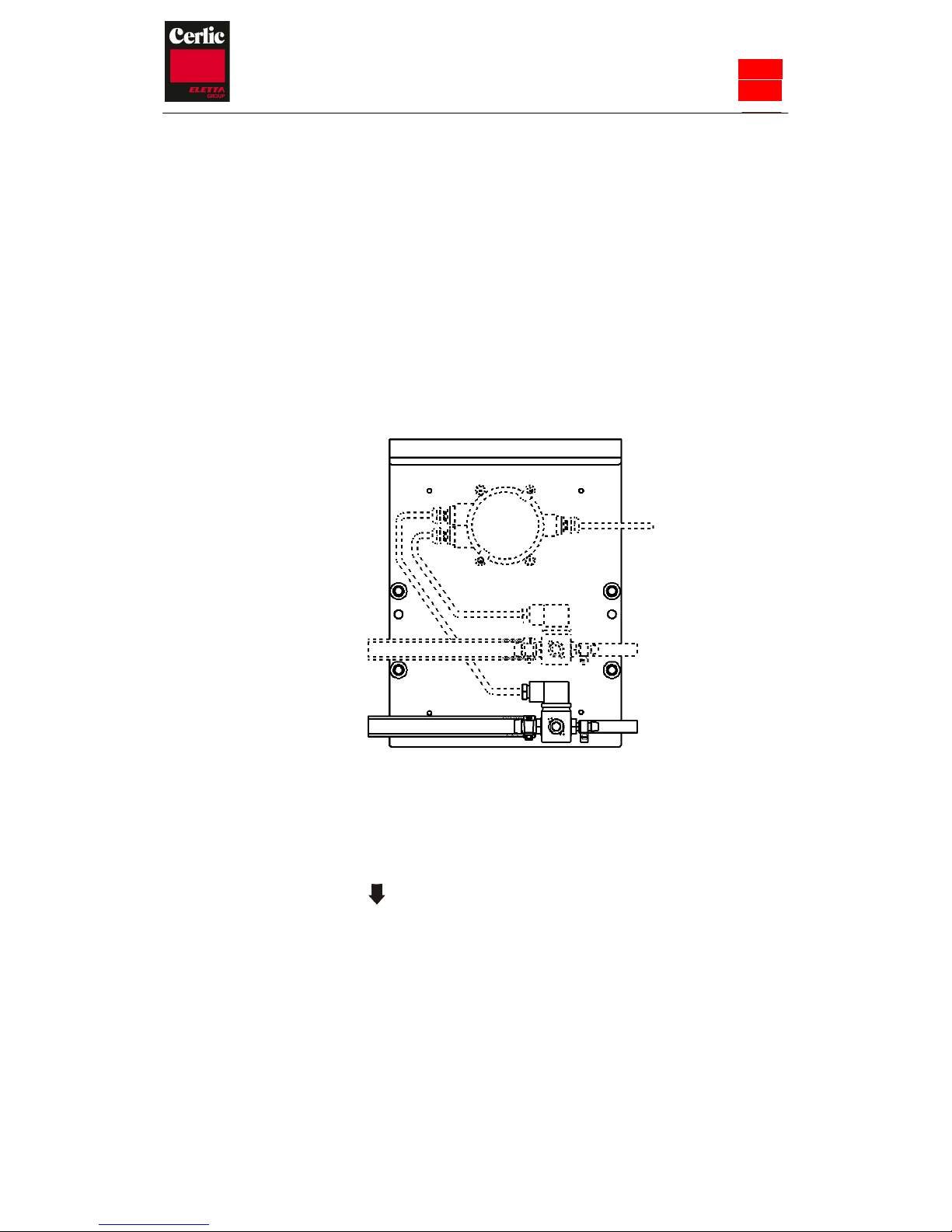

The sensor has a fixed, shielded 10 m (33’) M12 cable used for signal transmission

between the sensor and the BB1/BB2 control box. The cable sheath is made of Hytrel

and is highly resistant to aggressive materials and fluids.

3.

Measuring principle

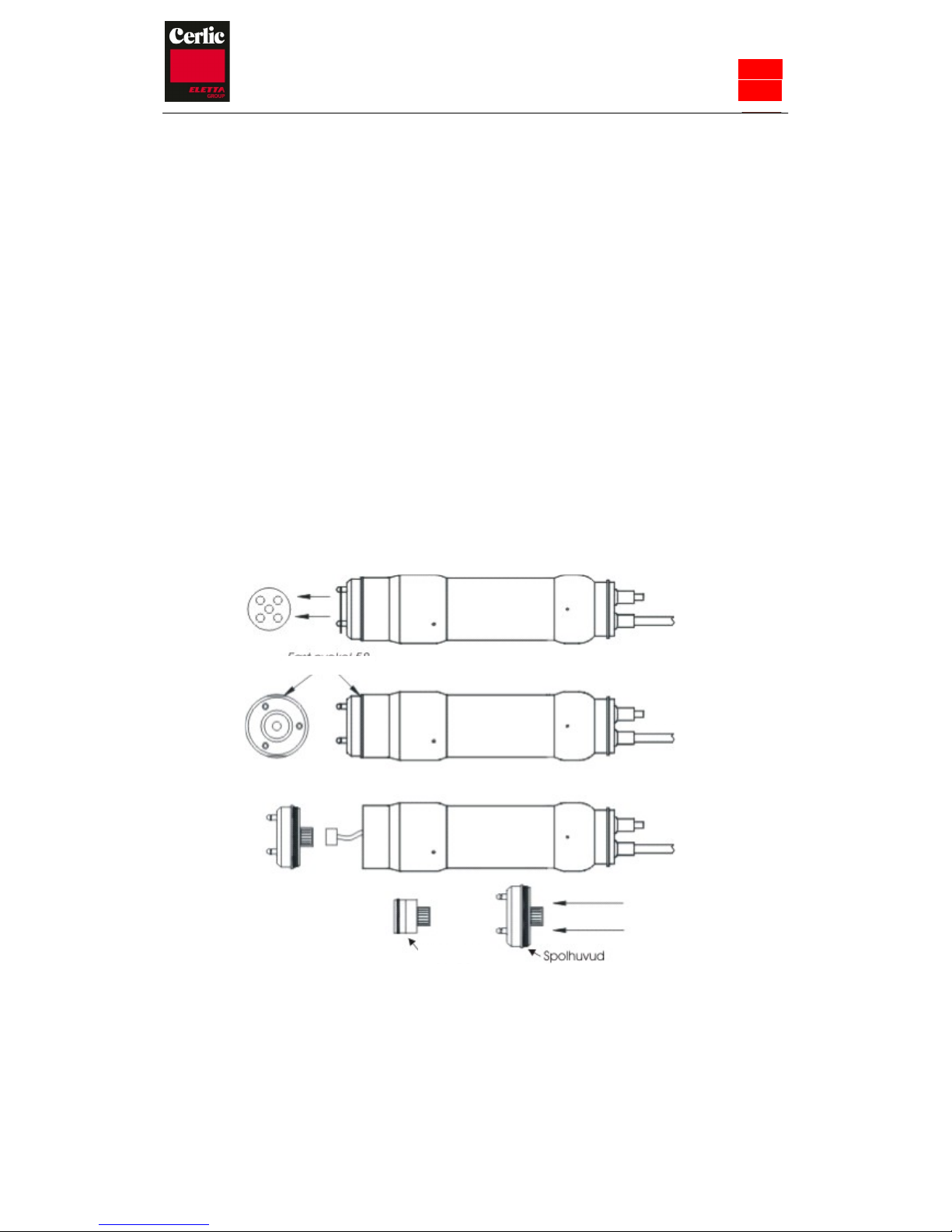

Clark cell, The electrode is a Clark type electrode with FEP membrane . The Clark cell

detects the oxygen though its reduction at the Gold electrode. The sensor consists of a

Gold cathode and Silver anode. A membrane covers the gold & silver electrodes and

blocks access of solids to the electrodes. Only dissolved gases such as oxygen can pass

thru the membrane, hence the reduction current responds to the oxygen concentration.

Active components included in the electrode are treated to maximize their life span.

Inside the electrode there is also a temperature sensor mounted in a way that minimizes

problems with temperature adjustments. This provides compensation of the electrode

due to temperature changes. There is a connector on the electrode for the O2X amplifier

cable. The temperature can be read on the BB1/BB2 and can be used as secondary

signal when an O2X sensor is configured to use two mA outputs. The temperature

measurement is not a precision measurement but should rather be seen as an indication.

Optical cell, The optical cell is using phase shift technology to determine the oxygen

concentration. A special coating is applied to the acrylic disc in the top of the optical

electrode and called sensor cap in the manual. The optical cap is not sensitive to UV

light, but it is recommended when doing an air calibration to have the sensor in the

shade. The Clark & Optical cells can be interchanged in the O2X DUO sensor but an

air calibration must be preformed. There is a connector on the electrode for the O2X

amplifier cable. The temperature can be read on the BB1/BB2 and can be used as

secondary signal when an O2X DUO sensor is configured to use two mA outputs. The

temperature measurement is not a precision measurement but should rather be seen as

an indication.