Page 12 IronHorse GSD5 DC Drives User Manual – 1st Ed, Rev E – 05/13/2020

1)

Recheck all wiring. Accidental grounds, loose or pinched wires on armature or speed pot wires may

damage the DC drive when power is applied.

2)

Check to see that the incoming power is of the correct voltage.

3)

Turn the speed pot to zero (fully CCW).

4)

Turn power on, and advance the speed pot while observing motor direction of rotation.

Power must be turned off again before step 5 can be accomplished!

5)

If the motor rotation is incorrect, turn power off at external disconnect, and reverse the +ARM and

-ARM connections.

6)

Check for satisfactory operation throughout the speed range.

7)

If operation is satisfactory, no readjustments are needed.

8)

If instability or surging is observed, or if maximum speed is higher than desired, refer to the “Trim

Pot Adjustments” section.”

9)

For other problems, consult the “Troubleshooting” section.

If the system is unstable after the previous Start-Up procedure, then adjust the trimpots as follows.

These adjustments are maintained, and periodic readjustments are not normally needed. However,

readjustments could be needed if the drive is operated beyond ±10% of the rated line voltage.

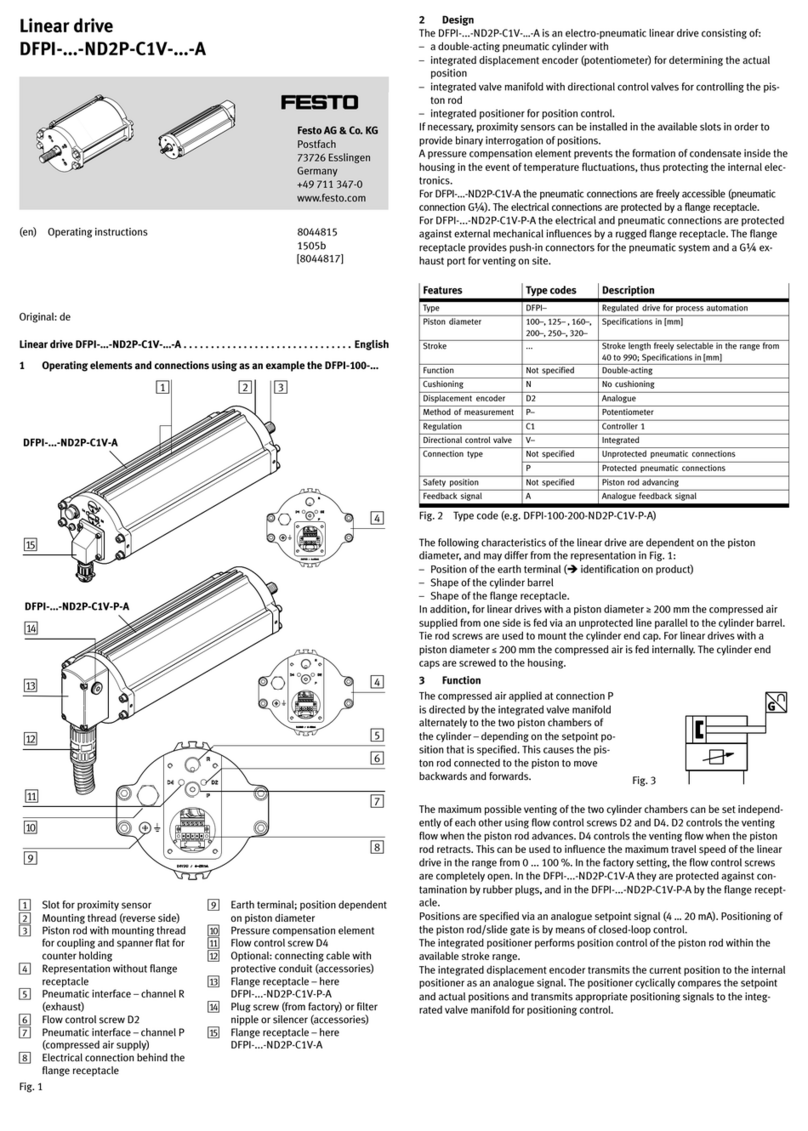

GSD5-240-10C, GSD5-240-10N4, GSD5-240-10N4-R Trim Pot Adjustment *

Sets maximum motor speed

when speed pot is set at

maximum (fully CW rotation).

CW rotation of MAX trim pot

increases maximum motor

speed.

1) TURN DRIVE POWER OFF!!

2) Connect a DC voltmeter: + to +ARM; - to -ARM.

3) Set meter voltage range: (90 VDC for 120 VAC; 180 VDC for 240 VAC).

4) Turn power on. Set Speed pot at 100%.

5) Adjust MAX trim pot to rated motor armature voltage as shown on meter.

NOTE: A tachometer or strobe may be used in lieu of a meter. Follow above

steps, except adjust MAX trim pot to rated motor base speed indicated by

tachometer or strobe.

Sets minimum motor speed

when speed pot is set at zero.

CW rotation will increase

minimum motor speed.

1) Set Speed pot to zero (fully CCW).

2) Rotate MIN trim pot CW until motor starts to rotate.

3) Slowly rotate MIN trim pot CCW until motor stops.

NOTE: If motor rotation is desired, rotate MIN trim pot CW until desired

MIN speed is reached.

Calibrates speed regulation.

Provides a means of

improving motor speed

regulation in the armature

feedback mode. If a

slowdown due to load change

is of no concern, rotate this

trim pot fully CCW.

1) Set Speed pot at 50%.

2) Observe motor speed at no load condition.

3) Apply full load to motor.

4) Turn IR COMP trim pot CW to obtain the same motor speed as with no load.

Limits DC motor armature

current (torque) to prevent

damage to the motor or

drive. The current limit is set

for the rated motor current.

CW rotation of this trim pot

increases the armature current

(or torque produced).

1) TURN DRIVE POWER OFF!

2) Connect a DC Ammeter between A1 on motor and +ARM on drive. This is

in series with the motor.

3) Turn power ON.

4) Set Speed pot at the 50% position.

5) Apply friction braking to motor shaft until motor stalls (zero rpm).

6) With motor stalled, set current at 125% of rated motor armature current by

adjusting CUR. LIM. trim pot.

Allows adjustment of

acceleration by user. CW rotation of the ACCEL trim pot increases acceleration time.

* Adjustments are performed with motor connected to drive.

DO NOT USE this adjustment procedure for GSD5-240-10C DC drives with GSDA-AI-A analog current input cards, for

GSD5-240-10N4-A drives, or for GSD5-240-10N4-V drives.

** For Max and Min adjustments of the GSD5-240-10C DC drive with GSDA-AI-A analog input cards, the GSD5-240-

10N4-A drive, or the GSD5-240-10N4-V drive, refer to the adjustment procedures on the following page.