2

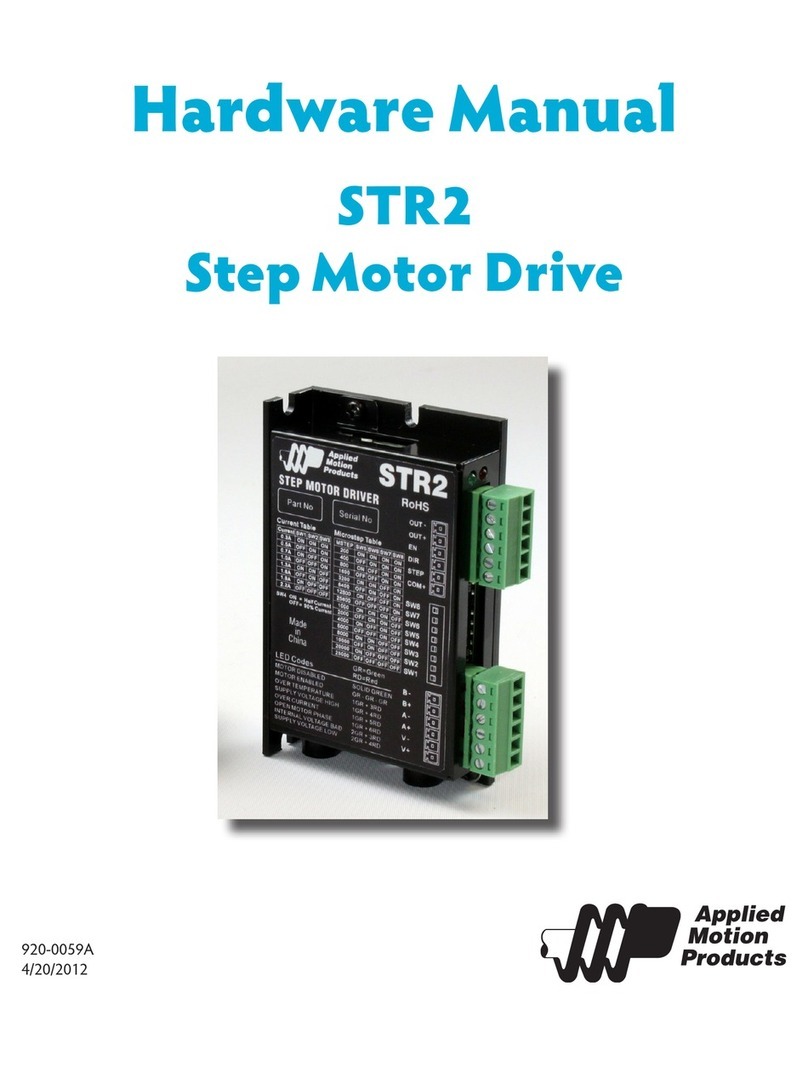

5000-235-001 STR2M

920-0067A

1/10/2013

Contents

Safety Instructions ............................................................................................................................................................................................................................. 3

Introduction........................................................................................................................................................................................................................................... 5

Features .................................................................................................................................................................................................................................................... 5

Block Diagram....................................................................................................................................................................................................................................... 6

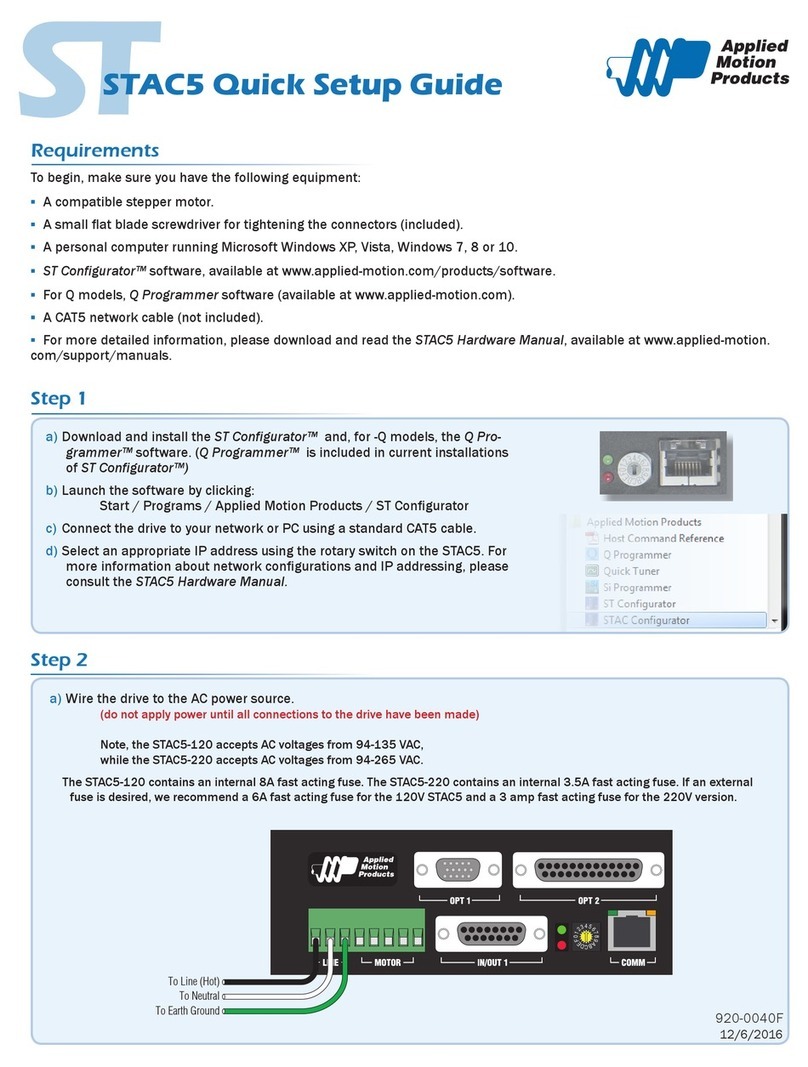

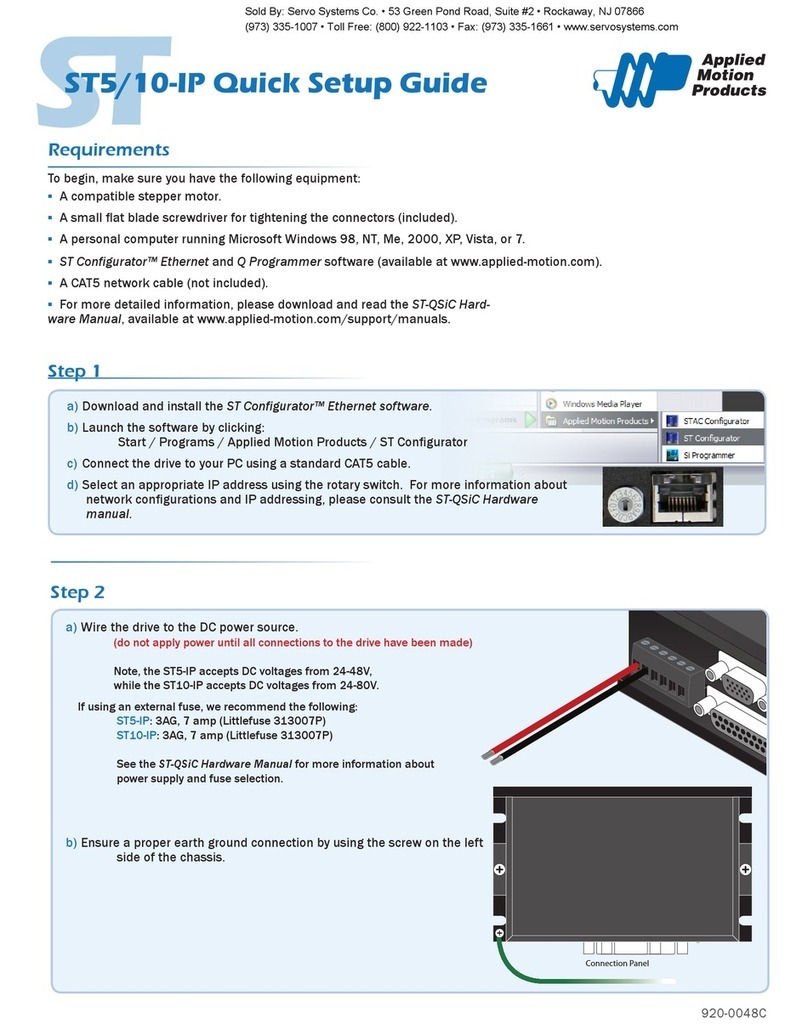

Geing Started..................................................................................................................................................................................................................................... 7

Mounting the Drive........................................................................................................................................................................................................................... 8

Connecting the Power Supply.................................................................................................................................................................................................... 8

Choosing a Power Supply........................................................................................................................................................................................................... 10

Voltage ......................................................................................................................................................................................................................................... 10

Current ......................................................................................................................................................................................................................................... 10

Multiple Drives Sharing One Power Supply ........................................................................................................................................................... 11

System Wiring Recommendations ......................................................................................................................................................................................... 12

Connecting the Motor.................................................................................................................................................................................................................. 13

Four Lead Motor ................................................................................................................................................................................................................... 13

Eight Lead Motor.................................................................................................................................................................................................................... 13

Connecting Input Signals............................................................................................................................................................................................................. 14

Connection Examples: STEP & DIR .............................................................................................................................................................................. 14

Connector Pin Diagram....................................................................................................................................................................................................... 14

Internal Circuit Diagram...................................................................................................................................................................................................... 14

Connection Examples: EN.................................................................................................................................................................................................. 15

FAULT Output................................................................................................................................................................................................................................... 16

Conguring the Drive.................................................................................................................................................................................................................... 17

Step 1: Seing the Current ............................................................................................................................................................................................... 17

Step 2: Seing Idle Current.............................................................................................................................................................................................. 18

Step 4: Step Size...................................................................................................................................................................................................................... 19

Step 5: Step Pulse Type...................................................................................................................................................................................................... 21

Step 6: Step Pulse Noise Filter......................................................................................................................................................................................... 21

Self Test................................................................................................................................................................................................................................................. 22

Drive Heating............................................................................................................................................................................................................................ 23

Mechanical Outline............................................................................................................................................................................................................... 24

Technical Specications...................................................................................................................................................................................................... 25

Mating Connectors and Accessories........................................................................................................................................................................... 26

Alarm Codes............................................................................................................................................................................................................................. 27

Connector Diagrams............................................................................................................................................................................................................. 27