Avia Propeller AV-723-1-D-C-F-R Specification sheet

O

OP

PE

ER

RA

AT

TI

IO

ON

N

A

AN

ND

D

I

IN

NS

ST

TA

AL

LL

LA

AT

TI

IO

ON

N

M

MA

AN

NU

UA

AL

L

REVERSIBLE HYDRAULICALLY CONTROLLED

VARIABLE PITCH PROPELLERS

(CONSTANT SPEED)

AV-723-1-D-C-F-R(P)

AV-725-1-E-C-F-R(P), (W)

AV-803-1-E-C-F-R(W)

AV-80 -1-E-C-F-R(W)

AV-8 -1-E-C-F-R(G), (P), (W)

Document number:

E

EN

N-

-1

13

32

20

0

ATA 61-10-20

Issue 4: October 06, 2017

Revision: March 4, 2019

The technical content of this document is approved

under authority of DOA No. EASA.21J.072.

Avia Propeller s.r.o., Beranových 65/666, 199 00 Praha 9 - Letňany, CZECH REPUBLIC

FOR OPERATORS AND SERVICE STAFF

THE PROPELLER IS A VITAL COMPONENT OF THE AIRCRAFT. IT IS VERY

IMPORTANT TO FOLLOW ALL INSTALLATION INSTRUCTIONS AND INSPECTION

PROCEDURES DESCRIBED IN THIS MANUAL.

FAILURE TO FOLLOW

THE INSTRUCTIONS AND PROCEDURES DESCRIBED IN THIS MANUAL

MAY CAUSE DAMAGE TO THE PROPELLER RESULTING IN AN AIRCRAFT

ACCIDENT.

ALL PROCEDURES DESCRIBED IN THIS MANUAL SHOULD BE PERFORMED

ONLY BY QUALIFIED PERSONNEL.

ANY ACTIVITIES BEYOND THE SCOPE OF THIS MANUAL TO BE PERFORMED

ONLY BY A PERSON TRAINED AND AUTHORIZED BY AVIA PROPELLER.

ALWAYS USE THE LATEST REVISION OF THIS MANUAL. THE LATEST

REVISION OF THIS MANUAL IS AVAILABLE FREE OF CHARGE AT

WWW.AVIAPROPELLER.COM.

VISIT WWW.AVIAPROPELLER FOR SERVICE BULLETINS, SERVICE

LETTERS AND SERVICE ADVISORIES THAT MAY BE ASSOCIATED WITH

THE PROPELLERS IN THIS MANUAL.

T

TH

HA

AN

NK

K

Y

YO

OU

U

F

FO

OR

R

C

CH

HO

OO

OS

SI

IN

NG

G

A

AV

VI

IA

A

P

PR

RO

OP

PE

EL

LL

LE

ER

R

P

PR

RO

OD

DU

UC

CT

T

Properly maintained it will give you many years of reliable service.

OPERATION AND INSTALLATION MANUAL

EN-1320

TABLE OF CONTENTS Page

LIST OF REVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II - 1

LIST OF EFFECTIVE PAGES . . . . . . . . . . . . . . . . . . . . . . . . . III-1

1. AIRWORTHINESS LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . 1 - 1

2. GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

3. MODEL DESIGNATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

4. DESIGN AND OPERATION INFORMATION . . . . . . . . . . . . . 4 - 1

5. INSTALLATION AND OPERATION INSTRUCTION . . . . . . . . 5 - 1

6. INSPECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

7. MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

8. TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

9. SHIPPING AND STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

10. TOOLING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

11. DRAWINGS AND PARTLISTS . . . . . . . . . . . . . . . . . . . . . . . . 11 - 1

12. PROPELLER CONTROL SYSTEM

(Installation with Jihostroj LUN-Series Governor) . . . . . . . . . . . 12 - 1

61-10-20

TABLE OF CONTENT Page I-1

2017

-

10

-

06

EN-1320

OPERATION AND INSTALLATION MANUAL

LIST OF REVISIONS

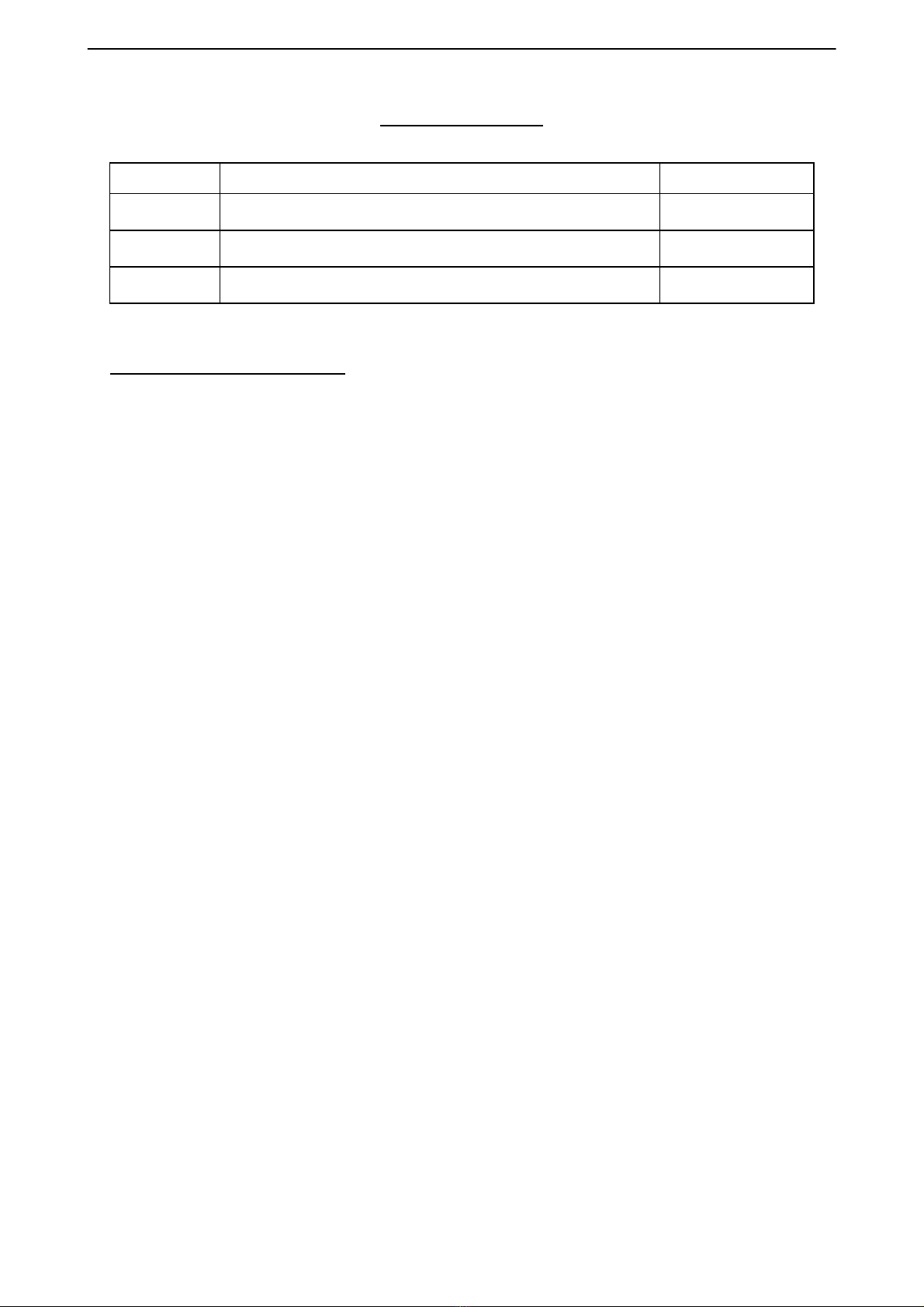

Rev.No. Page Revised Page Date

R-106/17 All 2017-10-06

R-71/18 Cover, II-1, III-1, 5-14 2018-07-27

R-23/19 Cover, II-1, III-1, 5-2, 5-14, 12-6, 12-10, 12-11, 12-16, 12-37 2019-03-04

REVISION R-23/19 - SUMMARY

Aeroshell Grease 22 added as replacement of Aeroshell Grease 5 and 6 throughout the manual.

Typo correction.

61-10-20

LIST OF REVISIONS Page II-1

201

9

-

03

-

04

OPERATION AND INSTALLATION MANUAL

EN-1320

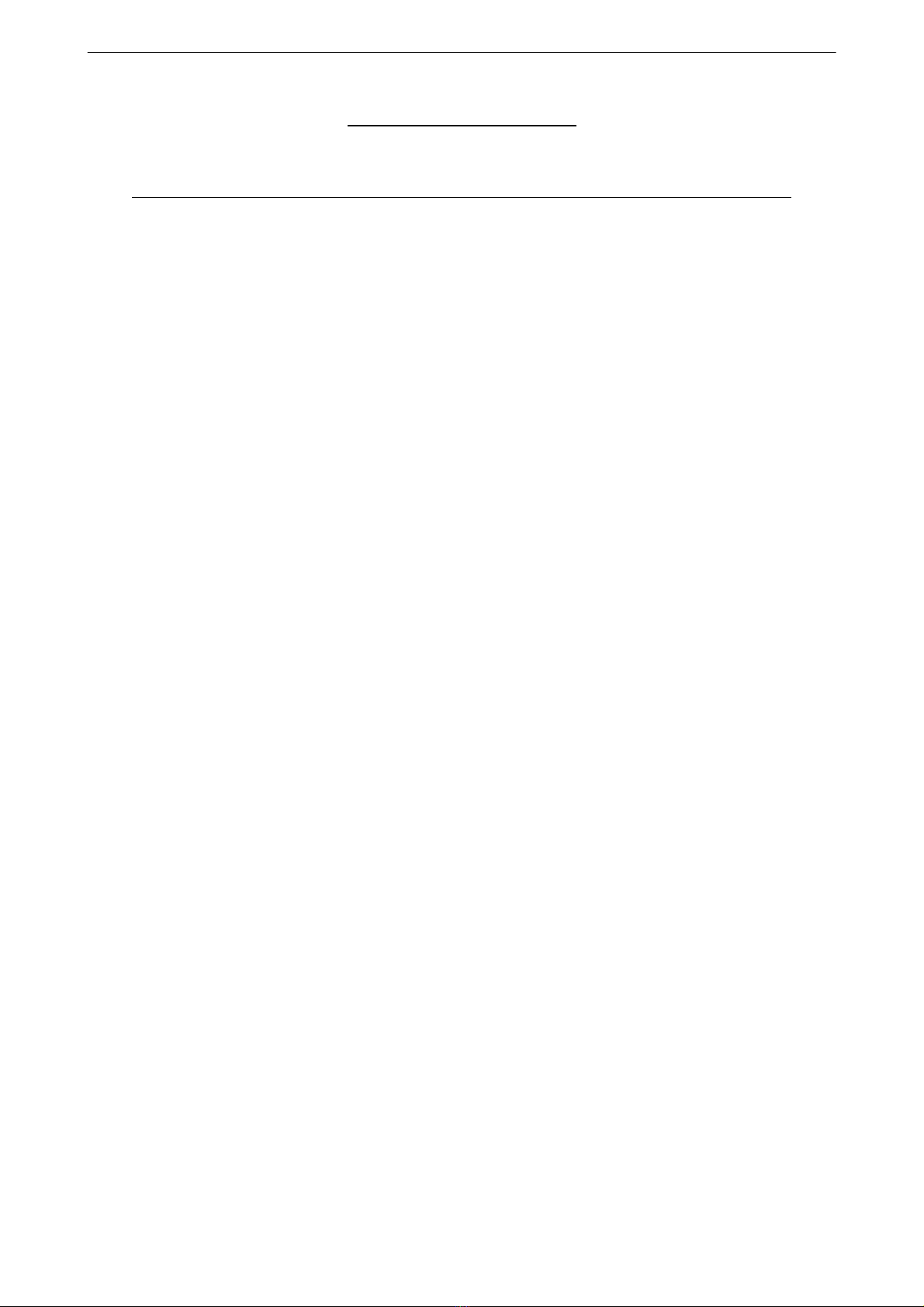

LIST OF EFFECTIVE PAGES

Page Date Page Date Page Date

Cover 2019-03-04 6-10 2017-10-06 12-8 2017-10-06

I-1 2017-10-06 6-11 2017-10-06 12-9 2017-10-06

II-1 2019-03-04 6-12 2017-10-06 12-10 2019-03-04

III-1 2019-03-04 6-13 2017-10-06 12-11 2019-03-04

6-14 2017-10-06 12-12 2017-10-06

1-1 2017-10-06 7-1 2017-10-06 12-13 2017-10-06

2-1 2017-10-06 7-2 2017-10-06 12-14 2017-10-06

2-2 2017-10-06 7-3 2017-10-06 12-15 2017-10-06

3-1 2017-10-06 7-4 2017-10-06 12-16 2019-03-04

3-2 2017-10-06 8-1 2017-10-06 12-17 2017-10-06

4-1 2017-10-06 8-2 2017-10-06 12-18 2017-10-06

4-2 2017-10-06 8-3 2017-10-06 12-19 2017-10-06

4-3 2017-10-06 9-1 2017-10-06 12-20 2017-10-06

5-1 2017-10-06 10-1 2017-10-06 12-21 2017-10-06

5-2 2019-03-04 11-1 2017-10-06 12-22 2017-10-06

5-3 2017-10-06 11-2 2017-10-06 12-23 2017-10-06

5-4 2017-10-06 11-3 2017-10-06 12-24 2017-10-06

5-5 2017-10-06 11-4 2017-10-06 12-25 2017-10-06

5-6 2017-10-06 11-5 2017-10-06 12-26 2017-10-06

5-7 2017-10-06 11-6 2017-10-06 12-27 2017-10-06

5-8 2017-10-06 11-7 2017-10-06 12-28 2017-10-06

5-9 2017-10-06 11-8 2017-10-06 12-29 2017-10-06

5-10 2017-10-06 11-9 2017-10-06 12-30 2017-10-06

5-11 2017-10-06 11-10 2017-10-06 12-31 2017-10-06

5-12 2017-10-06 11-11 2017-10-06 12-32 2017-10-06

5-13 2017-10-06 11-12 2017-10-06 12-33 2017-10-06

5-14 2019-03-04 11-13 2017-10-06 12-34 2017-10-06

5-15 2017-10-06 11-14 2017-10-06 12-35 2017-10-06

6-1 2017-10-06 11-15 2017-10-06 12-36 2017-10-06

6-2 2017-10-06 11-16 2017-10-06 12-37 2019-03-04

6-3 2017-10-06 12-1 2017-10-06 12-38 2017-10-06

6-4 2017-10-06 12-2 2017-10-06 12-39 2017-10-06

6-5 2017-10-06 12-3 2017-10-06 12-40 2017-10-06

6-6 2017-10-06 12-4 2017-10-06 12-41 2017-10-06

6-7 2017-10-06 12-5 2017-10-06 12-42 2017-10-06

6-8 2017-10-06 12-6 2019-03-04

6-9 2017-10-06 12-7 2017-10-06

61-10-20

LIST OF EFFECTIVE PAGES Page III-1

201

9

-

03

-

04

EN-1320

OPERATION AND INSTALLATION MANUAL

1.0. AIRWORTHINESS LIMITATIONS

This Airworthiness Limitations Section is EASA approved in accordance with Part 21A.31(a)(3)

and CS-P40(b) and 14 CFR Part 35.4 (A35.4). Any change to mandatory replacement times,

inspection intervals and related procedures contained in this section must also be approved.

The Airworthiness Limitations Section is FAA approved and specifies maintenance required

under §§ 43.16 and 91.403 of the Federal Aviation Regulations unless an alternate program

has been FAA approved.

1.1. Service Life Limits

1) The life limit should be established for certain part of the propeller assembly. This limit

requires the replacement of such part after a specified number of hours of operation (TSN,

Time Since New).

2) This section summarizes the life limited parts of propellers in this manual.

3) The blade life limit is not affected whether or not the de-icing components are installed.

4) Below mentioned life limits of the parts apply to all of propeller models and propeller-aircraft-

engine combinations, unless stated otherwise.

5) Life limited parts of AV series propellers for turbine engines

Part Life limit

Blade . . . . . . . . . . . . . . . . . 12 000 hours

Hub . . . . . . . . . . . . . . . . . . 12 000 hours

Bearing race . . . . . . . . . . . 12 000 hours

Blade bushing . . . . . . . . . . 12 000 hours (if applicable)

Cylinder . . . . . . . . . . . . . . . 12 000 hours (if applicable)

61-10-20

AIRWORTHINESS LIMITATIONS Page 1-1

2017

-

10

-

06

OPERATION AND INSTALLATION MANUAL

EN-1320

2.0. GENERAL

2.1. Statement of Purpose

This publication provides operation, installation and line maintenance information on the Avia

hydraulically controlled, variable pitch AV series propellers with aluminum blades. All models

are equipped with reverse and feathering capability.

In addition to the propeller assembly, the information on governing system with Jihostroj

LUN-Series governor is also adressed in this manual.

Installation, removal, operation and trouble shooting data is included in this publication.

However, the airplane and engine manufacturer's manuals should be used in addition to this

manual.

2.2. Overhaul

For the list of TBO limits of all Avia propellers refer to latest issue of Avia Service Bulletin No.1

available at Avia Propeller website at www.aviapropeller.com.

The overhaul is periodic process performed at specific intervals in which the propeller is

disassembled and inspected. Damaged parts are repaired or replaced. All sealing elements are

replaced. Corrosion preventive coatings of the parts are renewed. Propeller is reassembled,

adjusted and balanced.

The overhaul interval is usually referred to as Time Between Overhaul (TBO).

The TBO limit is based on operation limit expressed in hours of operation and on calendar limit

expressed in calendar months. The overhaul should be accomplished if one of this limit is

acquired, whichever occurs first.

The overhaul shall be accomplished only by Avia Propeller or authorized service station in

accordance with latest revision of the Overhaul manual mentioned in section „Related

documents“ in this chapter.

2.3. Related Documents

1) Avia Manual EN-1291 (61-10-91) - Overhaul Manual

2) Avia Manual EN-1370 (61-10-70) - Overhaul Manual for Metal Blades

3) Avia Service Bulletin No.1

Includes an overhaul intervals of all Avia propellers. Available on Avia website at

www.aviapropeller.com.

4) Other Avia service documents (Service Bulletins, Service Letters, Service Advisories)

which may relate to propellers in this manual are available on Avia website at

www.aviapropeller.com.

61-10-20

GENERAL Page 2-1

2017

-

10

-

06

EN-1320

OPERATION AND INSTALLATION MANUAL

2.4. Dimensions

All dimensions in this manual are in millimeters with equivalent in inches.

All temperature units in this manual are in Celsius grades with equivalent in Fahrenheit grades.

All pressure units in this manual are in megapascals with equivalent in pounds per square inch.

2.5. Part Replacement

Basically, only some outside mounted parts, such as propeller-to-engine o-ring, de-icing

cables and some other de-icing components, some fasteners, may be replaced in the field

by the user. Some other parts may be replaced in the field only by person trained and

authorized by Avia Propeller.

Contact the Avia Propeller for information on part replacement. Parts that did not come

through the manufacturer's quality control system will void the warranty and may render

the propeller unairworthy.

61-10-20

GENERAL Page 2-2

2017

-

10

-

06

OPERATION AND INSTALLATION MANUAL

EN-1320

3.0. MODEL DESIGNATION

3.1. Hub designation

A

V

-

72

5

-

1

-

E

-

C

-

F

-

R

(W)

-

( )

1

2

3

4

5

6

7

8

9

10

11

1 Avia Propeller (manufacturer)

2 V= Variable pitch propeller

3Type of blade shank

4 Number of blades

5 Consecutive number of series

6 Code for propeller flange

D = ARP 502, six mounting studs 1/2“-20UNF, two dowel pins,

pitch circle 4.0 inch (101,6 mm)

E= ARP 880, eight mounting studs 9/16“-18UNF, two dowel pin holes,

pitch circle 4.25 inch (107,95 mm)

7 Letter for counterweights

C= Counterweights for pitch change forces to increase pitch

8 Letter for feathering

F= Feathering capability

9 Letter for reverse

R= Reverse capability

10 Code for reverse system

(G) = Reverse system Garrett TPE-331-( )

(P) = Reverse system Pratt&Whitney PT6A-( )

(W) = Reverse system Walter M601-( ) / GE H-Series

11 Code for design changes

Small letter: Modification not affecting interchangeability

Capital letter: Modification restricting or excluding interchangeability

-R(W) blank = overspeed governor for 2080 rpm engines

-R(W)-A = overspeed governor for 1950 rpm engines

61-10-20

MODEL DESIGNATION Page 3-1

2017

-

10

-

06

EN-1320

OPERATION AND INSTALLATION MANUAL

3.2. Blade Designation

CFR ( )

230

-

433

( )

1 2 3

4 5

1 Code for pitch change pin position

CFR = pitch change pin for feathering and reverse ; pitch change forces

to increase pitch

2 Sense of rotation

blank = right-hand, tractor

3 Propeller diameter in cm

4Consecutive number of basic type

(includes design configuration and aerodynamic data)

5 Code letter for design changes

Small letter: Modifications not affecting interchangeability

Capital letter: Modifications restricting or excluding interchangeability

3.3. The complete propeller designation is a combination of both hub and blade designations,

separated by a slash mark ; for instance AV-725-1-E-C-F-R(W) / CFR230-433a.

3.4. The hub-serial No. starts with the year of manufacture. All records of the propeller are

registered in respect to this number.

3.5. The propeller for a certain aircraft-engine combination is always defined according the

hub- blade- spinner combination. For the actual blade settings, depending on the aircraft

model, the propeller logbook must be considered.

61-10-20

MODEL DESIGNATION Page 3-2

2017

-

10

-

06

OPERATION AND INSTALLATION MANUAL

EN-1320

4.0. DESIGN AND OPERATION INFORMATION

The variable pitch propeller consists of the following main groups:

- Hub with blade bearing

- Pitch change mechanism

- Propeller blades

- Counterweights

- Spinner

- Propeller governor

- Electrothermal de-icing system

4.1. Hub

The one-piece hub is made from forged or milled aluminum alloy with the outer surface

shot-peened and anodized.

Propellers with thread-type blades

The blade bearings are special designed ball bearings, whereas the balls act as split retainers

in order to hold the blades in the hub, creating an increased safety factor against blade loss.

The outer bearing race is a one-piece part and pressed into the hub, while the inner race is split

and installed on the blade shank. The blade preload is adjusted by the thickness of plastic

shims. Blade and bearing are held in the hub by a retention ring.

Propellers with threadless-type blades

The inner bearing race is located on the blade bushing, whereas the blade are screwed into the

bushing and tightened by the clamp. The outer bearing race is a one-piece part and pressed

into the hub. The blade preload is adjusted by the prestressing nut, which holds the blade

bearing and blade in the hub.

The pitch change of the blades is obtained with a pin in the blade shank or in the blade bushing

face. A plastic block connects the blade with the piston and the axial movement of the servo

piston turns the blades. On the front piston the return spring and the sleeve, which acts as high

(low) pitch stop, are installed.

The inner part of the hub is used as the cylinder for the pressure oil. This arrangement allows a

simple and lightweight design. The front spinner support is used to have the balance weights

installed.

On the Walter Reverse System the pitch change cylinder is installed on the hub front part.

4.2. Pitch Change Mechanism

The pitch change mechanism of the blades is obtained with a pin in the blade shank or on the

blade bushing. A plastic block connects the blade with the piston extension and the axial

movement of the servo piston turns the blades. On the front piston guide the return spring is

installed enabling feathering. With the Walter System the reverse system is dual acting,

whereas feathering is achieved by using oil pressure.

The hydraulic pitch change mechanism contains a piston. In the normal operating range the

pitch change piston moves between full feathering and the hydraulic low pitch stop. In the beta

range the hydraulic low pitch stop moves via the beta linkage until the needed negative thrust

is reached.

61-10-20

DESIGN AND OPERATION INFORMATION Page 4-1

2017

-

10

-

06

EN-1320

OPERATION AND INSTALLATION MANUAL

4.2.1. For Pratt&Whitney Application

Outside the hub there are check nuts and in the inner part of the hub there are 3 stop nuts.

High pitch/feathering can be set by turning the check nuts. Low pitch can be set by turning the

internal stop nuts The full reverse stop is not adjustable in the field.

4.2.2. For Garrett Application

Outside the hub are two check nuts. High pitch feathering stop can be adjusted by turning the

check nuts. The beta tube is installed in the guide rod. Due to turning the beta tube inside or

outside, the hydraulically low pitch stop can be adjusted.

The beta tube is secured by the screw AN3H-13A and the stop nut MS 20364-1032A.

Put on both sides washers AN 960-10.

4.2.3. For Walter Application

All stops are internal and can not be changed. No adjustment is necessary, because during

manufacturing all pitch settings were made.

4.3.

Propeller Blades

Propeller blades are made from aluminium alloy. They are turning in the ball bearings with one

set of balls in the propeller hub. Connection with the pitch change mechanism is made through

plastic pitch change blocks installed on the pins in the blade shank (threadless-type blades) or

on the blade bushing face (thread-type blades).

Propeller blades can be designed with counterweights installed on the blade shank.

Leading edges of the blades can be protected with polyurethane guards for mechanical

damages prevention.

4.4. Counterweights

Propellers may by equipped with counterweights on the blade shanks or as the part of the hub.

If governor supplied oil is lost during operation, force from counterweights move the blades to

high pitch and feather to prevent propeller overspeed.

4.5. Spinner

The spinnerdome is made from fiber reinforced composite or spinformed aluminum alloy. The

bulkhead is spinformed or truncated aluminium alloy.

If the spinner dome has no integrated stiffeners, then the front support is installed as part of the

hub. Filler plates increase the stiffness of the dome on the cutouts for the blades. The dome is

mounted on the supports by means of screws.

61-10-20

DESIGN AND OPERATION INFORMATION Page 4-2

2017

-

10

-

06

OPERATION AND INSTALLATION MANUAL

EN-1320

4.6. Propeller Governor

4.6.1. See Avia Manual No. E-1707 for Avia P-W( ) Series governors.

4.6.2. See Woodward Manual for:

Garret TPE-331-( ): No. 33091-( )

Pratt and Whitney PT6A: No. 33163-( ) Primary

No. 33048-( ) Overspeed

4.6.3. See Walter Manual for:

Walter M601-Series: No. 098 2302 Chapter 61.

4.6.4. See Propeller Control System chapter in this manual for information on propeller control system

associated with Jihostroj LUN-series governors.

4.7. Electrothermal De-icing System

The propeller may have electrical or liquid de-icing systems installed. The de-icer boots are

bonded onto the blades as usual. The rest of the electrical system is equal to existing

components, with slip ring and wire harness.

4.8. Oil

The propellers operate with the oil supplied from engine lubricating system. Refer to engine

manufacturer´s manual for more information.

61-10-20

DESIGN AND OPERATION INFORMATION Page 4-3

2017

-

10

-

06

EN-1320

OPERATION AND INSTALLATION MANUAL

5.0 INSTALLATION AND OPERATION INSTRUCTION

CAUTION 1: DO NOT USE THE SPINNER BULKHEADS TO SUPPORT THE WEIGHT OF THE

PROPELLER ASSEMBLY, OTHERWISE THEY COULD BE IRREPARABLY

DAMAGED.

CAUTION 2: DO NOT USE THE BLADES TO SUPPORT THE WEIGHT OF THE PROPELLER

ASSEMBLY, OTHERWISE THEY COULD BE DAMAGED.

CAUTION 3: TAKE CARE NOT TO DAMAGE THE DE-ICERS COMPONENTS (AS

APPLICABLE) FROM THE SLINGS WHEN LIFTING THE PROPELLER.

CAUTION 4: DO NOT STAND THE PROPELLER ON THE BETA RING OTHERWISE IT MAY

BE DAMAGED LEADING TO INCORRECT FUNCTION OF THE BETA SYSTEM.

REMOVE THE SHIPPING PLUG FROM PROPELLER MOUNTING FLANGE

AFTER IS HANGED ON THE CRANE FOR INSTALLING ON ENGINE.

WARNING: CLEANING AGENTS ARE FLAMMABLE AND TOXIC TO THE SKIN, EYES AND

RESPIRATORY TRACT. SKIN AND EYE PROTECTION IS REQUIRED. AVOID

PROLONGED BREATHING OF VAPORS. USE IN WELL VENTILATED AREA.

FOLLOW MANUFACTURER´S SAFETY PRECAUTIONS.

5.1.1 All propellers of these designs are only suitable for installation on flange type engines. The

code for the flange type can be seen from the model designation (see Chapter 3).

5.1.2 The described propellers are usually installed on the engine with the blades in feathering position.

5.2 Electrical propeller de-icing may be used optionally. Observe Aircraft Flight Manual for the

limitations during ground operation in order to avoid damage of the de-ice boots (overheating).

5.3 Spinner Dome Removal

a) Propeller AV-725 with metal spinner dome

Remove all screws attaching the spinner dome to the rear bulkhead and to the stiffeners

at the blade cutouts, and remove the spinner dome from the propeller. Do not remove

the screws attaching the stiffeners at the blade cutouts to the rear bulkhead.

NOTE: Do not remove the screws attaching the front bulkhead inside the spinner dome

(the screws approx. at half the height of the spinner dome). Remove the spinner

dome and front bulkhead as assemly.

If the screws attaching the spinner dome to the front bulkhead were removed by mistake,

remove the spinner dome and the front bulkhead from the propeller. See marking 1 to 5

inside the spinner dome (near the blade cutouts) and on the front bulkhead (near the rim)

and reinstall the front bulkhead into the spinner dome. Be sure that all screws are properly

tightened.

NOTE: Information on the screws attaching the spinner dome to the front bulkhead is not

applicable to models, where the front bulkhead is riveted to the spinner dome (no

screws in the area of the front bulkhead).

b) Propeller AV-725 with composite spinner dome and all other propeller models

Remove all existing screws attaching the spinner dome to the rear and front bulkheads and

to the stiffeners in the blade cutouts, and remove the spinner dome from the propeller. Do

not remove the screws attaching the stiffeners at blade cutouts to the rear bulkhead.

61-10-20

INSTALLATION AND OPERATION INSTRUCTION Page 5-1

2017

-

10

-

06

OPERATION AND INSTALLATION MANUAL

EN-1320

5.4 Installing the Blades into the Hub (except model AV-844)

a) Observe the label located on the blade. When installing the blade into the hub, make sure

that position number on the label corresponds with the number stamped on the hub, at

the bushing where the blade will be installed. See Figure 5-1.

CAUTION: IT IS IMPORTANT TO INSTALL THE BLADES INTO THEIR MATCHING

BUSHINGS IN THE HUB. OTHERWISE VIBRATIONS MAY OCCUR,

RESULTING IN DAMAGE TO THE ENGINE.

FIGURE 5-1

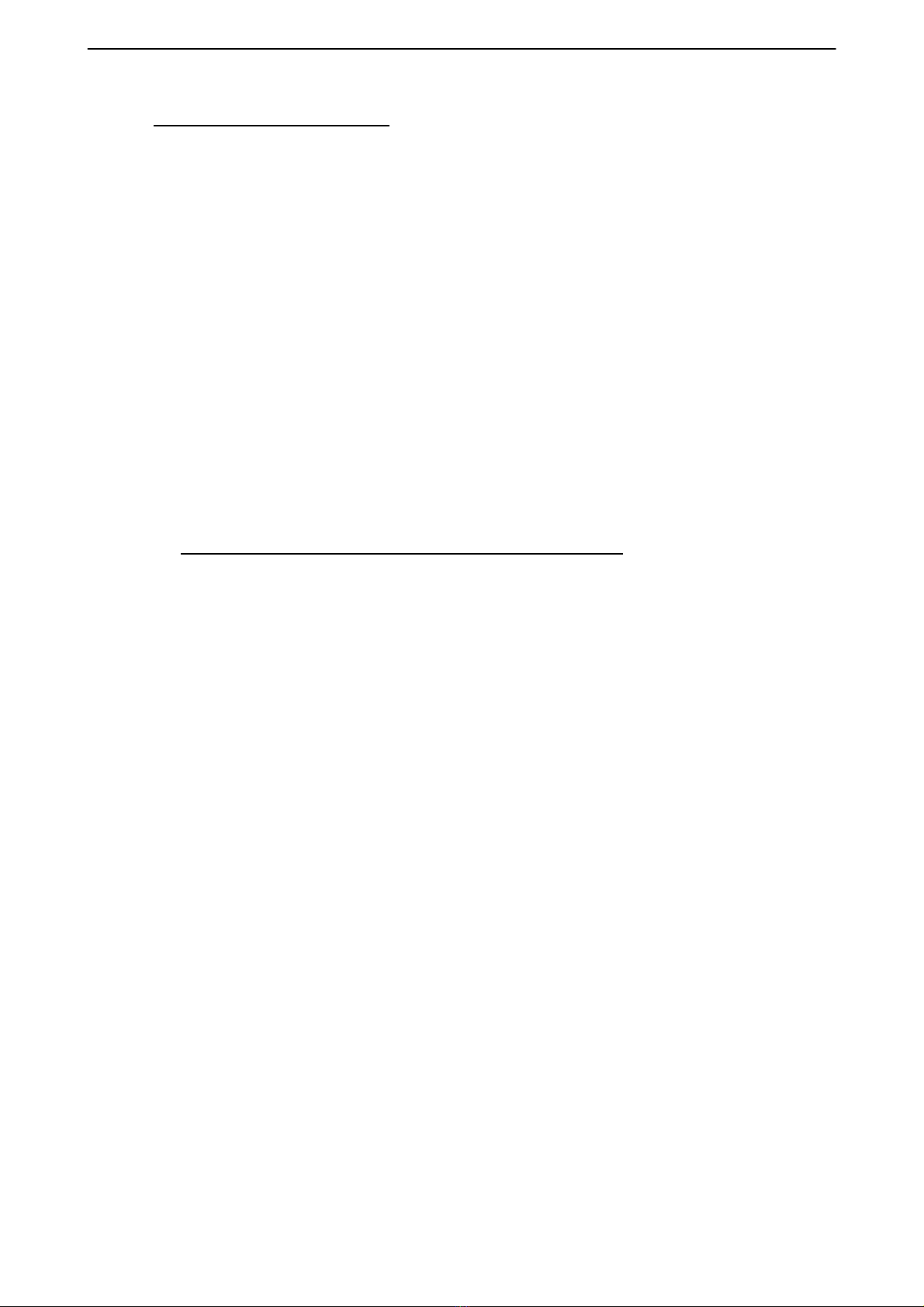

b) Check that o-ring is installed on the blade shank. See Figure 5-2. This o-ring is usually

installed on the shank when the blades are delivered for initial instalation.

NOTE: The o-ring prevents moisture to get into the blade bushing. Otherwise corrosion

of the blade and blade bushing may occur. This can cause the blade and blade

bushing will be scrapped at overhaul.

c) Make sure that blade shank and inside of the blade bushing are clean and dry. Clean with

lint-free cloth, either dry or lightly dampened in MEK, as necessary.

CAUTION: AVOID CONTACT OF THE O-RING WITH CLEANING SOLVENT.

d) Lightly grease the blade thread with Aeroshell Grease 5, 6 or 22.

CAUTION: DO NOT GREASE THE CLAMPING PORTION OF THE BLADE SHANK,

SEE FIGURE 5-2. IT MAY DECREASE CLAMPING ACTION LEADING

TO CHANGE OF BLADE ANGLE SETTING IN OPERATION.

e) Make sure that the blade clamp is fully released.

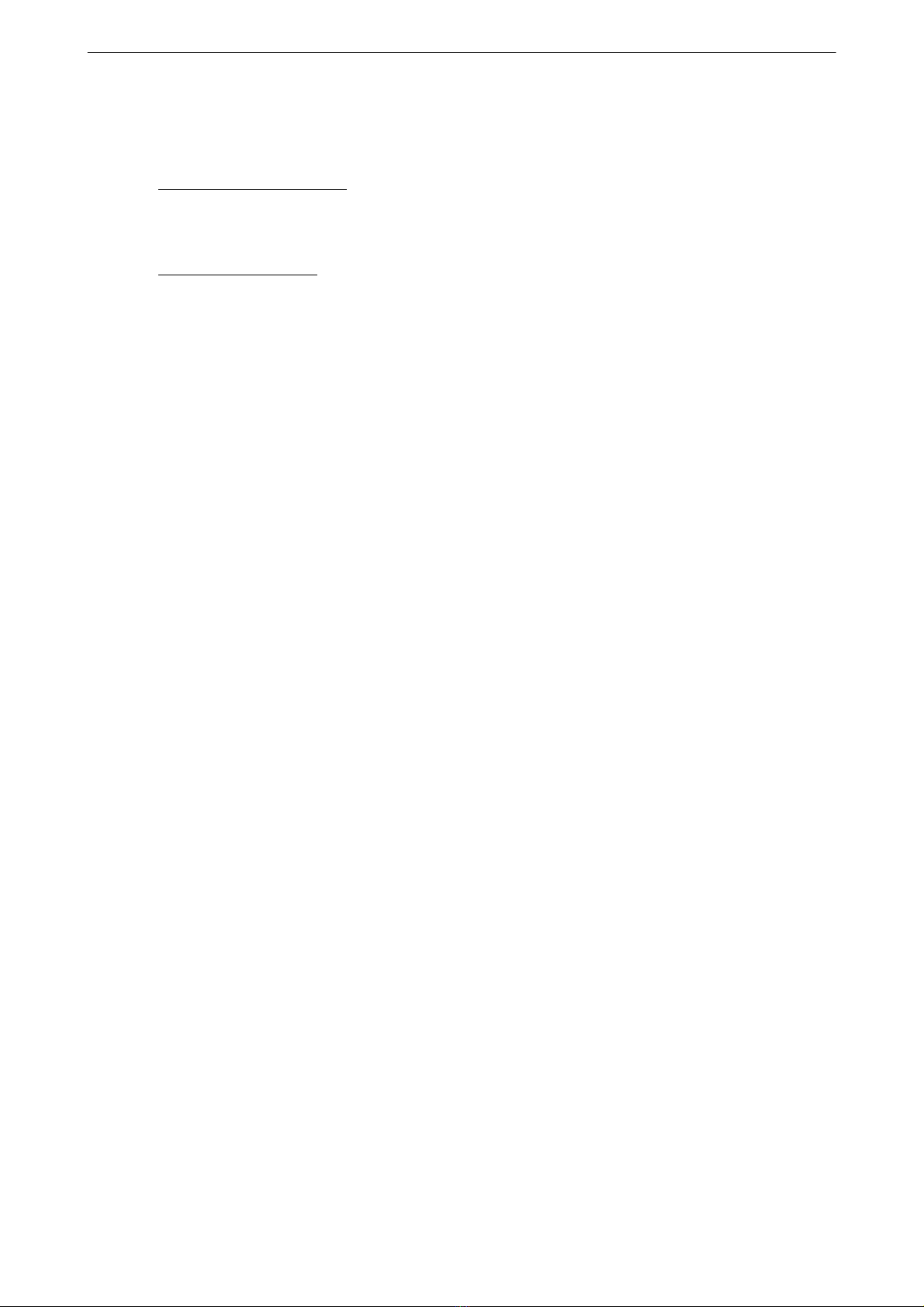

f) Slowly screw the blade into blade bushing until is fully screwed in. Then turn the blade

back to align the position mark on the blade with matching mark on the blade bushing.

See Figure 5-3.

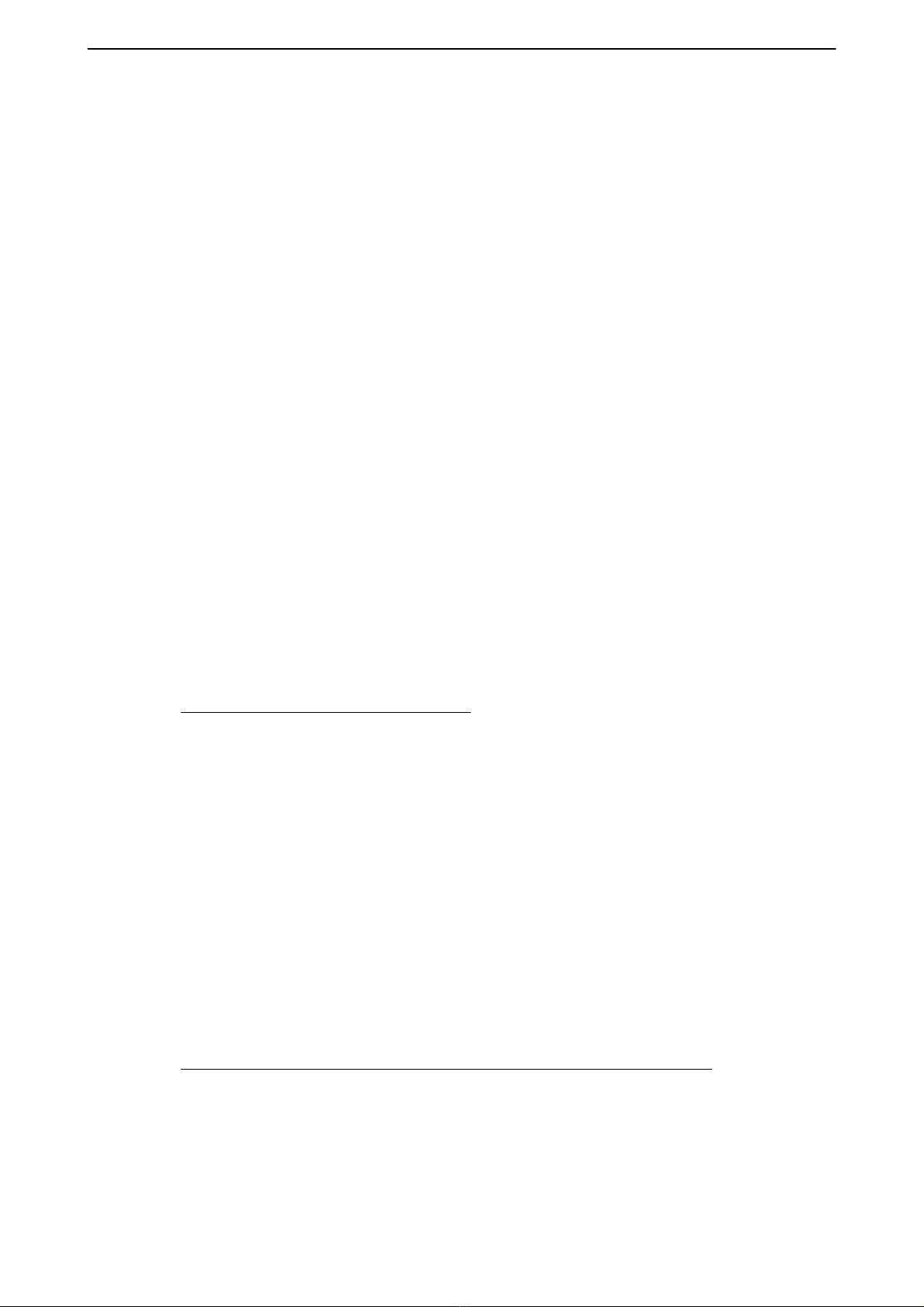

g) Position the clamp so that pin in the blade bushing is in center of the gap. See Figure 5-4.

61-10-20

INSTALLATION AND OPERATION INSTRUCTION Page 5-2

201

9

-

03

-

04

EN-1320

OPERATION AND INSTALLATION MANUAL

FIGURE 5-2

FIGURE 5-3

FIGURE 5-4

h) Lubricate the screw and nut with graphite grease. Tighten and torque the clamp to

65-70 Nm (48-52 ftlb).

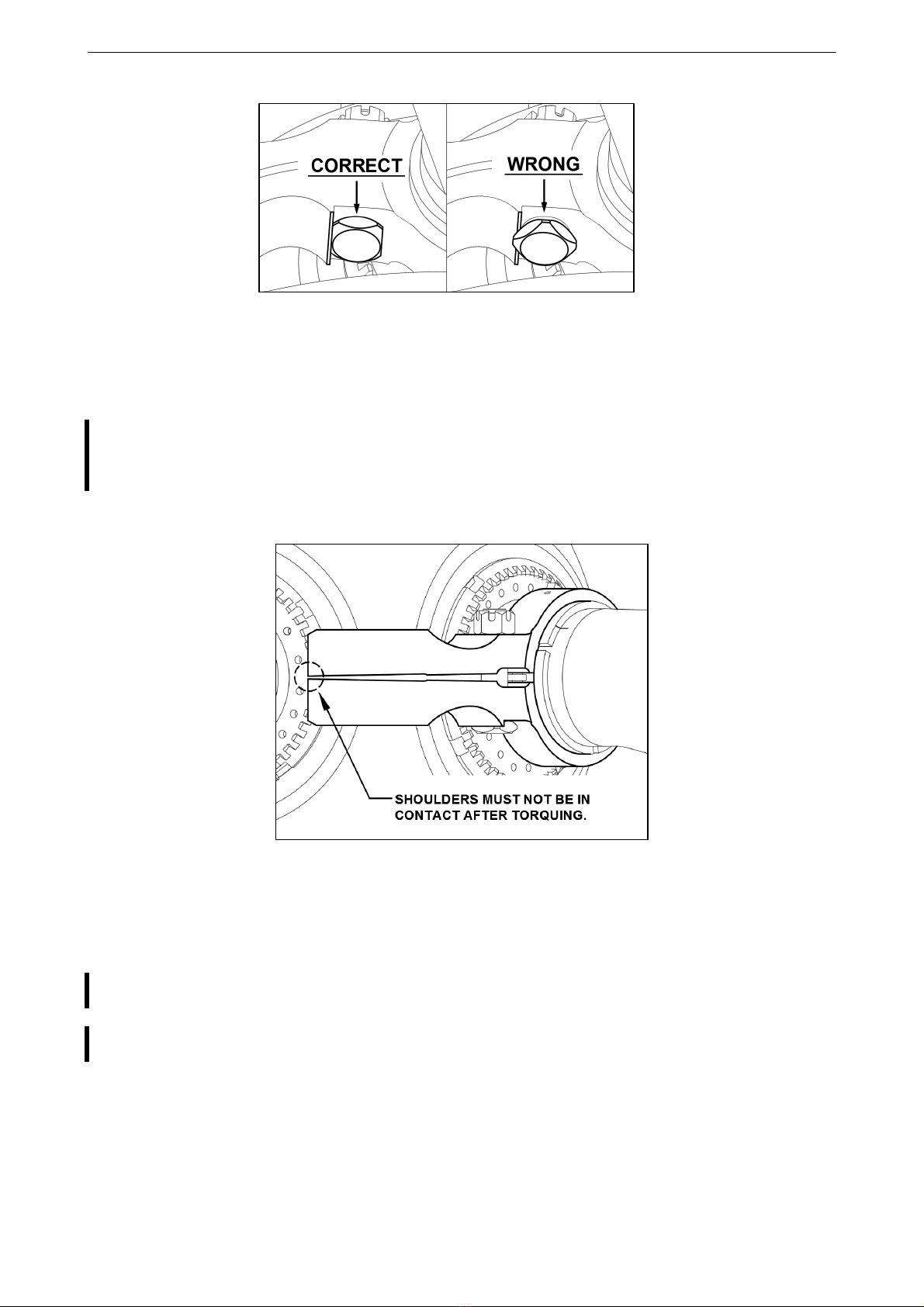

CAUTION: TAKE CARE TO CORRECT SEATING OF THE BOLT HEAD WHEN

TIGHTENING THE CLAMP - SEE FIGURE 5-5. HOLD THE BOLT HEAD

IN CORRECT POSITION WHILE TIGHTENING THE NUT. CHECK

THE CORRECT SEATING OF THE BOLT AFTER TORQUING.

INCORRECTLY TIGHTENED CLAMP WILL CAUSE THE CHANGE OF

BLADE ANGLE SETTING IN OPERATION.

61-10-20

INSTALLATION AND OPERATION INSTRUCTION Page 5-3

2017

-

10

-

06

OPERATION AND INSTALLATION MANUAL

EN-1320

FIGURE 5-5

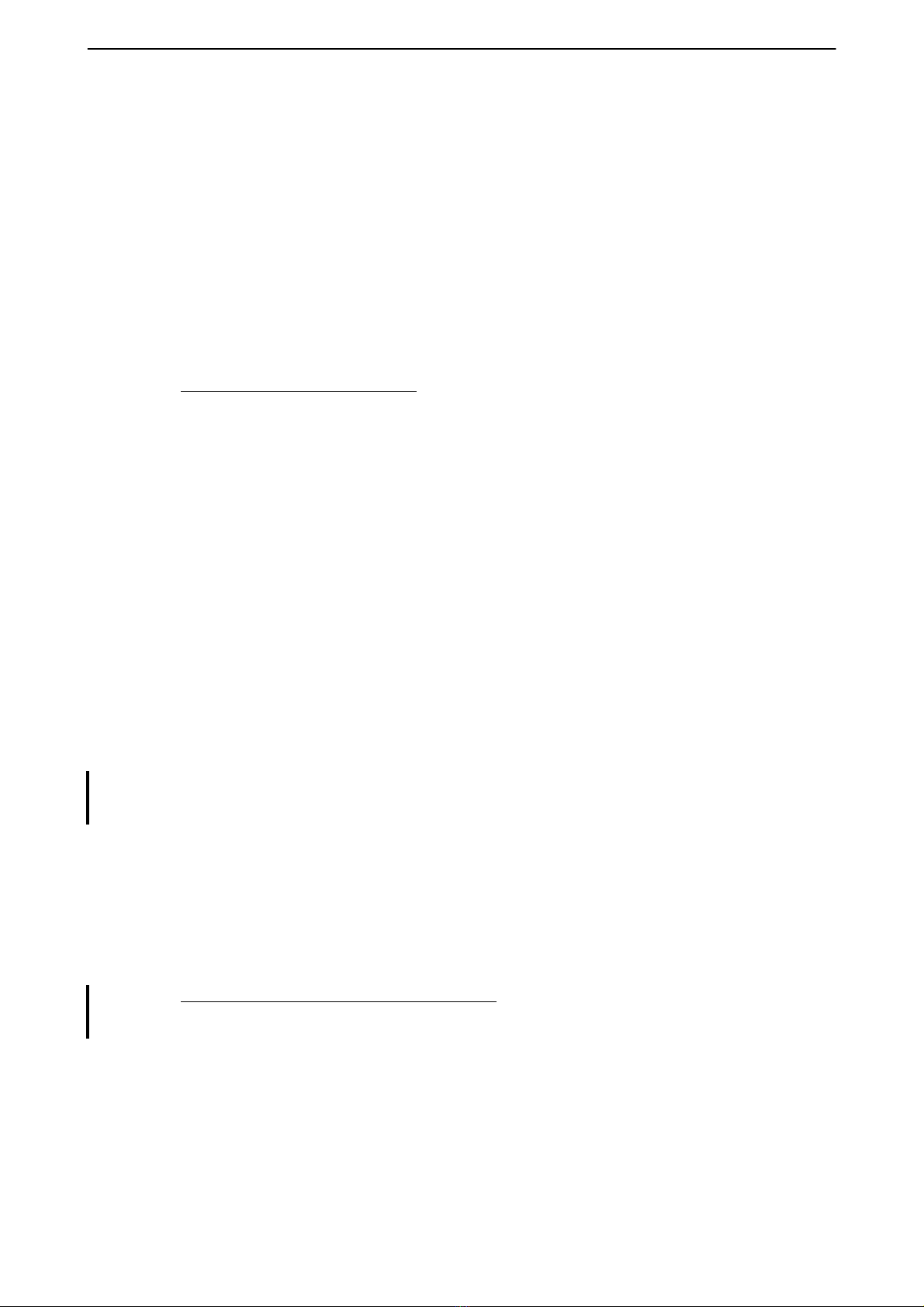

i) Check the clamp after tightening. The shoulders must not be in contact after tightening to

a specified torque. See figure 5-6.

CAUTION: THE CONTACT BETWEEN CLAMP SHOULDERS AFTER TORQUING

INDICATES THAT THE CLAMP IS NOT PROPERLY TIGHTENED TO

SPECIFIED TORQUE. IT MAY CAUSE THE CHANGE OF BLADE ANGLE

SETTING IN OPERATION.

FIGURE 5-6

j) As necessary, additionally tighten the nut to match the nearest cotter pin hole in the bolt.

Secure the nut with a cotter pin.

CAUTION 1: TURN THE NUT ALWAYS IN TIGHTENING DIRECTION, NEVER

OTHERWISE.

CAUTION 2: THE COTTER PIN MUST NOT BE REUSED. USE ALWAYS A NEW

COTTER PIN WHEN INSTALLING THE BLADE INTO THE HUB.

NOTE: THE CONTACT OF CLAMP SHOULDERS AFTER ADDITIONAL TIGHTENING

IS ACCEPTABLE.

61-10-20

INSTALLATION AND OPERATION INSTRUCTION Page 5-4

2017

-

10

-

06

EN-1320

OPERATION AND INSTALLATION MANUAL

5.5 Electrothermal De-icing System (if installed)

With the screws and toothed washers, connect the cables to matching contacts in the de-icers.

See marking on the cable and on the de-icer.

5.6 Before Installing the Propellers AV-725 and AV-844 Ending in -R(P)

Before installing the propeller on the engine, the beta ring must be pushed forward to allow

access to the propeller mounting flange. See Figures 5-7 and 5-8.

a) Check the distance 46,7±0,2 mm (1.84±0.008 inch) from the beta ring to the propeller

mounting flange.

b) Remove safety wire from the cover caps.

c) Unscrew the cover caps from the hub.

WARNING: BE CAREFUL WHEN REMOVING THE COVER CAP BECAUSE THE SPRING

FORCE UNDER THE CAP.

d) Remove the springs and spring guides from the hub.

e) Push the beta ring toward the propeller mounting flange. See Figure 5-9.

FIGURE 5-7

FIGURE 5-8

61-10-20

INSTALLATION AND OPERATION INSTRUCTION Page 5-5

2017

-

10

-

06

OPERATION AND INSTALLATION MANUAL

EN-1320

FIGURE 5-9

5.7 Before Installing the Propeller Ending in -R(G) on the Engine

Measure the distance “X“ (see Figure 5-10) for the dimension, how far the beta tube must be

turned in (was recorded during previous propeller removal). This is important to set the low

pitch stop.

The O-ring „B“ in the engine flange and the O-ring „A“ on the beta-tube (see Figure 5-10) must

be replaced with every propeller installation.

FIGURE 5-10

61-10-20

INSTALLATION AND OPERATION INSTRUCTION Page 5-6

2017

-

10

-

06

EN-1320

OPERATION AND INSTALLATION MANUAL

5.8 Installing AV-( )-E-( ) Propeller on the Engine

a) Hang the propeller on the crane hoist with a sling. Move the propeller to the engine

mounting flange.

WARNING: MARE SURE THE CRANE HOIST AND SLINGS HAVE A MINIMUM

OF 450 KG (1000 LBS) LIFTING CAPACITY.

CAUTION: TAKE CARE NOT TO DAMAGE DE-ICING COMPONENTS FROM

THE SLINGS, IF APPLICABLE.

b) Make sure the propeller flange and the engine flange are clean.

c) Check that o-ring is installed in the propeller mounting flange.

d) Models ending in -R(W) and -R(G)

Install the o-ring(s) into the engine flange (engine accessory).

e) Align mounting studs and dowel pin holes in the propeller flange with dowel pins and

mounting holes in the engine flange.

f) Carefully slide the propeller onto the engine flange.

NOTE: Depending on installation, there may be not enough space between propeller and

engine to insert mounting nuts with washers onto the studs, if the propeller is fully

slide onto the engine flange. In that case, the propeller to be slide onto the engine

flange in a few steps.

CAUTION: PLEASE NOTE THAT THE PROPELLER SHOULD NOT BE PULLED ONTO

THE ENGINE FLANGE WITH MOUNTING NUTS IN ORDER TO AVOID

DAMAGE TO THE PROPELLER AND TO AVOID SHEARING OFF CHIPS

CAUSING OIL LEAKS ON THE O-RING(S).

g) Make sure that propeller studs, nuts and washer are clean. Apply anti-seize compound per

MIL-PRF-83483 (e.g.LoctiteMoly 50) or Loctite 8012 Moly Paste to threads of studs and

mounting nuts; also to faces of nuts and washers.

h) Make sure that the propeller is fully seated on the engine flange throughout 360 degrees

of rotation. Torque all mounting nuts in the steps and sequences for “E” Flange, as shown

in Figure 5-11.

i) Thoroughly wipe the mounting studs, nuts and washer from anti-seize compound. After the

ground run of the engine, inspect the propeller flange side for any traces of anti-seize

compound on the brush block, slip ring, beta ring, and other parts. Thoroughly wipe before

flight.

CAUTION: ANI-SEIZE COMPOUND ON THE PARTS WILL CAUSE DAMAGE TO

THE PARTS IN OPERATION.

j) Installation with nonself-locking mounting nuts

Safety all mounting nuts with 0,81 mm (0.032 inch) stainless steel safety wire, two nuts per

safety.

61-10-20

INSTALLATION AND OPERATION INSTRUCTION Page 5-7

2017

-

10

-

06

This manual suits for next models

12

Table of contents