Aviation Concepts Cessna 185 Skywagon User manual

The Cessna 185 Skywagon is a large six passenger high wing mono plane with conventional

fixed gear and used a 6 cylinder Continental engine. In 1961 they started production and at the end

of its production run in the mid 1980’s they produced over 4,400 of this rugged aircraft which

became very popular as a back country and Alaska Bush plane. This plane has a high load lifting

capabilities and excellent STOL characteristics. Pilots love to fly and modify there Cessna 185 by

adding huge tundra tires, floats, ski’s, stall fences, vortex generators and drooped wing tips. So for

all you civilian buffs, there’s a lot color schemes out there. There are also some (not a lot) of

military color schemes or be creative with your own scheme.

The construction of the full scale 185 is mainly of aluminum and fully skinned. All the control

surfaces are sheeted in corrugated aluminum. With this model, balsa, lite ply and birch aircraft ply

are used in the construction and covered in film (Monokote or UltraCote).

This 1/3 scale model has a true scale outline with no deviations in wing or tail area’s, but has

been designed to be more of a sport scale build. I.e. open wing and fuselage structure. The airfoil

is not scale but uses a thickened Clark Y airfoil recommended by Peter Goldsmith. Thanks Pete!

The model construction is a full kit and built up. Although, this model is not a beginners build,

the fuselage is fairly easy to construct following the manuals‘ construction steps. The majority of

the fuselage is built flat on the work table. The wings are built up with traditional ribs and spars and

is built in one piece flat on the work bench with the use of build tabs on the outer wing panel. The

wings are finished in 1/8” thick balsa sheeting with cap strips. The wings are joined to the fuselage

with an aluminum wing tube and has aluminum wing struts. The stabilizer halves and fin uses

carbon fiber tubes with birch ply mounting tabs which makes it easy for removal.

Features; One piece fiberglass cowl, heavy duty two piece landing gear from 5/16” thick 6061

T6 aluminum. Functional doors and luggage door with latches and magnets. Laser cut windshields

and windows. CNC routered birch ply parts for clean no charred edges. Plenty of floor strapping

slots for receivers, batteries or telemetry mounting.

This model was thought up at an aero tow meet to fill the gap in large scale glider towing. Build

it as a tow plane “tug“, scale or a sport scale model. Thinking outside the box on this project… It

wound up being a consortium design project via text messaging about ideas and what features

they were looking for in a robust model that can handle the rigors of aero towing duty. Credit goes

out to the three tow pilots in the North East that started it all; Kevin Kremer, Jim Dolly and Len

Buffinton. Thanks guys! It was a lot of fun and new way of thinking, tinkering and designing

something different.

BIGGER FLIES BETTER ! HAPPY BUILDING! Gunny Bumburs owner Aviation Concepts rc

Although the construction manual covers almost every detail, you the builder are

responsible for the construction, final selection of materials and airworthiness of your

finished model. Read the manual, use the plans and don’t leave your brain at the shop door.

You, the builder, assume any and all responsibility for any error, omission or loss incurred

by building or flying this kit - as in all things you construct, you are the one responsible for

the use, liability or losses incurred in the process, if any.

TABLE OF CONTENTS

FUSELAGE

FORMER SUB ASSEMBLIES………………………………................................................................................................1

TOW PLANE PACKAGE ……………….............................................................................................................................2

TAIL GEAR MOUNT SUB ASSEMBLY….………………...................................................................................................2

FUSELAGE BOTTOM SUB ASSEMBLY.……………………….........................................................................................4

TOP SUB ASSEMBLY ………………..………………………………...................................................................................9

SIDE SUB ASSEMBLY ………………………………........................................................................................................11

DOUBLER SUB ASSEMBLY ……………………………………………............................................................................12

ATTACHING DOUBLER TO SIDE ASSEMBLY..............................................................................................................12

TEST FIT OF FORMERS………………...........................................................................................................................19

DOOR HINGES…………………………...........................................................................................................................19

GLUING FORMERS TO FUSELAGE BOTTOM….….....................................................................................................20

TEST FIT FUSELAGE SIDES AND TOP…….................................................................................................................22

GLUING ON THE FUSELAGE SIDES………………………………………......................................................................22

GLUE IN REMAINING FUSELAGE FORMERS..............................................................................................................23

LANDING GEAR MOUNTING STRUCTURE……...........................................................................................................25

INTERNAL FLOOR SECTIONS………………………………...........................................................................................29

FUSELAGE FORWARD BOTTOM SECTIONS………………………………...................................................................32

TAIL TUBE SOCKETS………………………………..........................................................................................................34

FUSELAGE TOP STRUCTURE………………………………...........................................................................................36

FUSELAGE CORNERS………………………………........................................................................................................45

LANDING GEAR COVER………………………………....................................................................................................49

PULL PULL CABLE EXIT……………………………….....................................................................................................52

RUDDER SERVO MOUNT……………………………….......…………………..................................................................53

TAIL CONE………………………………...........................................................................................................................54

ENGINE BOX……………………………….......................................................................................................................58

TOP DECKING……………………………….....................................................................................................................62

INSTRUMENT PANEL……………………………….........................................................................................................64

FUEL TANK PLATFORM……………………………….....................................................................................................65

WIND SHIELD………………………………......................................................................................................................65

WINDSHIELD MOUNTING FILLET & DASH HOOD………………………………...........................................................70

WINDSHIELD RE-INSTALLATION………………………………......................................................................................71

LUGGAGE DOOR………………………………................................................................................................................72

MAIN DOORS………………………………......................................................................................................................75

DOOR LATCH………………………………......................................................................................................................78

WINDOW SPACER FRAMES………………………………..............................................................................................79

STEERING SERVO MOUNT………………………………...............................................................................................79

TAIL WHEEL ASSEMBLY………………………………....................................................................................................80

MAIN WHEELS……………………………….....................................................................................................................81

FUSELAGE TRUSS BRACING………………………………............................................................................................83

FUSELAGE CONDUIT TUBES………………………………............................................................................................83

FUSELAGE SPLICE REINFORCING………………………………..................................................................................84

STEPS………………………………..................................................................................................................................85

REAR WING BOLT REINFORCING………………………………....................................................................................87

MOUNTING ENGINE………………………………............................................................................................................88

EXHAUST STACK EXTENSION………………………………..........................................................................................90

MOUNTING COWL………………………………...............................................................................................................92

COOLING BAFFLES………………………………............................................................................................................94

CHOKE & NEEDLE VALVE ACCESS………………………………..................................................................................95

NEEDLE VALVE MODIFICATION………………………………........................................................................................96

FIN AND RUDDER

TAIL TUBE SOCKETS……………………………….........................................................................................................97

FRAMING……………..……………………………….........................................................................................................97

SHEETING……………………………………………........................................................................................................100

TIPS, LEADING AND TRAILING EDGES………….......................................................................................................104

CARVING, SHAPING & SANDING………………..........................................................................................................107

HINGING……………………………………………...........................................................................................................107

MOUNTING FIN……………………………………..........................................................................................................107

TORQUE TUBE……………………………….................................................................................................................108

STABILIZER AND ELEVATOR..…………..........................................................................................................111

TOP SHEETING……………………………….................................................................................................................115

MOUNTING SERVO………………………………..........................................................................................................116

BOTTOM SHEETING……………………..…..................................................................................................................117

TIP BLOCKS….………………………………..................................................................................................................118

HINGING………………………………………..................................................................................................................119

HORN AND PUSHROD……………………....................................................................................................................120

RIGHT WING………………………………..................................................................................................................121

FLAP HINGING………..……………………....................................................................................................................146

WING TIPS…………….…………………….....................................................................................................................149

AILERON HINGING…..…………………….....................................................................................................................151

AILERON SERVO TRAY…………………... ..................................................................................................................153

WING STRUTS…………………………….................................................................................................................154

FINISHING………………………………......................................................................................................................161

BALANCING………………………………..................................................................................................................165

CONTROL THROWS……..……………..................................................................................................................167

FLYING………..……………………………...................................................................................................................167

ADDITIONAL ITEMS NEEDED……....................................................................................................................168

DRAWING SKETCHES………………………………...........................................................................BACK OF MANUAL

CUTTING TAIL TUBE SOCKETS TO LENGTH…..……………….................................................................….SKETCH 1

CUTTING TAIL TUBES TO LENGTH..…………………............................................................................……..SKETCH 2

STABILIZER & ELEVATOR SHEETING………….................................................................……………………SKETCH 3

TOP WING SHEETING LAYOUT………………….…………………..............................................................….SKETCH 4

BOTTOM WING SHEETING LAYOUT………………….………….................................................................….SKETCH 5

TIPS:

Carbon fiber, G-10 and fiberglass creates dangerous dust particles when cut or sanded. Use safety goggles and a

dust mask or respirator when working with these materials.

The fiberglass cowl has mold release on it. Before working with it, wash it thoroughly with luke warm soapy water.

The fuselage side view drawing 3-7 is full size. You wont be building on this drawing. It is there for your reference

and may be hung on your shop wall for convenience. No cutting up of the plans should be required. Maximum plan

size is 3 feet wide x 9 feet long. A pin-able building board is not needed, but if you wish to have one, then use a 4’ x 8’

sheet of homisote or sound board.

CAUTION! Neodymium magnets are not toys. Keep out of reach from children. These magnets can affect

pacemakers, ICD’s and other implanted medical devices. Magnets can affect magnetic media. Avoid placing near

electronic devices. Those with nickel allergies should avoid prolonged contact.

WARNING: This product contains chemicals known to the state of California to cause cancer, or birth defects or

other reproductive harm.

Gluing together hardwood pieces ie. Bass, spruce and birch ply. Because these pieces are very dense it is

recommended that you make “Gluing Dimple Holes” by drilling (1/32” dia. drill bit) multiple tiny dimpled holes in both

adjoining pieces. For general glue joints like this I like to use thick CA glue, or epoxy. Also, when gluing these pieces

together with epoxy do not clamp parts so tight together that the glue squeezes out of the joint. You will have a weak

bond. Where epoxy is called out with no set time, then use 5 minute. The longer set or working time of epoxy glue also

can make the joints stronger in dense plywood do to the longer migration time.

Other glues used.

If you are a fan of aliphatic wood glue then Tite Bond II is the best glue for all general construction. Except for joining

wing skin sheets together and gluing on the L.E. It is hard to sand and leaves a ridge. For these I like using the

aliphatic wood glue from the makers of Gorilla Glue. It dries faster and sands really easy.

For attaching the wing skins to the structure I found the foaming Gorilla Glue works best. It gives you more working

time to lay down the glue onto all those ribs. Aliphatic glues skins over way too soon but this is not a fully sheeted wing

so this is what I used on my prototype model.

Medium CA glue is my favorite for all other balsa general construction, while thin CA is primarily used to harden pre-

threaded screw holes in wood.

Note that some of the pictures in this manual may not exactly match with your kit. Parts may have been changed

or improved. Some pictures in the manual may not have good clarity. You can see the manual in PDF on our website.

Dowel alignment pegs are used to keep two parts in perfect position while gluing them together. Majority of them

will be from 1/8” dia. dowels. They should be cut longer than the two joining parts, hammered in and trimmed flush

unless told to do otherwise.

Laser cut parts can be snapped out or for cleaner removal use an x-acto knife to cut the small tabs that holds the

parts to the sheet. CNC routered plywood parts have to be cut out of the sheet. You can use a saw blade, chisel, cut-

off wheel or thin side cutters. The tabs have to be sanded flush. Tabs inside lightening holes can be cleaned up with a

drum sander on a Dremel tool.

FUSELAGE: (Former Sub Assemblies)

1. Glue together former F7A to F7B. Make sure both

etched formers’ call out part numbers are facing up

towards you.

2. Glue F7C to F7A using two alignment dowel pegs.

Then cut and sand the dowels flush. Make sure all

etched formers’ call out part numbers are facing up

towards you.

3. Glue F6A to F6B. Make sure both etched formers’

call out part numbers are facing up towards you.

4. Epoxy together F5A to F5B.

5. Epoxy together F4A to F4B.

6. Epoxy together F2A to F2B. Make sure both etched

formers’ call out part numbers are facing up towards

you.

1

(Tow Plane Package)

7. If you have purchased the “Tow Plane Package,”

now is a good time to install the four 6-32 blind nuts to

the back of former F5A/F5B. Back means that the

formers’ etched part call out numbers is down facing

the work bench.

8. Continuing with the “Tow Plane Package,” epoxy

into position FM4 etched part number face down using

four dowel alignment pegs. When cured, cut and sand

flush the dowel pegs.

(Tail Gear Mount Sub Assembly)

9. Epoxy together FL9A to FL9B using three alignment

dowel pegs. Do not get glue into the dowel peg holes.

These must be removed for later use. FL9B is on top

of FL9A with the round pocket and slot facing up. Do

not worry about getting glue into the 6 small holes.

Before the epoxy fully hardens clean the tail gear slot

and elongated hole of excess glue. Then remove the 3

dowel pegs.

2

10. When the epoxy has set or cured, Use a 1/16” dia.

drill bit and drill out the 6 holes.

11. Epoxy together FL10 using two dowel alignment

pegs. Use the 1/16” dia. drill bit and drill a bunch of

“Glue Anchor Holes” to a depth of about 1/16”. Before

the glue sets up, clean out the square hole of excess

glue using the tail gear wire.

12. Epoxy FL10 assembly onto FL9B using the tail

gear wire as a guide. Note; the block and wire has to

be pushed to the front as far as it will go. Drill dimple

holes in both adjoining pieces. Coat the end of the wire

with Vaseline or oil and clamp together.

3

13. When the epoxy has fully cured, use a punch to

pop out the wire over a vise.

14. Use a #2 drill bit to clean out the hole. Clean out

the slot for the wire inside radius by starting at a

shallow angle and working it forward. Test the fit of the

wire. It should not be tight or difficult to remove.

(Fuselage Bottom Sub Assembly)

15. The fuselage is built from the bottom on up. Hang

up the fuselage side view on your wall for reference.

Lay down drawing 4-7 onto your clean and flat work

bench.

4

16. When removing FB1 from the sheet be careful not

to break off the temporary square brace at the end.

Remove and discard the tail wire slot.

17. Glue together FB2A to FB2B.

18. Glue FB1 to FB2 assembly.

19. Using 3 alignment dowel pegs, place the FL9 tail

mount assembly onto the rear of F1B and trace around

its perimeter. This will be glued into place at a later

time. Leave in place for now.

5

20. Glue 1/4” square balsa sticks on top of the

fuselage bottom assembly along the sides (flush with

the edge of the lite ply.) Use aliphatic wood glue to

give you working time for positioning. Use a small

hammer to tap the T pins into the lite ply to hold the

sticks into position. When adding more lengths of

sticks, miter the ends at a 45° angle. Tip: use a stick

on the outside edge of the lite ply to help align the

edge of the stick you are gluing down. Remove this

stick and wipe up any excess glue that has squeezed

out.

21. When the glue has dried, remove the tail gear

mount assembly and sand the edges of the balsa

smooth and flush with the edge of the lite ply.

6

22. Place the bottom assembly balsa sticks side down

and glue onto the sides 3/8” balsa triangle stock.

23. Sand the little bit of the balsa that protrudes above

the lite ply flush. Then flip over and sand the other side

even and flush.

7

24. Trim and sand both ends flush and then remove

the temporary square brace.

25. Epoxy in the tail gear mounting assembly using 30

minute epoxy and the 3 dowel pegs. Also add some

gluing anchor dimples into the lite ply. Clean up any

epoxy that might have squeezed through on the other

side.

8

(Top Sub Assembly)

26. Glue together FT1 to FT2.

27. Glue FD7 and FD6 into position using alignment

dowel pegs. Do not glue the pegs in. Remove the pegs

and insert four 4-40 blind nuts.

28. Glue on FD8 using dowel pegs. Trim and sand

pegs flush.

29. Glue down 1/4” square balsa sticks. Notch them to

go over FD6 and FD8.

9

30. Add some epoxy around all the blind nuts.

31. Flip the top over and glue on the 3/8” balsa triangle

stock. Trim and sand both ends flush and the top and

bottom.

32. Glue on the two FR3 reinforcing.

33. Test fit all the formers onto the top assembly. They

must be a loose sliding fit and plug in fairly easily.

Sand where necessary.

10

(Side Sub Assembly)

34. Glue FS3A to FS3B.

35. Glue FS2A to FS2B.

36. Now glue these two assemblies together.

37. Finally glue FS1 into position.

38. Repeat steps for the other side.

11

(Doubler Sub Assembly)

39. Glue FD1A to FD1B.

40. Glue FD2A to FD2B.

41. Now glue these two assemblies together.

42. Repeat steps for the other doubler.

(Attaching Doubler to Side Assembly)

Important; You will be making a Right and

Left Hand Assembly! Steps shown is Right Hand

43. Sand finger joints smooth and flat. Also remove the

temporary braces.

44. Cut six 1/8” dia. dowel alignment pegs.

12

45. Lay the doubler down on top of the side aligning

the six alignment holes. Insert the dowel pegs.

46. Trace all the edges of the doubler onto the side

sheet. Then remove the doubler.

47. Cut half the length off of the bristles of an epoxy

brush or a chip brush and a an angle.

48. Use epoxy finishing resin, West System epoxy

resin, or thinned epoxy glue and brush on to the

fuselage side. Place the doubler onto the side aligning

the dowel peg holes and insert the pegs. Weight down

the assembly with sand bags or equivalent.

13

49. Repeat for Left Hand Assembly.

50. Glue FD3 into position using two dowel pegs.

Remove the pegs and insert two 4-40 blind nuts.

51. With the doubler side down, add three magnets to

the main door, No need to be concerned about the

magnets polarity at this time. Press a magnet into the

hole using a scrap piece of stick until it is flush with the

door jamb. Flip over the fuselage and add thin CA glue

around the circumference of the magnet. Repeat for

the other main fuselage main door.

14

52. Using the same procedure, add two magnets to the

left fuselage side luggage door. (There is no door on

the opposite side.)

53. Glue FD3 into position using three dowel alignment

pegs. The back end is to be flush with the bottom of

the fuselage. Then trim and sand the dowel pegs flush.

15

54. Glue on the 1/4” square balsa sticks. See drawing

5-7 for locations.

16

Table of contents

Popular Toy manuals by other brands

Enabling Devices

Enabling Devices ShihTzu Puppy user guide

REVELL

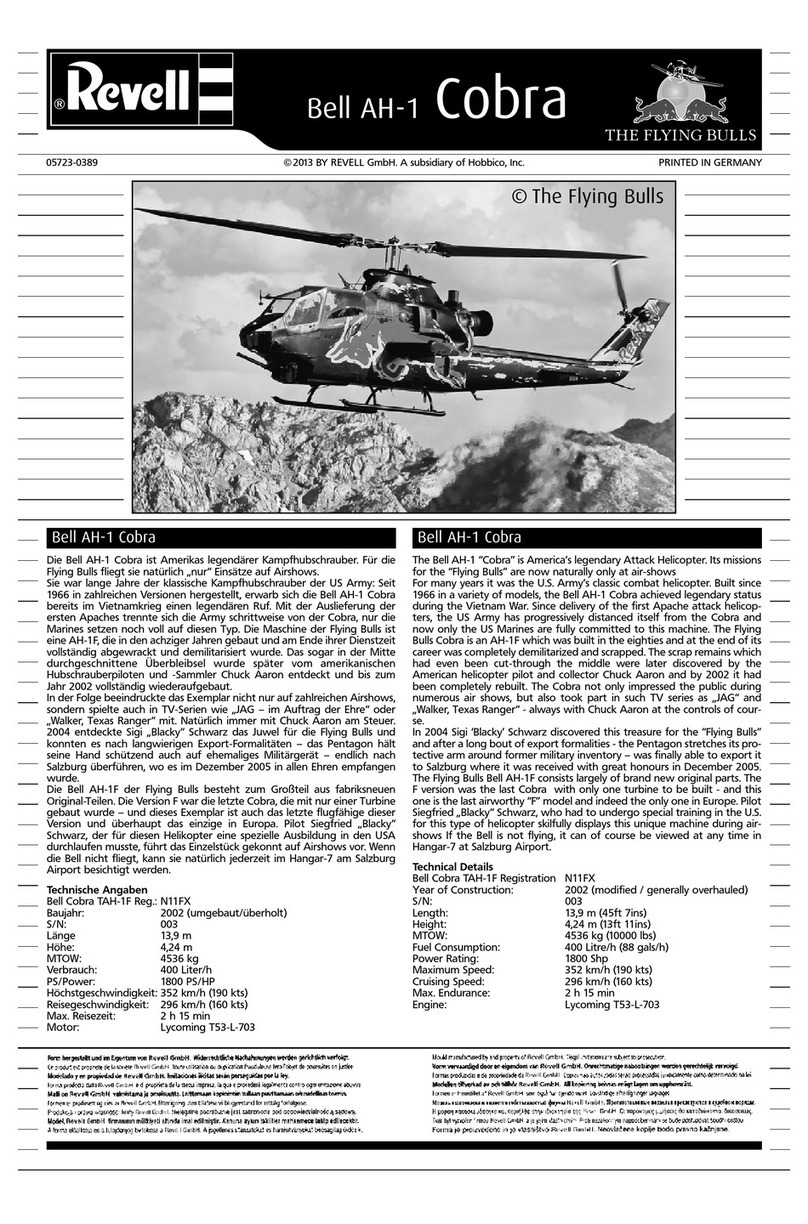

REVELL THE FLYING BULLS Bell AH-1 Cobra Assembly manual

K'Nex Education

K'Nex Education DOG manual

LEGO

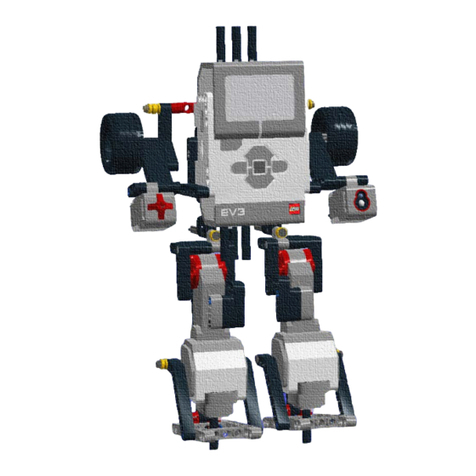

LEGO Mindstorms EV3 Build instructions

Mega Construx

Mega Construx Saban's Power Rangers Sabertooth Tiger Zord... Assembly instructions

Faller

Faller GOLDBECK 130890 instructions

krakpol

krakpol 211086 Assembly instructions

Mega Bloks

Mega Bloks 7860 quick start guide

Innovative Hobby Supply

Innovative Hobby Supply BK 1300 General assembly instructions

RC Logger

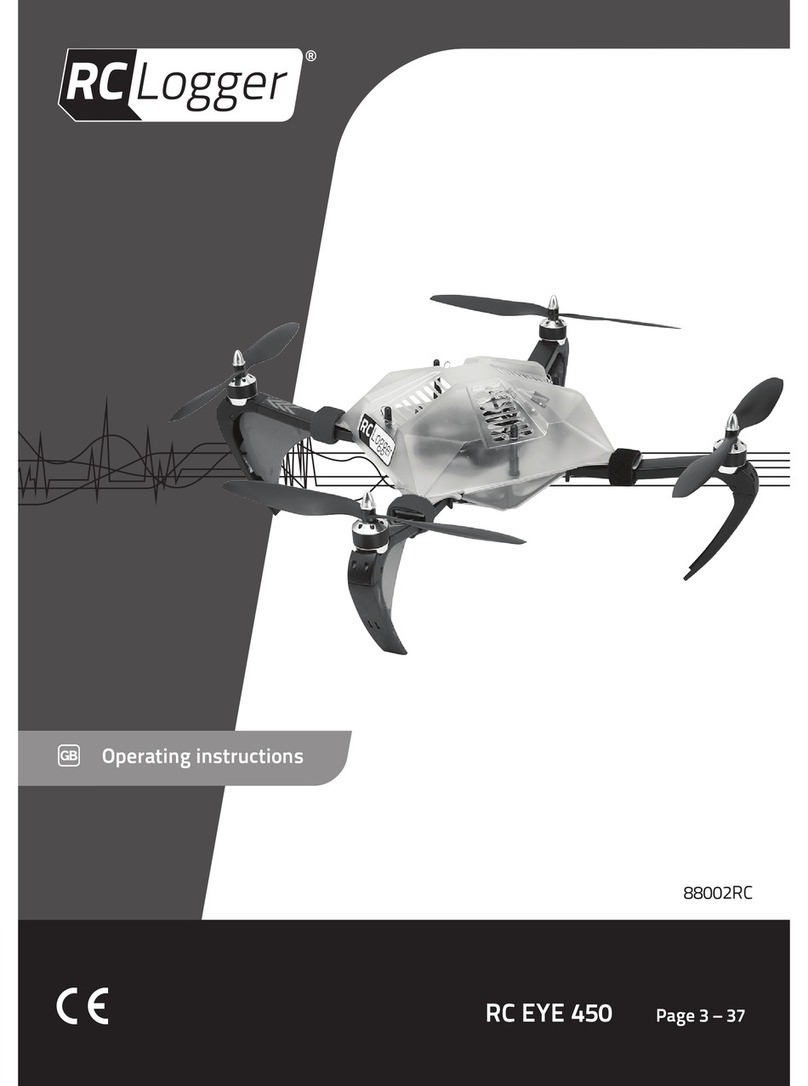

RC Logger 88002RC operating instructions

Lionel

Lionel B&M Paul Revere GP-9 owner's manual

BVM

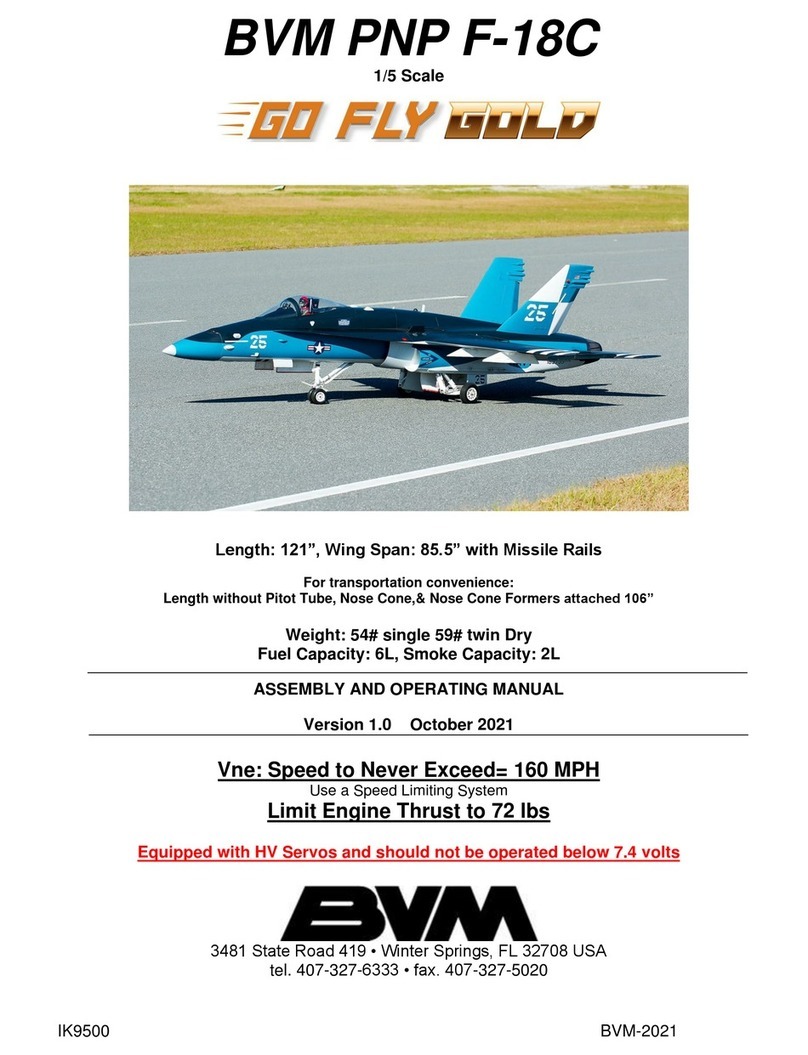

BVM Go Fly Gold F-18C Assembly and operating manual