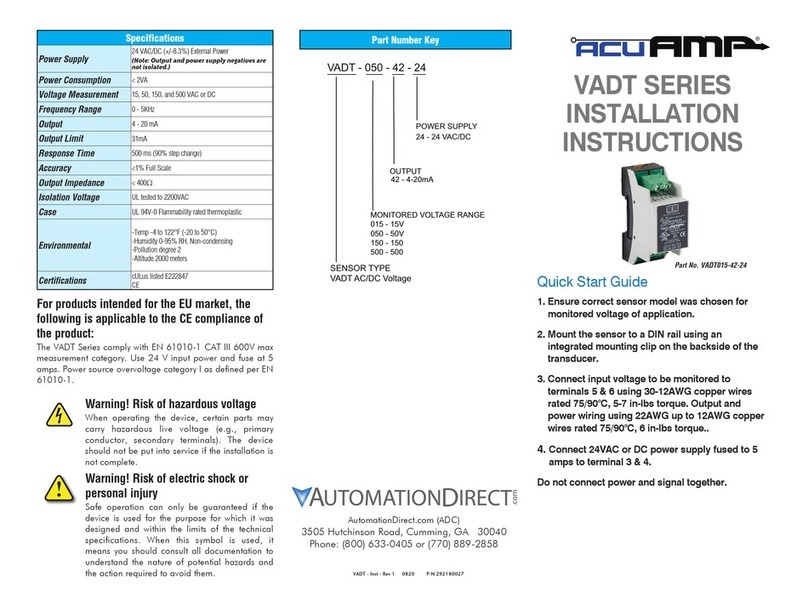

AutomationDirect DFT-AN-1A User manual

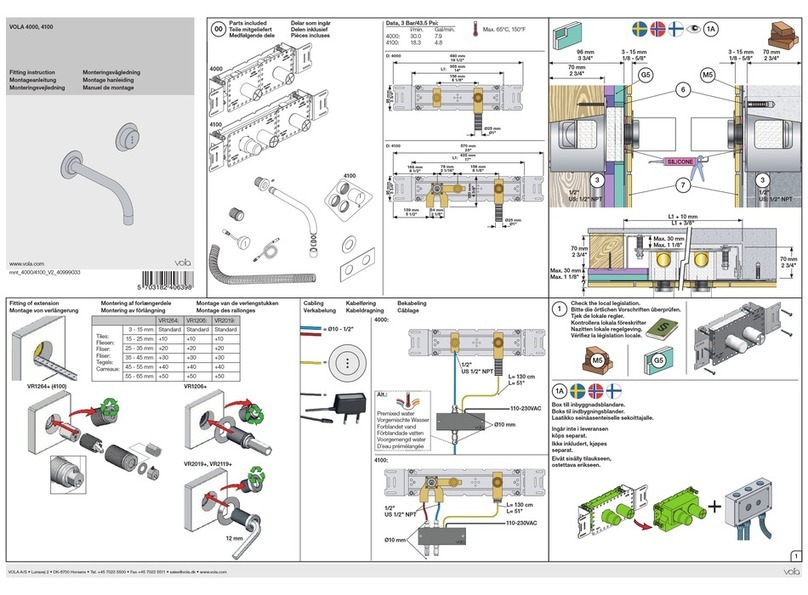

UB

10...30VDC

IA

200mAmax.

Housing PBTP

Amplifier for synthetic optical fibers

Partnumber

Sensing range (on mat white paper)

with CF-DB1-20

Wiring

NPN type - light/dark-ON output

COVADC117

(1)

(4)

(2)

(3)

schwarz

noir

black

blau

bleu

blue

+U

Teach

A

0V

B

R

39 V

braun

brun

brown

Last

charge

load

39 V

39 V rosa

rose

pink

100 k

W

6V8

47 k

W

47 k

W

Dimensions:

These proximity switches must not be used

in applications where the safety of people is

dependent on their functioning. Terms of

delivery and rights to change design reserved.

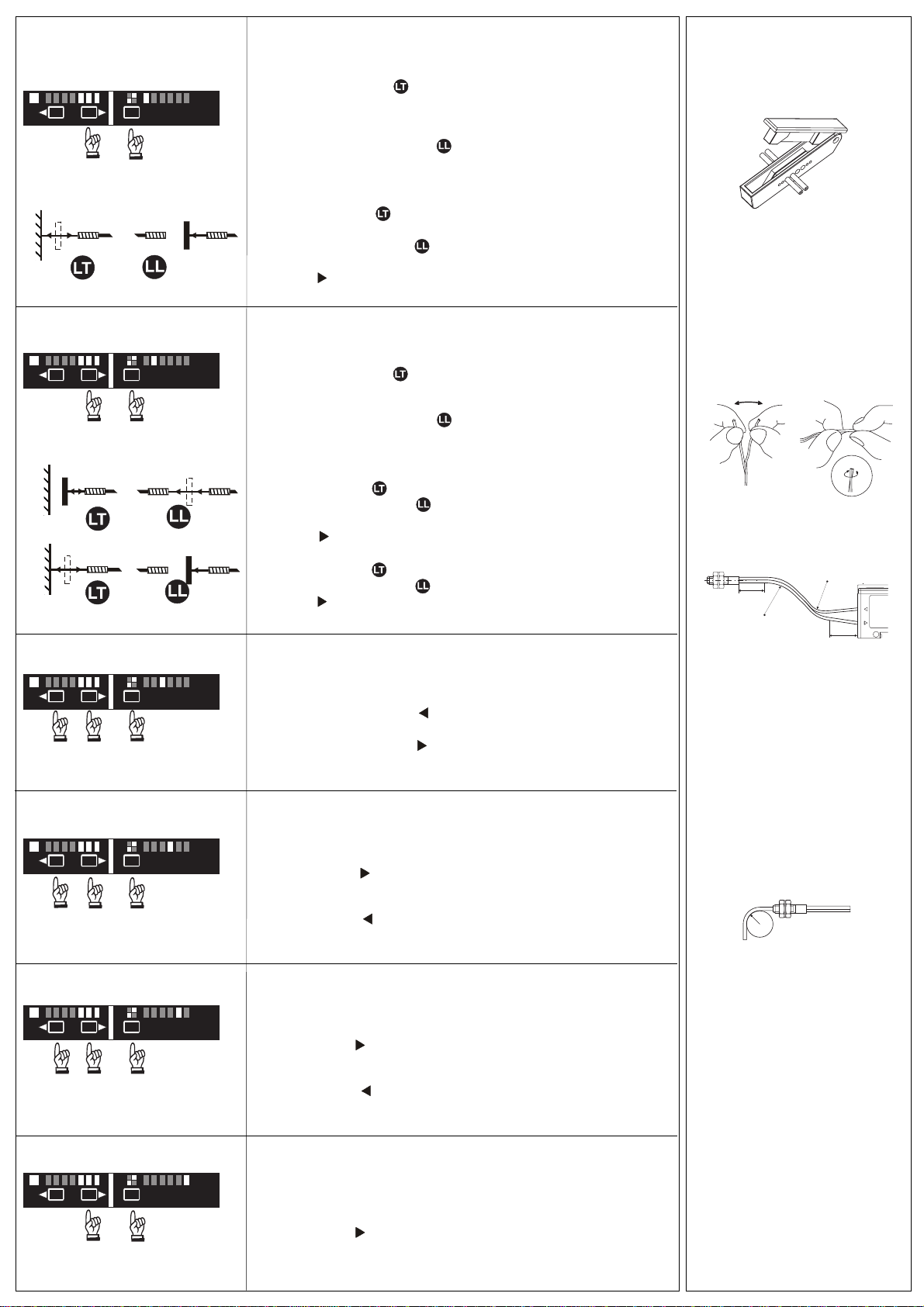

Max. distance / sensitivity

Remove target and background.

Execute Teach 1.

Placeemitterandreceiversothat

no light is transmitted. Execute

Teach 1.

Min. distance / sensitivity

Placefiber-opticheadabout5 mm

from white paper. Execute Teach

1.

Place emitter and receiver in

direct contact so that a maximum

of light is transmitted. Execute

Teach 1.

Remote teach launching

Launch by L signals or by closing

a contact at the “Teach” input.

Teach 1

: Remove target.

: Position target.

Send pulses T1 and T3.

Timing: T1, T3 = 0.5 ... 2 sec

T2 = 1.5 ... 2 sec

Teach 2

: Position target and back-

ground.

: Remove target.

Send pulse T1, then

: Remove target, leave back-

ground in position.

: Position target.

Send pulse T3.

Timing: T1, T3 = 0.5 ... 2 sec

T2 ≥≥

≥≥

≥3 sec

+U

A

0V

B

Teach

(1)

(4)

(2)

(3)

schwarz

noir

black

blau

bleu

blue

39 V

braun

brun

brown

39 V

39 V

rosa

rose

pink

100 k

6V8

47 k

47 k

DFT-AN-1A

200 mm

Ø4Ø 4

31,1

31,1

4

89

60

60

10

OUT

max

Time

Enter

Signal

Mode Status

Teach 1Teach 1

Teach 2Teach 2

Adjust

Delay

StretchStretch

Light-On

SWISS MADESWISS MADE

2,3

6,3

Ø 3,4Ø 3,4

46

46

35

3513

13

10,8

10,8

Ø4Ø 4

Device mounting

Mounting of the device is most

easily effected by snapping

/

onto a top-hat rail (according

to DIN / EN 50022).

Alternatively, fixing can be

effected using M3 screws

through the fixing holes

provided.

Toremove the device from the rail,

push towards the optical fiber ,

and lift .

Fixing the optical fibers

Lift catch .

Insert the optical fibers through

the two holes provided into

the device.

Lower catch .

Important:

Wheninserting the optical fibers,

the resistance of the device’s in-

ternal O-ring seal must be over-

come.

The optical fibers must be fed

right to the stop without fail.

The optical fibers must not be

crushed.

The sequence (emitter /

receiver) is usually immaterial,

however:

With coaxial optical fibers, the

optical fiber bundle must be

connected on the receiver side

. The emitter and receiver

openingsare markedwith arrows

on the housing.

Teach 1

Teach 2

Adjust

Delay

Stretch

Setting of the sensing range (teach) is carried out in one cycle, and can

be manually fine adjusted at any time (using the Adjust function, see

below).

Diffuse sensors : Teach only takes place on the background.

The target is not taken into consideration. The device adjusts

itself automatically to approximately 80% of the background

distance.

Through-beam sensors : Teach is effected with a target

located in the beam. The device automatically adjusts itself so

that approximately 80% of the darkening created by the target

triggers the switching process.

Diffuse sensors : Remove target, leave or place background in

position.

Through-beam sensors : Leave or place target in position.

Activate Teach 1 mode by pressing the Mode key twice.

Press /Enter key.Teach successful: The Status LED blinks green

for 5 seconds. The device is ready for use.

Setting of the sensing range (teach) is carried out in two cycles, and can

be manually fine adjusted at any time (using the Adjust function, see

below).

Diffuse sensors : Teach is effected firstly on the target, then

on the background. The device automatically adjusts itself to a

distance between that of the target and that of the background.

Through-beam sensors : Teach takes place firstly without the

target, then with the target located in the beam. The device

automatically adjusts itself to part of the darkening created by the

target.

Diffuse sensors : Position (or leave) target and background.

Through-beam sensors : Remove target.

Activate Teach 2 mode by pressing the Mode key 3 times.

Press /Enter key,the first cycle begins. Teach successful: The

Status LED lights up green. The device is ready for the second cycle.

Diffuse sensors : Remove target, leave background in position

Through-beam sensors : Position target.

Press /Enter key,the second cycle begins. Teach successful: The

Status LED blinks green for 5 seconds. The device is ready for use.

The detection zone can be set manually, or when set by the teach

function, can be manually fine adjusted. All activated functions (except

delay and stretch) are in operation, and the output switched.

Activate Adjust mode by pressing the Mode key 4 times.

For each press on the /Time key, the current detection zone is

increased by 1 increment.

For each press on the /Enter key, the current detection zone is

reduced by 1 increment.

Return to working mode by pressing the Mode key.

Switching of the output is delayed by the set time. In this way, short-term

disturbances can be suppressed. All activated functions (except delay

and stretch) are in operation, and the output switches.

Activate Delay mode by pressing the Mode key 5 times.

Pressing the /Enter key switches the delay (factory setting: 10

msec) on or off. The current status is shown by the Status LED (green

= Delay switched on).

Each time the /Time key is pressed, the delay time is increased by

10 msec, up to a maximum of 150 msec.

Return to working mode by pressing the Mode key.

Switching of the output is stretched by the set time. In this way, even

short pulses can be detected. All activated functions (except delay and

stretch) are in operation, and the output switches.

Activate Stretch mode by pressing the Mode key 6 times.

Pressing the /Enter key switches the stretching (factory setting: 10

msec) on or off. The current status is shown by the Status LED (green

= Stretch switched on).

Each time the / Time key is pressed, the stretch time is increased by

10 msec, up to a maximum of 150 msec.

Return to working mode by pressing the Mode key.

Setting of the output function (factory setting Light-ON, i.e. light switching

in operation as diffuse sensor, dark switching as through-beam sensor).

Activate Light-ON mode by pressing the Mode key 7 times. The current

status is shown by the Status LED (Light-ON LED off / Dark-ON

LED on).

Pressing the /Enter key changes the output function.

Return to working mode by pressing the Mode key.

Light/Dark-ON

Teach 1

Teach 2

Status

Mode

Adjust

Delay

Stretch

Light-ON

SWISS MADE

Signal

Time

max

OUT

Enter

Teach 1

Teach 2

Status

Mode

Adjust

Delay

Stretch

Light-ON

SWISS MADE

Signal

Time

max

OUT

Enter

Teach 1

Teach 2

Status

Mode

Adjust

Delay

Stretch

Light-ON

SWISS MADE

Signal

Time

max

OUT

Enter

Teach 1

Teach 2

Status

Mode

Adjust

Delay

Stretch

Light-ON

SWISS MADE

Signal

Time

max

OUT

Enter

Teach 1

Teach 2

Status

Mode

Adjust

Delay

Stretch

Light-ON

SWISS MADE

Signal

Time

max

OUT

Enter

Teach 1

Teach 2

Status

Mode

Adjust

Delay

Stretch

Light-ON

SWISS MADE

Signal

Time

max

OUT

Enter

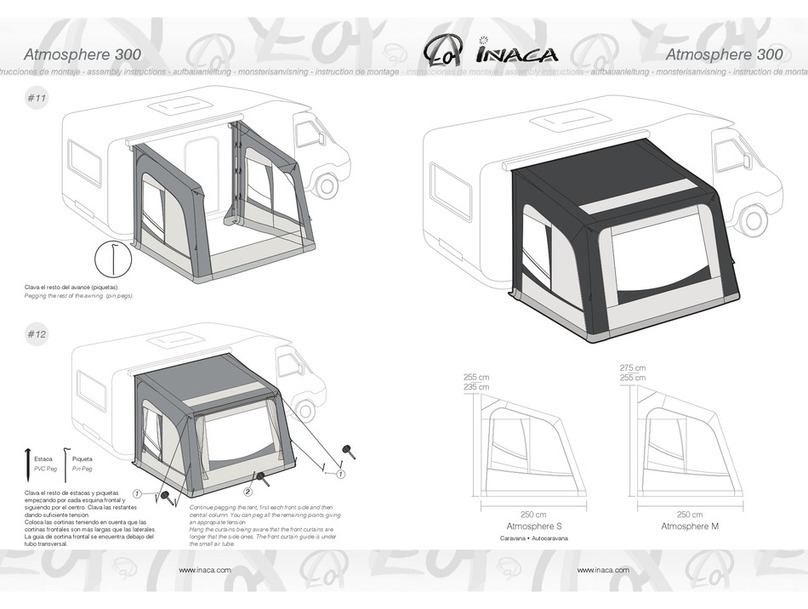

Cutting the optical fibers

Cut synthetic optical fibers to the

desired length. Use only the

cutting tool delivered with the

optical fibers.

A maximum of 3 cuts should be

made per cutting-tool hole.

Separating the optical fibers

Grasp the optical fiber ends with

both hands and pull both strands

apart to a length of about 50 mm.

According to the type (above all

for thin-fiber executions), prior

twisting helps.

Optical fiber mounting

(All diameters refer to the optical

diameter.)

No bending should occur in zone

“A”.

Fiber Ø 1 mm A ≥≥

≥≥

≥20 mm

Fiber Ø 0.5 mm A ≥≥

≥≥

≥10 mm

Fiber Ø 1.5 mm A ≥≥

≥≥

≥30 mm

High-flexibility fiber A ≥≥

≥≥

≥5 mm

Thebendingradius should not be

less than “R”.

Fiber Ø 1 mm R ≥≥

≥≥

≥25 mm

Fiber Ø 0.5 mm R ≥≥

≥≥

≥10 mm

Fiber Ø 1.5 mm R ≥≥

≥≥

≥40 mm

High-flexibility fiber R ≥≥

≥≥

≥2 mm

Bendablelight-outlet tubesshould

be bent as little as possible; best

bent around a cylindrical object.

Maximum 3 bends.

Tube Ø 2.5 mm r ≥≥

≥≥

≥20 mm

Tube Ø 1.2 mm r ≥≥

≥≥

≥10 mm

This product is protected by one or several of the

followingUSpatents:5182612,5767444,5675143,

5764351,6031430,6130489,6133654,6133988.

Furtherpatentspending.

A

A

R

R

split twist

r

Other AutomationDirect Accessories manuals