R-18

GP-S070

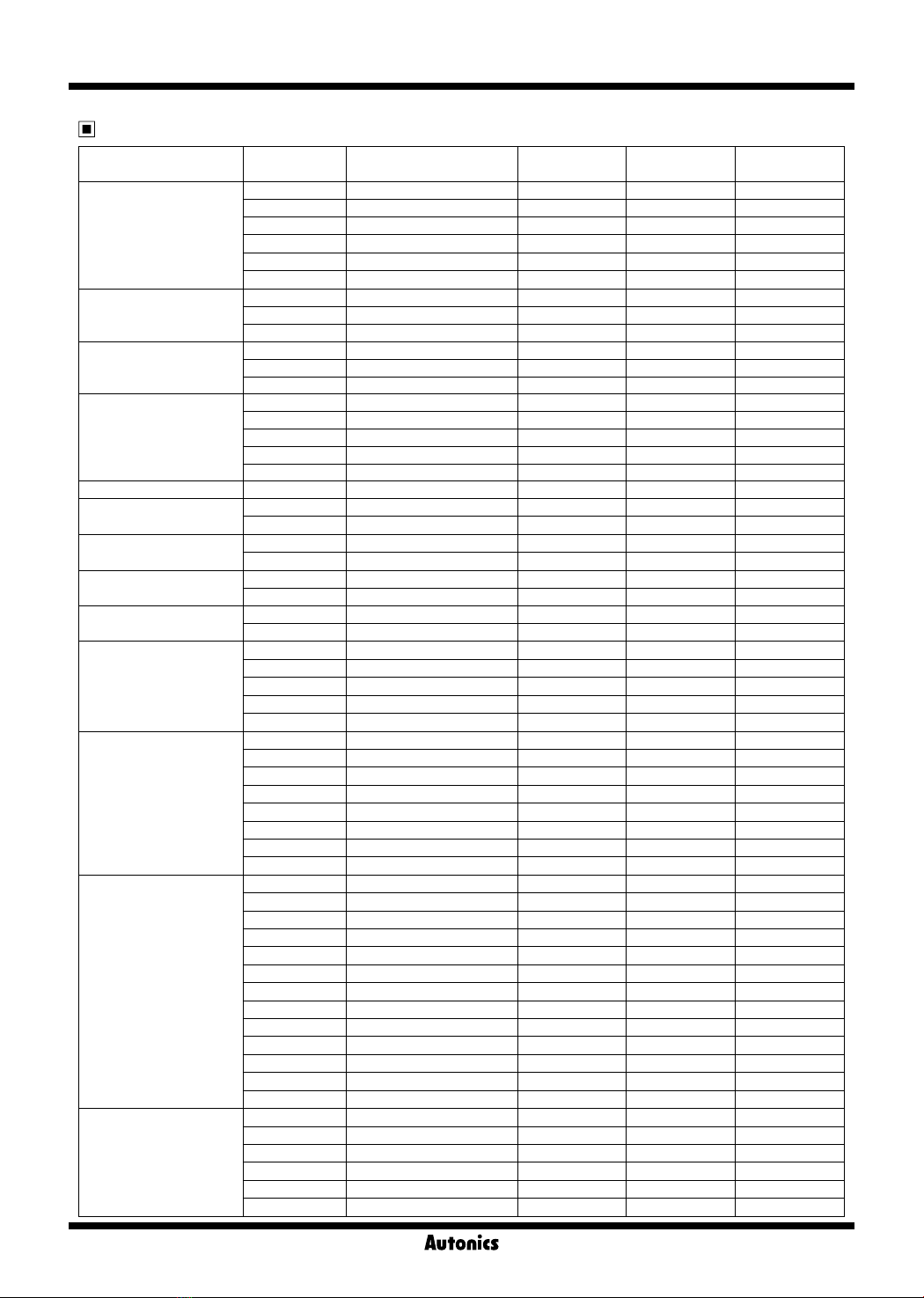

Model GP-S070-T9D6 GP-S070-T9D7

Power supply 24VDC

Allowable voltage range 90 to 110% of power supply

Power consumption Max. 7.2W

Display performance

LCD type 7 inch TFT Color LCD

Resolution 800×480 dots

Display area 152.4mm×94.44mm

Color 16,777,216 color

LCD view angle Within each 50°/ 60°/ 65°/ 65°of top/bottom/left/right

Backlight White LED

Brightness Adjustable by software

Graphic drawing

performance

Language※1English, Korean

Text • Vector font • 6×8, 8×8 ASCII character, high denition numbers

• 8×16 ASCII characters, 16×16 regional characters(1 to 8 times bigger for width, 0.5 to 5 times bigger for height)

Graphic drawing memory 16MB

Number of user screen 500 pages

Touch switch Analog touch

Serial interface Asynchronous method: Each port of RS232C, RS422

Each port of RS232C, RS422 Two ports of RS232C

USB interface Each of USB HOST, USB Device(Version 1.1)

Ethernet interface IEEE802.3(U), 10/100Base-T

Real-time controller RTC embedded

Battery life cycle Approx. 3 years at 25℃

Insulated resistance Min. 100MΩ(at 500VDC megger)

Ground 3rd grounding(max. 100Ω)

Noise resistance ± 0.5kV the square wave noise(pulse width: 1㎲) by the noise simulator

Withstanding voltage 500VAC 50/60Hz for a minute

Vibration Mechnical 0.75mm amplitude at frequency of 10 to 55Hz(for 1 min.) in each of X, Y, Z directions for 1 hour

Malfunction 0.5mm amplitude at frequency of 10 to 55Hz(for 1 min.) in each of X, Y, Z directions for 10 min.

Shock Mechanical 300m/s²(approx. 30G) in each of X,Y,Z directions for 3 times

Malfunction 100m/s²(approx. 10G) in each of X,Y,Z directions for 3 times

Environ

-ment

Ambient temperature 0 to 50℃, storage: -20 to 60℃

Ambient humidity 35 to 85% RH, storage: 35 to 85%RH

Protection IP65F for front panel

Accessory Fixing bracket: 4EA, Battery(included)

Approval

Unit weight Approx. 520g

Figure display Line, rectangle, circle, text, bitmap

Tags

Numeral display Displays the designated device as numerical value.(decimal, hexadecimal, octal, binary, real number)

ASCII display Displays the designated device value as ASCII character.

Time display Displays current time or date.

Alarm history Registers alarm history.

Alarm list Displays generated (not backed up) alarm.

Comment display Displays the designated comment as device status or value.

Lamp Displays lamp as device status.

Part display Displays the designated parts as device status and value.

Line graph Displays several device values with a graph of broken line.

Trend graph Displays change of device value for time with a graph of broken line.

Bar graph Displays a device value with a bar graph.

Statistic graph Displays a ratio of several device values with pie graph.

Panel meter Displays a device value as panel meter.

Touch key Screen is switched, word/bit device values are set when it touched.

Numeral input Congures user input value in device.

ASCII input Congures user input ASCII code value in device.

System information function Monitors/Controls GP operation from PLC.

Recipe function Reads/Writes several PLC device collectively.

Security function Only acceptable user can observe/operate important data.

Barcode read function Connects barcode reader, read barcode.

Floating alarm function Warning message is oated when alarm is generated.

Time operation Specic bit device is ON/OFF for designated day and time.

Overlap window Available to form dynamically overlapping another base screen on the base one.

Observe status function Changes PLC device status/value of PLC when trigger is generated.

※1: Language can be customized.

※Environment resistance is rated at no freezing or condensation.

Specifications

Functional description