1

Sales 800-633-0405 www.productivity2000.com

®

Warranty: Thirty-day money-back guarantee. Two-year limited replacement.

(See www.productivity2000.com for details).

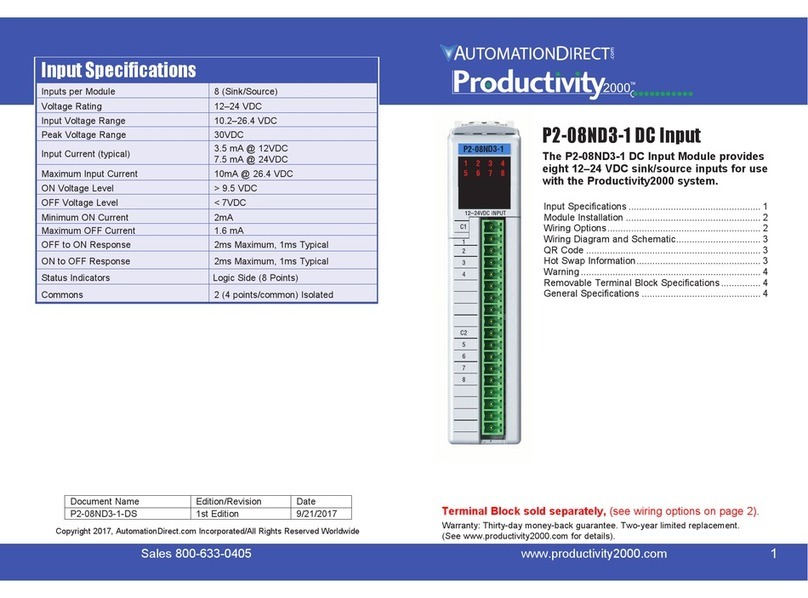

P2-HSI High-Speed Pulse Input

The P2-HSI High-Speed Input Module provides

dierential (line receiver, 5V max) and single

ended (5–24 V) inputs that accept up to 1MHz

of pulse/direction and quadrature signals on

each of the two independent input channels.

Additionally, four 5–24 VDC general purpose

high-speed inputs and four general purpose

5–24 VDC, 0.5A outputs are included for use

with any Productivity2000 System.

Warning .................................. 1

Connector Specifications..................... 1

QR Code ................................. 1

General Specifications ...................... 2

Status LEDs .............................. 2

Status Output Specifications .................. 2

Power Specifications ........................ 2

Single Ended (5–24 V) Input Specifications ...... 3

Differential (5V) Input Specifications ............ 3

Hot Swap Information ....................... 3

Module Installation ......................... 4

Wiring Options............................. 4

Frequency Measurement Details .............. 5

5V Encoder Inputs Wiring Diagram............. 6

24V Encoder Inputs Wiring Diagram............ 6

Status Inputs Wiring Diagram ................. 7

Status Outputs Wiring Diagram................ 7

Sinking I/O Wiring Diagram................... 8

Sourcing I/O Wiring Diagram ................. 8

Document Name Edition/Revision Date

P2-HSI-DS 4th Ed. 5/14/2020

Copyright 2018, AutomationDirect.com Incorporated/All Rights Reserved Worldwide

WARNING: To minimize the risk of potential safety problems, you

should follow all applicable local and national codes that regulate the

installation and operation of your equipment. These codes vary from

area to area and it is your responsibility to determine which codes

should be followed, and to verify that the equipment, installation, and

operation are in compliance with the latest revision of these codes.

Equipment damage or serious injury to personnel can result from

the failure to follow all applicable codes and standards. We do not

guarantee the products described in this publication are suitable for

your particular application, nor do we assume any responsibility for

your product design, installation, or operation.

If you have any questions concerning the installation or operation

of this equipment, or if you need additional information, please call

Technical Support at 770-844-4200.

This publication is based on information that was available at the

time it was printed. At AutomationDirect.com®we constantly strive to

improve our products and services, so we reserve the right to make

changes to the products and/or publications at any time without notice

and without any obligation. This publication may also discuss features

that may not be available in certain revisions of the product.

Connector Specifications

Connector Type IDC style header with latch, Omron XG4A-4034

Number of Pins 40 point

Pitch 0.1 in (2.54 mm)

QR Code

Use any QR Code reader application to

display the module’s product insert.