Page 4 For technical questions, please call 1-888-866-5797. Item 57637

SAFETY OPERATION MAINTENANCEINSTALLATION

Specific Safety Warnings

1. Risk of fire or explosion - do not spray

flammable liquid in a confined area or towards a

hot surface. Spray area must be well-ventilated.

Do not smoke while spraying or spray where

spark or flame is present. Arcing parts - keep

compressor at least 20 feet away from explosive

vapors, such as when spraying with a spray gun.

2. Risk of bursting - do not adjust regulator higher

than marked maximum pressure of attachment.

3. Risk of injury - do not direct air

stream at people or animals.

4. Do not use to supply breathing air.

5. Do not spray near open flames, pilot lights,

stoves, heaters, the air compressor, or any

other heat source. Most solvents and coatings

are highly flammable, particularly when

sprayed. Maintain a distance of at least 25 feet

from the air compressor. If possible, locate

the air compressor in a separate room.

6. Read all of the information concerning

coating products and cleaning solvents.

Do not use chlorinated solvents

(e.g. 1-1-1 trichloroethylene and

dichloromethane, also known as

methylene chloride) to clean spray guns.

Many spray guns contain aluminum,

which reacts strongly to chlorinated solvents.

Contact the solvent or coating manufacturer as

needed regarding potential chemical reactions.

7. Spraying hazardous materials may result in serious

injury or death. Do not spray pesticide, acid,

corrosive material, fertilizer, or toxic chemicals.

8. Paints and solvents may be harmful or fatal if

swallowed or inhaled. Avoid prolonged skin

contact with solvents or paints as they will

irritate skin. After any contact, immediately

wash off exposed area with hot, soapy water.

9. Air hose fittings may get hot during use.

Allow fittings to cool before disconnecting.

10. Do not leave compressor unattended

for an extended period while plugged in.

Unplug compressor after working.

11. Keep compressor well-ventilated.

Do not cover compressor during use.

12. Drain Tank daily and after use. Internal rust causes

tank failure and explosion.

13. Do not remove the valve cover or

adjust internal components.

14. Compressor head gets hot during operation.

Do not touch it or allow children nearby

during or immediately following operation.

15. Do not use the air hose to move the compressor.

16. The use of accessories or attachments not

recommended by the manufacturer may

result in a risk of injury to persons.

17. All air line components, including hoses, pipe,

connectors, filters, etc., must be rated for a minimum

working pressure of 150 PSI, or 150% of the

maximum system pressure, whichever is greater.

18. USE OF AN EXTENSION CORD IS NOT

RECOMMENDED. If you choose to use an

extension cord, use the following guidelines:

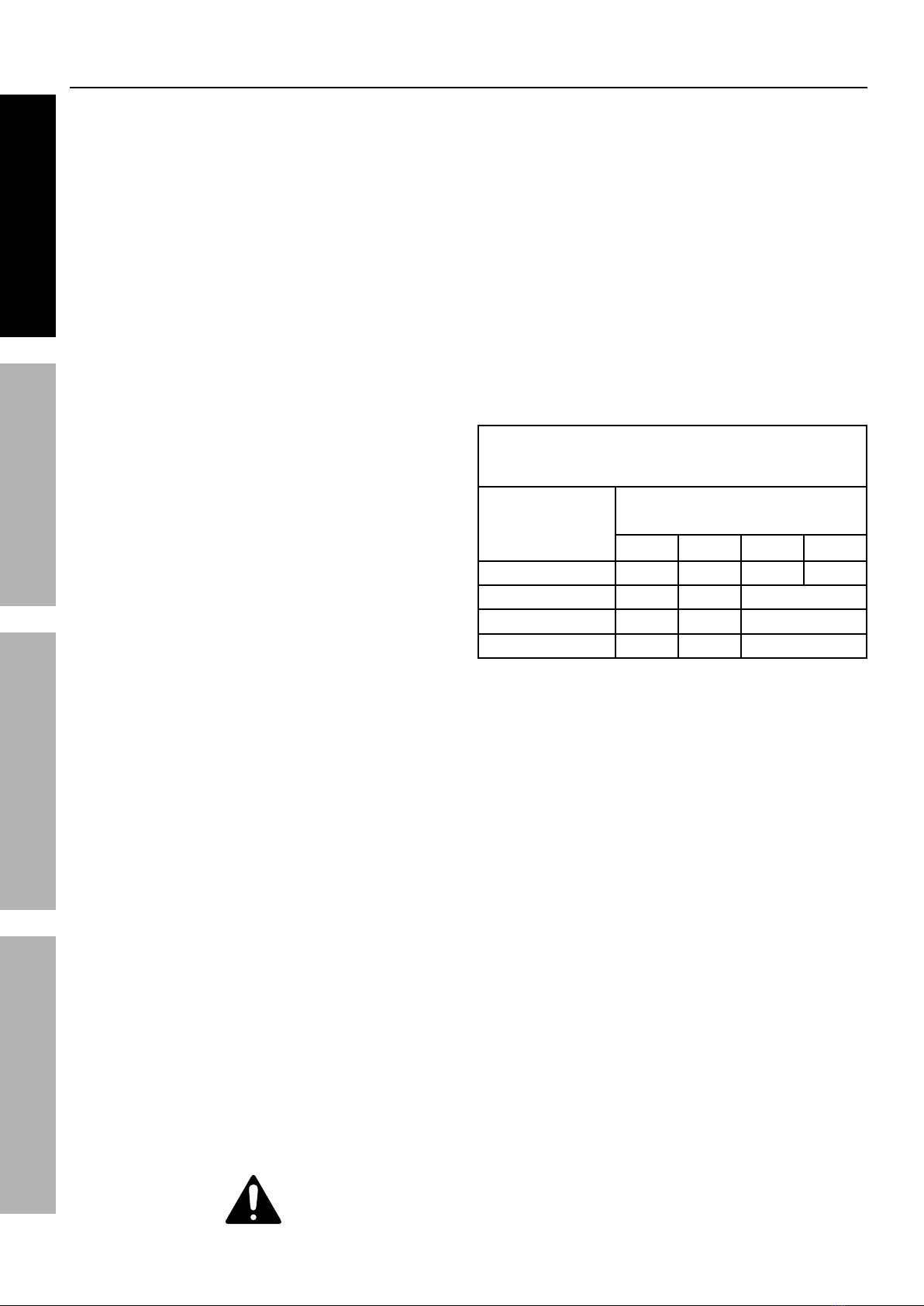

TABLE A: RECOMMENDED MINIMUM WIRE

GAUGE FOR EXTENSION CORDS

(120 VOLT)

NAMEPLATE

AMPERES

(at full load)

EXTENSION CORD

LENGTH

25′ 50′ 10′ 150′

0 – 6 18 16 16 14

6.1 – 10 18 16 Do not use.

10.1 – 12 16 16 Do not use.

12.1 – 16 14 12 Do not use.

a. Make sure your extension cord

is in good condition.

b. Be sure to use an extension cord which

is heavy enough to carry the current your

product will draw. An undersized cord will

cause a drop in line voltage resulting in loss

of power and overheating. Table A shows the

correct size to use depending on cord length

and nameplate ampere rating. If in doubt,

use the next heavier gauge. The smaller

the gauge number, the heavier the cord.

19. Maintain labels and nameplates on the

compressor. These carry important safety

information. If unreadable or missing, contact

Harbor Freight Tools for a replacement.

20. This product is not a toy.

Keep it out of reach of children.

21. People with pacemakers should consult their

physician(s) before use. Electromagnetic fields in

close proximity to heart pacemaker could cause

pacemaker interference or pacemaker failure.

SAVE THESE INSTRUCTIONS.