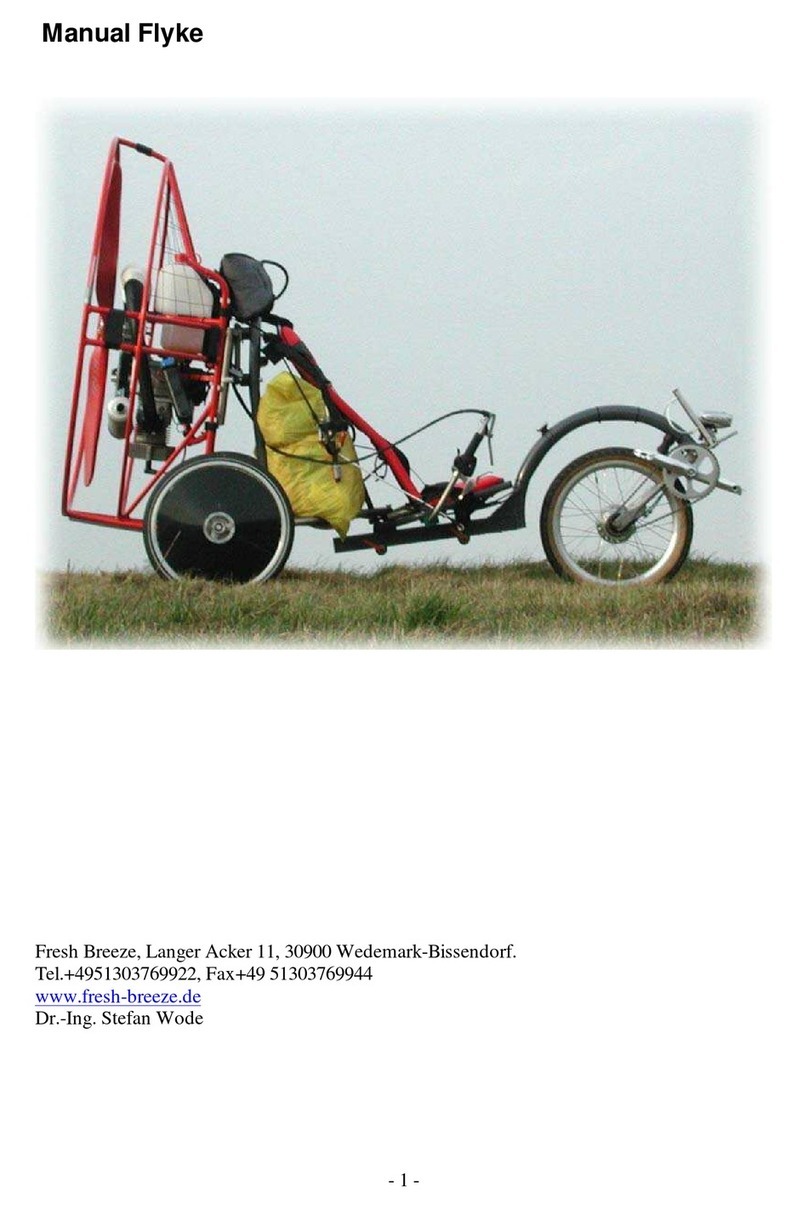

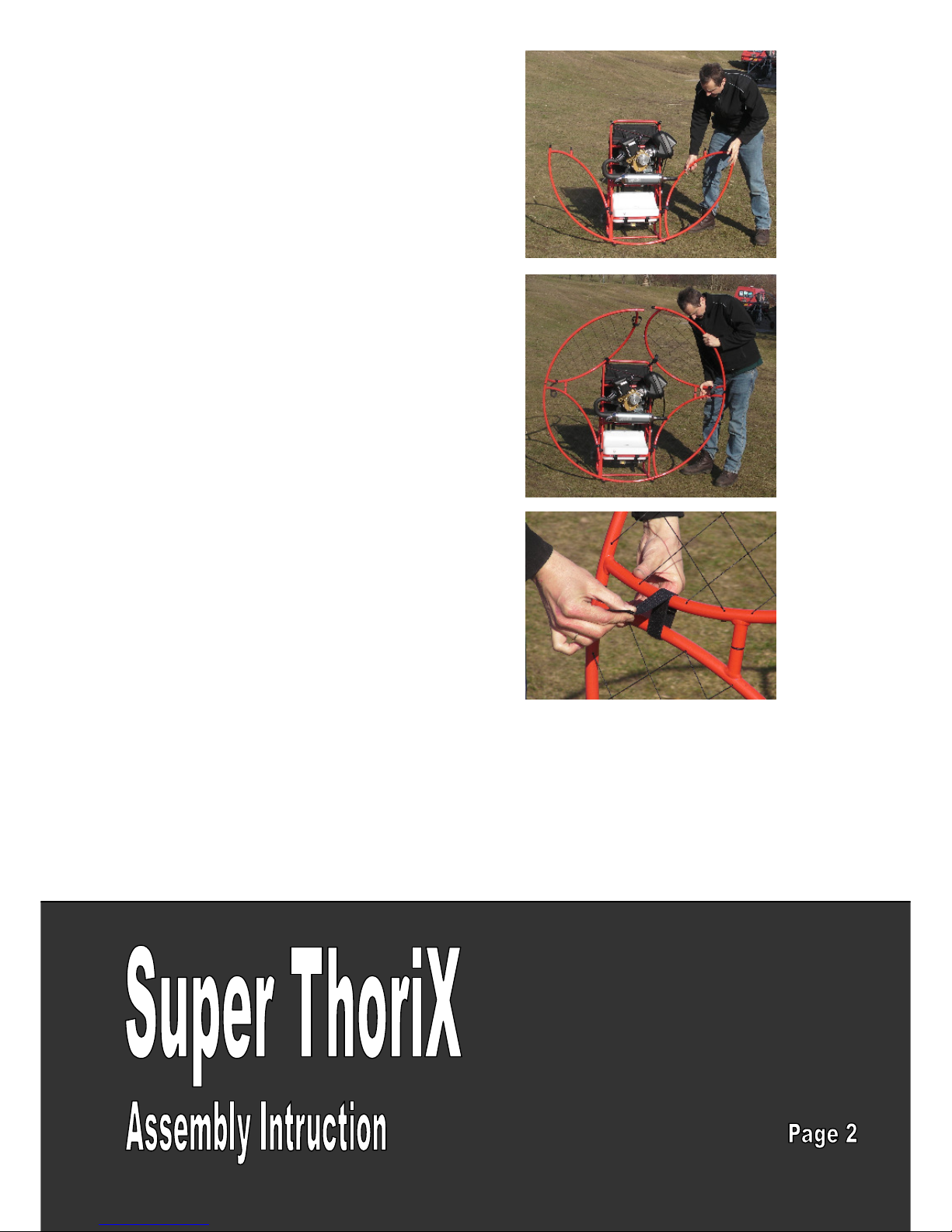

Prior to operation of this paramotor trike

the pilot should familiarize

themselves with this manual. It

contains operating instructions and

details pertaining to the maintenance

of the Super ThoriX.

The owner needs to become familare

with all aspect of operation and

maintenance prior to the use of this

motor and Trike.The owner needs also to

adhere to laws pertaining to their

own country regarding flight

restrictions and maintenance as well

as what is contained in this manual.

Information regarding important

updates to this model will be made

available via your importer, and

published in the relevant national

flying magazines under

http://www.freshbreeze.

de/en/service/dfgdfg.html

Please note:-Do not make any flights

in turbulent weather conditions

through as a paraglider in principle

receives its shape only by the

internal pressure. This can be

established only when normal air

flow conditions prevail. You need to

fly with increased caution when

thunderstorms are near by or

forecasted.

Under no circumstances should a

pilot fly too close to the storm front.

Land if ever in doubt. Other areas in

your country will also have flight

restrictions and laws of entry. These

include but are not limited to

military zones, controlled aircraft

areas and populated areas. Seek

information about an area before

taking flight as well as the

appropriate licensing.