HEDS-8937

AEAT-6600-T16 Magnetic Encoder Programmer Kit

User Manual

This preliminary data is provided to assist you in the evaluation of product(s) currently under development. Until

Avago Technologies releases this product for general sales, Avago Technologies reserves the right to alter prices,

specications, features, capabilities, functions, release dates, and remove availability of the product(s) at anytime.

1. Introduction

Overview

This user manual describes the Avago HEDS-8937 pro-

grammer kit. The AEAT-6600-T16 magnetic encoder

programming kit features real-time monitoring and

programming of the 32-bit OTP memory within the

AEAT-6600-T16 magnetic encoder IC. The HEDS-8937

kit includes the IC interface hardware that is supported

by PC software.The IC interface hardware is a microcon-

troller system that links the AEAT-6600-T16 encoder to

the PC through a USB cable. This user manual describes

the hardware and PC software setup and gives instruc-

tions on PC software operation.

Features

Bus-powered USB device

On-board 6.5 V programming voltage

Auto-power o when the AEAT-6600-T16 is

removed from the programming socket

Read and write the 32-bit OTP memory

Real-time monitoring of SSI, PWM, ABI or UVW

outputs

Real-time monitoring of MAG_HI and MAG_LOW

signals

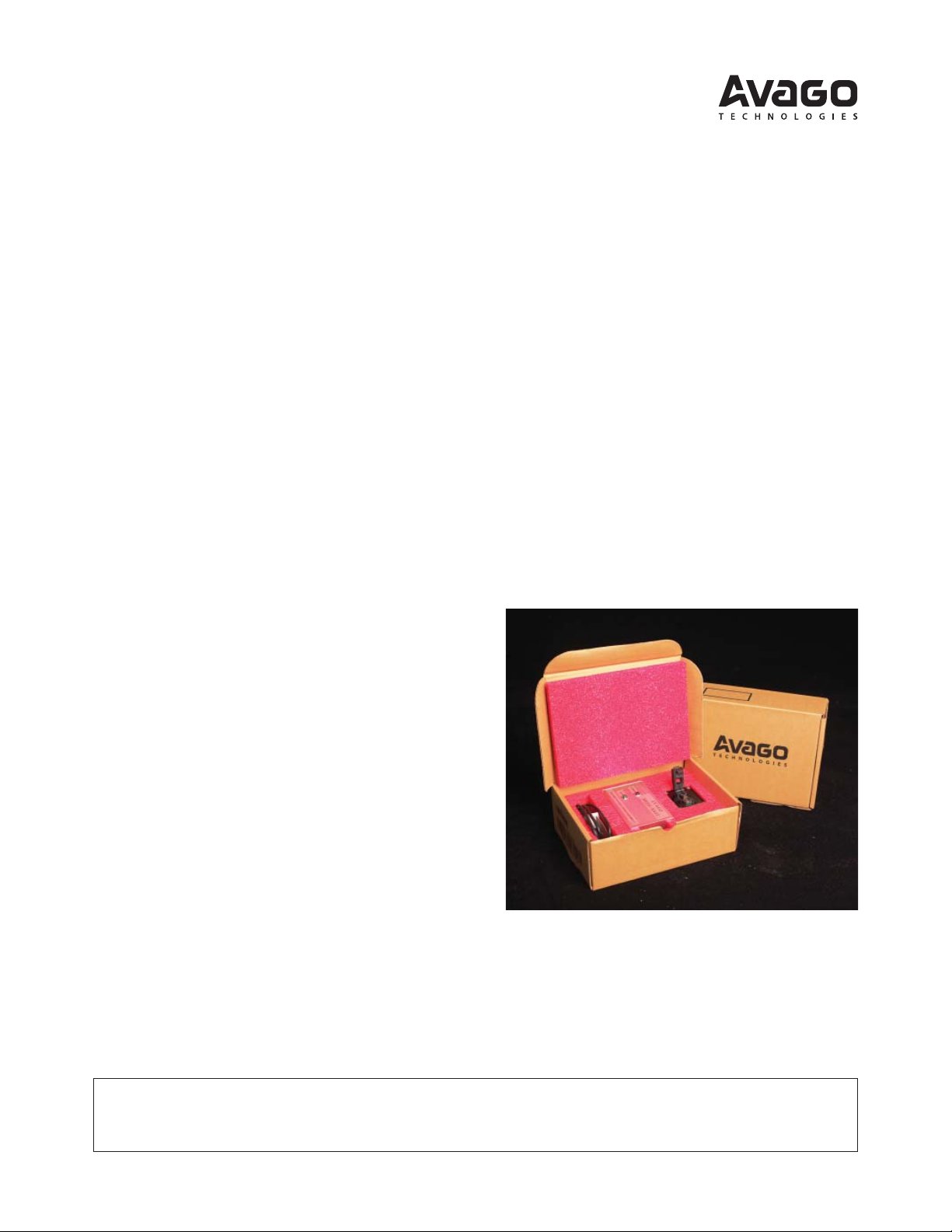

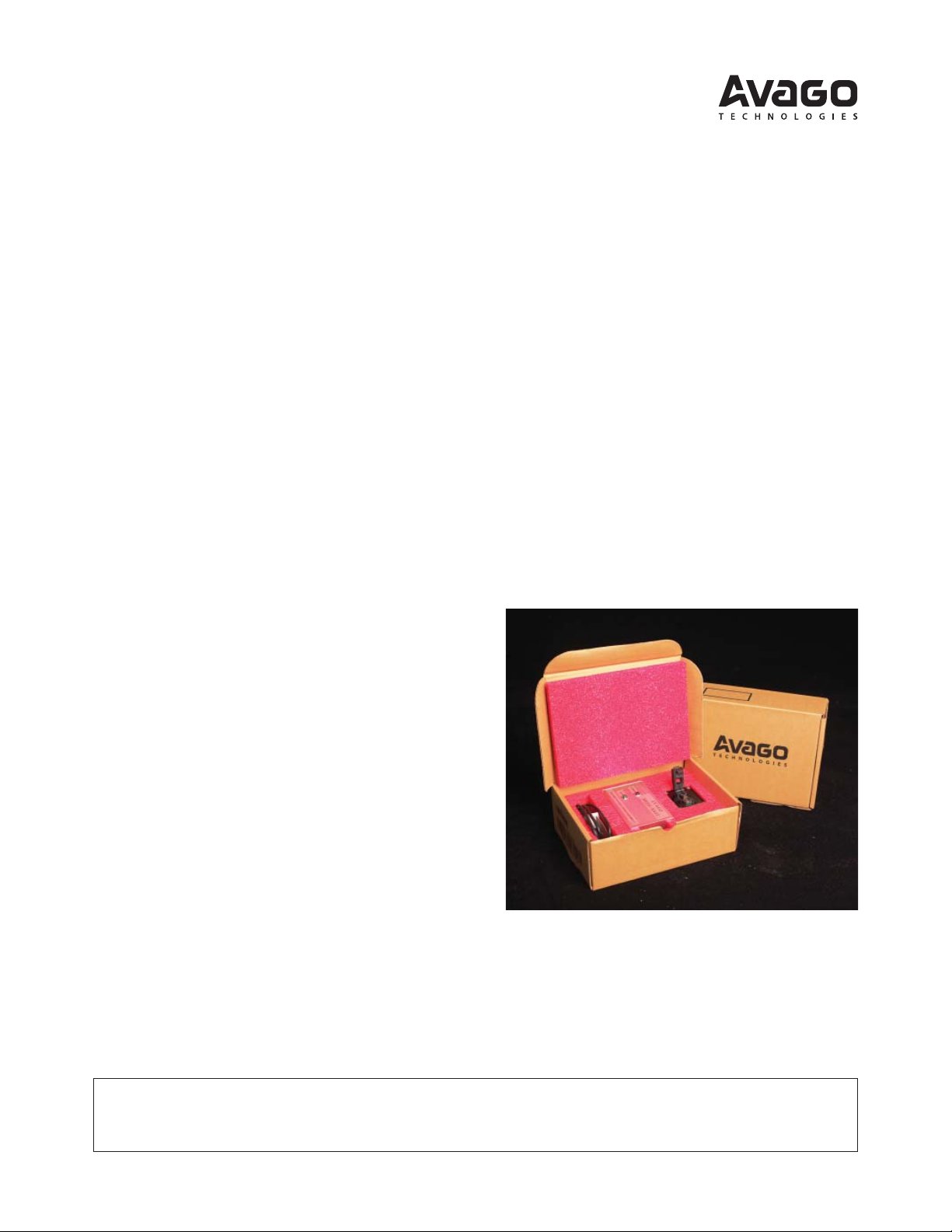

Figure 1. Inside the Programmer kit box

2. Hardware Component

Unpacking the Unit

The typical packing of the AEAT-6600-T16 magnetic

encoder programming kit is shown in Figure 1.

The kit contains:

1. USB cable

2. AEAT-6600-T16 magnetic encoder programmer

3. IC adapter socket

4. 16-pin ribbon cable

5. Installation CD