M-system RPPD User manual

RPPD

EM-1693 Rev.7P. 1 / 6

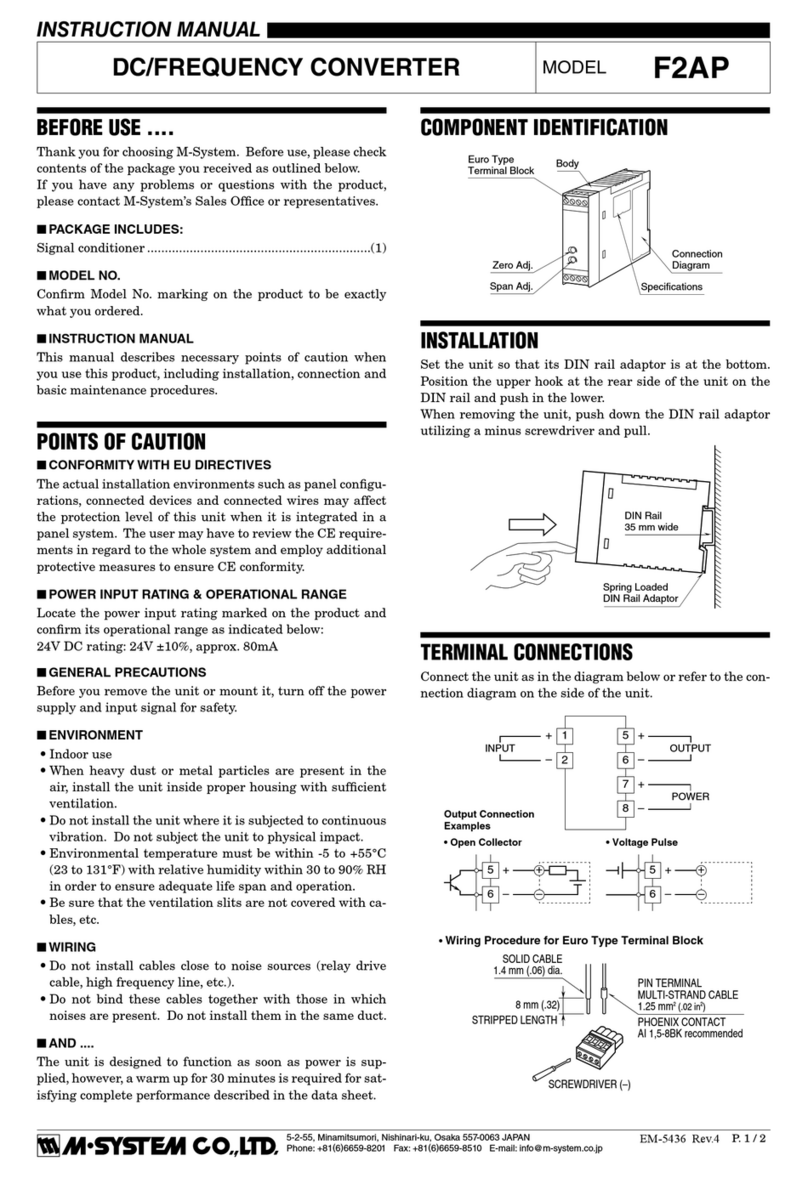

COMPONENT IDENTIFICATION

The shape of base socket may be different

for some models.

■ HOW TO OPEN THE FRONT COVER:

Position your finger on the hook at the top of front cover and

pull.

INSTRUCTION MANUAL

MODEL RPPD

PULSE ISOLATOR

(built-in excitation; rotary encoder use)

BEFORE USE ....

Thank you for choosing M-System. Before use, check the

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System's Sales Office or representatives.

■ PACKAGE INCLUDES:

Signal conditioner (body + base socket) ..................... (1)

Ordering Information Sheet ....................................... (1)

■ MODEL NO.

Check that model No. described on specification label is

exactly what you ordered.

■ INSTRUCTION MANUAL

This manual describes necessary points of caution when you

use this product, including installation and connection, hard-

ware setting, and basic maintenance procedures.

This unit is factory adjusted and calibrated according to the

Ordering Information included in the product package. If you

don't need to change the pre-adjusted setting, you can skip

the sections on hardware setting and calibration in this

manual.

POINTS OF CAUTION

■ CONFORMITY WITH CE EMC DIRECTIVE

• Install lightning surge protectors for those wires connected

to remote locations. For 24V DC power supply line, choose a

surge protector with its maximum surge voltage 40V or less

between lines. Recommended M-System model: MDP-D24.

■ POWER INPUT RATING & OPERATIONAL RANGE

• Check the power rating for the unit on the specification label.

85 – 132V AC rating: 85 – 132V, 47 – 66 Hz, approx. 5.5VA

12, 24, and 48V DC ratings: Rating ±10%, approx. 3.3W

110V DC rating: 85 – 150V DC, approx. 3.3W

■ UNPLUGGING THE UNIT

• Before you remove the unit from its base socket or mount it,

turn off the power supply and input signal for safety.

■ ENVIRONMENT

• Indoor use

• When heavy dust or metal particles are present in the air,

install the unit inside proper housing with sufficient ventila-

tion.

• Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

• Environmental temperature must be within -5 to +60°C (23

to 140°F) with relative humidity within 30 to 90% RH in order

to ensure adequate life span and operation.

■ WIRING

• Do not install cables (power supply, input and output) close

to noise sources (relay drive cable, high frequency line, etc.).

• Do not bind the unit's cables together with cables where

high noise levels are present. Do not install them in the same

duct.

■ AND ....

• The unit is designed to function as soon as power is

supplied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data sheet.

Body Base Socket

Connection

Diagram Label

Front Cover

Specification

Label

Front Cover (open)

Input Monitor LED PL2

Input Monitor LED PL1

■ FRONT PANEL CONFIGURATION

Clamp

(top & bottom)

DIN Rail

35mm wide

Spring Loaded

DIN Rail Adaptor

Shape and size of the base socket

are slightly different with various

socket types.

INSTALLATION

Detach the yellow clamps located at the top and bottom of the

unit for separating the body from the base socket.

■ DIN RAIL MOUNTING

Set the base socket so that its

DIN rail adaptor is at the bot-

tom. Position the upper hook

at the rear side of

base socket on the DIN rail

and push in the lower. When

removing the socket, push

down the DIN rail

adaptor utilizing a minus

screwdriver and pull.

■ WALL MOUNTING

Refer to the drawings in the

next page.

RPPD

EM-1693 Rev.7P. 2 / 6

5678

21

1110

80 (3.15)

50 (1.97) 107 (4.21)

136 (5.35) [3.3 (.13)]

80 (3.15)

20

(.79)

35.4 (1.39)

40 (1.57)

50 (1.97)

7.8 (.31)

CLAMP

(top & bottom)

DIN RAIL

35mm wide

2–4.5 (.18) dia.

MTG HOLE

25 (.98) deep

11–M3.5

SCREW

•When mounting, no extra space is needed between units.

39

4

Input Connection Examples ■Open Collector

Output Connection Examples

+

–

1

2

+

–

■Voltage Pulse

+

–

1

2

+

–

+

–

10

11

+

–

+

–

10

11

+

–

+

–

OUTPUT 1

1

2

U(+)

V(–) POWER

7

8

+

–

INPUT 1

3

4

+

–

OUTPUT 2

10

11

+

–

INPUT 2

9

6

5

SENSOR EXC.

+

–

OUTPUT 1

1

2

U(+)

V(–) POWER

7

8

+

–

3

4

+

–

5

6

Sensor excitation not provided for RS-422 line driver input.

+

–

OUTPUT 2

10

11

■RS-422 LINE DRIVER INPUT

ROTARY

ENCODER

5

9

6

+

10kΩ

100Ω

100Ω

■Dry Contact

+

–

–

3

4

+

–

Vsns

PWR

■2-Wire Current Pulse

•Built-in Excitation

5

9

6

+

Vsns

2-WIRE

PICK-UP

100Ω

3

4

–

2-WIRE

PICK-UP

•External DC Supply

5

9

6

–

2-WIRE

PICK-UP

+

+

DC SUPPLY

–

100Ω

3

4

–

2-WIRE

PICK-UP

+

+

DC SUPPLY

–

■Voltage Pulse

5

9

6

+

+

–

–

Vsns

PWR

3

4

+

–

–

+

A

φ

B

φ

A

φ

B

φ

■Power Photo MOSFET Relay

•AC Powered

1

2

LOAD

Relay or

Counter

Coil

Varistor or Spark

Quenching Circuit

•DC Powered

1

2

LOAD

Relay or

Counter

Coil

Spark Quenching

Diode

+

–

■RS-422 Line Driver Pulse

2

+

–

+

–

1

+

–

11

+

–

+

–

10

TERMINAL CONNECTIONS

Connect the unit as in the diagram below or refer to the connection diagram label on top of the unit.

■ DIMENSIONS mm (inch)

■ CONNECTION DIAGRAM

RPPD

EM-1693 Rev.7P. 3 / 6

FUNCTION & FEATURES

•Galvanically isolating pulse rate signals from a rotary

encoder

•Maximum input/output frequencies: 100 kHz

•Minimum input pulse width: 5 µsec. (dry contact, voltage/

current pulse input)

•Monitor LED provided to check that input pulses are

provided.

•Accepting a wide variety of input: 0.5 – 50V at the input

terminals

•Pulse logic can be converted.

•RS-422 line driver pulse input acceptable; converted into

dry contact or voltage pulse output.

•For one-shot output, a pulse rise or drop can be selected for

synchronization.

•Output 1 is available with power photo MOSFET relay.

H

L

VOLTAGE PULSE

or

RS-422 LINE DRIVER PULSE

OUTPUT WAVEFORM

OPEN COLLECTOR

or

PHOTO MOSFET RELAY

The pulse width in one-shot means the bold lined section of a pulse waveform.

*Pulse rise for RS-422 line driver pulse can not be detected.

No pulse width conversion

One-shot, detecting input pulse rise

Non

Inverted

VOLTAGE PULSE,

2-WIRE CURRENT PULSE or

RS-422 LINE DRIVER PULSE

DRY CONTACTINPUT WAVEFORM

H

H

L

H

H

L

L

H

L

OFF

ON

L

L

H

One-shot, detecting input pulse drop

H

L

No pulse width conversion

One-shot, detecting input pulse rise

Inverted

H

H

L

H

H

L

L

L

L

H

One-shot, detecting input pulse drop

OFF

ON

No pulse width conversion

One-shot, detecting input pulse rise

Non

Inverted

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

One-shot, detecting input pulse drop

No pulse width conversion

One-shot, detecting input pulse rise

Inverted

One-shot, detecting input pulse drop

*

*

*

*

I/O PULSE LOGIC

RPPD

EM-1693 Rev.7P. 4 / 6

HARDWARE SETTING & CALIBRATION

■ SW1 & 2 FUNCTIONS (SW1: Input 2, SW2: Input 1, SW1-3 and SW2-3 are used commonly to both inputs.)

■ INPUT FILTER

The tables below show the maximum frequency which can

pass through the filter when the sensitivity level is set to 2V.

The frequency may change according to the sensitivity level.

After turning the filter ON, check that the PL1 and PL2 blink

according to the input signals. If they do not, readjust the

sensitivity according to the instructions in the following

section.

•Noise Filter Type 1 (SW1/2–5 = ON)

DC Coupling AC Coupling

(SW1/2–8 = ON) (SW1/2–8 = OFF)

V p-p (V)

MAX. FREQ. (Hz)

V p-p (V)

MAX. FREQ. (Hz)

5 69 5 22

12 35 12 65

24 89 24 112

•Noise Filter Type 2 (SW1/2–6 = ON)

DC Coupling AC Coupling

(SW1/2–8 = ON) (SW1/–8 = OFF)

V p-p (V)

MAX. FREQ. (Hz)

V p-p (V)

MAX. FREQ. (Hz)

5 1220 5 256

12 329 12 664

24 851 24 1090

Sensitivity Adj. (V

H

)

Sensitivity Adj. (V

L

)

Sensor Excitation Adj.

O

N

2

1

3

4

5

6

7

8

Set each switch referring

to the table below.

O

N

2

1

3

4

5

6

7

8

SW2

SW1

Set each switch referring

to the table below.

(front cover open)

Input Monitor LED PL1

Input Monitor LED PL2

There is no need of hardware adjustment

for RS-422 line driver pulse input.

Unnecessary switches or LEDs are not provided.

SWITCH INPUT MODEL SUFFIX CODE

NO. SW FUNCTION A B C D H

SW1,2

– 1 ON with dry contact input (model suffix: A) ON OFF OFF OFF OFF

2ON with 2-wire current pulse input (model suffix: H) OFF OFF OFF OFF ON

3

SW1–3: Adjustable range of sensitivity level for V

L

(ON: 0 – 10V, OFF: 0 – 5V)

ON or OFF OFF

ON or OFF

OFF

SW2–3: Adjustable range of sensitivity level for V

L

(ON: 0 – 10V, OFF: 0 – 5V)

(required level)

(required

Refer to the section "SENSITIVITY ADJUSTMENT". level)

4Always ON ON

5Noise filter Type 1 (ON: with, OFF: without)

6Noise filter Type 2 (ON: with, OFF: without)

7Attenuator for input signal (ON: with, OFF: without) OFF * OFF * OFF OFF * OFF

Input voltage is attenuated to half the original amplitude with this switch ON.

(one-third for the model number suffix code A.)

8Input pulse sensing method (ON: DC coupled, OFF: AC coupled) ON

Turn this switch off with a 10V or greater offset.

*Set to ON with excitation voltage ≥24V.

ON or OFF according to the noise level. Refer

to the tables below for the max. frequency

which can pass through the filter.

RPPD

EM-1693 Rev.7P. 5 / 6

■ SENSITIVITY ADJUSTMENT

You can change the detection level with the sensitivity adj.

located behind the front cover. The VHdetermines the pulse

rise and the VLdetermines the pulse fall. With SW1/2-7 set

to ON, the input signal is scaled down by 1/2 (1/3 for the model

number suffix code A). Be sure that the sensitivity levels are

also scaled down by 1/2 (1/3 for the model number suffix code

A). See the Ordering Information Sheet included in the

package for the factory settings.

For the RS-422 line driver pulse input, there is no need of

adjustment because a line receiver conforming with the RS-

422 standard is incorporated.

•How to Change the Sensitivity

A voltmeter of class 0.5 or better accuracy with pointed

probes is required.

1) Connect the negative probe of voltmeter to the terminal 4

(6) of base socket. See the figure to the right.

2) If you need a noise filter, turn on the SW1/2–5 or SW1/2–

6.

3) Connect the positive probe to the test hole No. 2 and turn

the VHpotentiometer until the meter shows desired

value.***

4) Connect the positive probe to the test hole No. 3 and turn

the VLpotentiometer until the meter shows desired

value.***

5) Apply input signal and check that input monitor LED

(PL1 or PL2) blinks according to the input signal.****

***For the VH(VL) sensitivity level less than 5V, turn off the

SW2–3 (SW1-–3). For less than 10V, turn on the SW2–3

(SW1–3).

The voltage values approx. half the amplitude are recom-

mended for normal use.

You had better have a reasonable span between VHand VLin

order to prevent noise interference.

****If the LED does not blink correctly, the sensitivity level

may be out of the pulse amplitude. Check the offset, ampli-

tude, etc. and go through the adjustment procedure again.

Amplitude

Vinp-p

t

Volts

Sensitivity Level

Input Monitor LED

V

H

V

L

VOLTAGE PULSE (example)

Amplitude

Vinp-p

t

Volts

The voltage which remains across

the terminals with contact ON

V

H

Exc.

V

L

0V

OFF

ON

0V

DRY CONTACT (example)

1

2

+

3

+

V

H

V

L

–

Connect to

Terminal 4 (6)

of the base

socket.

Voltmeter

Test Holes

Input Monitor LED (PL1)

Sensitivity Adj. (VH)

Sensitivity Adj. (VL)

Input Monitor LED (PL2)

(front cover open)

RPPD

EM-1693 Rev.7P. 6 / 6

■ SENSOR EXCITATION ADJUSTMENT

You can change the sensor excitation voltage with the sensor

excitation adj. located behind the front cover. If you need to

change it, check that the required current is within the

specification.

•How to Change the Excitation

A voltmeter and ammeter of class 0.5 or better accuracy are

required.

1) Connect the voltmeter across the terminals 9 – 6.

2) Connect the ammeter to terminal 9.

3) Turn the potentiometer until the meter shows the desired

value.

Check that the current value indicated on the ammeter is

within the allowable limit. If the value is greater than the

limit, lower the voltage value or connect a separate power

source. Otherwise, the transmitter may fail.

25

5

12

24

60 120

CURRENT (mA)

VOLTAGE (V)

Voltage (V) ×Current (A) ≤600mW

MAINTENANCE

■ TROUBLESHOOTING

Refer to the flow chart below.

V

A

Ammeter

Voltmeter

+

–OUTPUT 1

1

2

U(+)

V(–) POWER

7

8

+

–

INPUT 1 3

4

+

–OUTPUT 2

10

11

+

–

INPUT 2

9

6

5

SENSOR

EXC.

Checking & Maintenance

To TERMINAL CONNECTIONS (P.2)

End of Checking

Is the power supply voltage (Terminal 7 – 8) at the proper level?

Is the load connected to sensor excitation within allowance?

Check that the load resistance meets the described specification.

All wires connected

according to the connection

diagram?

Is the PL1 blinking

according to the input signal?

To HARDWARE SETTING & CALIBRATION,

Refer to the sensitivity adjustment. (P.5)

Check the input connection again and make

sure that the input matches descriptions

in the ordering information sheet.

No

Yes

No

To HARDWARE SETTING & CALIBRATION,

Refer to the SW1 setting. (P.4)

No

Yes

Is the PL2 blinking

according to the input signal?

Yes

Yes

M-SYSTEM WARRANTY

M-System warrants such new M-System product which it manufactures to be free from defects in materials and workmanship during the 36-month period following the date that such

productwasoriginallypurchasedifsuchproducthasbeenusedundernormaloperatingconditionsandproperlymaintained,M-System'ssoleliability,andpurchaser'sexclusiveremedies,

under this warranty are, at M-System's option, the repair, replacement or refund of the purchase price of any M-System product which is defective under the terms of this warranty. To

submit a claim under this warranty, the purchaser must return, at its expense, the defective M-System product to the below address together with a copy of its original sales invoice.

THIS IS THE ONLY WARRANTY APPLICABLE TO M-SYSTEM PRODUCT AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. M-SYSTEM SHALL HAVE NO LIABILITY FOR CONSEQUENTIAL, INCIDENTAL OR

SPECIAL DAMAGES OF ANY KIND WHATSOEVER.

M-System Co., Ltd., 5-2-55, Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN, Phone: (06) 6659-8201, Fax: (06) 6659-8510, E-mail: [email protected]

Table of contents

Other M-system DC Drive manuals