Aventech FTK100 User manual

Rev: 1.00

Date: 08.01.2013

Page: 1 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N: FTK100-OM

Aventech Research Inc.

110 Anne Street South, Unit 23

Barrie, Ontario, Canada L4N 2E3

Tel: (705) 722-4288

Fax: (705) 722-9077

Web: www.aventech.com

Rev: 1.00

Date: 08.01.2013

Page: 2 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

Issued

Date

Name

Signature

Function

08.01.2013

Bruce H. Woodcock

DE

Checked

Date

Name

Signature

Function

08.01.2013

Bruce H. Woodcock

DE

Approved

Date

Name

Signature

Function

08.01.2013

Bruce H. Woodcock

HD

Customer Approval (as required)

Date

Name

Signature

Function

Table of Functions

CUST Customer

DE Design Engineer

HD Head of Design Engineering

PM Production Manager

QM Quality Manager

Rev: 1.00

Date: 08.01.2013

Page: 3 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

NOTICES

WARRANTY

Aventech Research Inc. products are warranted to be free from defects in material and

workmanship under normal use and service for a period of one year beginning on the

date of shipment. This warranty extends only to the original buyer or end-user customer

of an Aventech Research Inc. authorized reseller. This warranty does not apply to any

product which, in Aventech Research Inc’s opinion, has been misused, altered,

neglected, contaminated, or damaged by accident or abnormal conditions of operation

or handling.

Aventech Research Inc’s warranty obligation is limited, at Aventech Research Inc’s

option, to refund of the purchase price, free of charge repair, or replacement of a

defective product which is returned to within the warranty period.

To obtain warranty service, return the product to the nearest Aventech Research Inc.

authorized reseller, or direct to the address provided below:

Aventech Research Inc.

110 Anne Street South, Unit 23

Barrie, Ontario, Canada L4N 2E3

Tel: (705) 722-4288

Fax: (705) 722-9077

Shipping costs to Aventech Research Inc. are the responsibility of the end customer

(FOB Destination). Aventech Research Inc. assumes no risk for damage in transit.

Following warranty repair, the product will be returned to Buyer, transportation prepaid

(FOB Destination). If Aventech Research Inc. determines that failure was caused by

neglect, misuse, contamination, alteration, accident, or abnormal condition of operation

or handling, including overvoltage failures caused by use outside the product’s specified

rating, or normal wear and tear of mechanical components, Aventech Research Inc. will

provide an estimate of repair costs and obtain authorization before commencing the

work. Following repair, the product will be returned to the Buyer transportation prepaid

and the Buyer will be billed for the repair and return transportation charges (FOB

Shipping Point).

Aventech Research Inc. warrants that product firmware will operate substantially in

accordance with its functional specifications. Aventech Research Inc. does not warrant

that firmware will be error free or operate without interruption.

Rev: 1.00

Date: 08.01.2013

Page: 4 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

The material contained in this document is provided “as is,” and is subject to being

changed, without notice, in future editions. Further, to the maximum extent permitted by

applicable law, Aventech Research Inc. disclaims all warranties, either express or

implied, with regard to this manual and any information contained herein, including but

not limited to the implied warranties of merchantability and fitness for a particular

purpose. Aventech Research Inc. shall not be liable for errors or for incidental or

consequential damages in connection with the furnishing, use, or performance of this

document or of any information contained herein. Should Aventech Research Inc. and

the user have a separate written agreement with warranty terms covering the material in

this document that conflict with these terms, the warranty terms in the separate

agreement shall control.

THIS WARRANTY IS BUYER'S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. AVENTECH RESEARCH INC. SHALL NOT BE LIABLE

FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR

LOSSES, INCLUDING LOSS OF DATA, ARISING FROM ANY CAUSE OR THEORY.

COPYRIGHT

© Aventech Research Inc. 2013. No part of this manual may be reproduced in any form

or by any means (including electronic storage and retrieval or translation into a foreign

language) without prior agreement and written consent from Aventech Research Inc. as

governed by Canadian and international copyright laws.

Rev: 1.00

Date: 08.01.2013

Page: 5 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

RECORD OF REVISIONS

Date

Issue

Page

Paragraph

Firmware

Revision

Comments

08.01.2013

1.00

All

All

Preliminary Draft

Rev: 1.00

Date: 08.01.2013

Page: 6 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

FIRMWARE REVISIONS

Date

Firmware

Revision

Comments

08.01.2013

1.10

Firmware version initial release

Rev: 1.00

Date: 08.01.2013

Page: 7 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

TABLE OF CONTENTS

1.0 Introduction.......................................................................................................................... 9

2.0 Quick Start..........................................................................................................................10

2.1 Verify the List of Supplied Items ....................................................................................................... 10

2.2 Charging the Unit .............................................................................................................................. 10

2.3 FTK100 and Calibration Fixture External Features............................................................................ 10

2.4 Connecting the Calibration Fixture to the FTK100............................................................................ 12

2.5 Installing the Calibration Fixture....................................................................................................... 12

2.6 Installing the Interface Cable ............................................................................................................ 13

2.7 Turning the Unit On .......................................................................................................................... 13

2.8 Resetting the Device ......................................................................................................................... 14

2.9 Turning the Device Off ...................................................................................................................... 14

3.0 Menu Features and Functions.............................................................................................15

3.1 Test.................................................................................................................................................... 15

3.1.1 IBIT............................................................................................................................................ 16

3.1.2 CBIT .......................................................................................................................................... 16

3.1.3 Pressure Test............................................................................................................................ 17

3.1.4 Magnetic Sensor....................................................................................................................... 18

3.1.5 Accelerometer.......................................................................................................................... 19

3.1.6 GPS ........................................................................................................................................... 19

3.1.7 Thermistor................................................................................................................................ 21

3.1.8 Humidity Sensor ....................................................................................................................... 22

Storing Data on USB................................................................................................................................ 23

3.2 Settings........................................................................................................................................... 25

3.2.1 Date and Time .......................................................................................................................... 25

3.2.2 Brightness................................................................................................................................. 26

3.2.3 Screen Timeout ........................................................................................................................ 26

3.2.4 Default Settings........................................................................................................................ 27

3.3 Maintenance ..................................................................................................................................... 28

Rev: 1.00

Date: 08.01.2013

Page: 8 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

3.3.1 Device Under Test (DUT) Firmware Update .............................................................................. 28

3.3.2 FTK100 Firmware Update ................................................................................................... 29

4.0 Error Messages and Troubleshooting..................................................................................30

5.0 Mechanical Drawing............................................................................................................31

Rev: 1.00

Date: 08.01.2013

Page: 9 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

1.0 Introduction

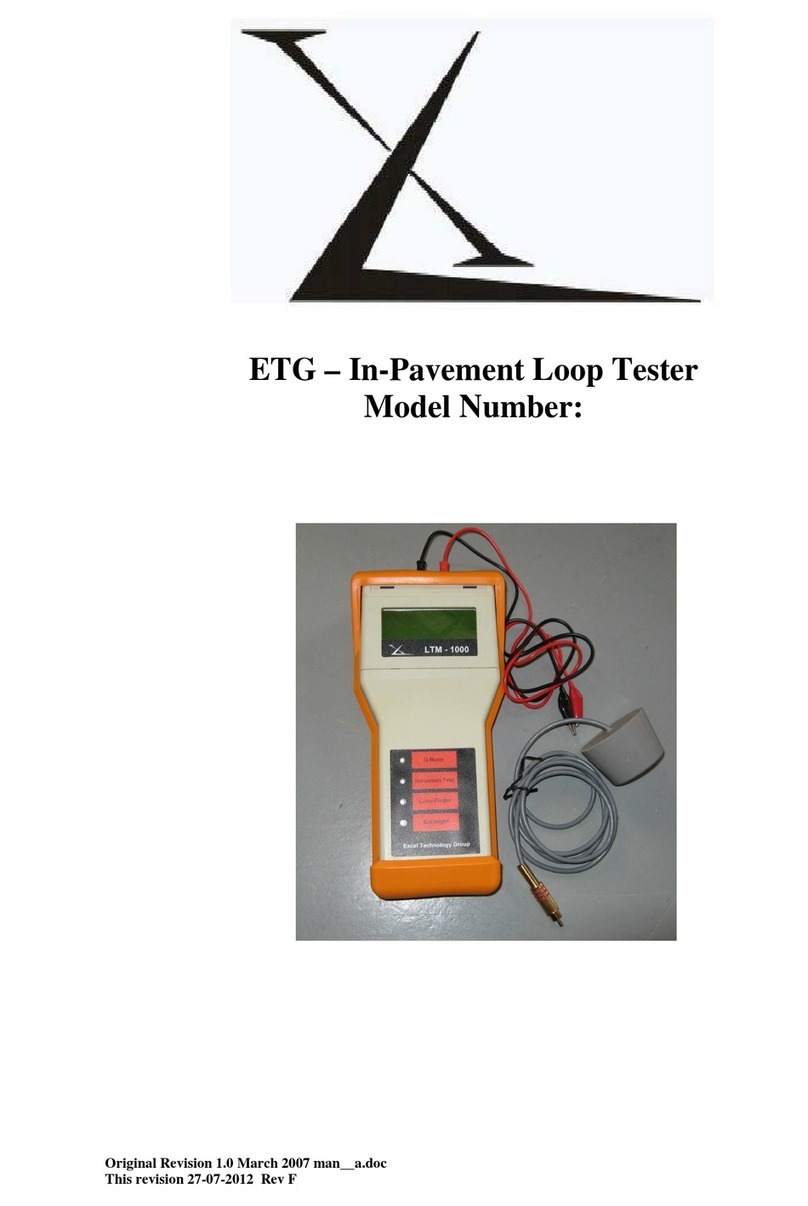

The Aventech Research Inc. FTK100 is an integrated Field Test Kit which provides

an extensive set of testing functions to verify the operational status of Aventech’s

line of airborne air-data, GPS and inertial system products. FTK100 test

functionality includes:

•Validation and calibration of pressure channel measurements for both pitot-

static and five-hole probes including barometric, pitot-static, angle-of-attack

and angle-of-sideslip pressures

•Display of three-axis accelerometer and rate sensor measurements for

validation of inertial subsystem

•Display of GPS receiver data for validation of GPS subsystem

•Display of three-axis magnetic sensor measurements

•Display of temperature and humidity measurements for validation of

environmental / meteorological subsystem

•Reporting of IBIT status

•Reporting of CBIT status

•Firmware update capability for both the FTK100 unit itself as well as the

attached instrumentation

Features of the FTK100 include:

•3.5” Colour QVGA (320 X 240) TFT Touch-screen LCD display

•Intuitive easy-to-use menu driven operating system

•Integrated pump, plenum and valve system for provision of test pressures

•High-speed CAN AERO port for communication with the device under test

•One 15 psi pressure port for testing / calibrating barometric sensors

•Five 1 psi pressure ports for testing / calibrating pitot-static, angle-of-attack

and sideslip pressures

•Integrated USB port for storage of data files and test reports which can then

be easily transported to other computer systems

•Internal Real-Time Clock (RTC) for time stamping validation / calibration

reports

•Integrated Lithium Ion battery providing up to 10 hours run time

•Integrated battery charging electronics with 100-240 50-60 Hz VAC plug-in

wall charger

•Integrated battery gauge for reporting battery charge status

The FTK100 interfaces with a variety of air-data probe calibration fixtures and can

be utilized as a standard pressure calibration device. FTK100 full functionality exists

for the Aventech Research Inc. ARIM200 Air Data Probe and ARIM320 Air / Inertial

/ Meteorological Digital Data System.

Rev: 1.00

Date: 08.01.2013

Page: 10 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

2.0 Quick Start

One of the first things you will want to do with your FTK100 Field Test Kit is to

become familiar with its external controls and connections. We have written the

exercises in this chapter to prepare your FTK100 for use and help you get familiar

with some of its operations.

2.1 Verify the List of Supplied Items

The first thing you will want to do is verify that you have received the following items

with your Field Test Kit. If anything is missing, please contact your approved reseller

or Aventech Research Inc. directly.

One hand-held FTK100 Field Test Kit control unit

One Calibration Fixture

Six lengths of plastic tubing

One wall-mount 12.8 VDC output power supply for charging battery

This Operating Manual

2.2 Charging the Unit

Although the unit will have been fully charged before it left our facility, it is

recommended that you charge the unit before its first use.

2.3 FTK100 and Calibration Fixture External Features

Figure 1: FTK100 Front and Left Hand Side Panel Features

Rev: 1.00

Date: 08.01.2013

Page: 11 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

Figure 2: FTK100 Top Panel Features

Figure 3: Integrated Stylus for use with LCD Touchscreen

Figure 4: Typical Calibration Fixture Tubing Connections (ARI320 Version Shown)

Rev: 1.00

Date: 08.01.2013

Page: 12 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

2.4 Connecting the Calibration Fixture to the FTK100

This section describes how to connect the calibration fixture to the FTK100 control

module.

The FTK100 supports calibration fixtures designed to test pressures on standard

pitot-static probes and five-hole probes. A calibration fixture designed to test the

five-hole probe integrated into the ARIM320 is shown in Figure 4. For testing the

more common pitot-static probes, tubing is only required to be connected between

the pitot tubing connector on the forward face of the calibration fixture, and the static

tubing connector furthest aft on the side of the calibration fixture. If a five-hole probe

is being tested, as shown in Figure 4, tubing must also be connected to the angle-

of-attack (alpha) connectors in the vertical plane and sideslip connectors in the

horizontal plane. Please note that the calibration five-hole probe calibration fixtures

are typically designed so that the static connector is on the same side as the Alpha+

connector. This allows the user to orient the calibration fixture correctly when

installing it on the probe.

Both the FTK100 control module and Aventech Research Inc. calibration fixtures

utilize 1/8” OD quick connect / disconnect fittings to interface to the interconnecting

pressure tubing. To install the tubing simply insert it as far as possible into the fitting

and it will lock in place. To disconnect, push down on the orange collar on the fitting

and pull the tubing out.

Six lengths of 1/8” OD tubing will have been provided with your field test kit which

should be installed between the pressure connections show on the calibration

fixture in Figure 4 and the labeled input ports on the FTK100 shown in Figure 2.

2.5 Installing the Calibration Fixture

For pitot-static probes, orientation of the calibration fixture is not important however,

for five-hole probes it is critical. As described in Section 2.5, the static pressure

fitting is typically located on the same side as the alpha+ pressure fitting.

Install the calibration fitting onto the measurement boom by sliding it over the boom

while insuring the static pressure fitting is pointing straight up. This will insure that

the remaining pressure fittings are oriented correctly relative to the pressure ports

on the measurement boom. Slide the fixture as far as it will go onto the boom and

then apply a small amount of longitudinal force to the fixture to compress the O-

rings against the nose of the boom and seal off the pressure ports to the calibration

fixture. While applying this force, rotate the collar located at the rear of the

calibration fixture clockwise, when looking at the front of the fixture, gently to lock

the fixture onto the probe boom.

Rev: 1.00

Date: 08.01.2013

Page: 13 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

Some calibration fixtures will be manufactured with a clear acrylic front to allow the

user to observe that the pressure inputs in the calibration fixture are correctly

oriented with the pressure ports on the probe.

2.6 Installing the Interface Cable

Install the CAN Interface cable between the FTK100 and Device Under Test (DUT).

2.7 Turning the Unit On

To begin a test both the DUT and the FTK100 have to be turned on in that order. To

power the FTK100 depress and release the power switch shown in Figure 1.

As the unit boots up and runs its internal self-tests the splash screen shown in

Figure 5 below will appear showing the unit`s current firmware version and build

number, manufacturing date and calibration date.

Figure 5: FTK100 Splash Screen

At completion of the start-up procedure the main FTK100 operating system menu

window will appear as shown in Figure 6 below.

Figure 6: FTK100 Operating System Main Menu Window

Rev: 1.00

Date: 08.01.2013

Page: 14 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

The FTK100 operating system windows consists of a status bar and display area

with menu buttons to access and run various test, settings, and maintenance

functions programmed into the unit.

The status bar appears in each menu window providing any necessary status

information, the current time from the real-time clock just to the right of centre-

screen and the battery charge status in the right-hand corner. Home button at the

top left corner can be used to navigate to the main window from any other windows.

2.8 Resetting the Device

The device can be reset at any point by pressing and holding the on/off button for

more than five seconds and releasing it once the touch screen shuts down.

Note: All test results will be erased once the device is reset.

2.9 Turning the Device Off

To shut down the device, the on/off push button should be pressed and held for one

to two seconds and released.

Note: The device cannot be turned off while it is in the test mode. In order to turn it

off, you have to exit from the test mode and make sure the screen is showing either

the home/main page or any other subpages such as test, settings, or maintenance.

Rev: 1.00

Date: 08.01.2013

Page: 15 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

3.0 Menu Features and Functions

3.1 Test

After pressing the Test button on the main menu, the FTK100 will immediately

connect with the DUT, download and subsequently display the CAN AERO Node ID

number, serial number and firmware version of the DUT.

Figure 7: Connecting to DUT and Obtaining Probe Information

The DUT Node ID, Serial number and software ID data are displayed for three

seconds, after which the Test Menu is displayed:

Figure 8: Test Window

Rev: 1.00

Date: 08.01.2013

Page: 16 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

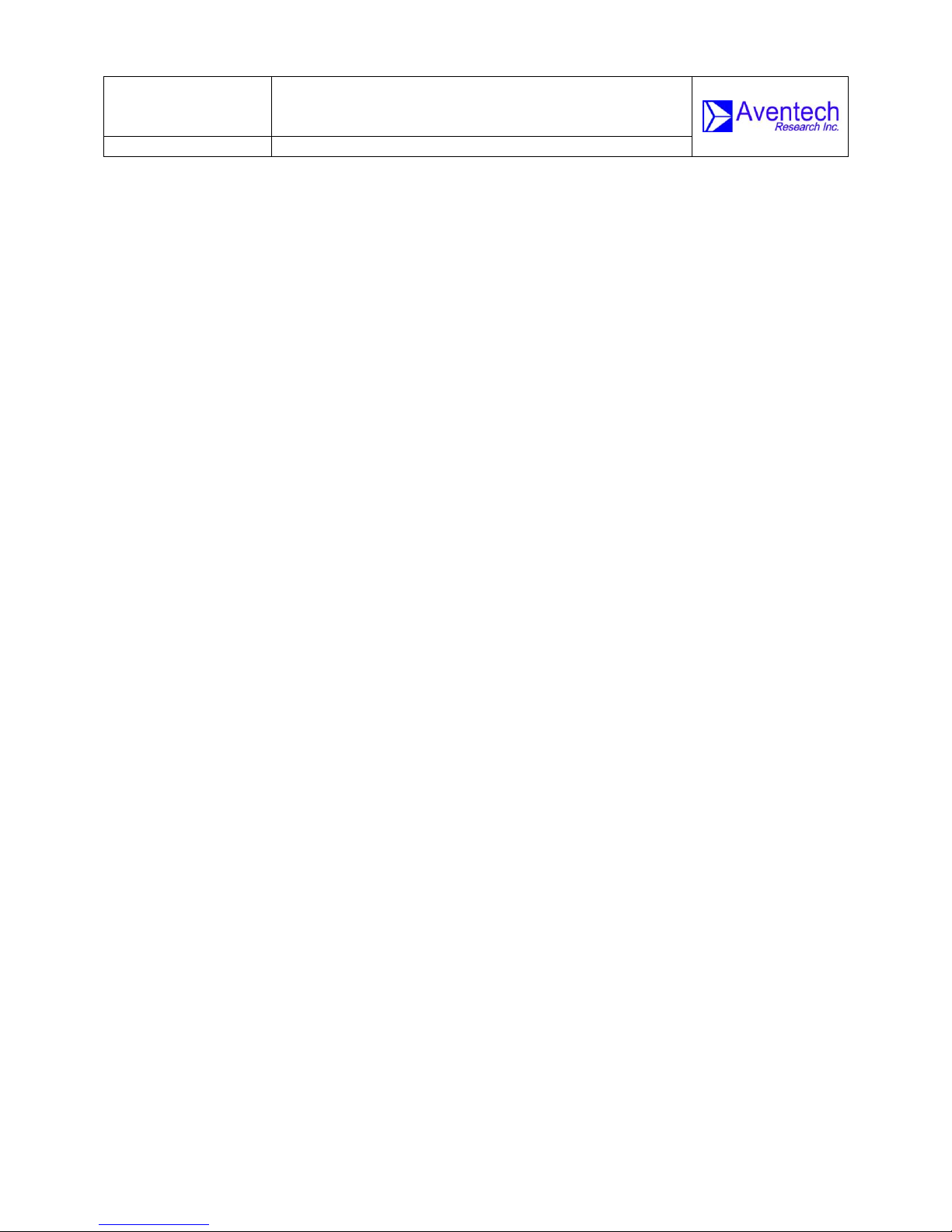

3.1.1 IBIT

The FTK100 will send an IBIT request to the DUT and the 32-bit status word sent

in reply from the DUT will be displayed in hexadecimal format. To assist

interpretation, the output includes text descriptions of each non-zero bit occurring

in the status word, each representing a particular error condition.

Figure 9: Ibit Test

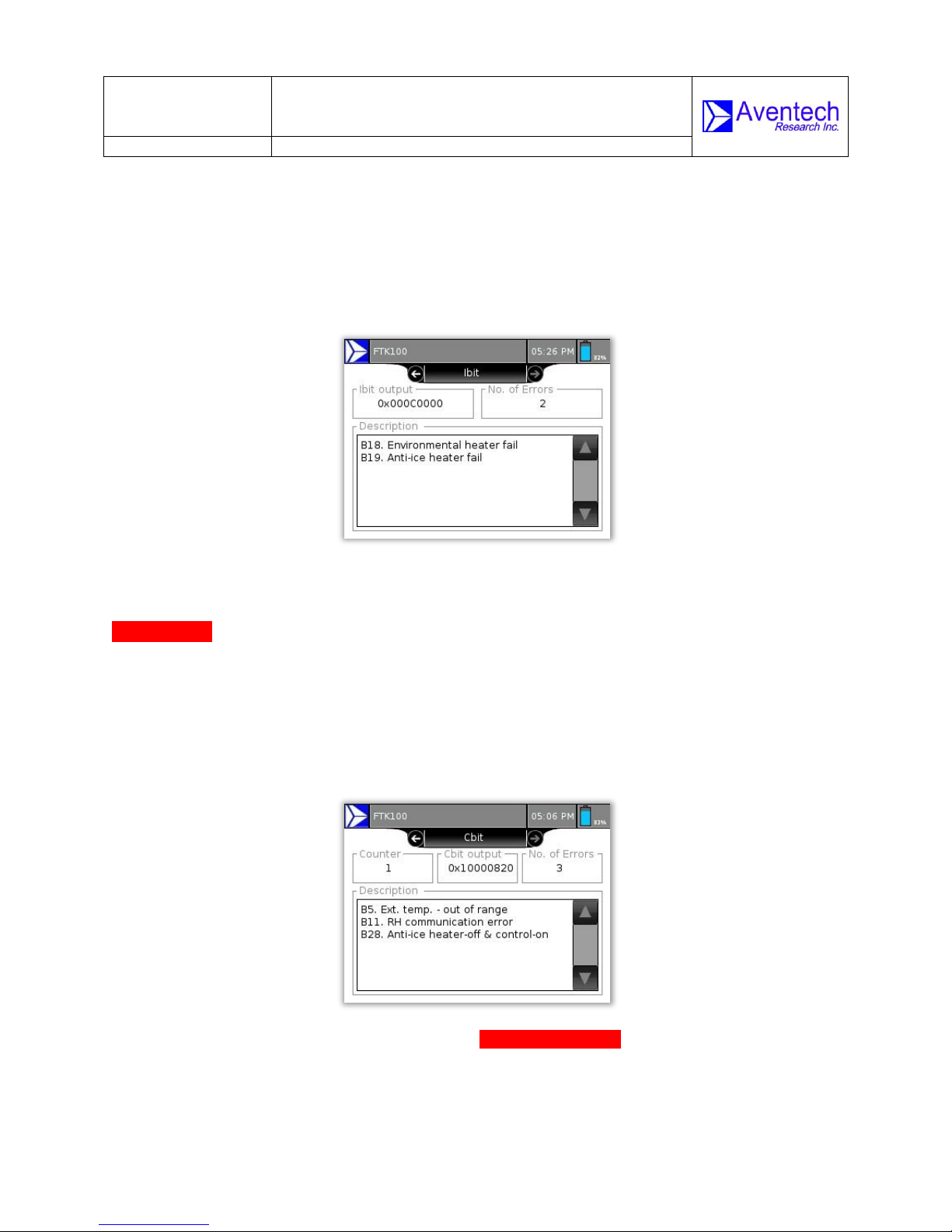

3.1.2 CBIT

CBIT data is continuously generated by the DUT under normal operation. The

FTK100 sends a request at 1Hz to continuously receive and monitor the latest

CBIT values being generated by the system. Two different CBIT values will be

output along with text-based descriptions of all non-zero bits denoting various

error conditions.

Figure 10: Cbit Test (change the image)

Rev: 1.00

Date: 08.01.2013

Page: 17 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

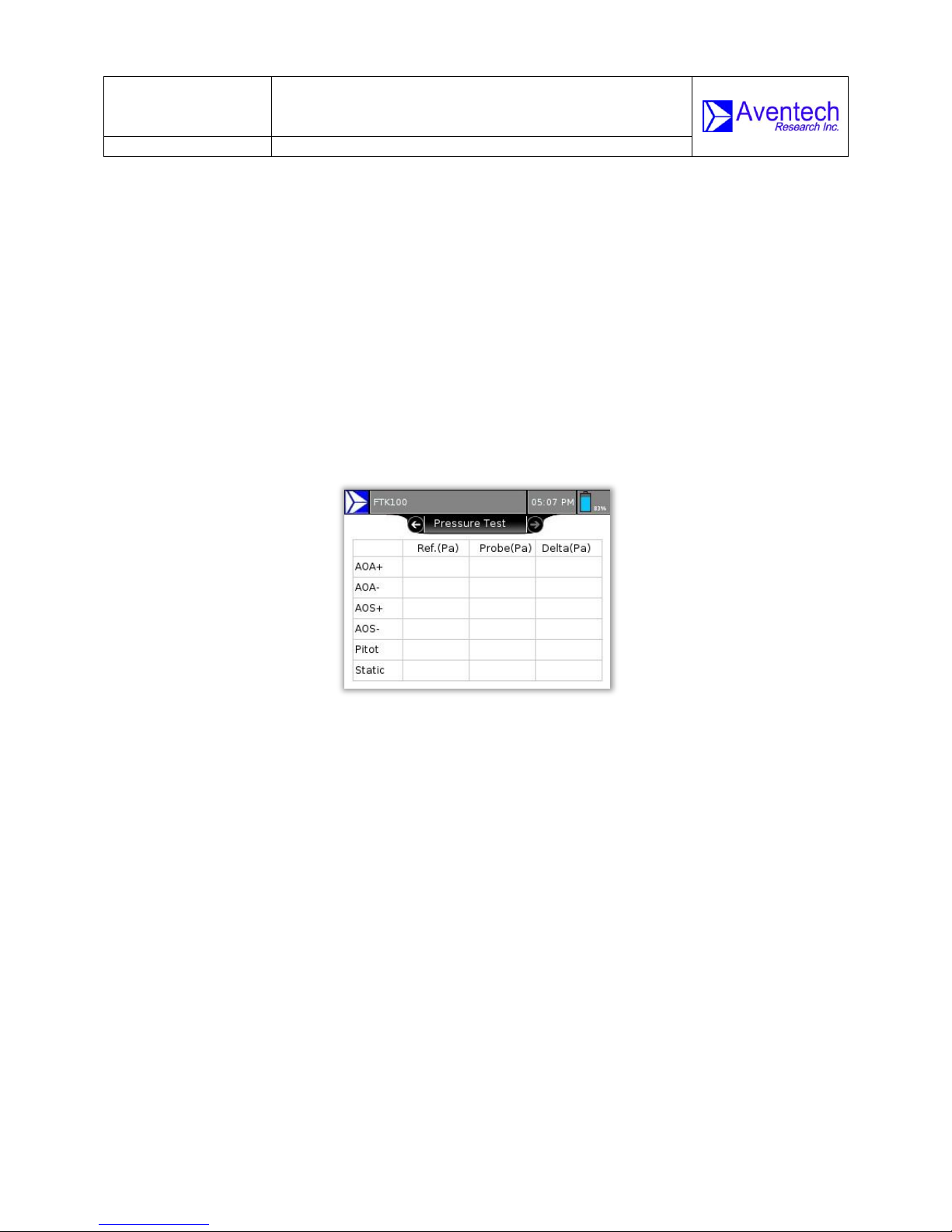

3.1.3 Pressure Test

This feature will perform a pressure test of all five pressure ports on the tip of the

air-data probe and the ring of static-pressure ports around its circumference.

This test can be performed only if the appropriate probe adapter is firmly secured

to the DUT and is connected to the FTK using the supplied tubing.

Immediately after the Pressure Test is selected, the internal pump will begin to

pressurize the system to approximately 3000Pa. If any leaks are present, as

would occur if the probe adapter is not properly in place, the pump will continue

to run until a timeout error is generated if the target pressure is not reached

within 6 seconds. If the no leaks occur, the pump will bring the system up to test

pressure in approximately 1 second. The following window will then be displayed:

Figure 11: Pressure Test Layout

After a 5 second settling period, valves will be activated to introduce the test

pressure to the AOA+ (ALPHA+) pressure port. The FTK100 will read the

pressure data sensed by the DUT across the CAN AERO connection and record

data from its own internal reference pressure sensor for a period of five seconds.

After this sampling period, the valves are switched to disconnect the AOA+ port

and return it to ambient atmospheric pressure, and simultaneously connect the

internal pressure plenum to the AOA- (ALPHA-) port. During the following 5

second settling period, the pump is given ability to re-engage and recharge the

plenum if necessary. If this occurs, a further 5s settling period is introduced

before data is collected from both the DUT and reference pressure sensor. This

process continues through all pressure ports in the following order: AOA+, AOA-,

AOS+ (BETA+), AOS- (BETA-), Pitot-Static. After data has been collected for the

pitot-static test, the valves switch to change the direction of air-flo w between the

pump and internal plenum so as to generate a vacuum. The pump runs and

takes the plenum pressure down to approximately 90kPa. The static pressure

Rev: 1.00

Date: 08.01.2013

Page: 18 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

port is then activated and now the internal reference barometric sensor is

sampled concurrently with data from the DUT access across the CAN AERO

network connection.

The status bar will display status information as the test progresses through all

stages.

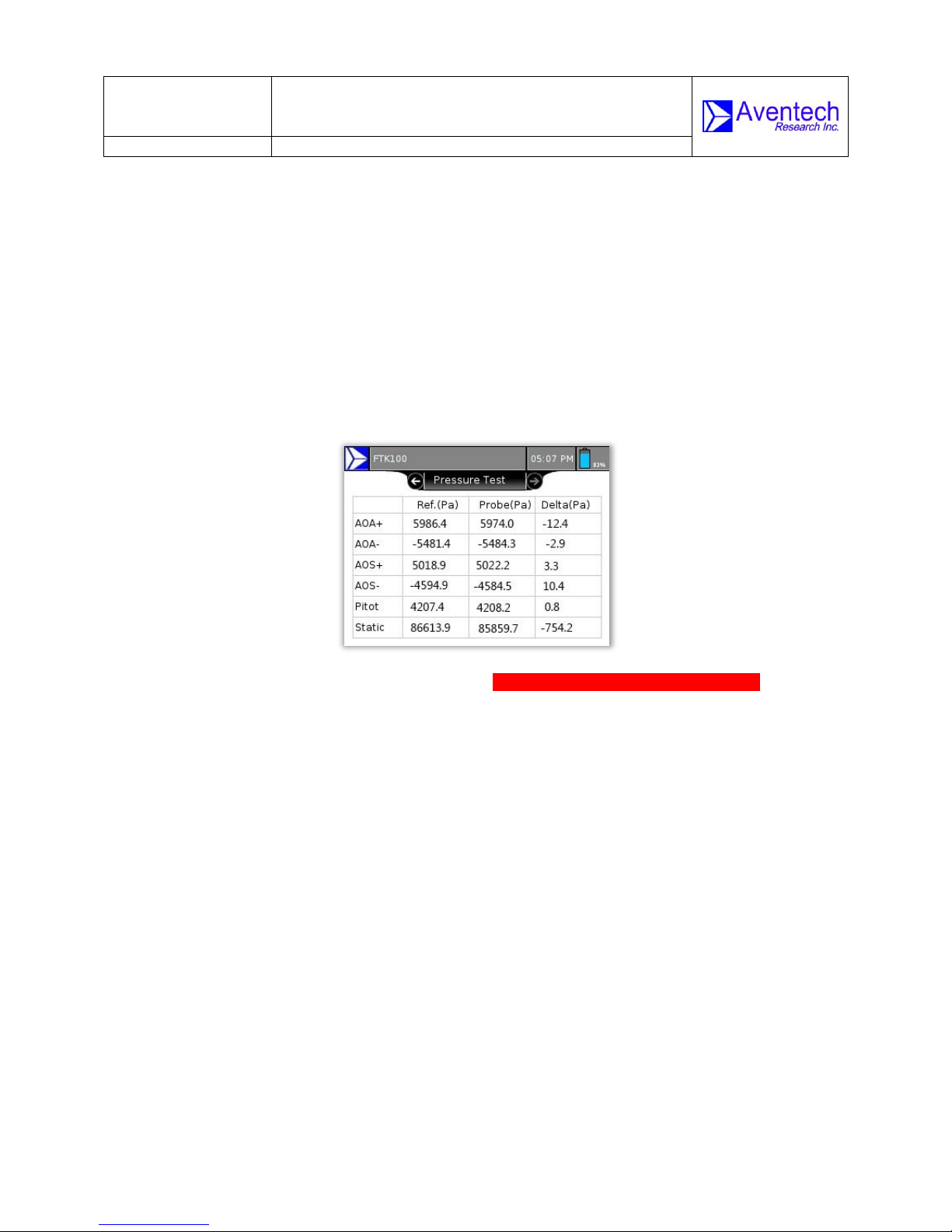

Once the test is complete, mean values are computed from the approximately

150 data points sampled during each stage of the test. Mean values from the

reference sensors, the DUT and the differences between them are displayed in a

tabular format:

Figure 12: Sample Pressure Test Results(change the image –static is wrong)

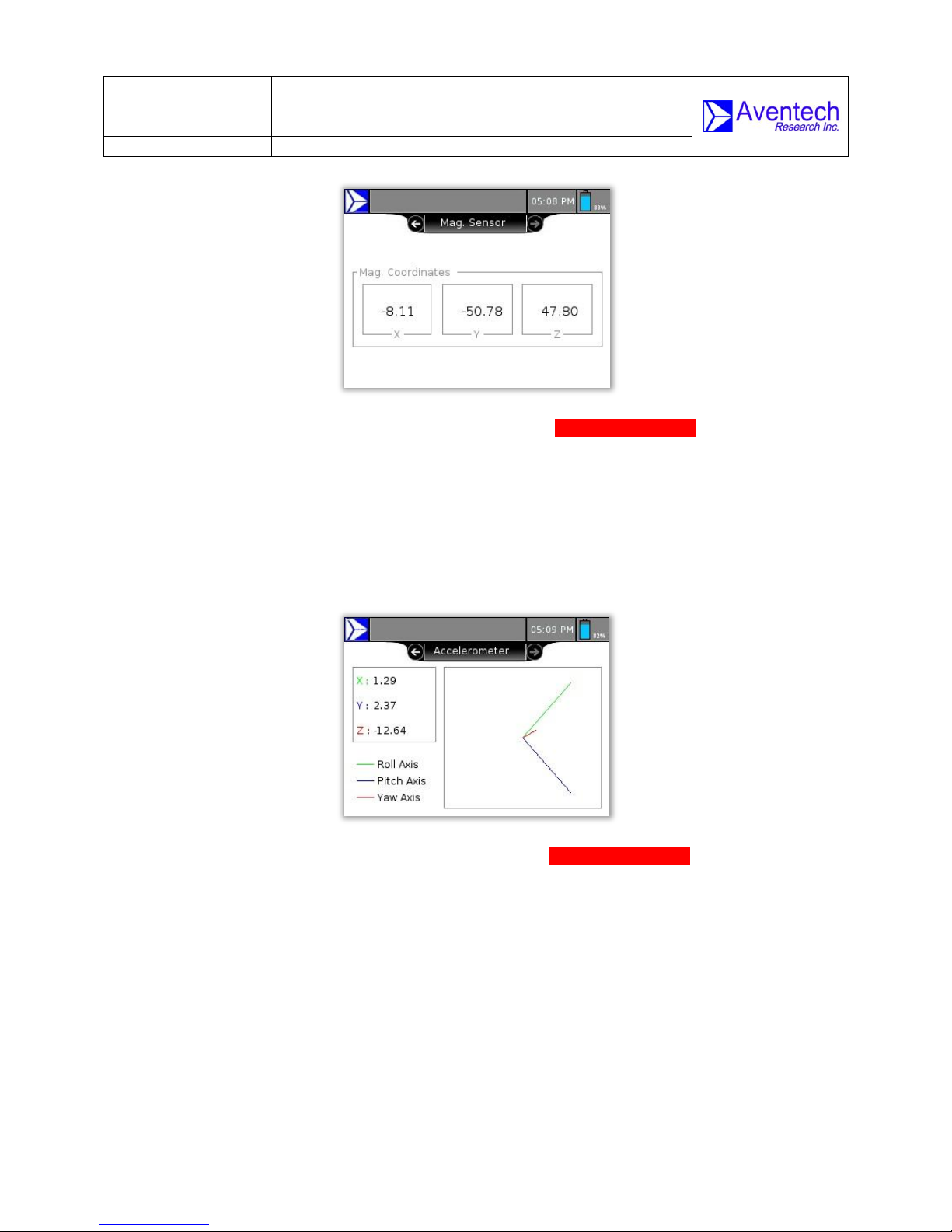

3.1.4 Magnetic Sensor

Magnetic sensor test results will show the magnetic coordinates which are generated by

the magnetic sensor at 1 Hz frequency. A compass on the screen will indicate the

approximate heading direction of the DUT.

Rev: 1.00

Date: 08.01.2013

Page: 19 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

Figure 13: Magnetic Sensor Test Results(change the image)

3.1.5 Accelerometer

Accelerometer test results will show the raw data from roll (x), pitch (y), and yaw

(z) accelerometers. A 3D animation of each axis will also be displayed on the

screen to compare the results with DUT’s orientation.

Figure 14: Accelerometer Test Results (change the image)

3.1.6 GPS

GPS test results show the location of the device under test such as latitude,

longitude, and altitude. In addition, it also provides number of satellites that are

used to obtain the results, position type, and solution status.

Rev: 1.00

Date: 08.01.2013

Page: 20 of 31

FTK100 FIELD TEST KIT

OPERATING MANUAL

Document-P/N:

FTK100-OM

© Aventech Research Inc. 2013. All Rights Reserved.

Figure 15: GPS Test Results

Position type and description are shown in the following table:

Table 1: Position Type and Description

Position Type

Description

0

No solution

1

Position has been fixed by FIX POSITION command

2

Position has been fixed by the FIX HEIGHT/AUTO command

8

Velocity computed using instantaneous Doppler

16

Single point position

17

Pseudorange differential solution

18

Solution calculated using corrections from an SBAS

19

Propagated by a Kalman filter without new observations

20

OmniSTAR VBS position

32

Floating L1 ambiguity solution

33

Floating ionospheric-free ambiguity solution

34

Floating narrow-lane ambiguity solution

48

Integer L1 ambiguity solution

49

Integer wide-lane ambiguity solution

50

Integer narrow-lane ambiguity solution

51

RTK status where the RTK filter is directly initialized from the

INS filter

52

INS calculated position corrected from the antenna

53

INS pseudorange single point solution –no DGPS corrections

54

INS pseudorange differential solution

55

INS RTK floating point ambiguities solution

56

INS RTK fixed ambiguities solution

64

OmniSTAR HP/XP position

65

OmniSTAR XP position

66

Position solution using CDDPS correction

Table of contents