6

Using the Board

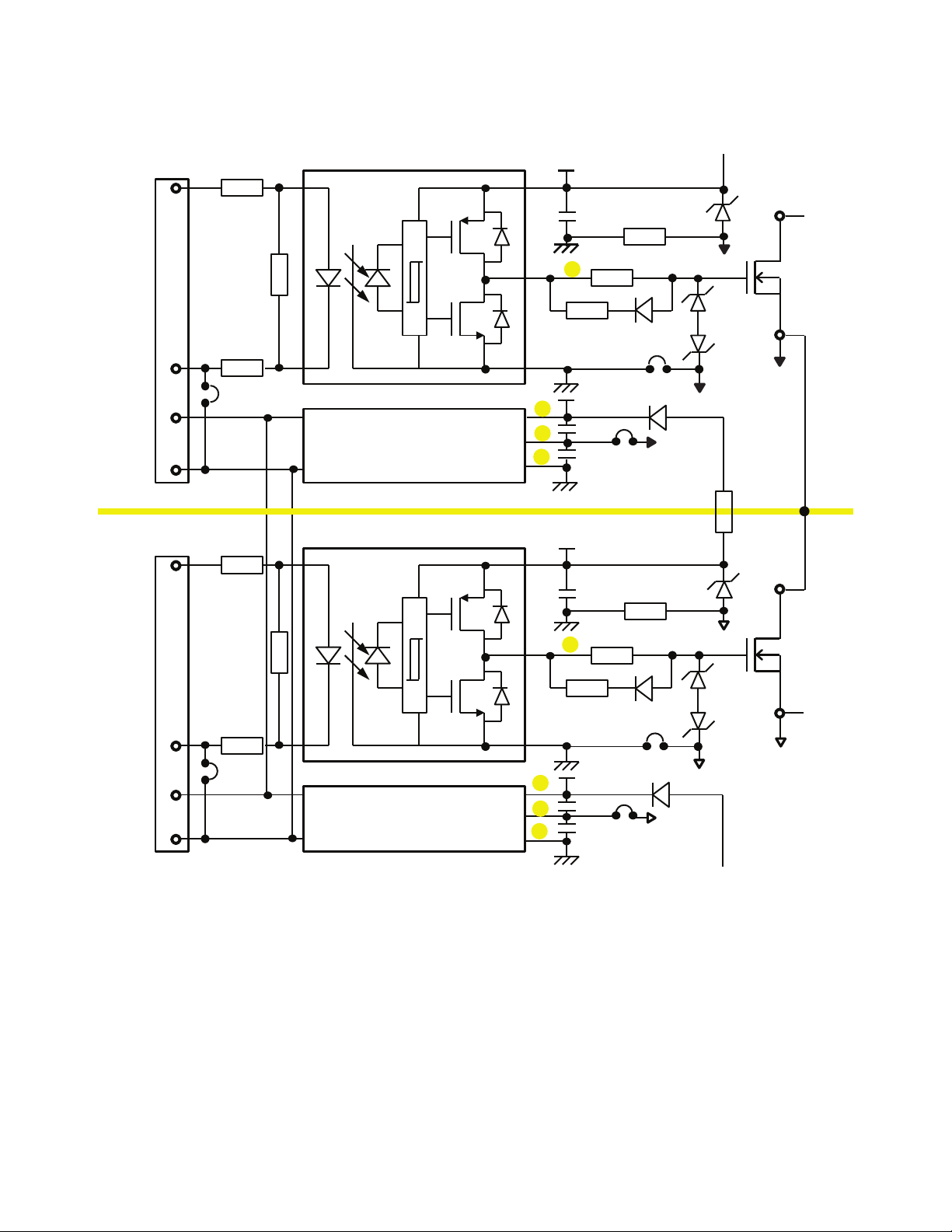

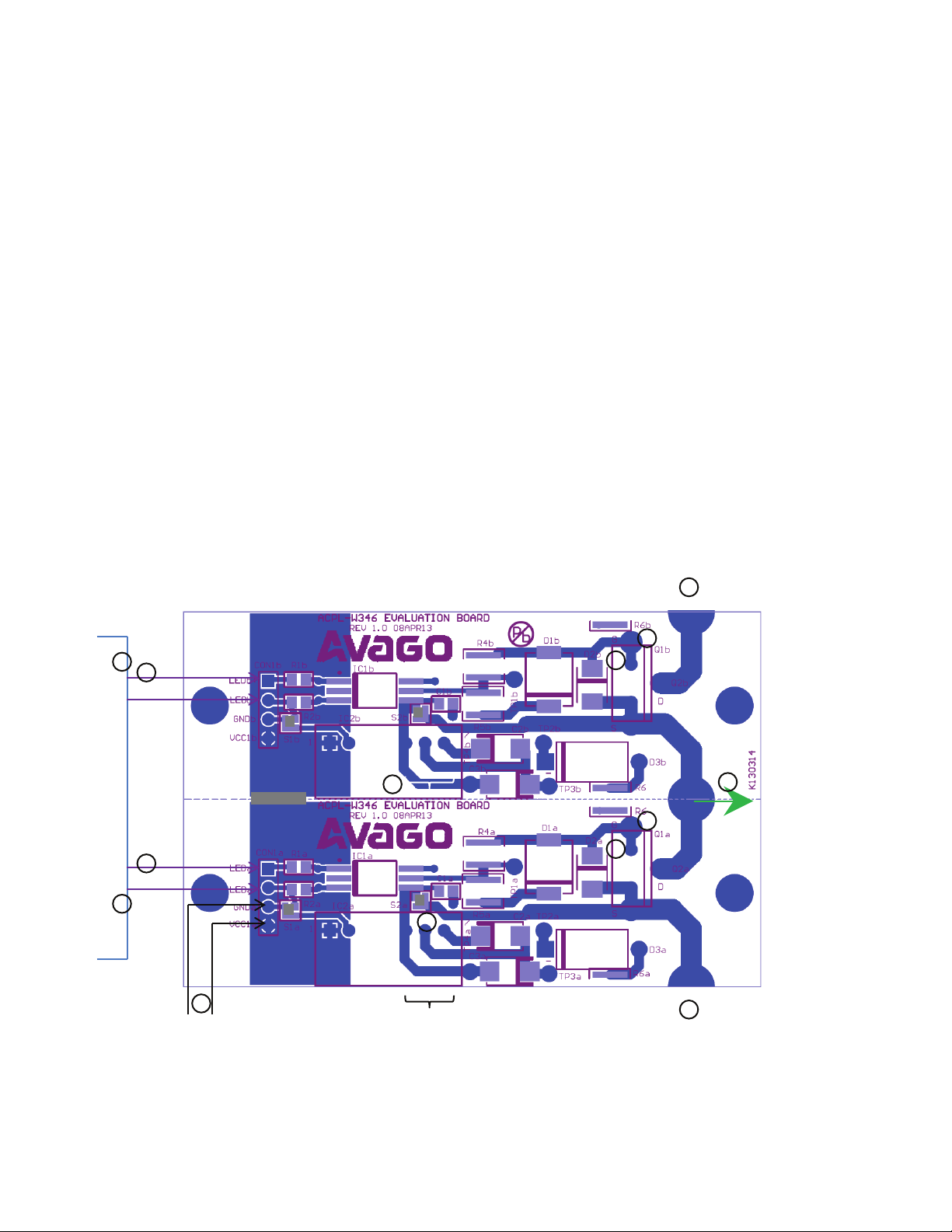

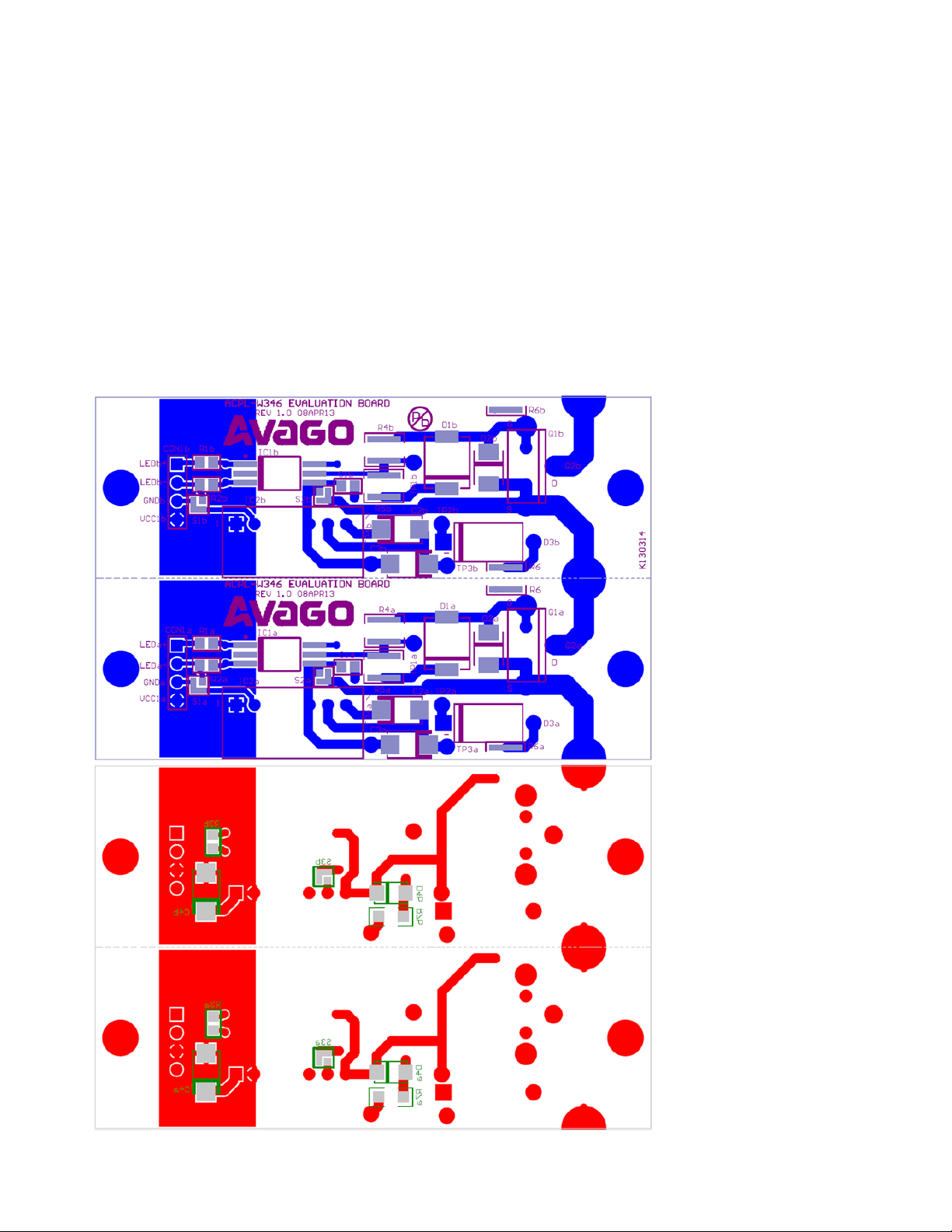

It is easy to prepare the evaluation board for use. You just need to solder cables for DC supplies, have proper cables for

HVDC+/HVDC- high voltage bus, and load connections. The evaluation board has a default connection as shown in

Table 1 when it is shipped to the customer. We oer several power supply schemes from which you can choose.

Power Supply Schemes

The evaluation board is built with DC supply exibility in mind; choose a power supply scheme from the seven available.

Table 1 shows all the possible power supply schemes that work for the evaluation board. A description of each scheme

is given; you are encouraged to explore each scheme and decide which one works best for your needs:

1. Scheme 1 is the simplest and possibly the cheapest scheme. A +5 V isolated DC supply is supplied externally to

power the low voltage Vcc1 circuit. Another external supply (+12 V~20 V for Vcc2a) is needed for the gate driver driving

the power MOSFET at the bottom inverter arm. Vcc2b supply is obtained from Vcc2a by bootstrapping. For this to

work, the bootstrap components D3b and R6 must be connected, all S2 jumpers must be shorted so that no negative

supply of Vee is allowed, and the Signal Input 2 is at 180°out of phase to Signal Input 1. All S2 jumpers are shorted to

connect Vee to Veso that there are no negative supplies. S3 jumpers are shorted by default but this has no eect on

actual operation of the board. Contact Avago Technologies if bootstrapping operation works are required.

2. Scheme 2 is similar to Scheme 1: it has Vcc1 and Vcc2a supplies. However, as the power MOSFET used gets bigger,

so does the driving power. Because a bootstrapped power supply can only handle a lower driving power, it is not

suitable for use when Qg of power MOSFET rises above 200 nanocoulombs (nC). A third external supply (+12 V~ 20

V for Vcc2b) will be needed.

3. Scheme 3 is similar to Scheme 2 in that it uses three external supplies at Vcc1, Vcc2a and Vcc2b. Scheme 3, however, has

the advantage of getting negative supplies for Vee (or Veea and Veeb) by introducing a 12 V Zener diode at D4 and R7

of around 1 kΩto provide proper biasing current at D4. For this scheme to work, both the S2 and S3 jumpers must be

open while the external supplies (+15 V ~ 24 V) on the high voltage driver side are to be connected acrossVcc2 and Vee

pins only, not the Vepin. As the external supply changes from +15 V to +24 V, Vcc2 will stay at +12V, but Vee changes

from -3 V to -12 V, all w.r.t. virtual ground at Ve.

4. Scheme 4 is another simple scheme; an alternative to Scheme 1. Here, only one external supply for Vcc1 is needed.

Vcc2a is obtained by a lower power DC/DC converter at IC2a, with Vcc1 as Vin and +12 V output at Vcc2a w.r.t. Vea. Vcc2b

supply is obtained from Vcc2a by bootstrapping. For this to work, the bootstrap components D3b and R6 must be

connected, all S2 jumpers must be shorted so that no negative supply of Vee is allowed, and the Signal Input 2 should

be 180°out of phase to Signal input 1. S2 is shorted to connect Vee to Veso that there is no negative supply. S3

jumpers are shorted by default but this has no eect on actual operation of the board.

5. Scheme 5 is similar to Scheme 4: it has Vcc1 and a DC/DC converter for Vcc2a. However, as the power MOSFET used

gets bigger, so does the driving power. Because a bootstrapped power supply can only handle a lower driving power,

it is not suitable for use when Qg of power MOSFET rises above 200 nanocoulombs (nC). A second DC/DC converter at

IC2b with Vcc1 as Vin and +12 V output at Vcc2b w.r.t .Veb. All S2 jumpers are shorted to connect Vee to Veso that there

are no negative supplies. S3 jumpers are shorted by default but this has no eect on actual operation of the board.

6. Scheme 6 is similar to Scheme 5 with the use of Vcc1 and two DC/DC converters. Each DC/DC converter, however, has

dual outputs set at ±12 V to allow for the availability of negative Vee (at Veea and Veeb). Therefore, all S2 jumpers must

be open, while all S3 jumpers must be shorted.

7. Use Scheme 7 if dual-output ±12 V DC/DC converters are not available or dual-output ±9 V DC/DC converters are

preferred. 12 V Vcc2 can still be obtained using ±9 V DC/DC converters by introducing a 12V Zener diode at D4 and R7

of around 1kΩto provide proper biasing current at D4. For this scheme to work, both the S2 and S3 jumpers must be

open. As the total voltage across Vcc2 w.r.t. Vee stays at 18V (=9V+9V), Vcc2 of 12 V will be obtained through the 12 V

D4 Zener diode, and -6V at Vee, all w.r.t. virtual ground at Ve.