AUTROFIELDBUS Protocol Converter, BSD-321/EX

Autronica Fire and Security AS

Fire and Security, Trondheim, Norway. Phone: + 47 73 58 25 00, fax: + 47 73 58 25 01

Oil & Gas, Stavanger, Norway. Phone: + 47 51 84 09 00, fax: + 47 51 84 09 99

Maritime Sales, Spikkestad, Norway. Phone: + 47 31 29 55 00, fax: + 47 31 29 55 01

Visit Autronica Fire and Security’s website: www.autronicafire.com

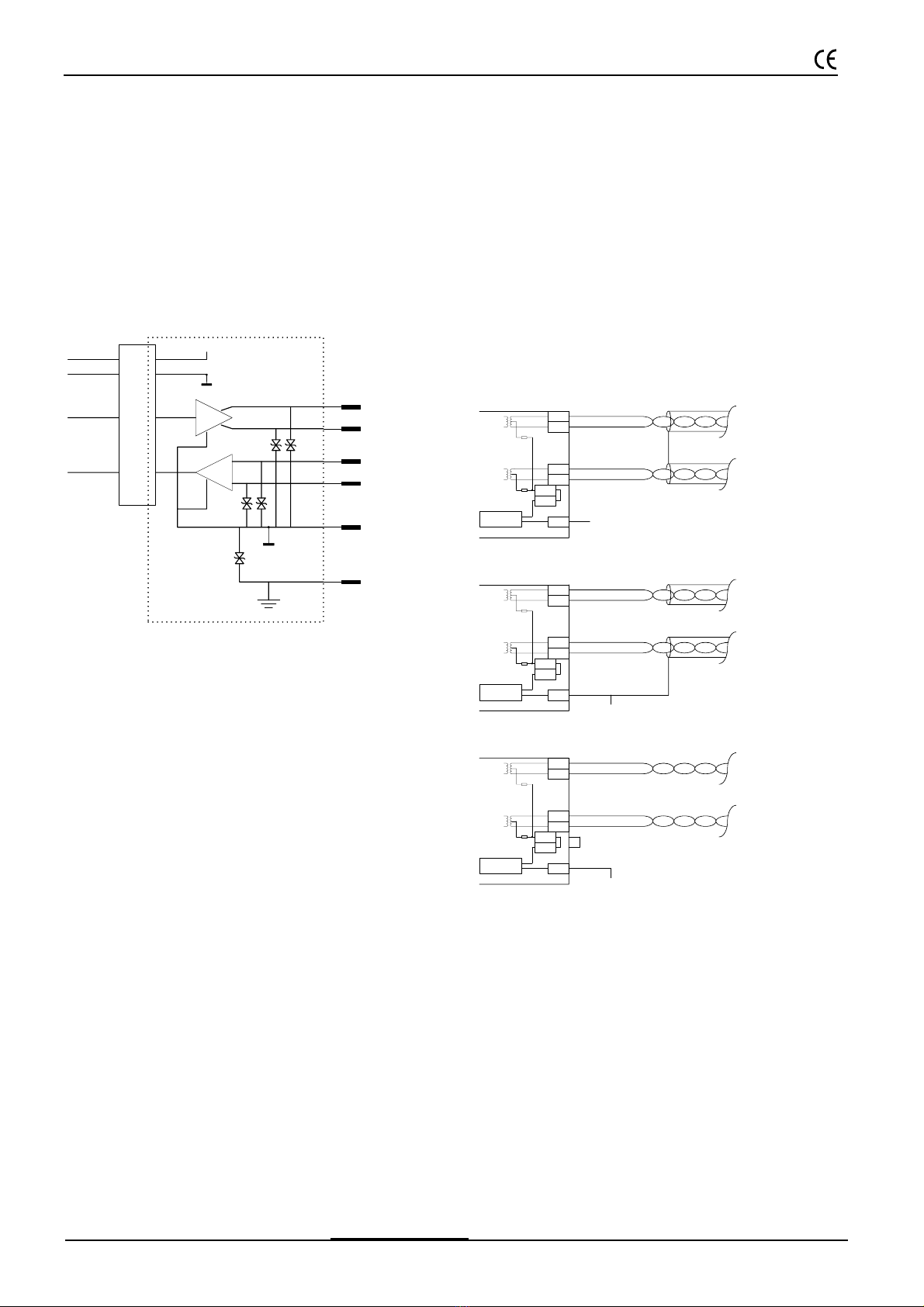

The BSD-321 is intended for use with 24VDC power

supplies. It may be used in single or dual earth sys-

tems.

19

20

21

BSD-321/Ex

+24V

0V

DC power supply

+24 in

0V in

IE

PE-bar

BSD-321/Ex power,

Single earth system

19

20

21

BSD-321/Ex

+24V

0V

DC power supply

+24 in

0V in

IE

PE-bar

BSD-321/Ex power,

Dual earth system

System IE

System PE

For further earth & shielding information reference

to the System Description AutroSafe IFG.

Order number: 116-P-ASAFE-IFG/XE.

RS-485 Detector interface with loop-back

4

6

8

13

15

17

AA

BB

A

B

ref

BSD-321/Ex detector

AA

BB

A

B

ref

BSD-321/Ex detector

A

B

RS-485 cable shielding

RS-485 cable shielding

RS-485 earth

fault sensor

RS-485 earth

fault sensor

RS-485 branch connection (local loop-back):

RS-485 loop connection (remote loop-back):

Port 0

Port 1

Port 0

Port 1 4

8

13

15

17

6

Loop-back of RS-485 can be done either locally on

BSD-321 or remotely with loop to/from detector.

The BSD-321 requires a RS-485 loop-back connec-

tion. Loop-back is used to give increased system

safety. The extra port verifies the communication

path. This also opens the option to using RS-485

loop connection for dual communication paths to the

detectors.

Loop-back for optimum safety is required for SIL2

applications (To be approved).

Switches S1 and S2 must be set accordingly for

correct termination.

Local loop-back:

• Set S2-6 OFF (Disable EOL resistor for port 1)

• The detector at the other end of the RS-485 bus

must enable its EOL resistor

Remote loop-back:

• Set S2-6 ON (Enable EOL resistor for port 1)

• None of the detectors must have EOL resistors

Earth fault detection on the RS-485 bus

Earth fault detection is enabled on the RS-485 link

by when S2-2 is ON. The monitoring circuit monitors

unintended connection between the A+ wire (inter-

nal connector 17) and the port 0 ref wire (connector

28), or between the B- wire (internal connector 18)

and the port 0 ref wire (internal connector 28).

The ”ref” signal on the detector

The ref signal on the detector is the detectors

”common” signal for the RS-485. This signal may be

connected to IE (or earth in single earth systems),

to the detectors power supply 0V or it may be iso-

lated (floating).