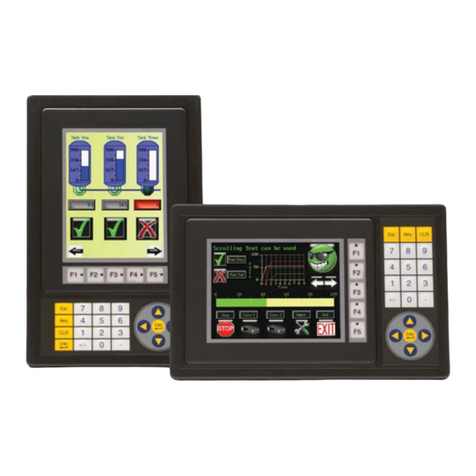

AutomationDirect Optimate OP-1212 User manual

OP-1212

Lamp/Pushbutton Panel

Manual Number OP-1212-M

WARNING

Thank you for purchasing automation equipment from Automationdirect.com™, doing business as,

AutomationDirect. We want your new automation equipment to operate safely. Anyone who installs or uses this

equipment should read this publication (and any other relevant publications) before installing or operating the

equipment.

To minimize the risk of potential safety problems, you should follow all applicable local and national codes that regulate

the installation and operation of your equipment. These codes vary from area to area and usually change with time. It is

your responsibility to determine which codes should be followed, and to verify that the equipment, installation, and

operation are in compliance with the latest revision of these codes.

At a minimum, you should follow all applicable sections of the National Fire Code, National Electrical Code, and the

codes of the National Electrical Manufacturer’s Association (NEMA). There may be local regulatory or government

offices that can also help determine which codes and standards are necessary for safe installation and operation.

Equipment damage or serious injury to personnel can result from the failure to follow all applicable codes and

standards. We do not guarantee the products described in this publication are suitable for your particular application,

nor do we assume any responsibility for your product design, installation, or operation.

Our products are not fault--tolerant and are not designed, manufactured or intended for use or resale as on--line control

equipment in hazardous environments requiring fail--safe performance, such as in the operation of nuclear facilities,

aircraft navigation or communication systems, air traffic control, direct life support machines, or weapons systems, in

which the failure of the product could lead directly to death, personal injury, or severe physical or environmental

damage (”High Risk Activities”). AutomationDirect specifically disclaims any expressed or implied warranty of fitness

for High Risk Activities.

For additional warranty and safety information, see the Terms and Conditions section of our Desk Reference. If you

have any questions concerning the installation or operation of this equipment, or if you need additional information,

please call us at 770--844--4200.

This publication is based on information that was available at the time it was printed. We at AutomationDirect

constantly strive to improve our products and services, so we reserve the right to make changes to the products and/or

publications at any time without notice and without any obligation. This publication may also discuss features that may

not be available in certain revisions of the product.

Trademarks

This publication may contain references to products produced and/or offered by other companies. The product and

company names may be trademarked and are the sole property of their respective owners. AutomationDirect

disclaims any proprietary interest in the marks and names of others.

Copyright 2010, Automationdirect.com™Incorporated

All Rights Reserved

No part of this manual shall be copied, reproduced, or transmitted in any way without the prior, written consent of

Automationdirect.com Incorporated.AutomationDirect retains the exclusive rights to all information included in

this document.

AVERTISSEMENT

Nous vous remercions d’avoir acheté l’équipement d’automatisation de Automationdirect.comMC, en faisant des affaires

comme, AutomationDirect. Nous tenons à ce que votre nouvel équipement d’automatisation fonctionne en toute sécurité.

Toute personne qui installe ou utilise cet équipement doit lire la présente publication (et toutes les autres publications

pertinentes) avant de l’installer ou de l’utiliser.

Afin de réduire au minimum le risque d’éventuels problèmes de sécurité, vous devez respecter tous les codes locaux et

nationaux applicables régissant l’installation et le fonctionnement de votre équipement. Ces codes diffèrent d’une région à

l’autre et, habituellement, évoluent au fil du temps. Il vous incombe de déterminer les codes à respecter et de vous assurer

que l’équipement, l’installation et le fonctionnement sont conformes aux exigences de la version la plus récente de ces

codes.

Vous devez, à tout le moins, respecter toutes les sections applicables du Code national de prévention des incendies, du

Code national de l’électricité et des codes de la National Electrical Manufacturer’s Association (NEMA). Des organismes de

réglementation ou des services gouvernementaux locaux peuvent également vous aider à déterminer les codes ainsi que

les normes à respecter pour assurer une installation et un fonctionnement sûrs.

L’omission de respecter la totalité des codes et des normes applicables peut entraîner des dommages à l’équipement ou

causer de graves blessures au personnel. Nous ne garantissons pas que les produits décrits dans cette publication

conviennent à votre application particulière et nous n’assumons aucune responsabilité à l’égard de la conception, de

l’installation ou du fonctionnement de votre produit.

Nos produits ne sont pas insensibles aux défaillances et ne sont ni conçus ni fabriqués pour l’utilisation ou la revente en tant

qu’équipement de commande en ligne dans des environnements dangereux nécessitant une sécurité absolue, par

exemple, l’exploitation d’installations nucléaires, les systèmes de navigation aérienne ou de communication, le contrôle de

la circulation aérienne, les équipements de survie ou les systèmes d’armes, pour lesquels la défaillance du produit peut

provoquer la mort, des blessures corporelles ou de graves dommages matériels ou environnementaux (”activités à risque

élevé”). La société AutomationDirect nie toute garantie expresse ou implicite d’aptitude à l’emploi en ce qui a trait aux

activités à risque élevé.

Pour des renseignements additionnels touchant la garantie et la sécurité, veuillez consulter la section Modalités et

conditions de notre documentation. Si vous avez des questions au sujet de l’installation ou du fonctionnement de cet

équipement, ou encore si vous avez besoin de renseignements supplémentaires, n’hésitez pas à nous téléphoner au

770--844--4200.

Cette publication s’appuie sur l’information qui était disponible au moment de l’impression. À la société AutomationDirect,

nous nous efforçons constamment d’améliorer nos produits et services. C’est pourquoi nous nous réservons le droit

d’apporter des modifications aux produits ou aux publications en tout temps, sans préavis ni quelque obligation que ce soit.

La présente publication peut aussi porter sur des caractéristiques susceptibles de ne pas être offertes dans certaines

versions révisées du produit.

Marques de commerce

La présente publication peut contenir des références à des produits fabriqués ou offerts par d’autres entreprises. Les

désignations des produits et des entreprises peuvent être des marques de commerce et appartiennent exclusivement à

leurs propriétaires respectifs. AutomationDirect nie tout intérêt dans les autres marques et désignations.

Copyright 2010, Automationdirect.com Incorporated

Tous droits réservés

Nulle partie de ce manuel ne doit être copiée, reproduite ou transmise de quelque façon que ce soit sans le consentement

préalable écrit de la société Automationdirect.com Incorporated.AutomationDirect conserve les droits exclusifs à

l’égard de tous les renseignements contenus dans le présent document.

1

Manual Revisions

If you contact us in reference to this manual, be sure to include the revision number.

Title: OP--1212 Lamp/Pushbutton Panel

Manual Number: OP--1212--M

Issue Date Effective Pages Description of Changes

Original 11/96 41 Original Issue

Rev. A 5/98 10

15 Added cable OP--2CBL--1

Changes per MU--OP--001, 5/7/97

Rev. B 5/2010 All Updated manual to present date

1i

Table of Contents

Getting Started

The Purpose of this Manual 2.........................................................

Configuration Software 2.............................................................

Supplemental Manuals 2.............................................................

Technical Assistance 2..............................................................

How the OP-1212 Works 3...........................................................

Using the Pushbutton Panel...5 Easy Steps 4............................................

Step 1: Prepare Your Labels (Pages 5--6) 4.............................................

Step 2: Install the Panel (Pages 7--14) 4...............................................

Step 3: Use OP--WINEDIT Software 4.................................................

Step 4: Configure the Panel to Work with your PLC (Pages 15) 4..........................

Step 5: Write the Ladder Logic (Pages 19--31) 4........................................

Preparing the Labels

Applying Text to Each Label 5........................................................

Template for Creating Labels 6.......................................................

Installing the Panel

Panel Specifications: 7................................................................

Physical Specifications 7.............................................................

Environmental Specifications 7.......................................................

Operating Specifications 7...........................................................

Dimensions for Mounting 8...........................................................

Power and Cabling Requirements 9....................................................

What Are Your Application Needs? 9..................................................

Programming Cable 10...............................................................

PLC to Panel Cable 10...............................................................

Choosing the Proper Connecting Cables 12..............................................

Connecting a Power Supply 14..........................................................

Power Supply Connections 14.........................................................

Connecting the Panel to your Personal Computer 15......................................

Assigning an Address to the OP-1212 15................................................

How to Set the Address 15............................................................

The Termination Resistor 15...........................................................

Using the OP--9001 to Connect Multiple Panels 16........................................

Understanding the OP-1212 Panel

Overview 17.........................................................................

Memory Mapping 17..................................................................

Lamps 17...........................................................................

Flashing the Lamps 18................................................................

LEDs and Separation Mode 18........................................................

Flashing the LEDs 18.................................................................

Force Functions 18...................................................................

ii Table of Contents

Applying Ladder Logic

General Concepts 19...................................................................

Memory Mapping 19..................................................................

Addressing Conventions 20...........................................................

Three Different Ways to Use the Panel 22...............................................

Method 1: Bit-of-Word DirectLOGIC and Allen-Bradley 22.................................

Method 2: Internal Relays (All Options Used) 22..........................................

Method 3: Remapping (Selected Options) 22............................................

Using bit--of--word with the OP--1212 23..................................................

Using Ladder Logic 23................................................................

Using All Functions with DirectLOGIC 24................................................

Using Ladder Logic 24................................................................

Using All Functions with the DL305 PLCs 25.............................................

Using Ladder Logic 25................................................................

Using Selected Functions with DirectLOGIC PLCs (not DL305 PLCs) 26....................

Using the Remapping Process 26......................................................

Using Ladder Logic with DirectLOGIC PLCs 27..........................................

Using Ladder Logic with the DL305 29..................................................

Using the OP-1212 with an Allen-Bradley PLC 31.........................................

Using Ladder Logic with Allen--Bradley PLC 31..........................................

Troubleshooting the OP-1212 Panel

Troubleshooting 32...................................................................

Panel Configuration 32...............................................................

Panel to PLC Communications 33......................................................

Panel Operation 33...................................................................

European Union Directives

Technical Support 35.................................................................

SELV Circuits 35.....................................................................

Environmental Specifications 35.......................................................

Preventative Maintenance and Cleaning 35..............................................

External Fuse Protection for Input Power 35.............................................

Appendix A: Worksheets

Index

Getting Started

2

Getting Started

This manual shows you how to install, operate and maintain the OP-1212 Lamp

Pushbutton Panel. It includes wiring diagrams and power requirements, as well as

the information you need for selecting the proper connecting cables.

All OptiMate panels are configured using

the OptiMate OP--WINEDIT

configuration software.

OP--WINEDIT software is compatible

with computers running

Windows 95/98/2000/NT/XP.

OP--WINEDIT is ordered as a separate

item from the OptiMate panel from

AutomationDirect.

The software is loaded onto your

personal computer and simple follow the

setup instructions in the supplied user

manual and the built--in HELP screens.

The software allows setup of your

complete application, including the type

of PLC being used.

Note that OP--WINEDIT is also used to

configure the OP--9001,

Communications Master panel. The

software can be used with Allen--Bradley

PLCs.

There are several other manuals you will find helpful or necessary:

DRespective PLC User Manual for the PLC(s) you are using with the OptiMate

panel.

DOP--9001--M Communications Master User Manual provides details of how to

use the OP-9001 for connecting multiple OP-Panels to a single CPU.

DDirectSOFTtUser Manual--Shows you how to use the DirectSOFT

Windows software to write your ladder logic for DirectLOGICtPLCs.

If you are not successful with implementing the information in this manual, you may

call AutomationDirect technical support at (800) 633-0405, Monday through Friday

from 9:00 A.M. to 6:00 P.M. Eastern Standard Time. The technical support team will

work with you to answer your application questions. If you have a comment or

question about our products, services, or manuals which we provide, please fill out

and return the suggestions card included with this manual.

The Purpose of

this Manual

Configuration

Software

Supplemental

Manuals

Technical

Assistance

Getting Started 33

The purpose of the panel is to provide you with both pushbuttons (12) and lamps (12)

so that you can have status and control functions that will work with your PLC. An

additional benefit of this panel is found in the LEDs that are in the upper left hand

corner of each pushbutton. These LEDs can operate as indicators to reflect the

status of the individual pushbutton, or they can operate independent of the

pushbutton status. The LEDS can turn ON or OFF and even flash for added

attention.

To link the pushbuttons, LEDs, and lamps to your PLC, the OP-1212 uses a

technique called “memory mapping”. This technique ties the pushbuttons, LEDs,

and lamps to specific reserved areas of memory in the PLC. You can use any

available memory as long as it is consecutive.

The base register address is entered during configuration using the OPWinEdit

software. Each of the functions for the pushbuttons, LEDs, and lamps are

controlled by the status of their assigned bits within the memory words that you

have reserved. You interface these words of memory through your ladder logic.

Prior to connecting the OP-1212 to

your PLC, load the OP--WINEDIT

configuration software onto your

personal computer, and begin to

define how you want to use the

functions that have been designed

into the panel. Among other

decisions, you are prompted to fill in

a base register address. In the

example we have shown here, we

have used V40600 as the start of

the mapped memory addresses.

The same OP--WINEDIT

configuration software used for the

AutomationDirect product is also

used for the Allen-Bradley product.

As you move through the screens,

one of the key items you complete

is the base register address for

storing data relative to the

pushbuttons. In the example, we

have used N7:0 as the start of the

mapped memory addresses. This

means the PLC file number is 7 and

the base address is 0.

How the OP-1212

Works

AutomationDirect

Allen-Bradley

Getting Started

4

Using the Pushbutton Panel...5 Easy Steps

First, you need to prepare the labels for each of

the pushbuttons and lamps. The labels insert

into plastic sleeves behind the main cover. To

access the sleeve, you merely snap loose the

front bezel.

Preparing for installation, you will want to

check the individual specifications. These

include dimensions, power requirements,

cabling requirements, and NEMA ratings.

We include information you will need for

mounting; i.e. cutout dimensions, cabling

requirements, components needed, etc.

External Power

Cables

You will need the OP--WINEDIT configuration

software in order to configure the panel and

PLC. OP--WINEDIT is ordered as a separate

item from the OptiMate panel from

AutomationDirect.

The software is used for both DirectLOGIC

and Allen--Bradley PLCs.

After setting a DIP switch on the rear of the panel

and attaching the programming cable, you are

ready to configure your panel. The simple and

easy-to-follow screens make configuration a

painless process.

DIP

Switch

The amount of ladder logic programming

knowledge you need is very basic. In most

cases, you are already familiar with the

elements of logic that are required. We’ll

give you examples in the final section of

this manual, and you will see right away

just how easy it is.

C100

OUT

C101

Y10

OUT

Y11

Step 1: Prepare

Your Labels

(Pages 5--6)

Step 2: Install the

Panel

(Pages 7--14)

Step 3: Use

OP--WINEDIT

Software

Step 4: Configure

the Panel to Work

with your PLC

(Pages 15)

Step 5: Write the

Ladder Logic

(Pages 19--31)

Preparing the Labels 5

Preparing the Labels

Preparing the labels for the OP--1212 panel requires you to slide a legend

transparency into two pockets in the panel overlay. Use the following procedure:

1. Remove the bezel from the module by unsnapping the four tangs that hold the

bezel to the module frame.

2. Create a legend transparency. There are several ways of doing this. A template is

provided on the next page that gives you the available dimensions. The nicest

legends result from using a computer graphics program and a laser printer to

create the transparency.

Bezel

Finished Legend

Window Frame

Insert legend between window

frame and cabinet

3. Slide the finished legend into the pocket space between the window frame and

LED bars.

4. Re--attach the bezel by snapping the bezel onto the case.

Applying Text to

Each Label

Preparing the Labels

6

Template for Creating Labels

0.60

0.15

0.40

0.20

0.35

3.00

0.10

Dimensions in Inches

0.10

0.15

0.07

3.60

0.60

0.70

3.00

Installing the Panel 7

Installing the Panel

In this section you will be given all of the information you need to install the panel.

Before actually installing the OP-1212 panel, it may be helpful to examine the

specifications and make sure that the requirements of your application are met.

Panel Specifications:

Weight 18 ounces...............................

Panel Fasteners Four 6x32 threaded studs.......................

NEMA Rating NEMA 4..........................

Operating Temperature 0°to 50°C.................

Storage Temperature --20°to 80°C...................

Operating Humidity 5 to 95% (non-condensing).....................

Air Composition No corrosive gases permitted........................

Power Budget Requirement 7 VA @ 8 -- 30 VDC.............

570 mA @ 12 VDC (all Lamps and

LEDs ON)

285 mA @ 24 VDC (all Lamps and

LEDs ON)

Power Connector Removable Terminal Block...................... 2 position

Absolute Maximum Voltage 32 VDC..............

Diagnostics Power On, CPU...........................

Communication Link RS232 or RS422.................... 4800, 9600 and 19200* baud

15 pin female D type connector

*Only 4800 and 9600 baud will work

with Allen-Bradley PLCs.

Physical

Specifications

Environmental

Specifications

Operating

Specifications

Installing the Panel

8

Dimensions for Mounting

8.85

8.40

0.75

Example panel mounting

Dimensions in Inches

0.5

1.75

Cutout Area

0.23

0.16 DIA

2.00

3.50

3.50

Installing the Panel 9

Power and Cabling Requirements

Your communication cable requirements depends on your particular application.

There are two types of configuration possibilities: point-to-point (a single operator

interface connected to a PLC) and multi-drop (multiple operator interfaces

connected to a PLC).

DPoint-to-Point -- If you only need one operator interface connected to one

PLC, then choose the appropriate cables from the chart on page 11.

DMulti-drop -- By using an OptiMate OP--9001 Communications Master,

multiple Optimate units can be connected to a single PLC. Up to 31 individual

units can be connected in a daisy-chain fashion to the OP--9001.

Communications are via RS422 between the OP--9001 and the operator

interfaces. When using a quality shielded cable, a total distance of up to 4000

feet between the OP--9001 and the last operator interface unit in the chain

can be achieved. If the distance is 30 feet or less, a ribbon cable with

easy-to-install crimp-on ribbon connectors can be used.

OP-9001

Power Supply OP-panels

DL405 CPU Base

Power

Source

1. Point-to-Point

A single cable connection

from the PLC to the panel

gives you access to the

PLC’s data registers and

ladder logic.

2. Multi-drop

Multiple OP-panels can be interfaced to a single PLC.

This requires the use of the OP-9001 Communications

Master. With the Communication Master, up to 31

panels can be interfaced to a single CPU port. Each can

be programmed for entirely different functions. Panels

can be distributed up to 4000 feet* from the OP-9001.

*NOTE: Please read and follow the cabling requirements in the OP-9001 User

Manual (OP-9001-M) when using multiple panels. Failure to follow the guidelines of

the User Manual may affect the integrity of the RS422 link, resulting in

communication errors.

What Are Your

Application

Needs?

Installing the Panel

10

The diagrams shown below give the connector specifications including the pinouts

for each end of the available connecting cables.

The OP-ACBL--1 is used to connect your OP-1212 panel to your computer for

programming.

OP-ACBL--1

This cable must be used to configure the panel.

Computer

Panel

1= not used

2= Dout

3= Din

4= not used

5= 0V

6= not used

7= not used

8= not used

9 = not used

10= not used

11= not used

12= not used

13= not used

14= not used

15= not used

5= 0V

4= not used

3= Dout

2= Din

1= not used

9=not used

8= CTS

7= RTS

6=not used

DB9 DB15

33

22 55

7

8

1

15

1

9

The OP-ACBL--1 (shown above) is also used to connect Allen-Bradley SLC 5/03 and

5/04 PLCs to an OP-1212 panel. Since the OP-1212 is compatible with all of the

DirectLOGIC PLCs, the cabling requirements will vary depending on the PLC type

being used. Refer to the table on the next page for matching the proper cable to your

PLC. Pin diagrams refer to the ends of the cables and not the communication ports.

Programming

Cable

PLC to Panel Cable

Installing the Panel 11

OP-2CBL

OP-3CBL

OP-4CBL--1

OP-4CBL--2

See the next page for matching your PLC to the correct cable.

1234

PLC

Panel

345621

1= 0V

2= not used

3= Din

4= Dout

5= not used

6= not used

1= Din

2= Dout

3= not used

4= 0V

8= YOM

7= CTS

6= not used

5= not used

4= On-line

3= Din

2= Dout

1= YOP

8= not used

7= 0V

6= not used

5= CTS

4= RTS

3= Din

2= Dout

1= not used

1= not used

2= Dout

3=Din

4= not used

5= 0V

6= not used

7= not used

8= not used

9= not used

10= not used

11= not used

12= not used

13= not used

14= not used

15= not used

13= not used

12= not used

11= not used

10= not used

9= not used 21= not used

20= not used

19= not used

18= not used

17= not used

16= not used

15= not used

14= not used

25= not used

24= not used

23= not used

22= not used

RJ12

RJ11

RJ12 (PLC) DB15

43

23

RJ11 (PLC)

23

21

DB15

54

DB15 (PLC)

23

23

DB15

54

RJ12

RJ11 DB15

DB15

DB15

DB15DB25

DB15

13

14

15

1

7

8

DB25 (PLC)

23

23 57

4

5

DB15

51

1

25

1

15

15= tied (0V)

14= tied (0V)

13= tied (0V)

12= not used

11= not used

10= not used

9= not used

1

15

OP-ACBL--2

Mini--DIN DB15

DB15

73

24 52

34

2

5

7

1

68

8 Pin Mini DIN

Din +

Din --

Dout +

Dout --

RTS+

CTS+

RTS--

CTS--

= Dout+

= Dout --

= Din--

= Din +

PLC Panel

11

12

9

10

0V =0V

5

RS422 Pinout

O P -- 2 C B L -- 1

8= not used

7= 0V

6= not used

5= CTS

4= RTS

3= RXD

2= TXD

15-pin (PLC)

23

23

DB15

57

DB15

15-pin

15= not used

14= not used

13= not used

12= not used

11= not used

10= not used

9= not used

4

5

Installing the Panel

12

Choosing the Proper Connecting Cables

OptiMate Cables

F

a

m

i

l

y

CPU

P

o

r

t

C

a

b

l

e

F

am

i

l

y

C

P

U

(or other device)

P

ort

C

a

b

l

e

DirectLOGIC

D

L

0

5

:

D

0

-

-

0

5

Port 1 (RJ12) OP-2CBL

DL05

D

L

0

5:

D

0

--

0

5Port 2 (RJ12) OP-2CBL

DirectLOGIC

D

L

0

6

:

D

0

-

-

0

6

Port 1 (RJ12) OP-2CBL

DL06

D

L

0

6

:

D

0

--

0

6

Port 2 (15 pin) OP-2CBL--1

DirectLOGIC

DL105 DL105: F1--130 One port (RJ12) OP--2CBL

D2--230 One port (RJ12) OP--2CBL

D

2

-

-

2

4

0

Top port (RJ12) OP--2CBL

D

i

rec

t

LOGIC

D

2

--

2

4

0

Bottom port (RJ12) OP--2CBL

D

i

r

e

c

t

L

O

G

I

C

DL205 D2--250--1 Top port (RJ12) OP--2CBL

D2--260 Bottom port (15 pin) O P -- 2 C B L -- 1

D2--DCM (module) Only one (25 pin) O P -- 4 C B L -- 2

D3--330 Requires DCU* O P -- 4 C B L -- 2

D3--330P Requires DCU* OP-4CBL--2

D

i

rec

t

LOGIC

D

3

-

-

3

4

0

Top port (RJ11) OP-3CBL

D

i

r

e

c

t

L

O

G

I

C

DL305

D

3

--

3

4

0

Bottom port (RJ11) OP-3CBL

D

3

-

-

3

5

0

Top port OP-2CBL

D

3

--

3

5

0

Bottom port OP-4CBL--2

D

4

-

-

4

3

0

Top port (15-pin) OP-4CBL--1

D

4--4

3

0

Bottom port (25-pin) OP-4CBL--2

D

4

-

-

4

4

0

Top port (15-pin) OP-4CBL--1

D

i

t

L

O

G

I

C

D

4--44

0

Bottom port (25-pin) OP-4CBL--2

DirectLOGIC

DL405 Phone Jack (RJ12) OP-2CBL

D

L

4

0

5

D4--450 Top port (15-pin) OP-4CBL--1

Bottom port (25-pin) OP-4CBL--2

D4--DCM (module) One port (25-pin) OP-4CBL--2

Slice I/O panels One port (15-pin) OP-4CBL--1

GE®Series 1 IC610CPU105, 106 Requires DCU* OP-4CBL--2

GE®Series

90/30 All models (311--351) RS422 serial port Not available

GE®Fanuct

Series 90 Micro All models RS422 serial port Not available

MODICON ModBus RS45 OP--MCBL--1

OptiMate Panel Cables

Depending on which PLC you are

using, you may require as many

as two cables--one to connect the

panel to a personal computer for

configuration; and one to

connect the panel to the PLC.

Here are the requirements:

DOP-ACBL-1: all units require this

cable for configuration. This isa 9-pin

male to 15-pin male cable that

connects your personal computer to

the OptiMate unit. (This cable is also

used to connect an OptiMate panel to

the Allen-Bradley SLC--500 PLC.

DCPU Cables: You will also need the

appropriate cable to connect your

CPU to the OptiMate unit. Use the

chart shown to the right to choose the

correct communications cable.

DOP-ACBL-2: The8PinMini--DINisa

non standard connector used for the

Micrologix 1000. We recommend

using the OP--ACBL--2 cable and

modifying the length for any

applications between 6.56 -- 50 ft.

OP--9001 Cable Connectors

If you’re planning to use multiple

panels and an OP--9001, then

you’ll need to build your own

custom cables. Since the proper

cable choice really depends on

your application, we offer the

following connectors.

DOP--CMCON--1 — pack of 4 ribbon

cable connectors.

DOP--CMCON--2 — pack of 4

solder-type connectors.

For electrically noisy environments,

we recommend a good shielded

cable, such as Belden 9729 or

equivalent. This type of cable will

require the solder-type connectors.

If you’re going 30 feet or less, you

can use ribbon cable. For ribbon

cable, we recommend Belden

9L28015 or 3M 3365/15. See

Page 14 for more information.

* requires RS232 Data Communications Unit (D3--232--DCU)

** also DC versions

Installing the Panel 13

OptiMate Cables (cont’d)

F

a

m

i

l

y

CPU

P

o

r

t

C

a

b

l

e

F

am

i

l

y

C

P

U

(or other device)

P

ort

C

a

b

l

e

325--07, PPX:325--07 Requires DCU* OP-4CBL--2

330--37, PPX:330--37 Requires DCU* OP-4CBL--2

TI305t/

S

I

M

A

T

I

C

®325S--07 (or 325 w/ Stage Kt) Requires DCU* OP-4CBL--2

S

IM

A

TI

C

®

TI305t330S--37, PPX:330S--37 Requires DCU* OP-4CBL--2

T

I

3

0

5

3

3

5

-

-

3

7

P

P

X

:

3

3

5

-

-

3

7

Phone Jacks (RJ11) OP-3CBL

3

3

5--

3

7,

P

P

X

:

3

3

5--

3

7If DCU is used* OP-4CBL--2

425--CPU, PPX:425--CPU ** One port (15-pin) OP-CBL--1

4

3

0

-

-

C

P

U

P

P

X

:

4

3

0

-

-

C

P

U

Top port (15-pin) OP-4CBL--1

TI405t/

S

I

M

A

T

I

C

®

4

3

0

--

C

P

U

,

P

P

X

:4

3

0

--

C

P

U

Bottom port (25-pin) OP-4CBL--2

S

IM

A

TI

C

®

TI405t

4

3

5

-

-

C

P

U

P

P

X

:

4

3

5

-

-

C

P

U

*

*

Top port (15-pin) OP-4CBL--1

T

I

4

0

5

4

3

5--

C

P

U

,

P

P

X

:4

3

5--

C

P

U

*

*

Bottom port (25-pin) OP-4CBL--2

Smart SlicetI/O panels One port (15-pin) OP-4CBL--1

Allen-Bradley

SLC500 5/03

5/04 Bottom port OP-ACBL--1

Allen--Bradley Micrologix1000/1200/1500 One port (8--pin Mini

Din) OP-ACBL--2

* requires RS232 Data Communications Unit (D3--232--DCU)

** also DC versions

Installing the Panel

14

Connecting a Power Supply

The OP-1212 panel can operate on DC voltages between 8 and 30 VDC rated at 7

watts. Connect the panel to a power supply (within the required voltage range and

wattage) using the terminal block connector supplied. The connector is polarized to

prevent reversing the connections. The male receptacle on the rear of the panel will

only connect in one way with the female connector that is supplied with your

OP-1212 panel. Pin 1 is the positive connection, while Pin 2 is the negative, or

ground, connection.

You must use an external power supply that

can deliver voltages in the 8 to 30 VDC

range, and can supply 7 watts of power.

Install the female connector to

a cable for attachment to your

power supply.

+GND

A two-prong male con-

nector is on the rear of

the unit. Your OP-panel is

shipped with the female

connector.

Model Current Consumed at 12VDC

OP-1212 240mA (all Lamps and LEDs OFF)

570mA (all Lamps and LEDs ON)

120mA (all Lamps and LEDs OFF)

285 mA (all Lamps and LEDs ON)

Current Consumed at 24VDC

NOTE: Consult our catalog or website, www.automationdirect.com, to purchase a power

supply.

Power Supply

Connections

Table of contents

Other AutomationDirect Control Panel manuals